One-time thermoform composite mold for nickel-titanium shape memory alloy patellar concentrator and operation method thereof

A memory alloy and composite mold technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of increasing the production cost of products, the impact of material strength is large, and the number of molding times, etc., to save costs and reduce processing procedures. , reduce the effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

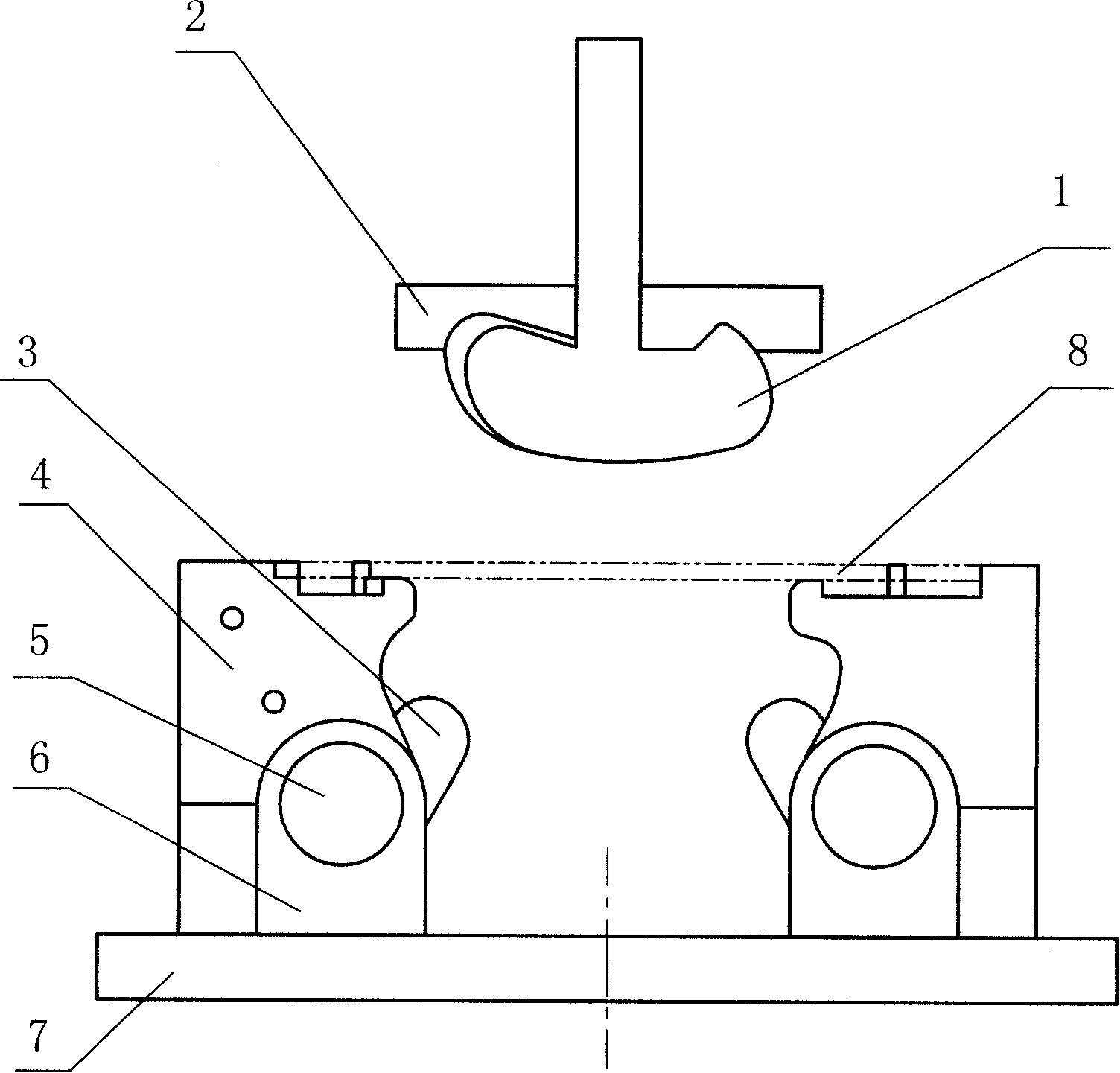

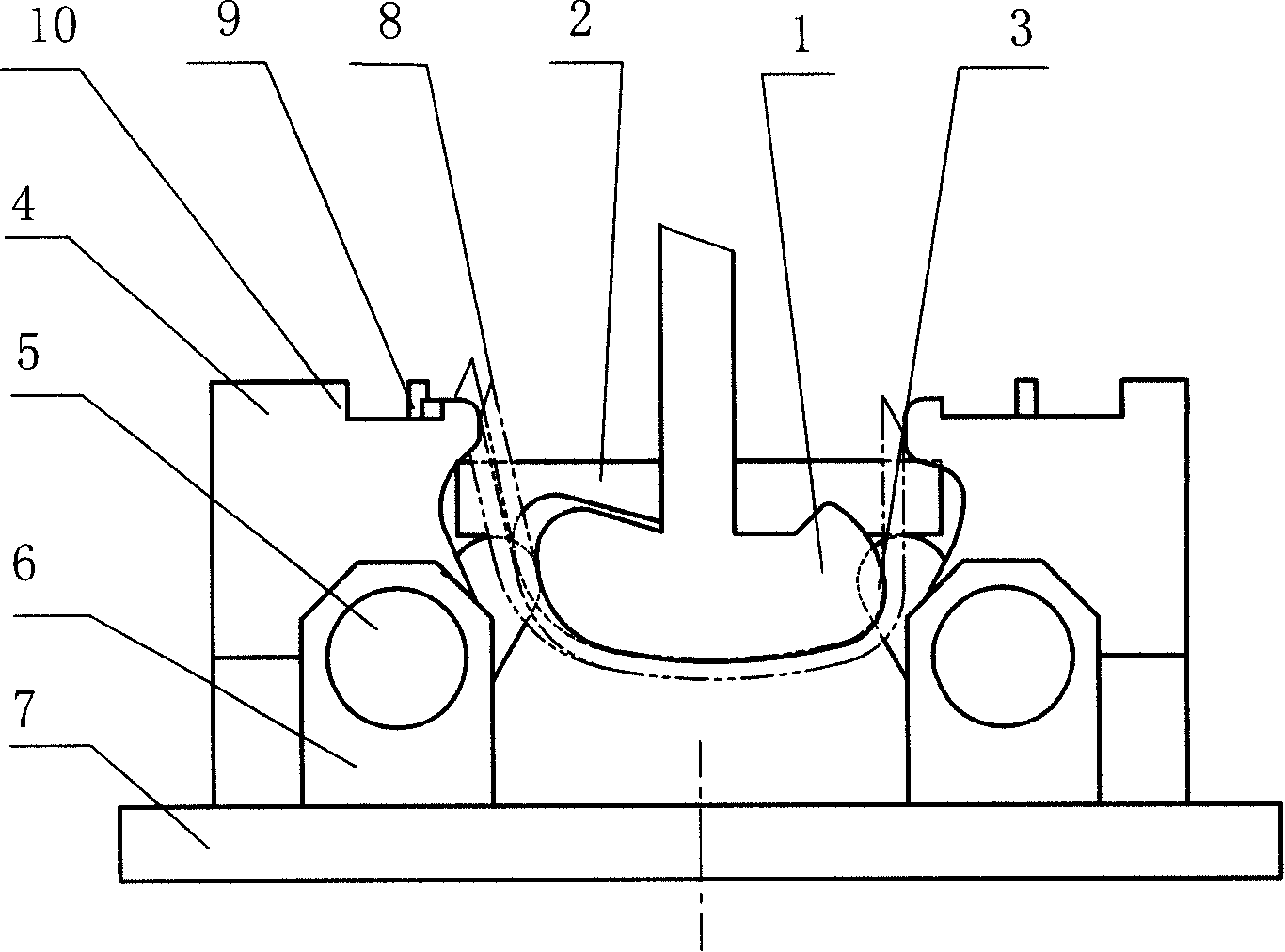

[0035] The invention includes an upper punch and a lower die. Set the upper punch at the top, the lower die at the bottom, the side close to the operator is the front of the mold, and vice versa is the rear of the mold.

[0036] It is characterized in that the upper punch includes a convex module 1 and a pressing plate 2 .

