Vacuum system for laser processing

A laser processing and vacuum system technology, which is applied in the field of vacuum systems, can solve the problems of metal materials that cannot be processed by laser, and achieve the effects of ensuring laser processing quality, improving reliability, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

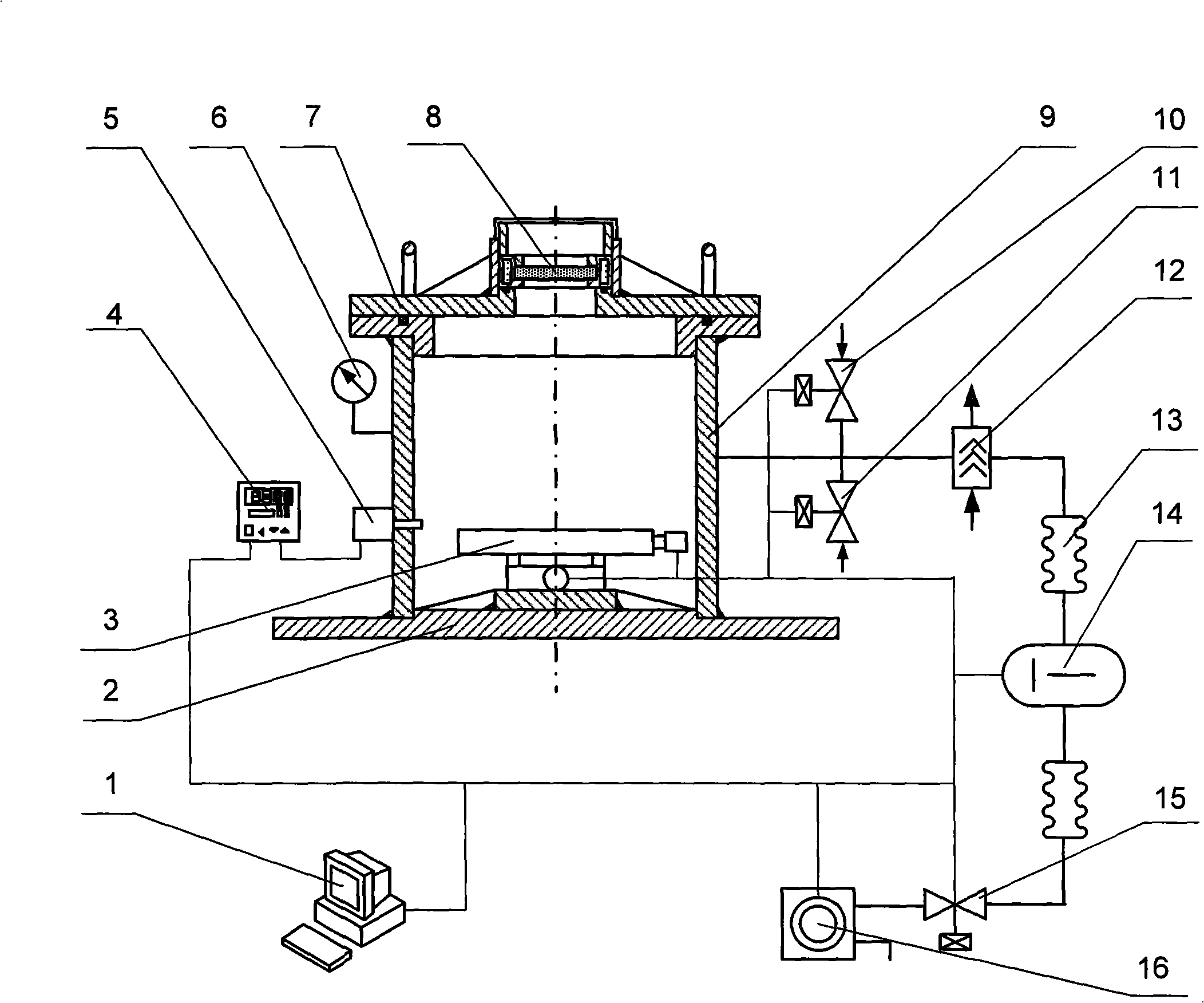

[0033] see Figure 1-Figure 11 , a vacuum system for laser processing, which is included in the laser processing equipment system, the laser processing equipment is equipped with a vacuum system for laser processing, the system is mainly composed of a vacuum box body and a matching vacuum pump , an inflatable assembly and a computer control module 1 that controls and connects them.

