Method for manufacturing capacitor in parallel connection outside core

A manufacturing method and capacitor technology, which can be used in winding capacitors, multilayer capacitors, multiple fixed capacitors, etc., can solve problems such as environmental pollution, and achieve the effect of reducing product cost and stabilizing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

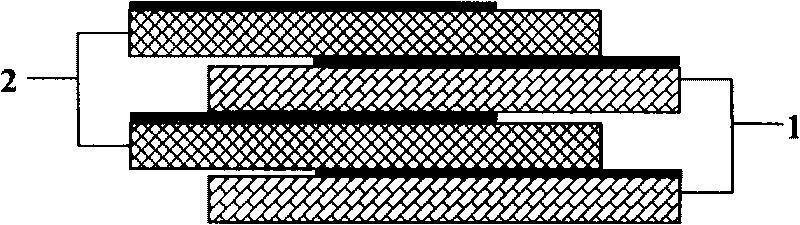

[0033] Embodiment one (see figure 1 ):

[0034] This example is a capacitor with a parallel connection inside the core, as shown in the figure: the capacitor is wound into a capacitor core through a layer of metallized polyester film 1 and a layer of metallized polypropylene film 2 in parallel, and the metallized polyester film The thicknesses of the film 1 and the metallized polypropylene film 2 can be matched in different thicknesses, so as to achieve the best matching of capacity stability at different temperatures.

[0035] The internal shunt capacitor process steps are:

[0036] 1. Use a winding machine to wind a layer of metallized polypropylene film and a layer of metallized polyester film into a capacitor core. The thickness of the film material can be selected and proportioned according to actual needs;

[0037] 2. Flatten the capacitor core and place it on the cold-press fixture, and set the surface pressure of the core to 1.20~1.40kg / mm 2 , pressurize the core fo...

Embodiment 2

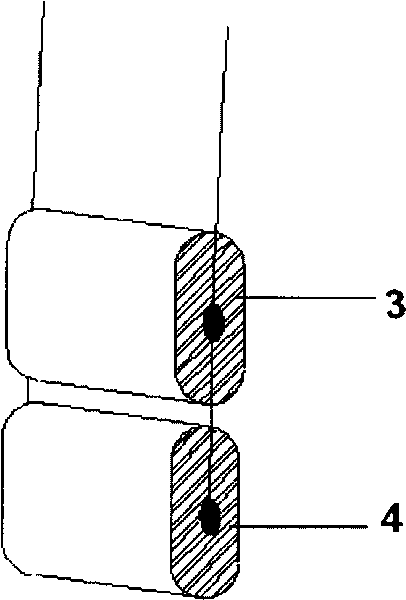

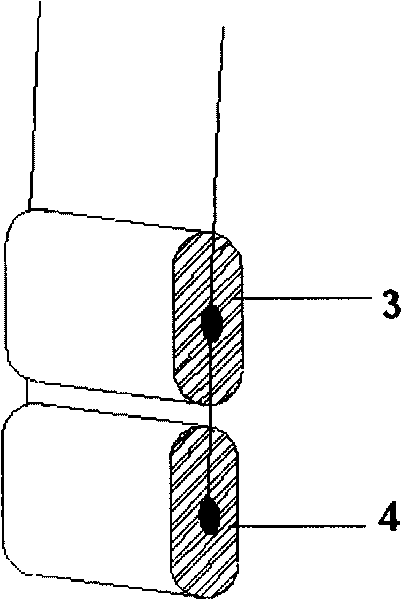

[0045] Embodiment two (see figure 2 ):

[0046] This example is a capacitor with external parallel connection of the core, as shown in the figure: the capacitor is externally connected in parallel through a core 3 wound by a metallized polyester film and a core 4 wound by a metallized polypropylene film. Capacitors, the capacities of the two capacitor cores can be freely matched, so as to achieve the best match of capacity stability at different temperatures.

[0047] External shunt capacitor process steps:

[0048] 1. Use a winding machine to wind two layers of metallized polypropylene film into a capacitor core, and wind two layers of metallized polyester film into a capacitor core. The core capacity is wound according to the pre-designed ratio;

[0049] 2. After flattening the capacitor cores, place them on the cold pressing fixture respectively, and set the surface pressure of the cores to 1.20~1.40kg / mm 2 , pressurize the core for 5 minutes, then put the metallized p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com