Manufacturing method capable of effectively improving product life of capacitor

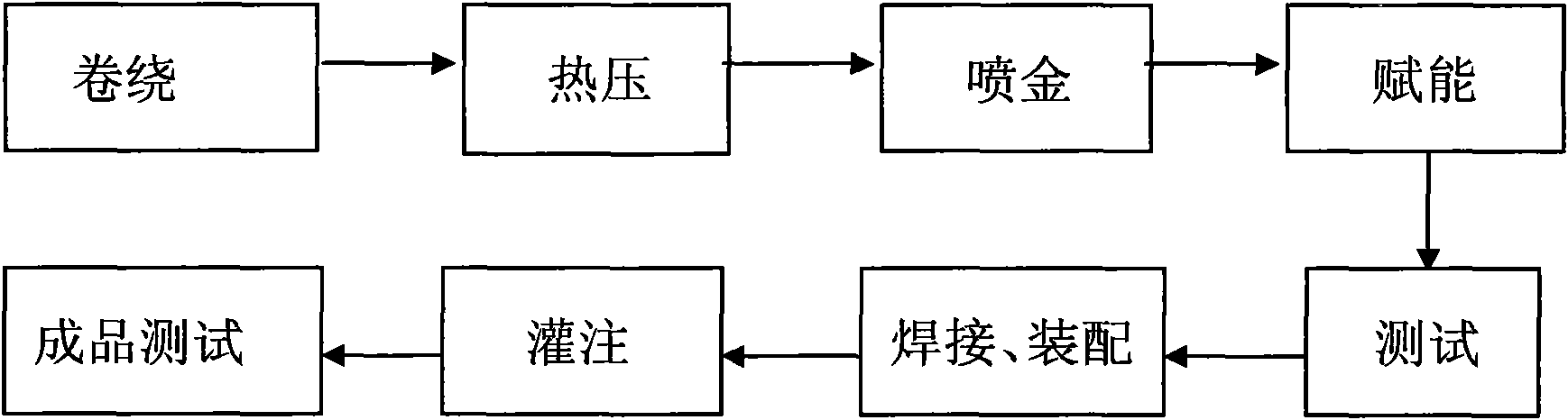

A production method and technology of product life, applied to capacitors, capacitor manufacturing, wire-wound capacitors, etc., can solve problems such as short life and unstable product quality, and achieve the effect of improving product life and stabilizing product capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

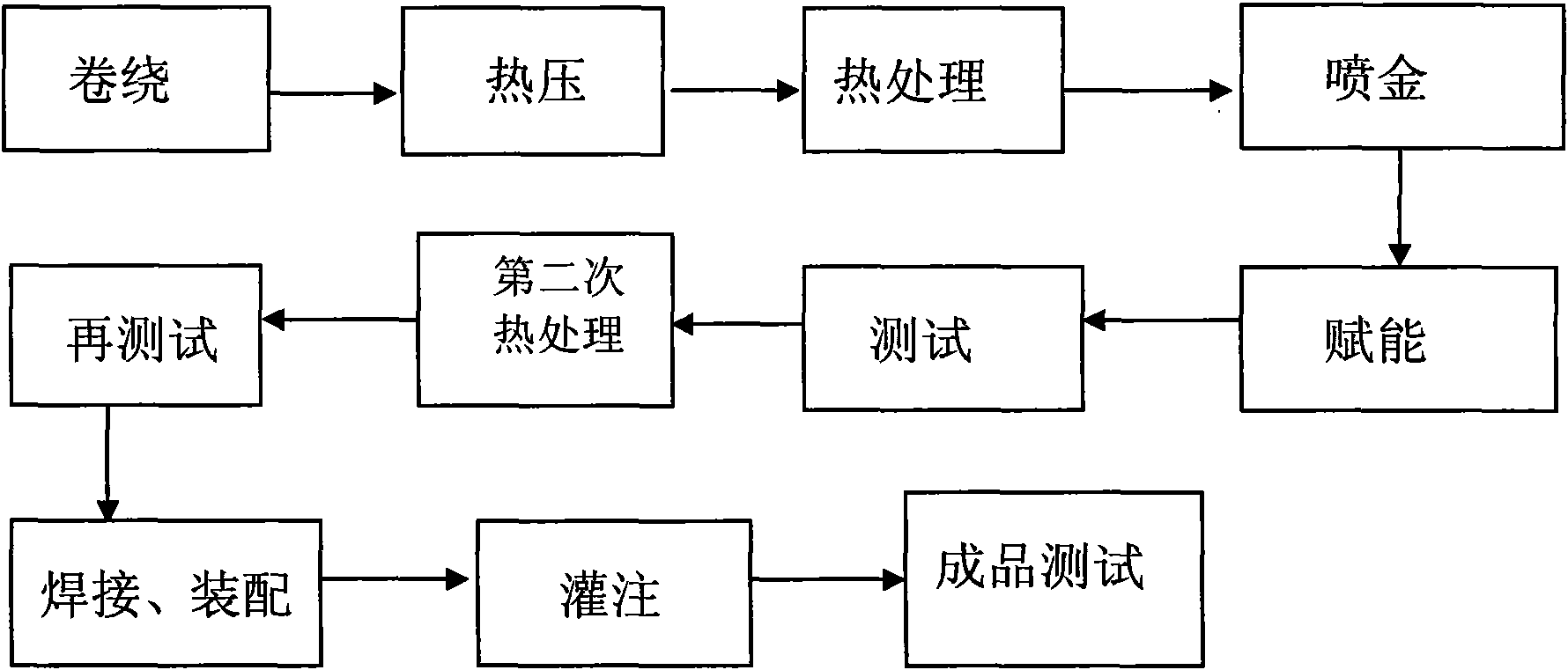

[0012] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail. figure 2 It is a schematic diagram of the production method of the present invention. The present invention includes the following production steps: the first step: winding, the second step: hot pressing, the third step: heat treatment, the fourth step: gold spraying, the fifth step: empowerment, The sixth step: testing, the seventh step: the second heat treatment, the eighth step: retesting, the ninth step: welding and assembly, the tenth step: pouring, the eleventh step: finished product testing.

[0013] The specific steps and methods are as follows:

[0014] Step 1: Winding. It is wound by automatic winding equipment. According to the product, set the technical parameters such as winding speed, slope, number of turns, and inner and outer sealing temperature, and adjust the flip motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com