Weak-atmosphere environment laser welding device and method

An atmospheric environment, laser welding technology, used in laser welding equipment, welding equipment, metal processing equipment and other directions, to ensure long-term operation, reduce manufacturing costs, and ensure high-quality welding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A laser welding method in a weak atmosphere environment, comprising the following steps:

[0037] S1. Put the workpiece to be welded into the working cabin, and make the atmosphere in the working cabin form a protective gas atmosphere under low vacuum through the protective gas storage device and exhaust device;

[0038] S2. Turn on the gas circulation device, the welding head emits laser light through the light-transmitting lens set on the surface of the working cabin, and welds the workpiece to be welded. After the welding is completed, the workpiece is taken out.

[0039] In step S1, the protective gas atmosphere under the low vacuum is obtained by a pressure sensor and an oxygen content sensor in the working chamber, the low vacuum degree of the pressure sensor is 10-1000Pa, and the oxygen content of the oxygen content sensor is below 1000ppm .

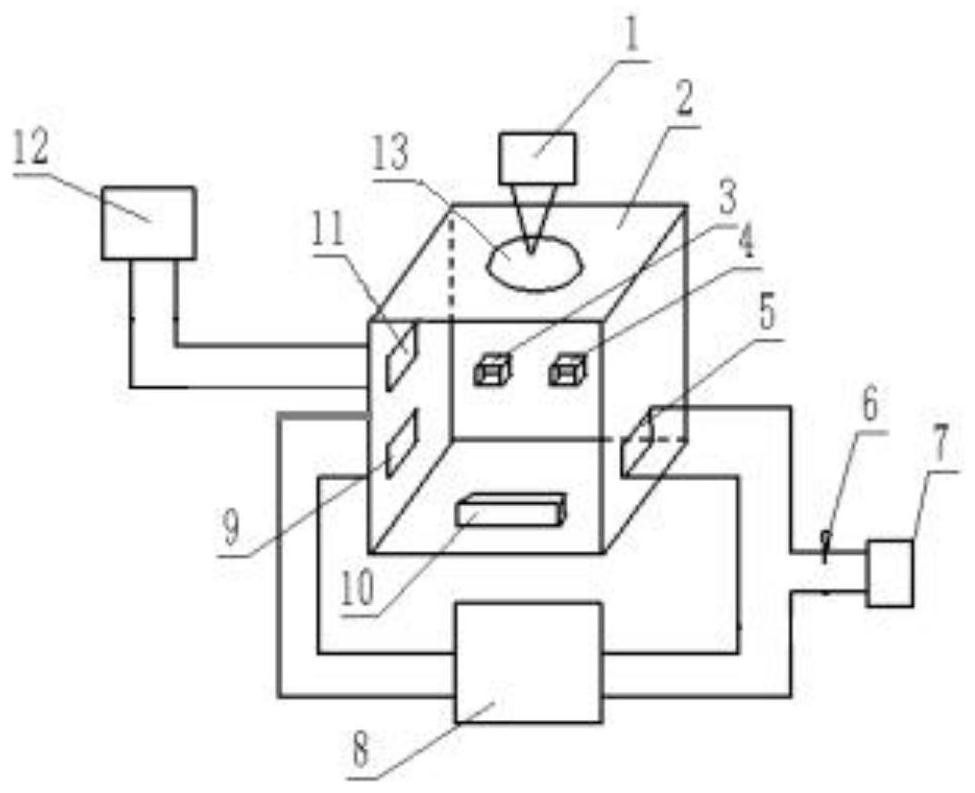

[0040] Such as figure 1 As shown, the device for laser welding in a weak atmosphere environment using the method includ...

Embodiment 2

[0047] A laser welding method in a weak atmosphere environment, comprising the following steps:

[0048] S1. Put the workpiece to be welded into the working cabin, and make the atmosphere in the working cabin form a protective gas atmosphere under low vacuum through the protective gas storage device and exhaust device;

[0049] S2. Turn on the gas circulation device, the welding head emits laser light through the light-transmitting lens set on the surface of the working cabin, and welds the workpiece to be welded. After the welding is completed, the workpiece is taken out.

[0050] In step S1, the protective gas atmosphere under the low vacuum is obtained by the pressure sensor and the oxygen content sensor in the working chamber, the low vacuum degree of the pressure sensor is 100 Pa, and the oxygen content of the oxygen content sensor is below 1000 ppm.

[0051] The method is a laser welding device in a weak atmosphere environment, including a working cabin, a welding head i...

Embodiment 3

[0058] A laser welding method in a weak atmosphere environment, comprising the following steps:

[0059] S1. Put the workpiece to be welded into the working cabin, and make the atmosphere in the working cabin form a protective gas atmosphere under low vacuum through the protective gas storage device and exhaust device;

[0060] S2. Turn on the gas circulation device, the welding head emits laser light through the light-transmitting lens set on the surface of the working cabin, and welds the workpiece to be welded. After the welding is completed, the workpiece is taken out.

[0061] In step S1, the protective gas atmosphere under the low vacuum is obtained by the pressure sensor and the oxygen content sensor in the working chamber, the low vacuum degree of the pressure sensor is 400Pa, and the oxygen content of the oxygen content sensor is below 1000ppm.

[0062] In step S2, the gas circulation device is opened so that the gas flow circulating in the working cabin is at 40M 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com