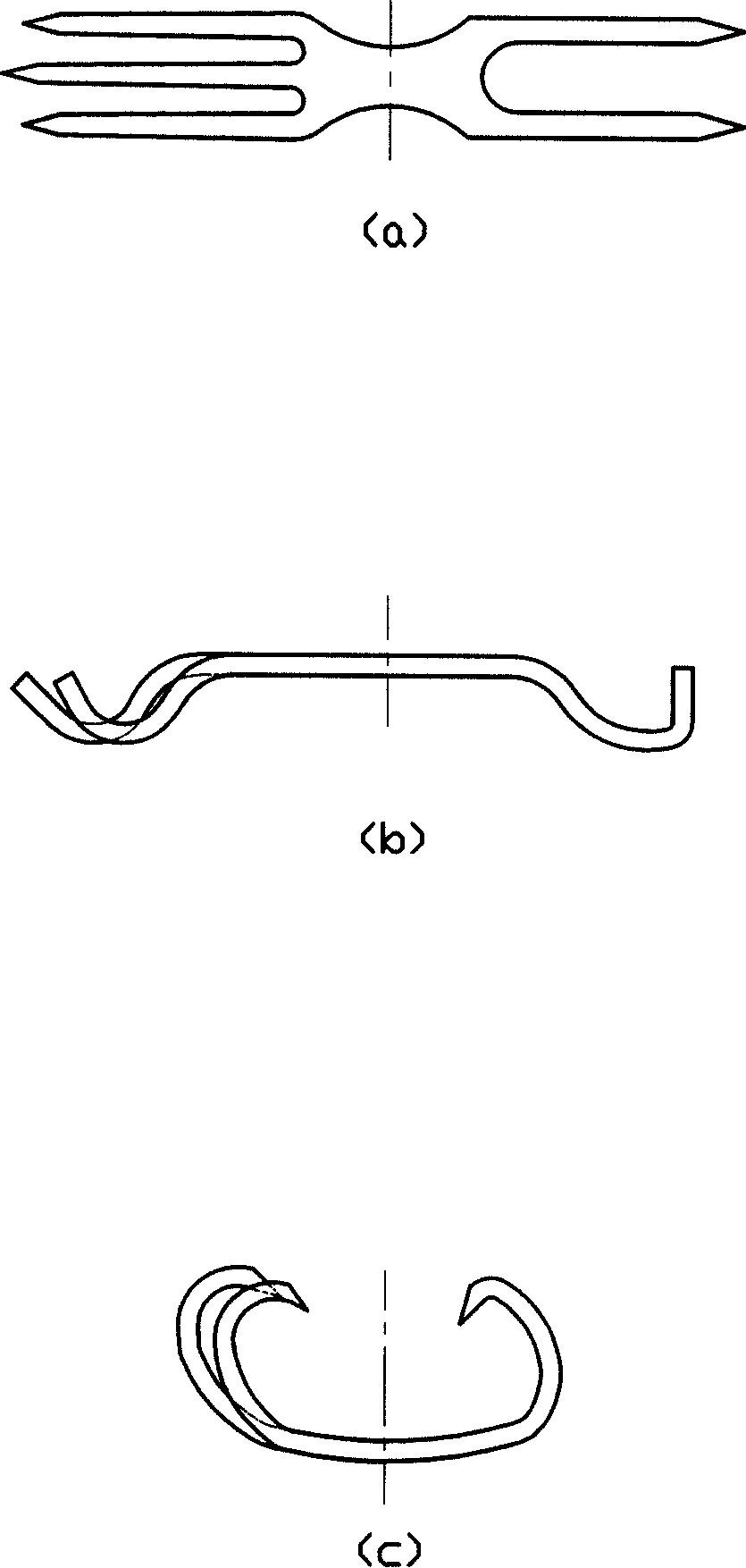

[0037]The convex module 1 is a waist-shaped entity with circular arcs at both ends, and its shape and size match the patella concentrator 8 after bending, that is, one side is an arc-shaped m claw, and one side is an arc-shaped claw. n claws, between m claws and n claws is a flat bottom plate, between the claws of m claws and n claws, there are vacant grooves greater than the width of the claws. In this embodiment, m is three, and n is two.

[0038] The pressing plate 2 of the upper punch is elongated, located behind the convex module 1 and above the lower end surface of the convex module 1 .

[0039] The lower die includes a concave module 4 and a cam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com