Die gap gas-aid ejection pin mechanism

A technology of clearance gas and thimble, which is applied in the field of mold accessories to reduce deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

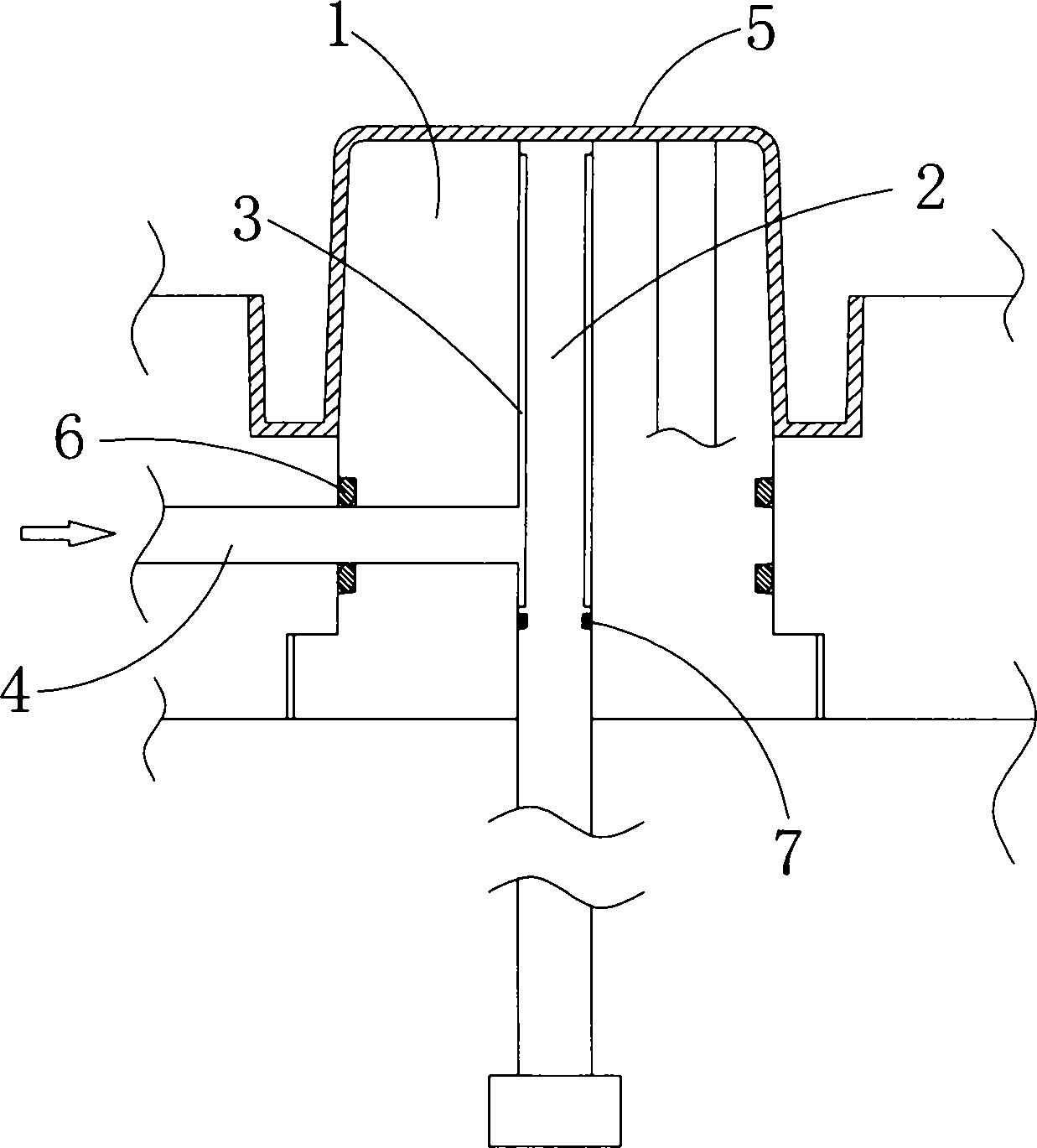

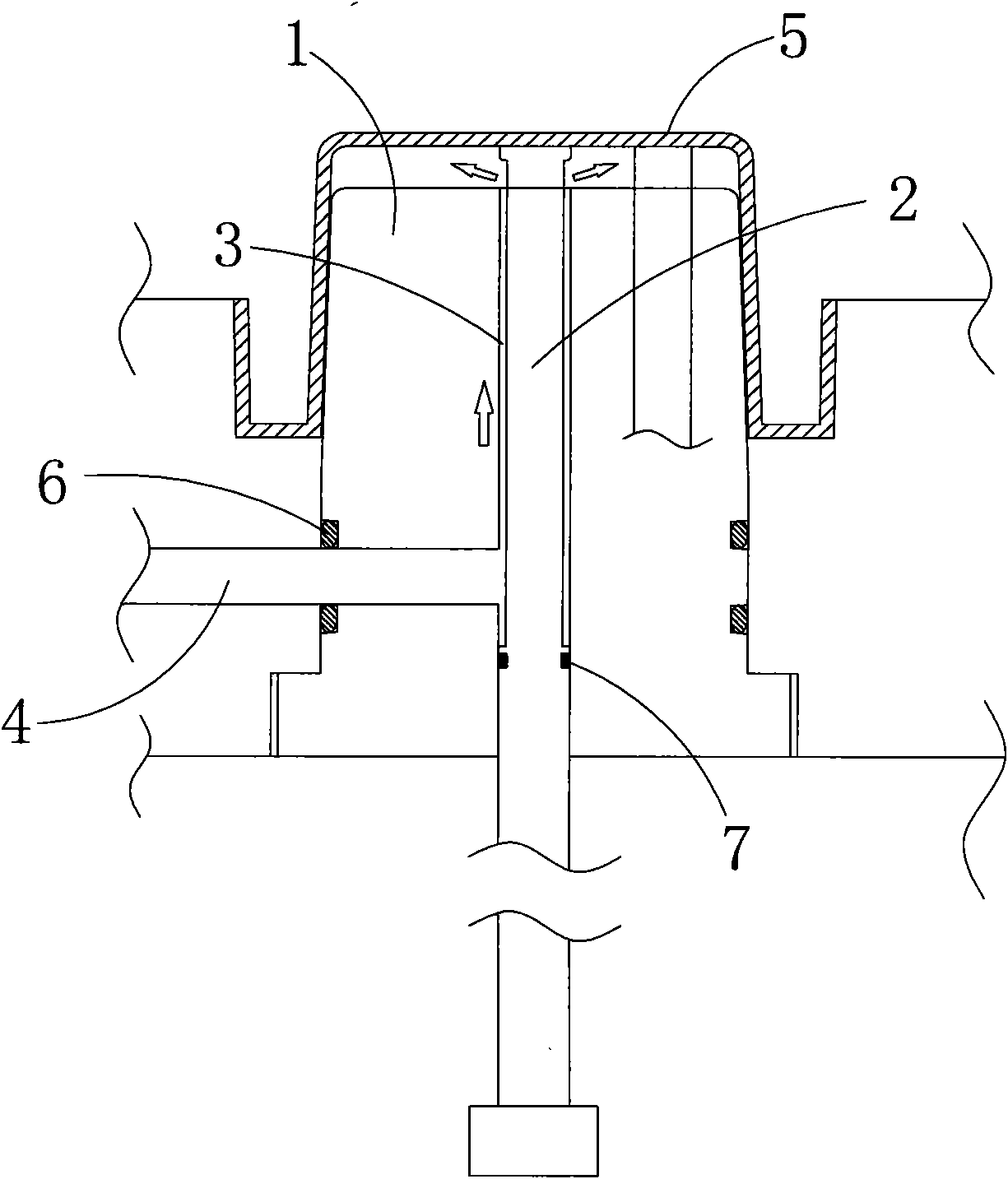

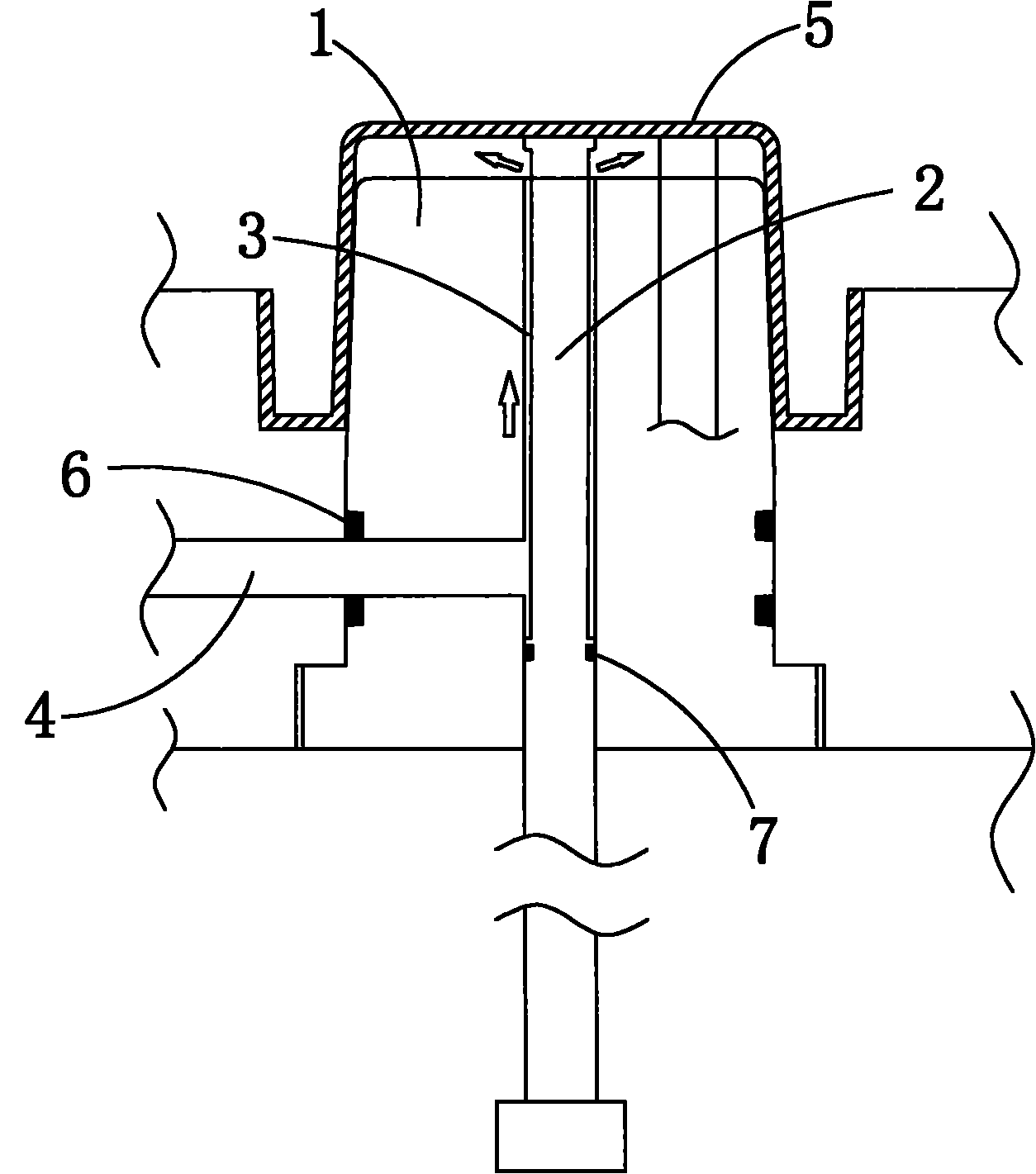

[0013] Embodiment: A mold gap gas-assisted thimble mechanism, the middle part of the mold core 1 is provided with a thimble groove penetrating up and down, and a gap gas-assisted thimble 2 is interspersed in the thimble groove. There is a gap 3 between the outer surface of the middle part of the air-assisted thimble in the gap and the inner surface of the thimble groove. Gas channel 4, one end of the gas channel communicates with the outside and the other end communicates with the gap 3, external compressed gas can pass through the gas channel, the diameter of the lower part of the gas-assisted thimble 2 in the gap is larger than the middle diameter, so The lower part of the gap gas-assisted thimble closely fits the thimble groove, and when the gap gas-assisted thimble 2 is ejected, the gas channel 4 , the gap 3 and the ejection surface of the product 5 communicate with each other. The middle part of the gap gas-assisted thimble of the present invention is processed so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com