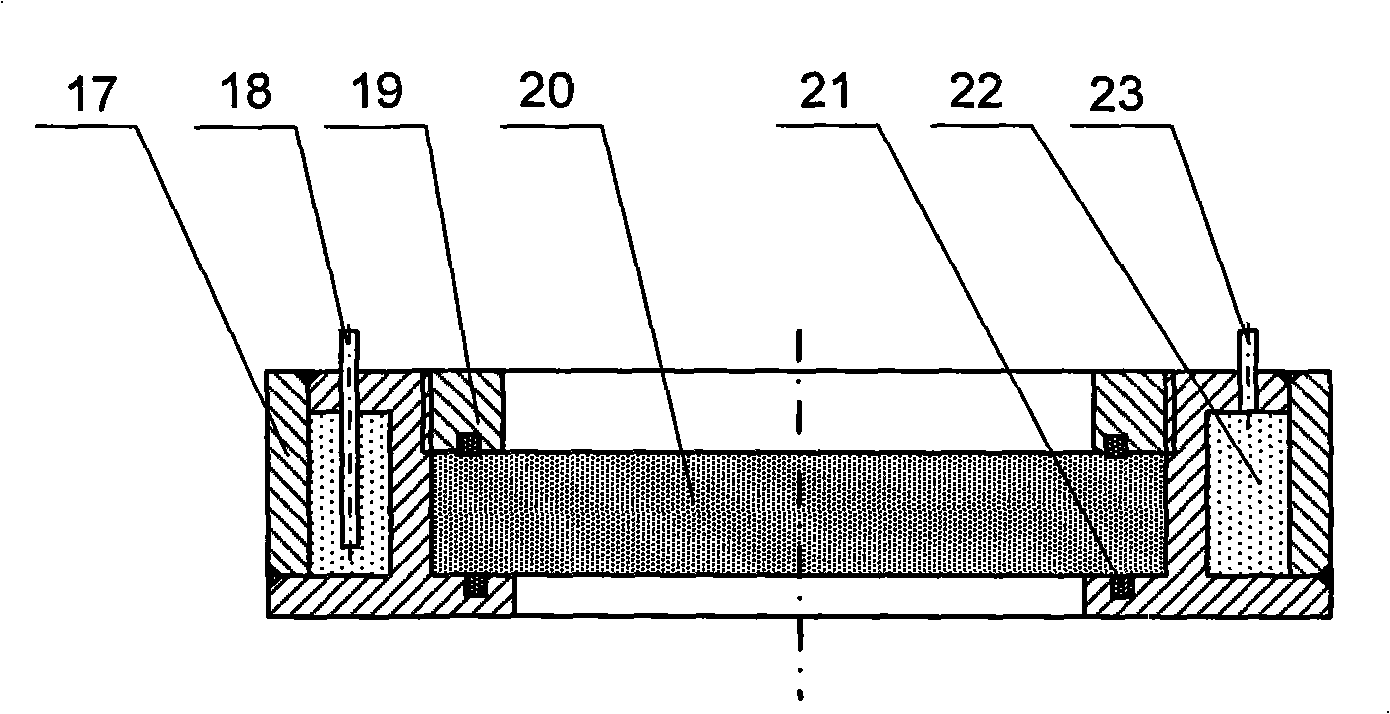

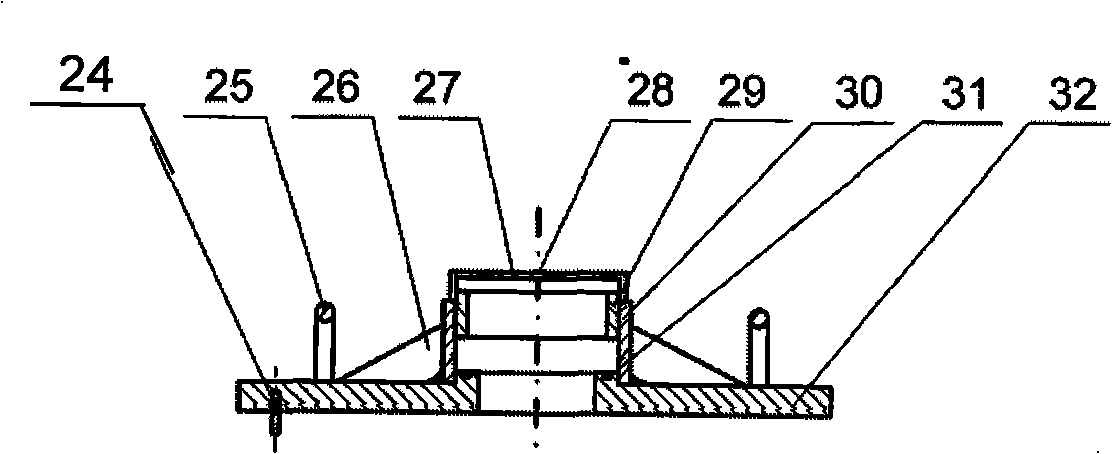

[0034] The worktable assembly 3 in the vacuum box body is placed on the base assembly 2, which is sealed in the box by the vacuum box body assembly 9 and the vacuum box cover assembly 7; a vacuum box is also provided on the vacuum box cover assembly 7. box window assembly8.

[0035] The vacuum box cover flange 38 at the top of the vacuum box assembly 9 is provided with a box cover positioning hole 33, a box cover rubber sealing groove 34 is provided along the flange circumference, and a vacuum box side wall 37 is provided with a vacuum box. Sensor connection port 35, vacuum pressure gauge connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com