Mining truck tie rod catching handle assembly

A technology for tie rods and automobiles, which is used in steering tie rods, pivot connections, vehicle parts, etc., can solve the problems of unsatisfactory lubrication of ball bowls and ball studs, inconvenient oil filling, and easy loosening of the adjustment cover. Improve stability and prevent loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

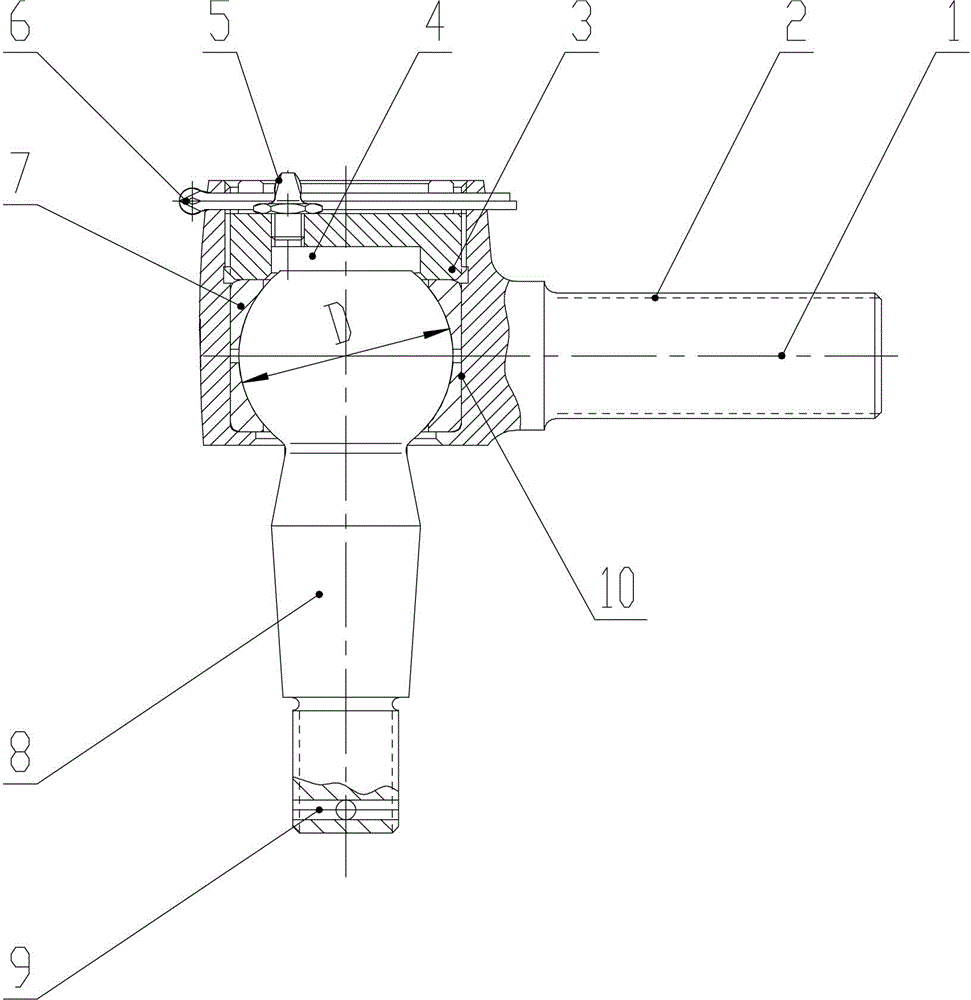

[0011] see figure 1 , the present invention has receiver 1, is provided with installation hole 10 in receiver 1, and ball bowl 7 is housed in installation hole 10, and ball stud pin 8 is installed in ball bowl 7; Adjustment cover 3; in particular: said adjustment cover 3 is provided with an oil inlet groove 4, and the top of the adjustment cover 3 is equipped with an oil nozzle 5, and the oil nozzle 5 communicates with the oil inlet groove 4, and there is an opening between the adjustment cover 3 and the handle 1 pin 6.

[0012] In this embodiment, the handle of the handle 1 is provided with a thread pair 2 .

[0013] In this embodiment, the tail of the ball stud 8 is provided with an anti-loosening ring installation groove 9 for installing an anti-loosening ring.

[0014] The diameter D of the ball stud 8 in this embodiment is 65 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com