Cutting mechanism and heading machine

A cutting head and oil-feeding technology, which is applied in cutting machinery, mining equipment, earthwork drilling, etc., can solve problems such as difficult dust cleaning, affecting work efficiency, and bearing failure, so as to reduce the probability of entering the bearing cavity and improve The effect of working efficiency and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. Various preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

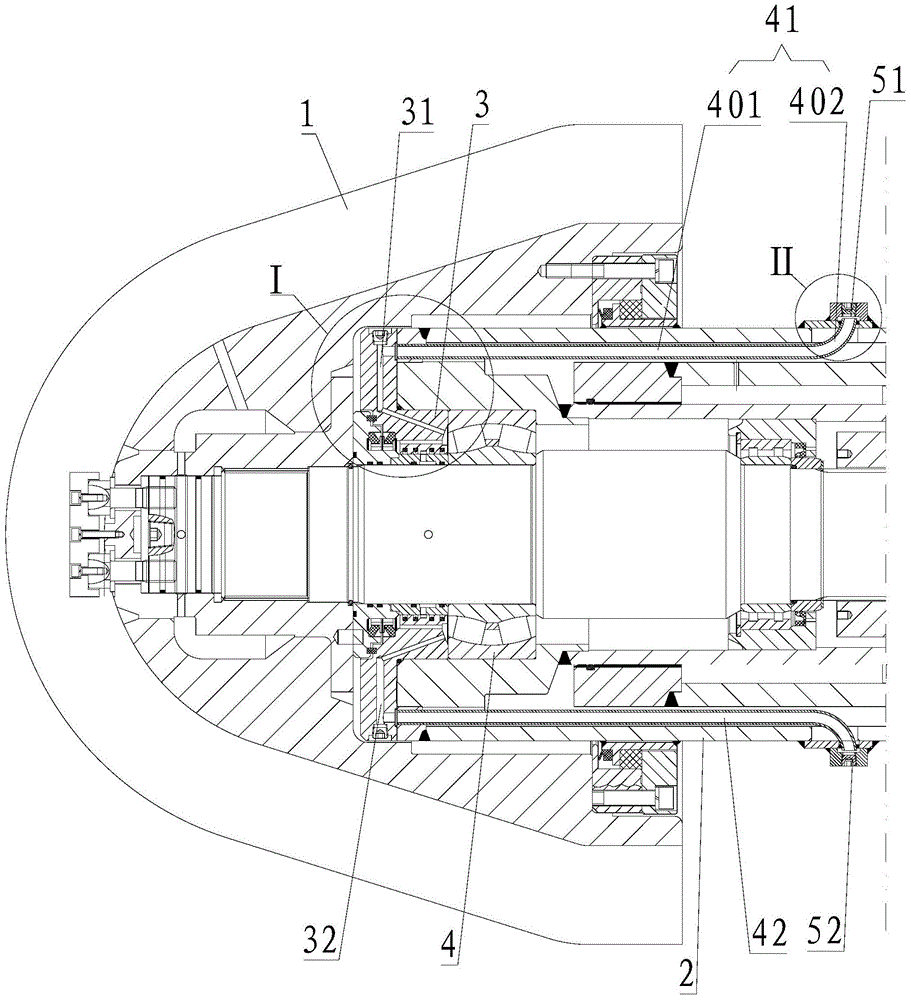

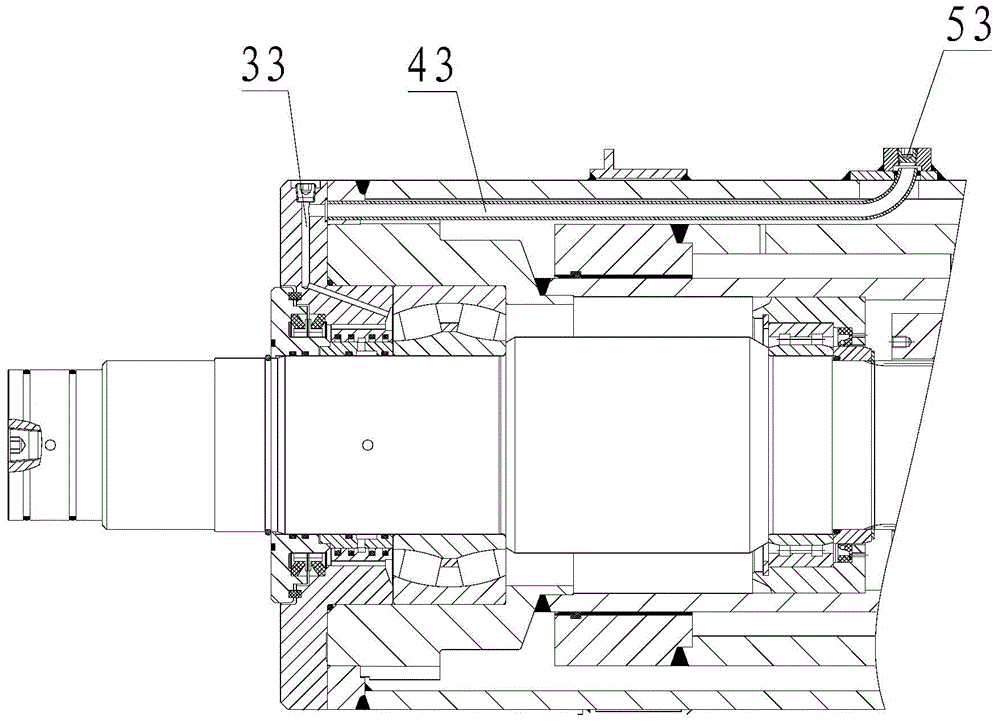

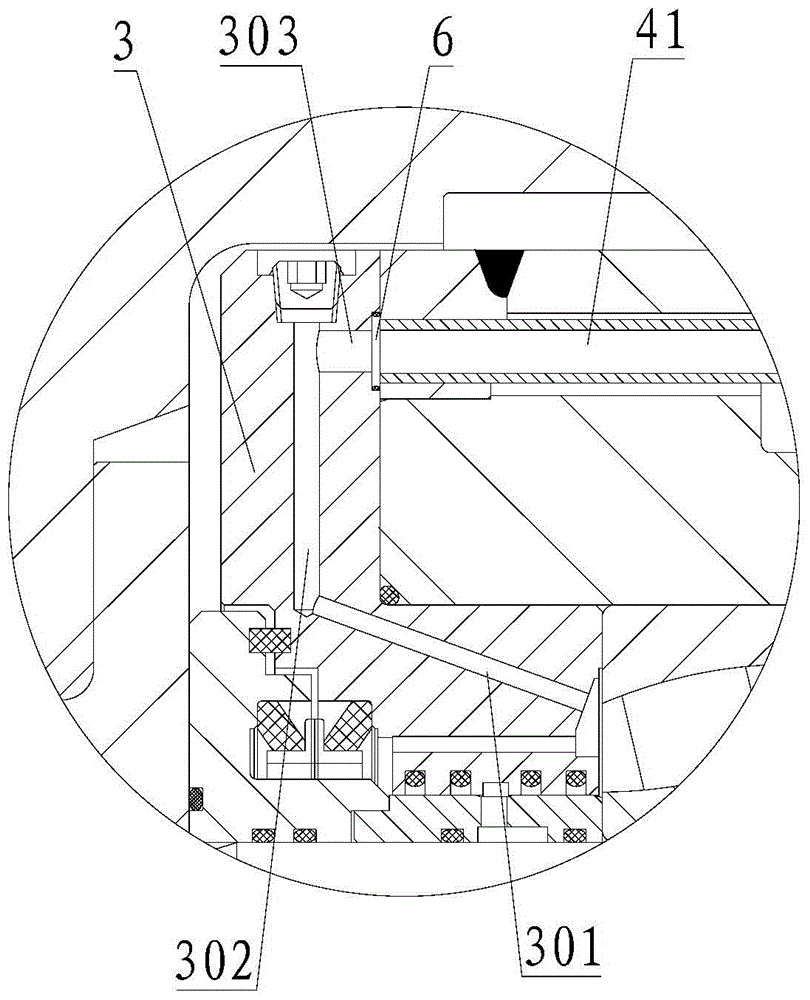

[0035] See figure 1 and figure 2 , which shows the structure of the cutting mechanism provided by the embodiment of the present invention. This cutting mechanism comprises cutting head 1, telescopic part, bearing 4 and floating seal frame 3; Floating seal frame 3 is provided with: oil inlet passage 31, oil discharge passage 32 and oil overflow passage 33; Oil inlet passage 31, The oil discharge passage 32 and the oil overflow passage 33 communicate with the bearing cavity of the bearing 4;

[0036] The cutting mechanism also includes:

[0037] Oil inlet pipeline 41, oil discharge pipeline 42 and oil overflow pipeline 43; communicated, and the other end communicates with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com