Double-main-shaft double-working-table gantry type heavy wood composite processing center

A composite machining center and double worktable technology, applied in the field of wood processing, can solve problems such as unfavorable production efficiency and long total processing time for one part, and achieve the effect of ensuring workpiece processing quality, good dustproof effect, and ensuring longevity and performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

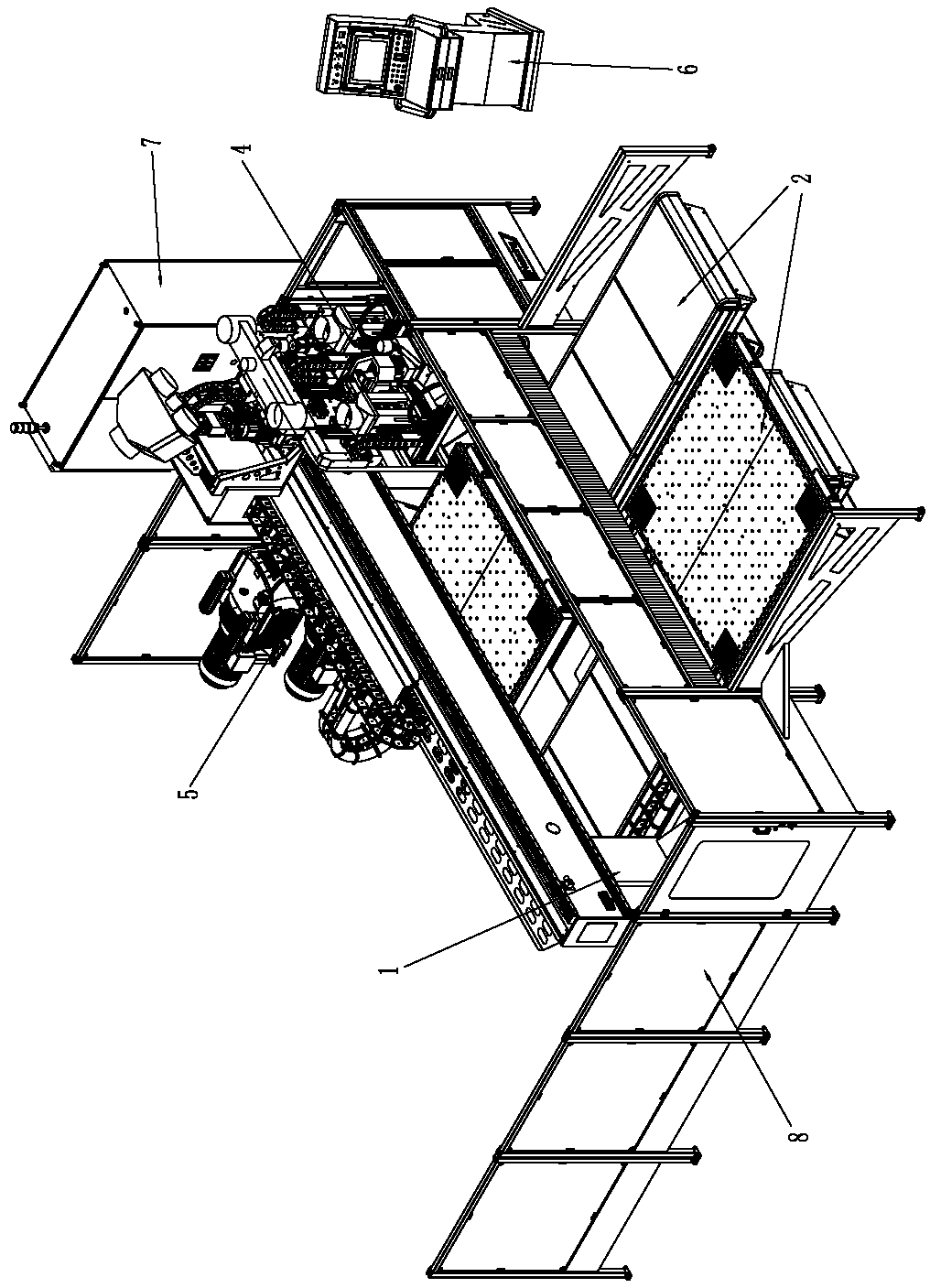

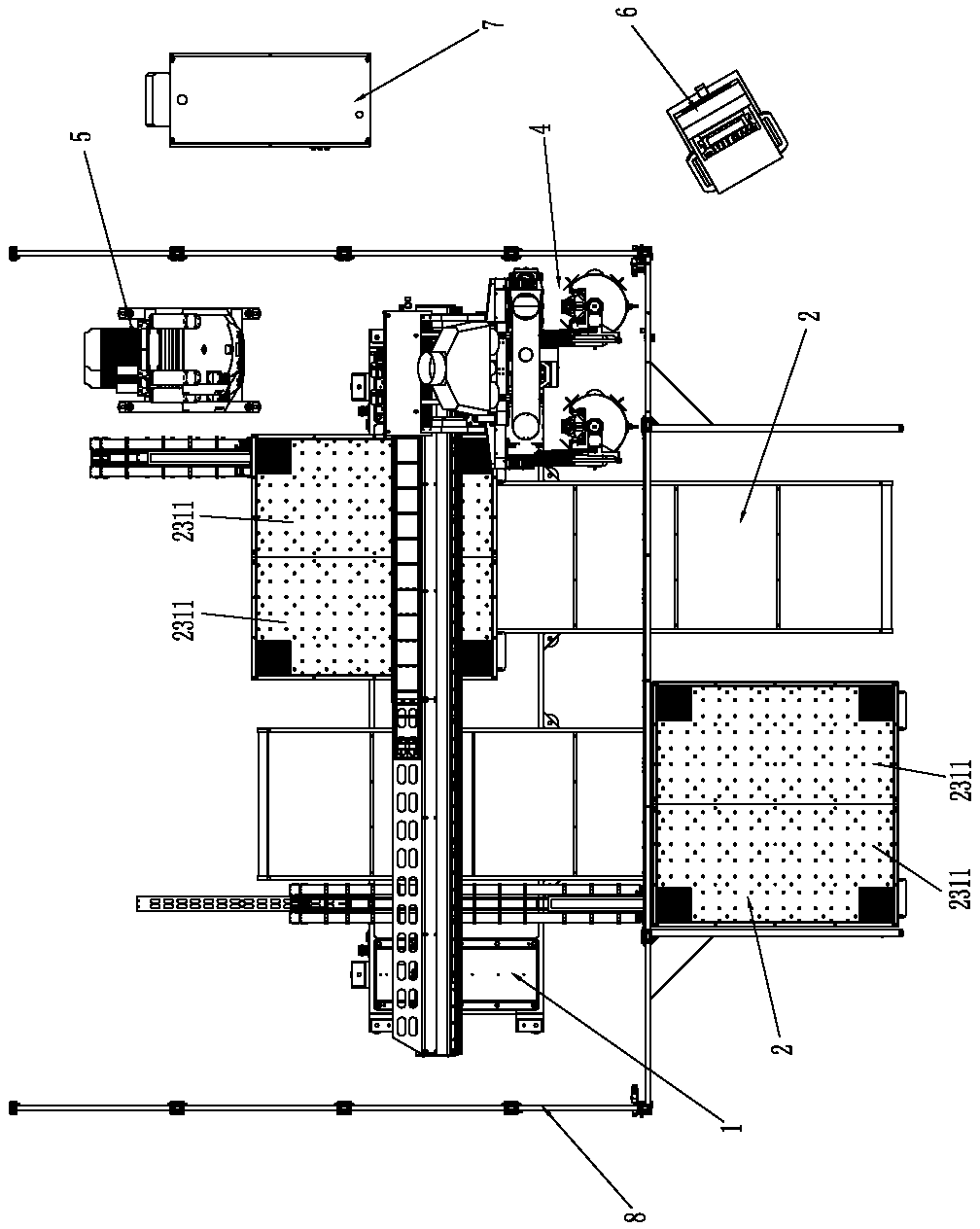

