Electronic vacuum pump for brake vacuum booster of new energy vehicles

A technology for vacuum boosters and new energy vehicles, which is applied in the direction of pumps, machines/engines, mechanical equipment, etc. It can solve the problems that cannot meet the requirements of automobile brakes, vacuum pumps cannot meet the requirements of electric vehicle brakes, etc., to prevent stuck, High vacuum efficiency and reduced frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

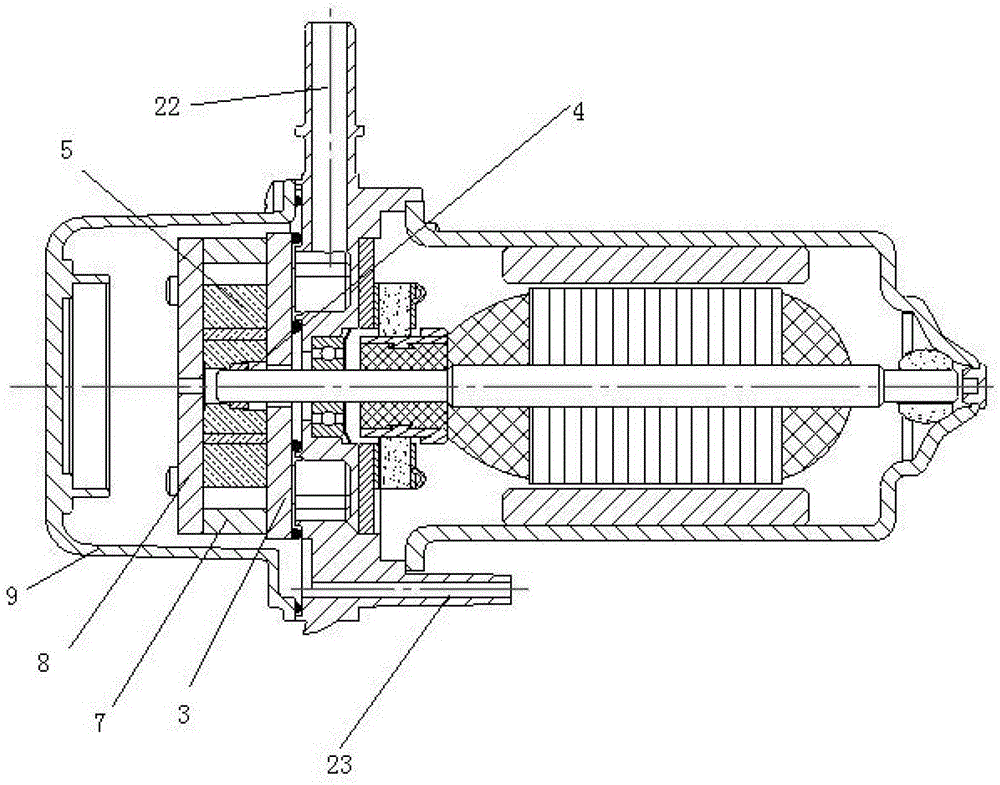

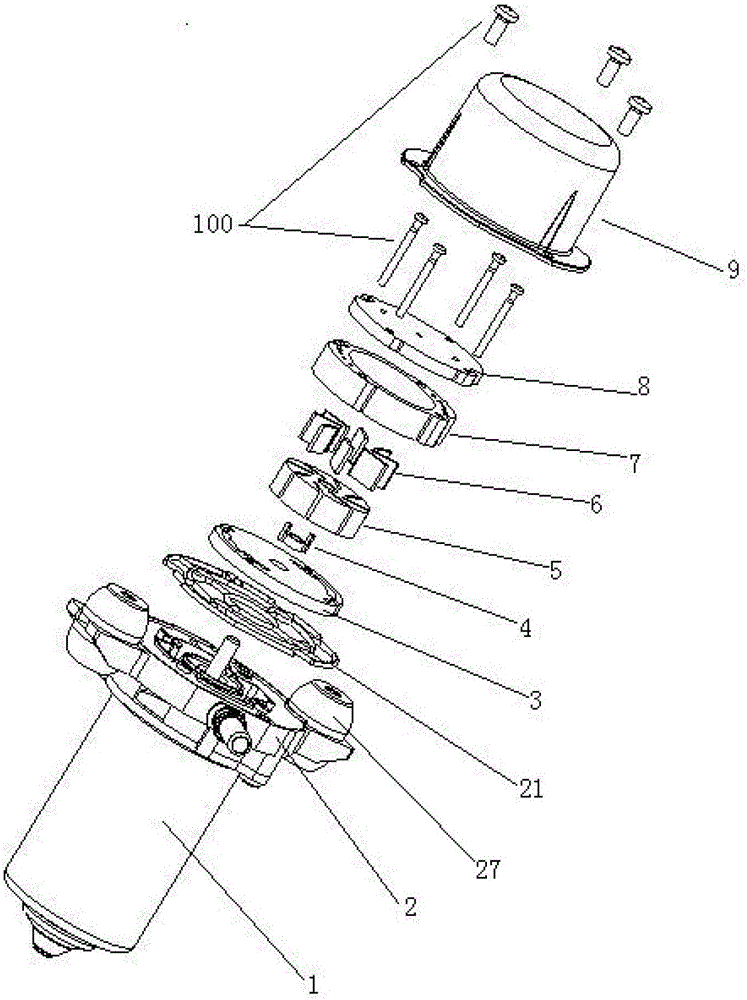

[0054] See figure 1 and figure 2 , the electronic vacuum pump for the new energy vehicle brake vacuum booster in this embodiment includes a motor assembly 1, a support base 2, a pump chamber lower cover 3, a drive sleeve 4, a pump rotor 5, blades 6, a