Pressurized impregnation machine for preparing aluminum electrolytic capacitor

An aluminum electrolytic capacitor, pressurized impregnation technology, applied in drying/impregnation machines, etc., can solve the problems of waste of resources, waste of impregnation liquid, cumbersome processing steps, etc., and achieve the effects of reducing losses, saving costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

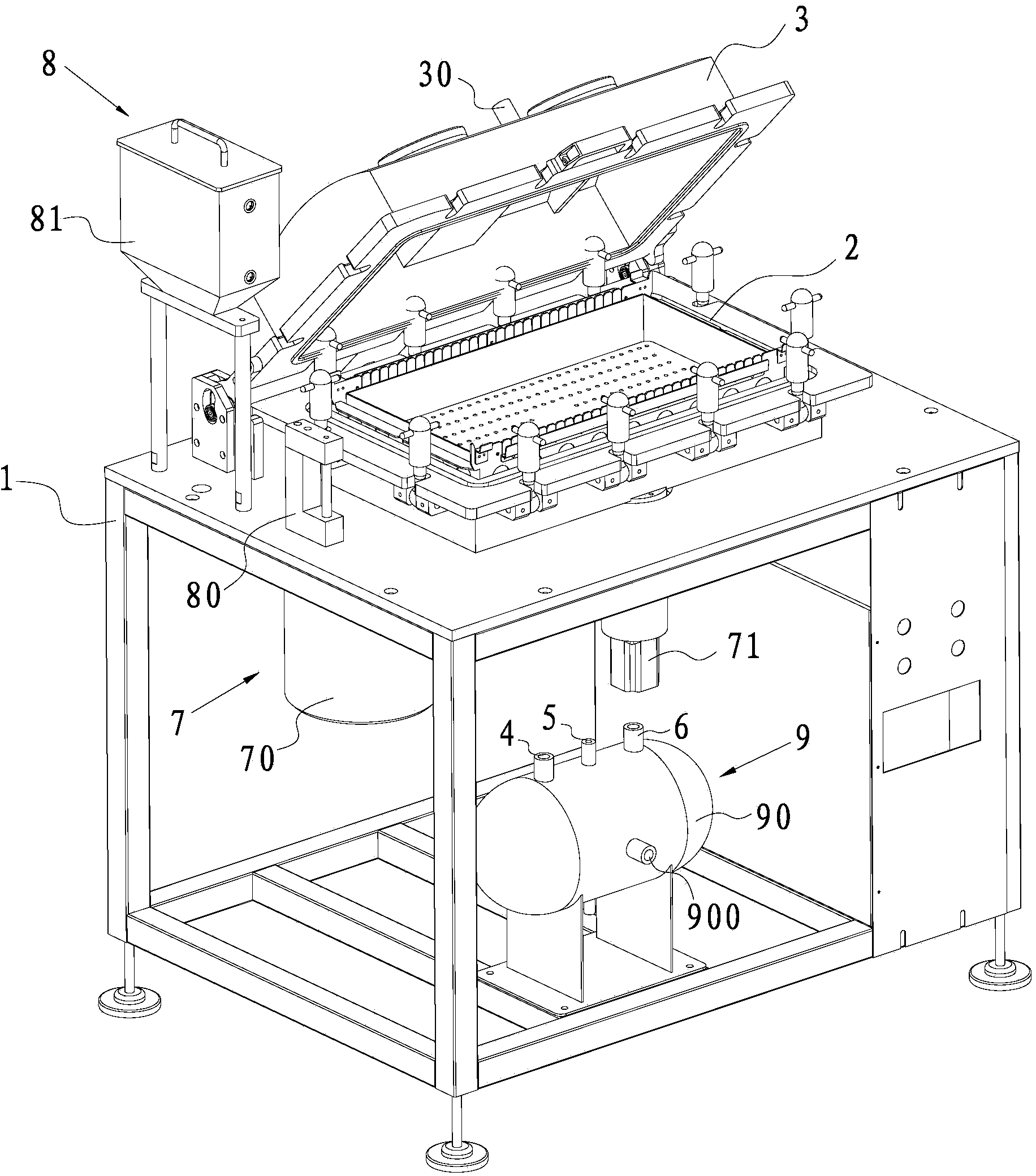

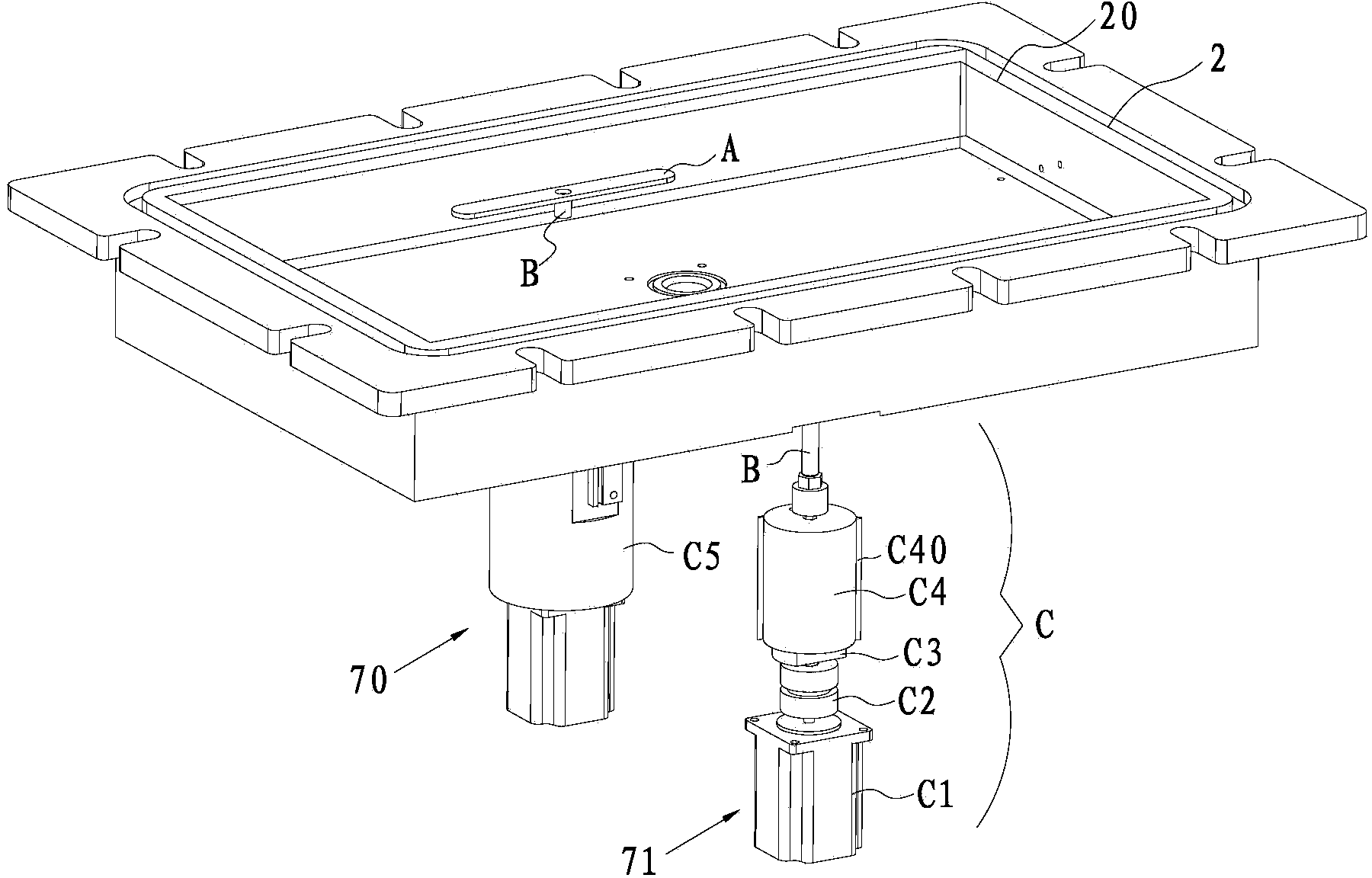

[0018] Such as figure 1 and figure 2 As shown, this embodiment provides a pressurized impregnation machine for preparing aluminum electrolytic capacitors, which includes a frame 1, an impregnation tank 2 arranged on the frame 1, and is sealed with the notch of the impregnation tank 2 to form a sealing cover for the impregnation section 3. Set the carrier for placing the impregnation on the impregnation tank 2, the vacuum tube 4, the air release tube 5, and the compressed air tube 6 connected to the impregnation section, especially, an inner tank 20 is provided in the impregnation tank 2, The bottom of the liner 20 is close to the bottom of the impregnation tank 2, and there is a gap between the periphery of the liner 20 and the inner wall of the impregnation tank 2, and the pressure impregnation machine also includes a lifting mechanism located in the gap for adjusting the height of the carrier 7.

[0019] Further, the above-mentioned lifting mechanism 7 includes a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com