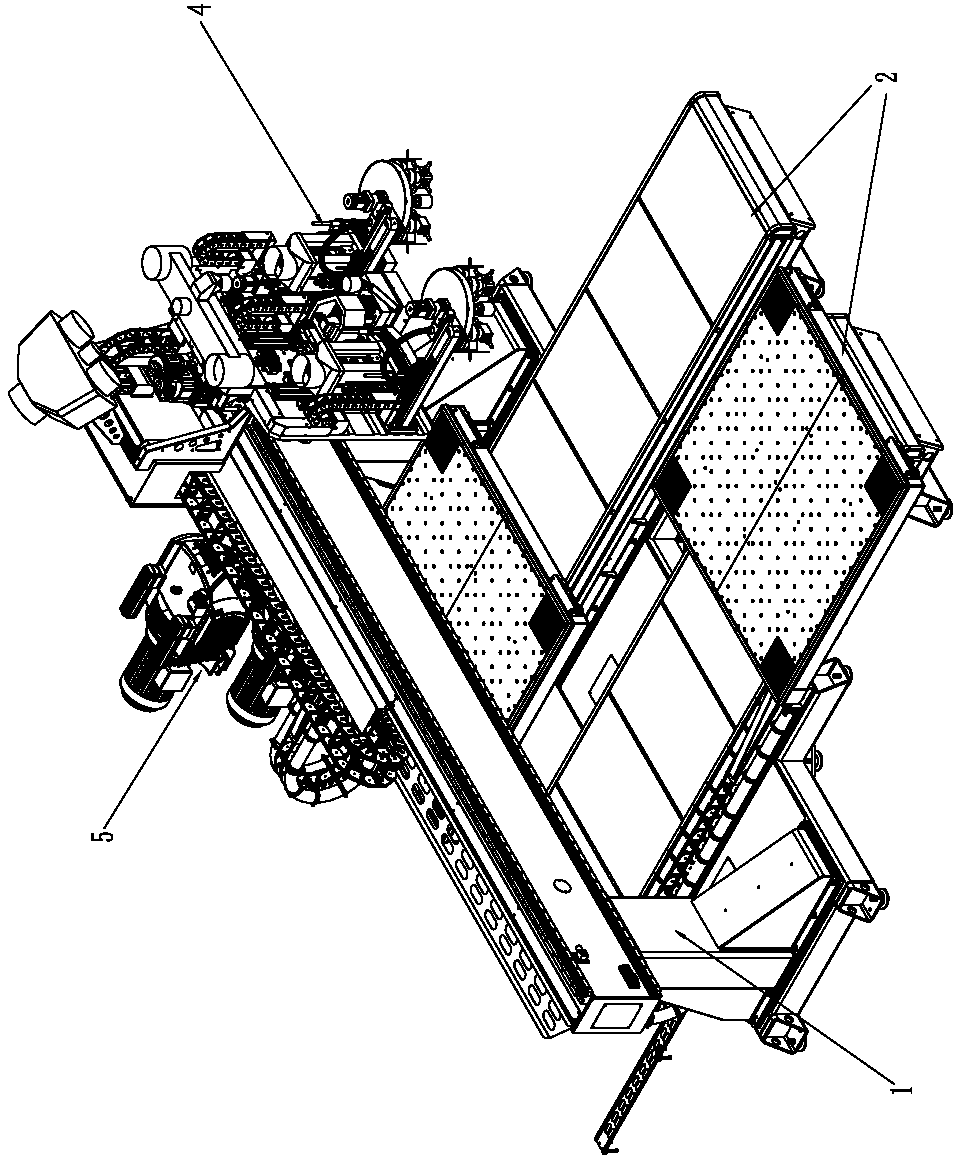

[0044] Please refer to Figure 1 to Figure 28 As shown, it shows the specific structure of the embodiment of the present invention. This double-spindle double-table gantry-type heavy-duty wood composite machining center includes a bed 1, a double-worktable 2, an XZ-axis slide table 3, and a Machine head 4, vacuum pump assembly 5, control cabinet 6 and electric box 7; figure 1 and figure 2 As shown, the periphery of the whole machine is provided with a safety guardrail 8, which ensures the safety of the operator. The control cabinet 6 in this embodiment is a mobile control cabinet, so that it is more convenient to operate.

[0045] The specific structure of the above-mentioned main components is introduced in detail as follows:

[0046] Such as Figure 5 to Figure 8 As shown, the bed 1 includes a base 11, a column 12, and a crossbeam 13 that are separately arranged and assembled together in a detachable manner. , and, the base 11, the column 12 and the beam 13 all include st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com