Half stamp forging forming die

A forming die and punching forging technology, applied in the field of punching and forging forming die, can solve the problems of high cost, low efficiency and high cutting cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

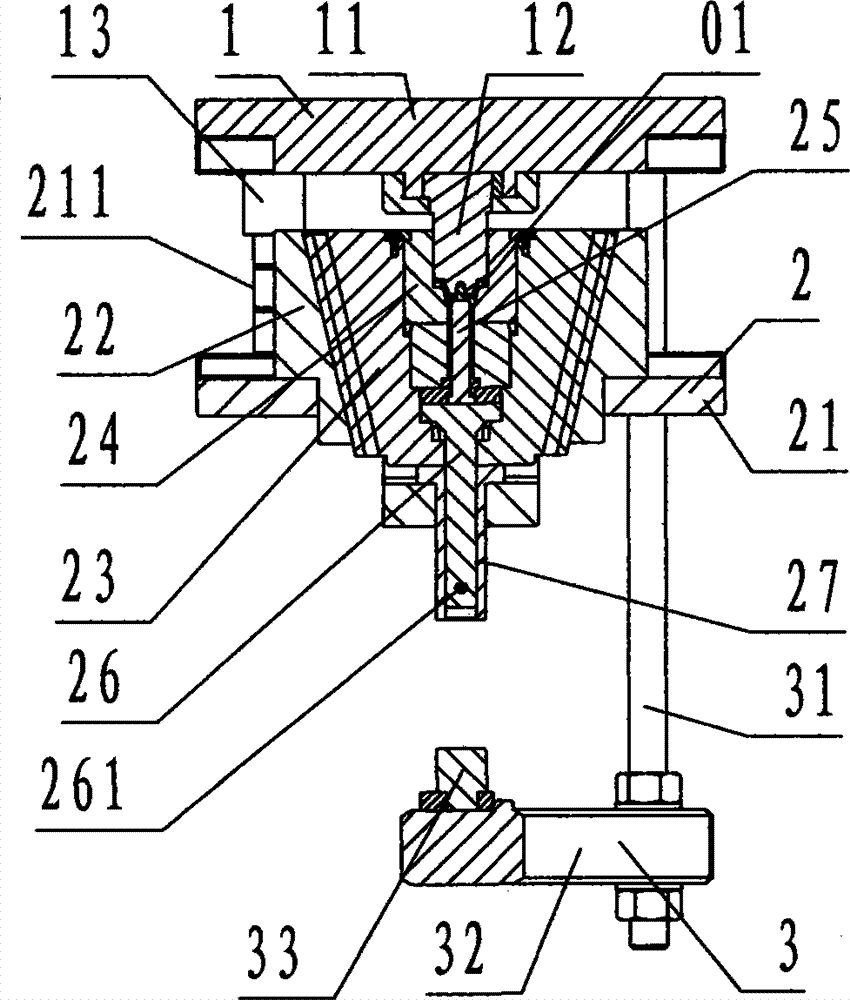

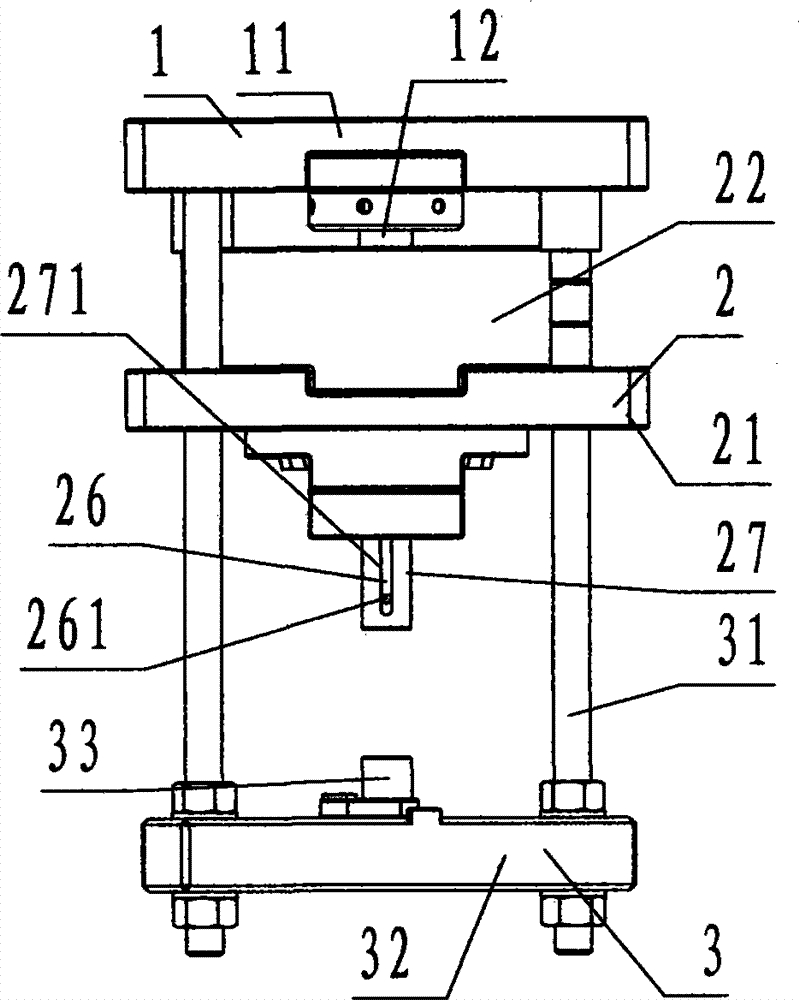

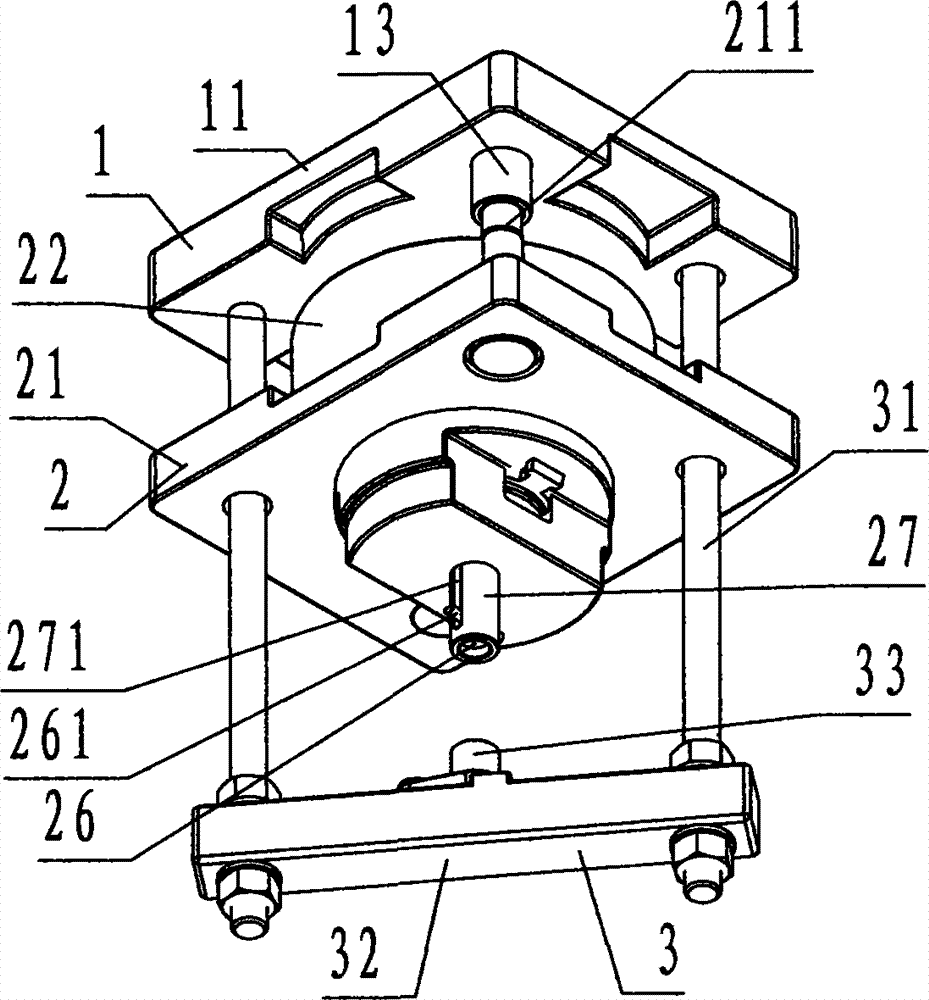

[0033] refer to Figure 1 to Figure 8, a conforming stamping and forging molding die of the present invention includes an upper die 1, a lower die 2, and a stripper 3, wherein: the upper die 1 is composed of an upper die carrier plate 11 and a core punch 12, and the The upper mold support plate 11 is a rectangular plate-shaped steel member. The two opposite corners of the upper mold support plate 11 are provided with guide sleeves 13 for cooperating with the guide pillars 211, and the other two opposite corners are provided with guide sleeves 13 for connecting pull rods 31. The step through hole is called the tie rod fixing hole; the lower center of the upper mold carrier plate 11 is provided with a downwardly protruding core punch 12, and the core punch 12 is provided on the bottom to match the shape of the upper part of the undercut product 01. Profiled cylindrical steel member;

[0034] The lower mold 2 is composed of a base 21, a guide post 211, a tapered cavity cover 22,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com