A high brazing rate vacuum welding method based on plasma cleaning

A plasma cleaning and vacuum welding technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problem of reducing interface bonding strength, ductile creep and fatigue life, reducing thermal conductivity, electrical conductivity, affecting welding Mechanical properties and other issues, to achieve the effect of improving heat conduction, eliminating cleaning links, and improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

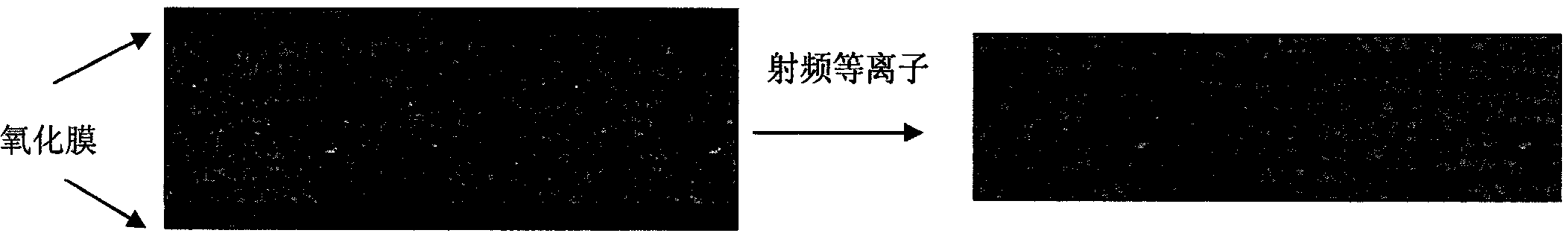

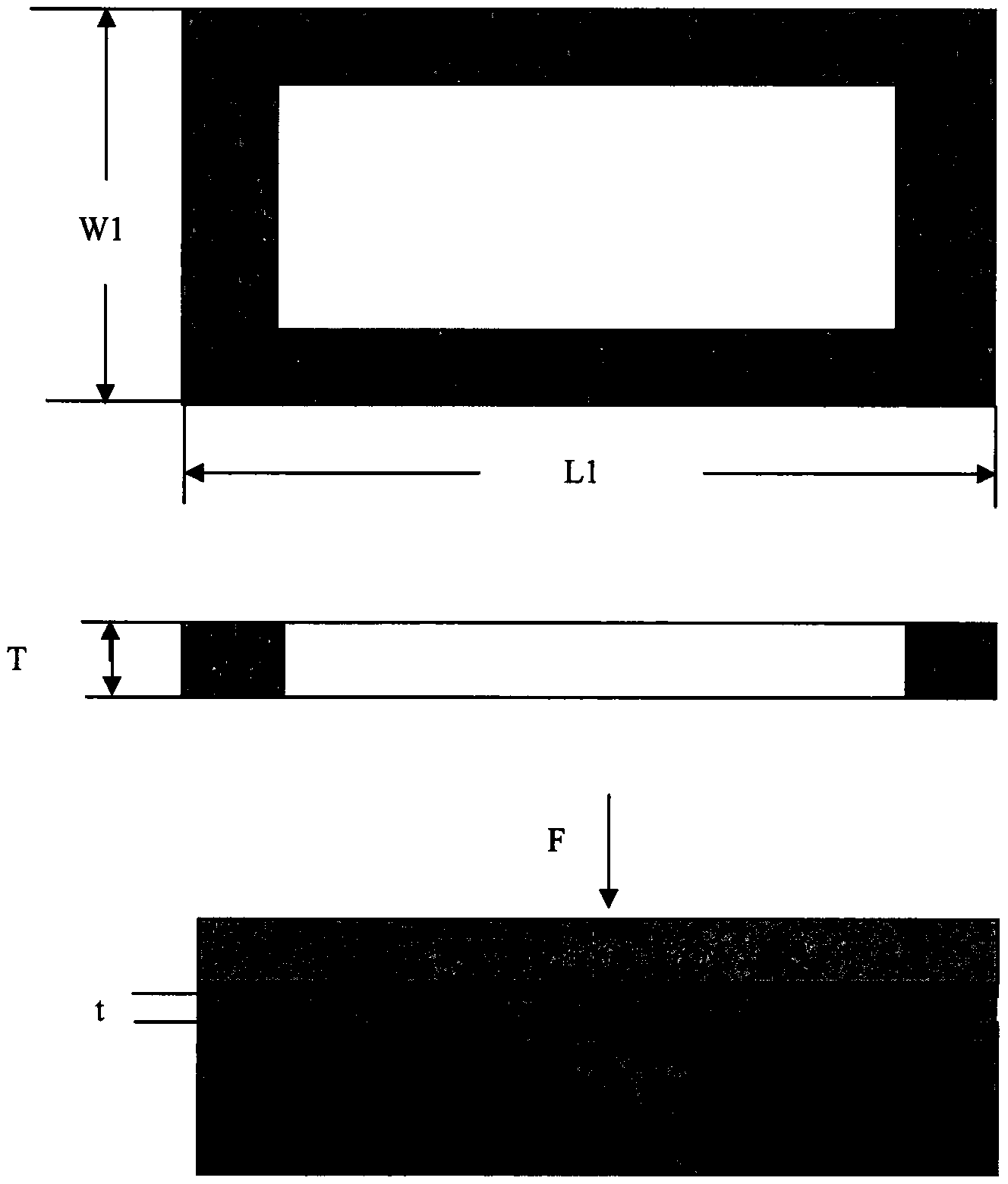

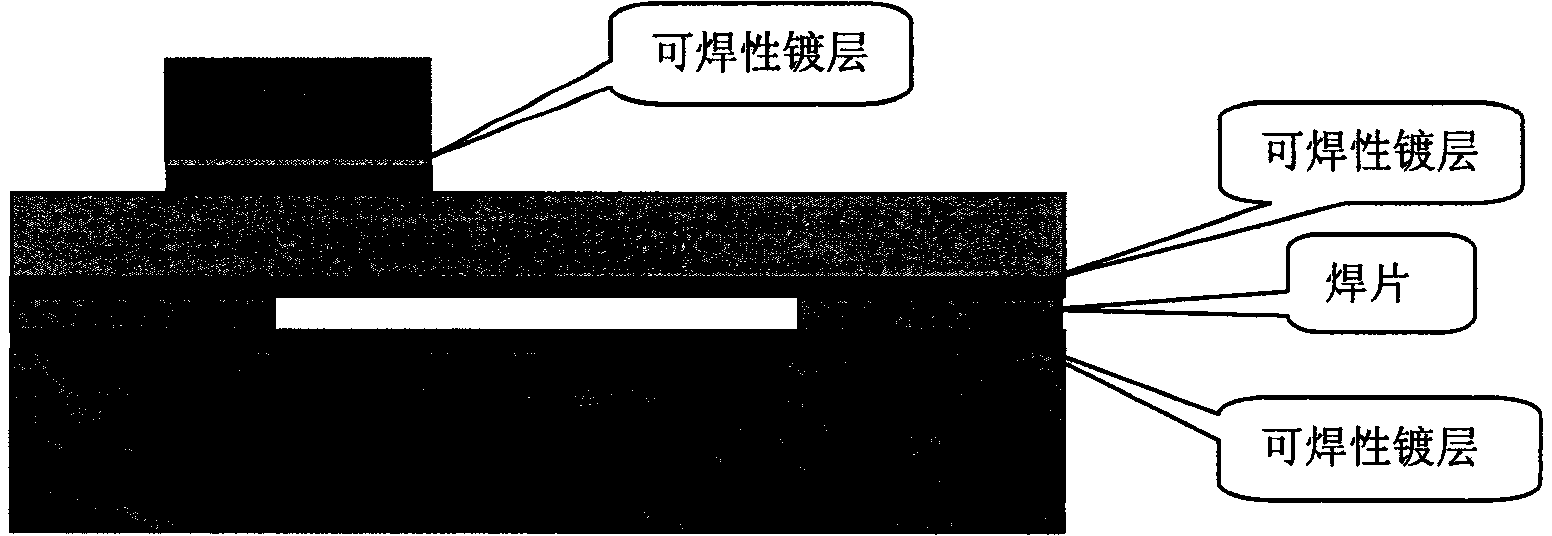

[0022] The present invention changes the existing solder from flux-containing solder paste to flux-free solder sheet by analyzing the relationship between the void rate of workpieces after soldering and the shape of solder. The void rate of the solder joint interface is composed of the air bubble rate + debonding rate, that is, the voids at the solder joint interface have debonding caused by non-wetting or inclusions in addition to air bubbles. Flux residue and oxidation are the main factors leading to debonding. The use of flux can effectively remove the oxide layer on the surface of the solder and the pad, improving soldering reliability, but at the same time, it is easy to produce flux residues, resulting in debonding; without using flux, the oxide layer cannot be removed, and the solder is difficult to wet on the pad surface, thus cause debonding. Therefore, we choose to use soldering sheet instead of soldering paste to eliminate the negative impact of flux. At the same t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com