Hydraulic gear grinding clamp

A fixture and hydraulic technology, applied in the direction of gear teeth, gear cutting machines, manufacturing tools, etc., can solve the problems of wasting manpower, long clamping operation time, gear skew, etc., and achieve the effect of efficient positioning and easy oil filling operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail in conjunction with specific inventions below.

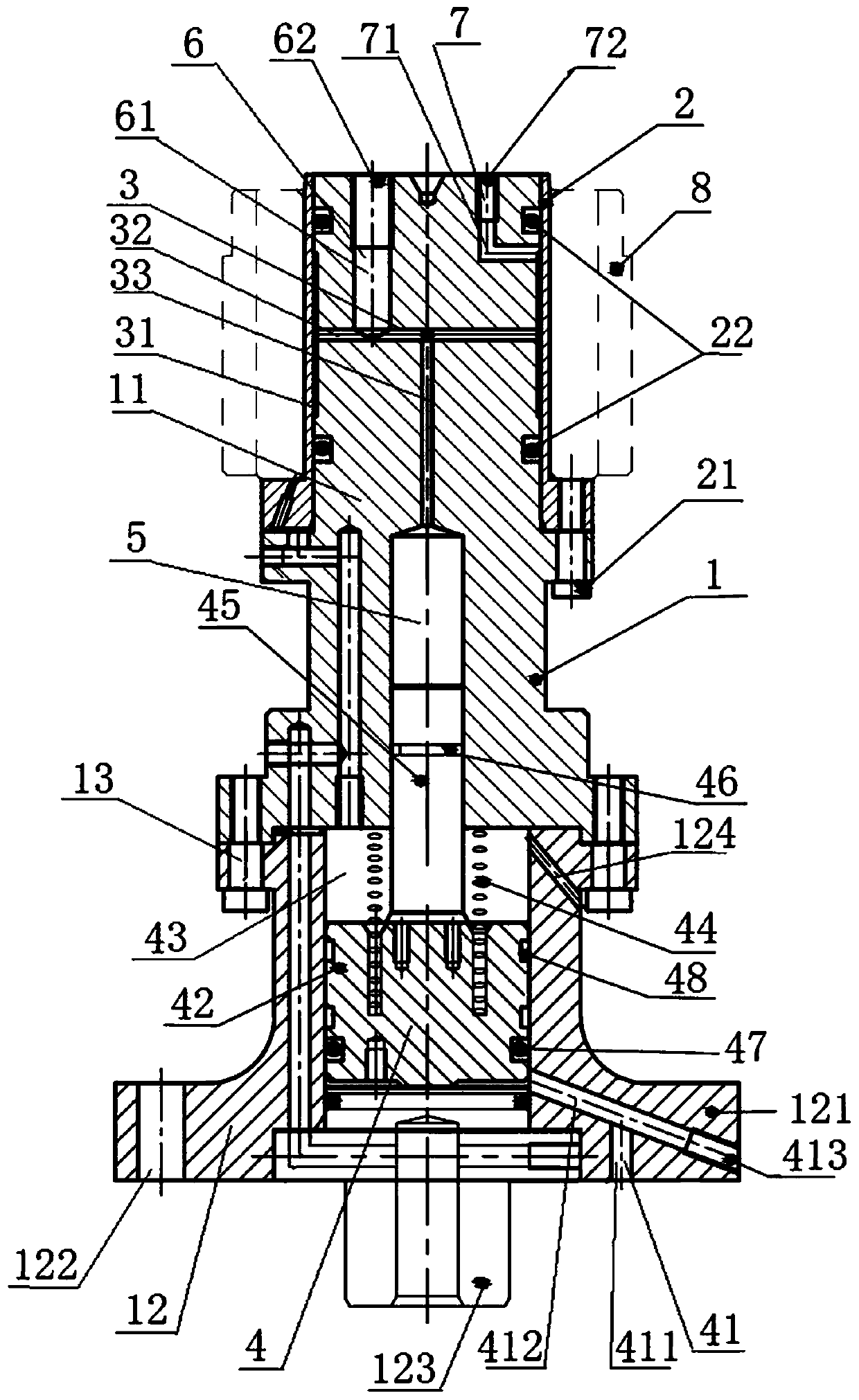

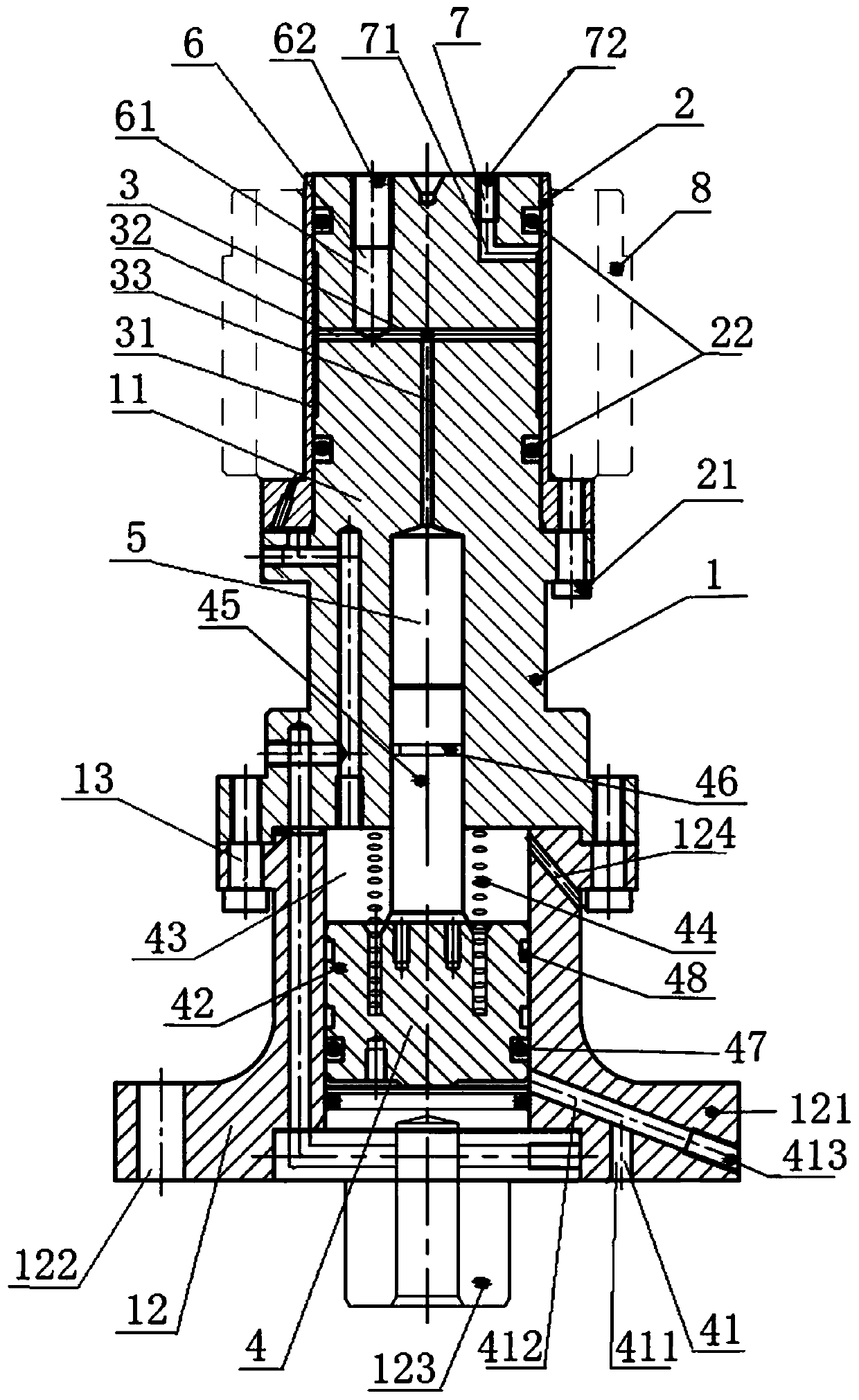

[0024] A hydraulic gear grinding fixture, combined with figure 1 As shown, it includes a clamp body 1 , an elastic sleeve 2 , an upper oil storage chamber 5 , an elastic sleeve tightening oil passage 3 and a hydraulic drive structure 4 .

[0025] The fixture body 1 is divided into a fixture upper body 11 and a fixture lower body 12 , and the fixture upper body 11 and the fixture lower body 12 are fixedly connected by hexagon socket bolts 13 . The lower part of the fixture lower body 12 is provided with a base 121, and the middle part of the base 121 is provided with a positioning shaft 123, and the positioning shaft 123 is used for inserting the fixture body 1 into the gear grinding machine workbench to realize the positioning of the fixture body 1. A connecting hole 122 is opened on the base 121, and the connecting hole 122 is used for passing a bolt to fix the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com