Processing method for reinforcing soft clay ground through vacuum preloading in combination with electro-osmosis method

A vacuum preloading method and treatment method technology, which is applied in the fields of soil protection, infrastructure engineering, construction, etc., can solve problems such as low efficiency, uneven reinforcement of soil, silting of plastic drainage boards, etc., and achieve the goal of improving treatment efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

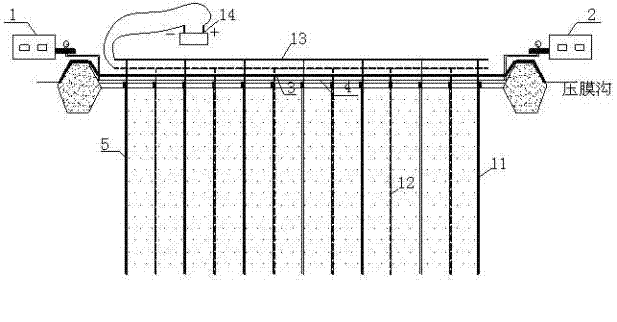

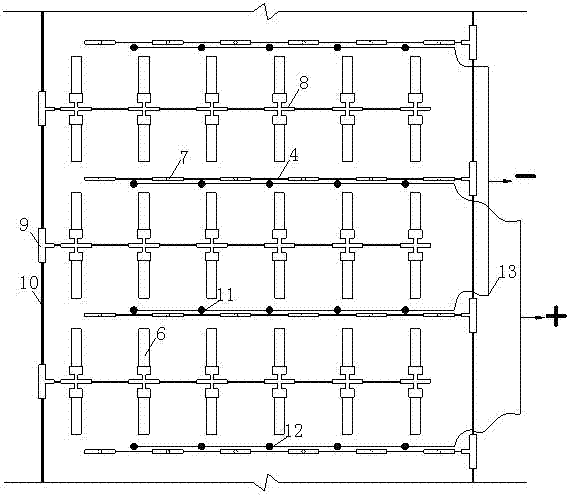

[0034] see Figure 1 to Figure 4 , a treatment method for vacuum preloading combined with electroosmosis to strengthen soft clay foundations, comprising the following steps:

[0035] ① Arrangement of three-dimensional closed vacuum preloading system:

[0036] The vacuum preloading method used in the joint reinforcement of vacuum preloading and electroosmotic method is a three-dimensional airtight independent vacuum preloading method, and its construction layout process is as follows:

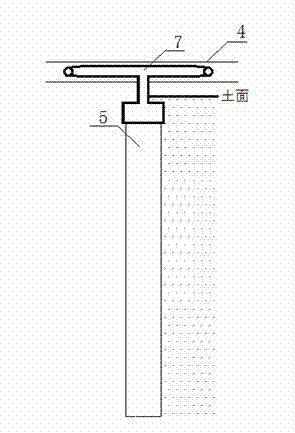

[0037] a. After the first geotextile is laid on the site that needs to be treated, the plastic drainage boards 5 in the soil are laid in rows, and the plastic drainage boards 5 in the soil are connected to the airtight sealed steel wire water pipe 4 through the sealing joint 7 of the plastic drainage board in the soil. Then each sealed steel wire water pipe 4 is connected to the airtight sealed steel wire main pipe 10 respectively through the tee joint 9 to form a plastic drainage board draina...

Embodiment 2

[0045] This embodiment is basically the same as Embodiment 1, especially in that:

[0046] In this embodiment, the drainage system of the plastic drainage board in the soil and the drainage system of the plastic drainage board on the surface of the soil independently perform switch control and vacuum adjustment to realize the independent manual regulation of the vacuum in the soil and the vacuum under the membrane, and according to the vacuum preloading According to the actual needs of the implementation stage, adjust the optimal ratio of the vacuum degree in the soil to the vacuum degree under the membrane, greatly improve the vacuum degree transmission and the treatment effect of deep soil, the construction is fast, efficient and energy-saving, and intelligent control can be realized.

Embodiment 3

[0048] This embodiment is basically the same as the previous embodiment, and the special features are:

[0049] In this embodiment, the electroosmotic electrode adopts ordinary light round steel bar, and the diameter of the steel bar used as the electroosmotic cathode 11 is smaller than the diameter of the steel bar used as the electroosmotic anode 12, no special design is required for the electrode structure, and the selection and production costs of the electrode are low .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com