Prediction device for tapered roller bearing during configuration of pretightening force

A technology of tapered roller bearing and prediction device, applied in the direction of bearing assembly, bearing, bearing components, etc., can solve the problems of high assembly, affecting bearing preload or axial clearance, bearing clearance change, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

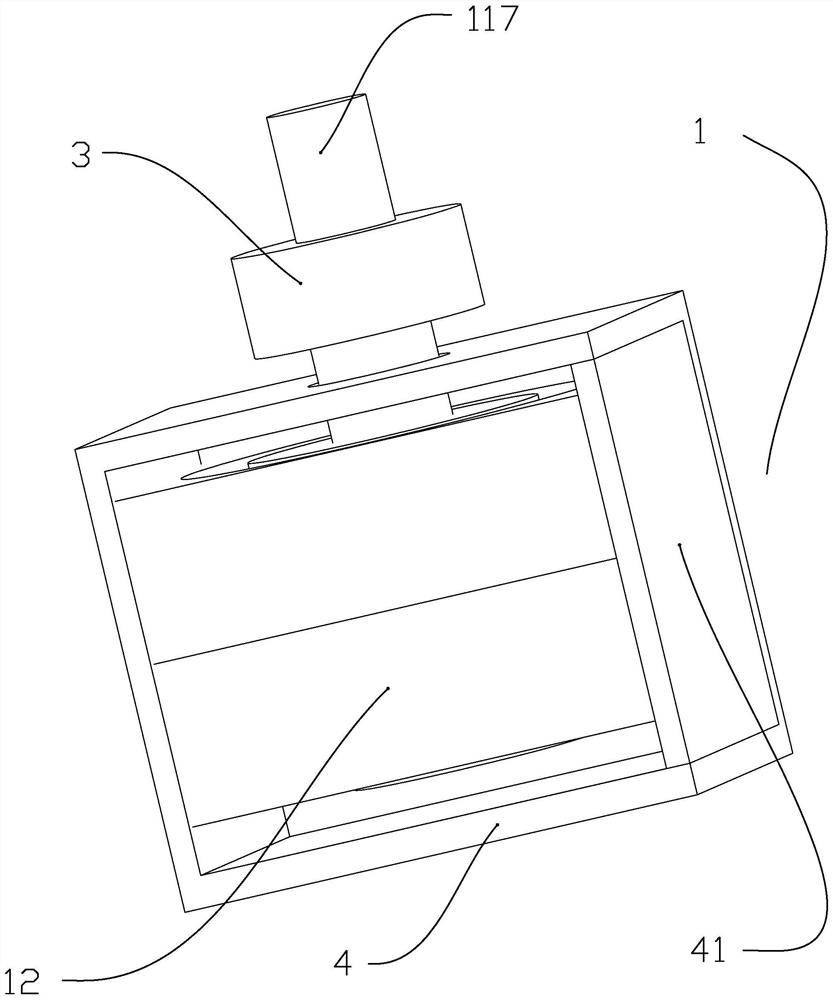

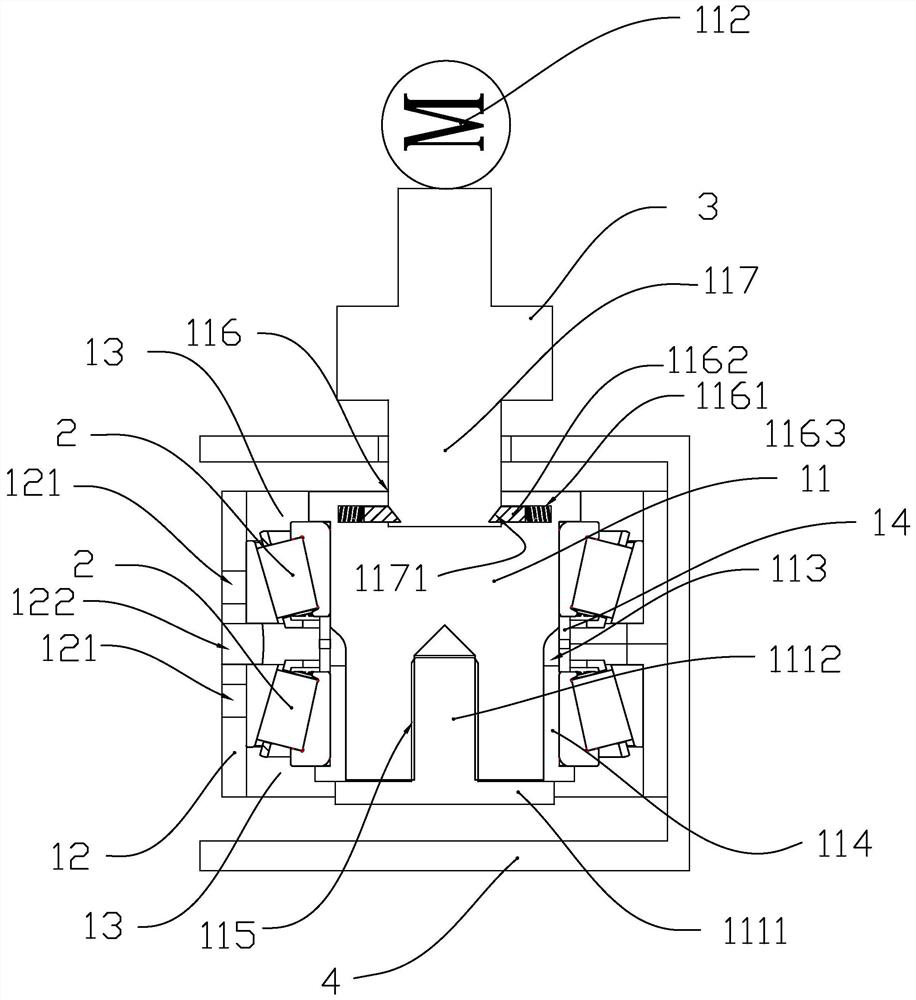

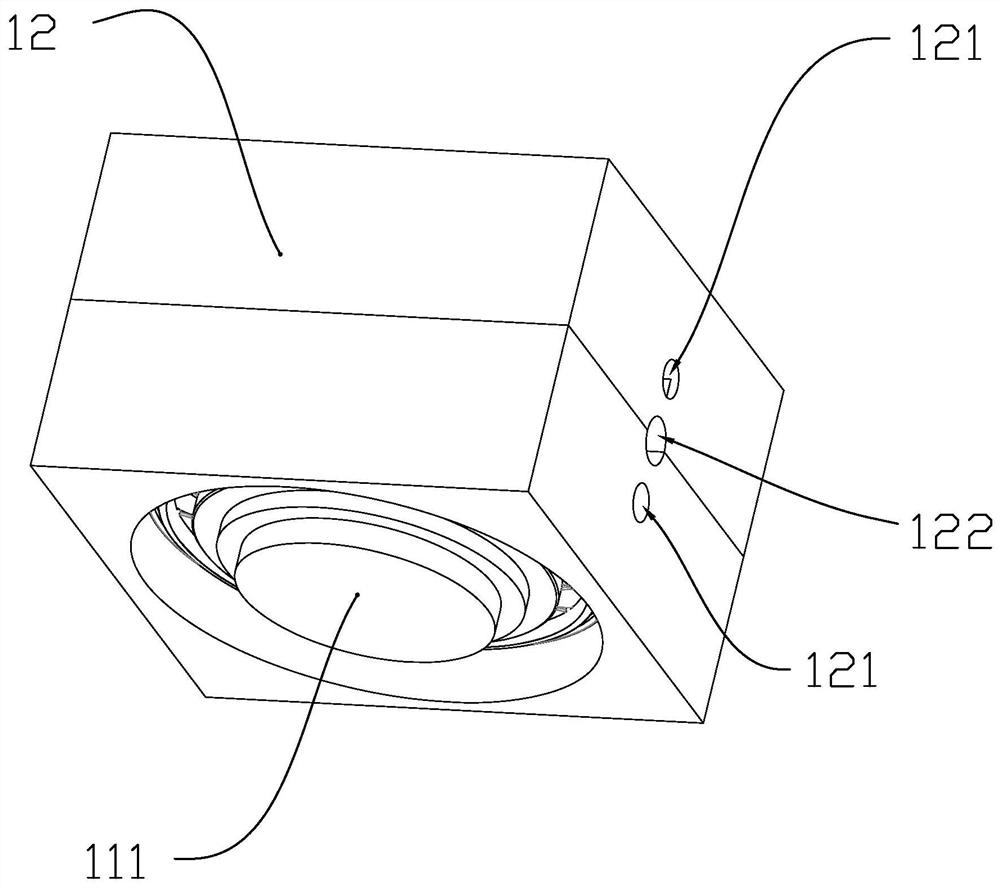

[0027] Specific embodiments of the present invention such as Figure 1-3 As shown, a tapered roller bearing configuration preload prediction device includes a bearing tooling 1, the bearing tooling 1 includes a mandrel 11 for mounting the bearing 2 to be tested and a bearing that matches the outer ring of the bearing 2 to be tested. The housing 12 has two bearing installation stations 13 on the mandrel 11, a lock nut 111 is connected to one end of the mandrel 11, and a motor 112 is connected to the other end, and the motor 112 is connected to the mandrel 11 through The shaft 117 is connected, and the mandrel 11 is provided with a connection hole 116 for the connection shaft 117 to embed. The inner wall of the connection hole 116 is provided with a guide groove 1161, and a push rod 1162 is arranged in the guide groove 1161. A spring 1163 is arranged between the push rod 1162 and the bottom surface of the guide groove 1161 to drive the push rod 1162 to abut against the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com