pump chamber 7, and a pump chamber upper cover 8. Pump body cover 9 and fixing pin 100. The pump chamber lower cover 3 , the drive sleeve 4 , the pump rotor 5 , the vane 6 , the pump chamber 7 , the pump chamber upper cover 8 and the fixing pin 100 are arranged in the pump body cover 9 . The lower cover 3 of the pump chamber, the driving sleeve 4 and the pump rotor 5 are coaxially arranged with the output shaft of the motor assembly 1 .

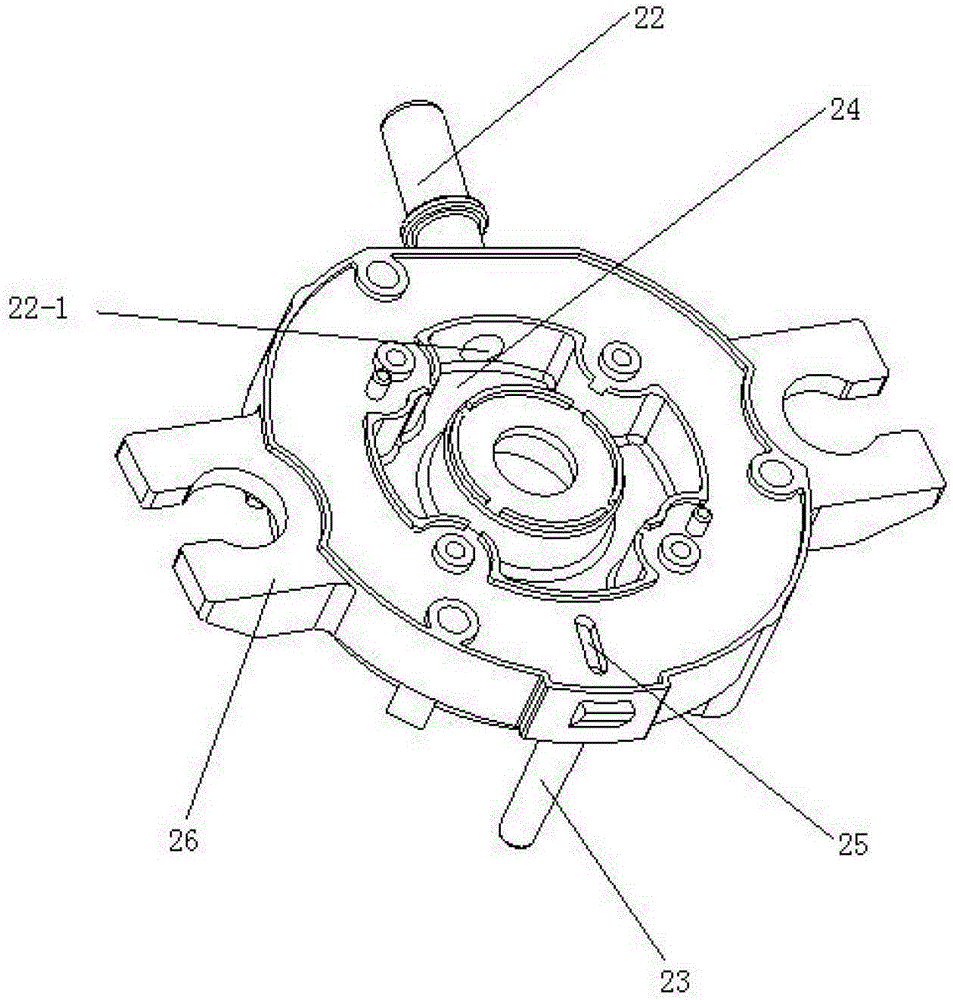

[0055] See image 3 , the support base 2 includes a sealing ring 21 , an air inlet pipe 22 , an air outlet pipe 23 , an air storage cavity 24 , an air outlet 25 , a mounting frame 26 and an installation sleeve 27 . The support base 2 is fixedly connected with the motor assembly 1 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com