Core mold, manufacturing method of core mold and irregular composite pipe forming method

A composite material and molding method technology, which is applied in the field of mandrel and its preparation, and composite special-shaped tube molding, which can solve the problems of inconvenient demoulding and complicated molding process, and achieve easy demoulding, high surface precision and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

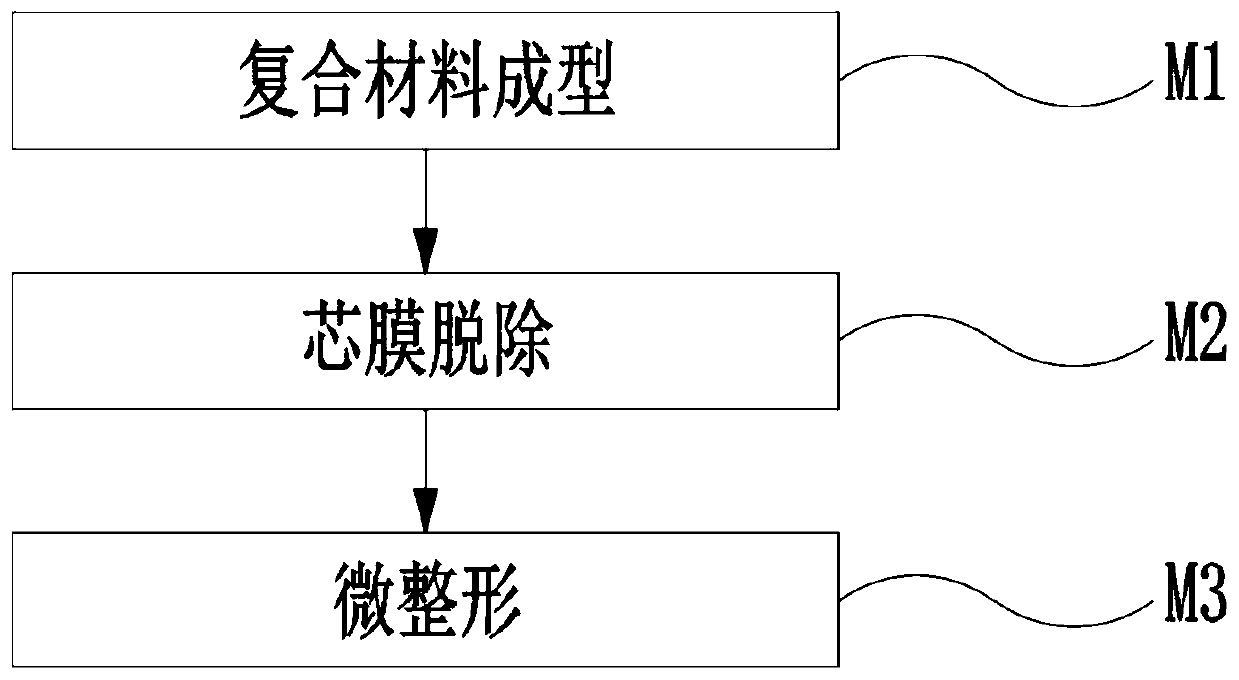

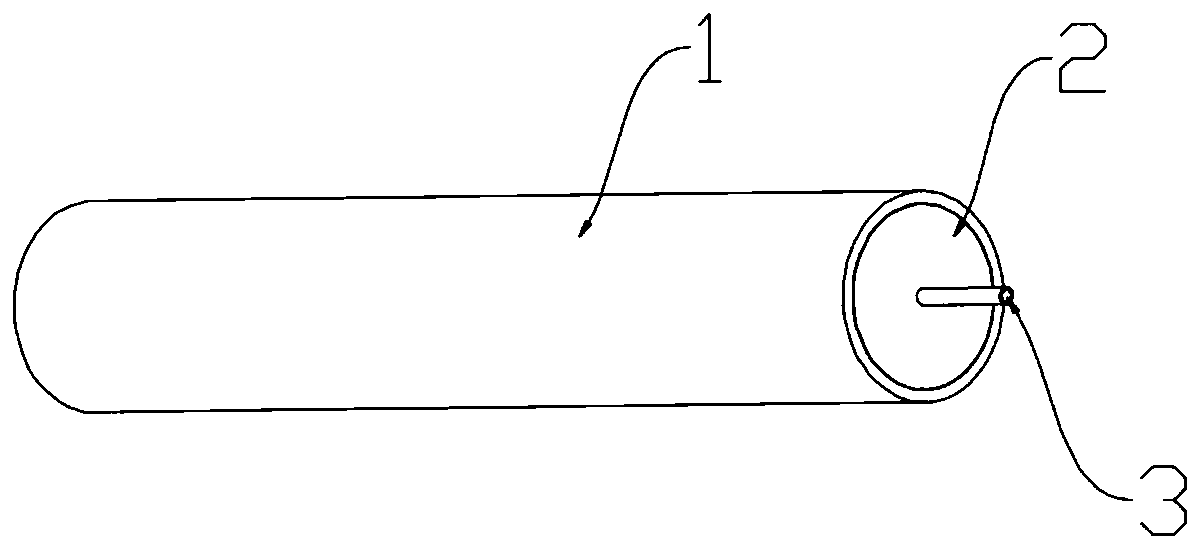

[0036] For special-shaped pipes with relatively complex structures, especially composite special-shaped pipes, due to their complex structure and cumbersome manufacturing process, it is difficult to remove the mandrel, and the mandrel is easily damaged during the removal process. Deformation of shaped tubes.

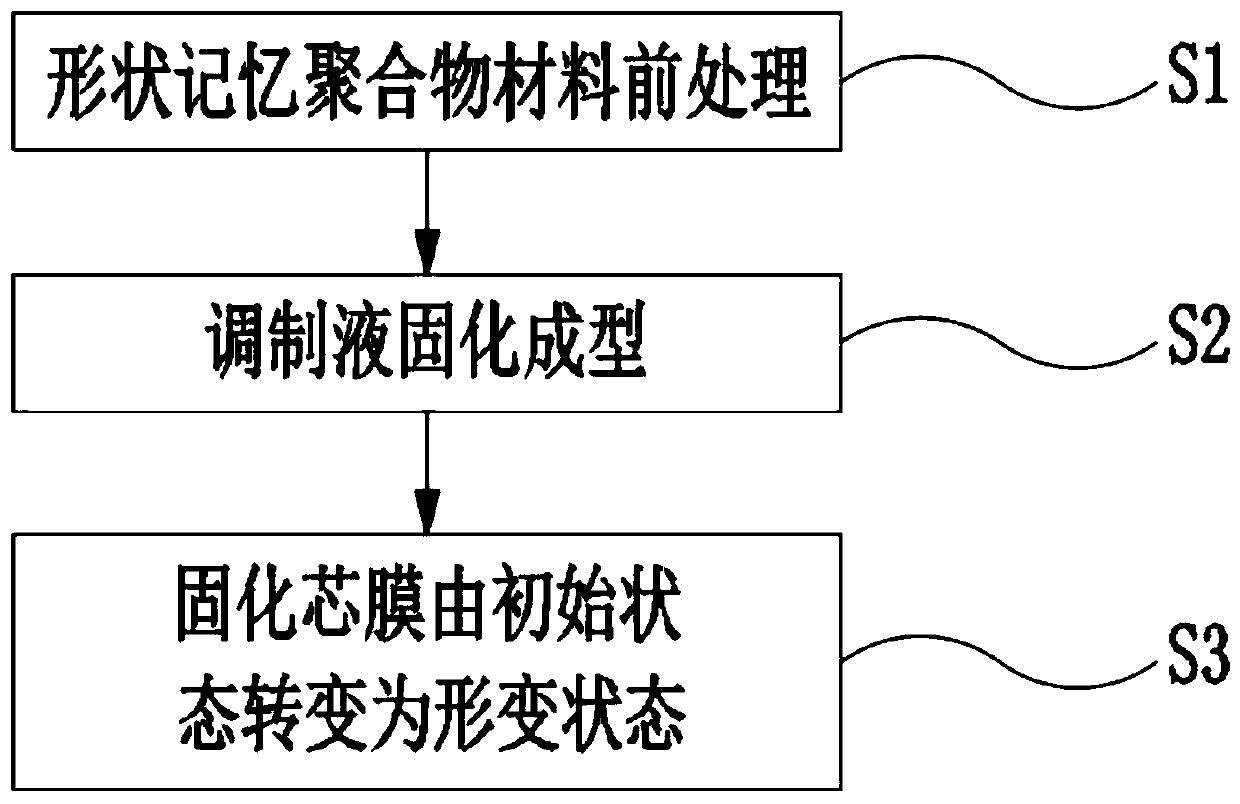

[0037] The present invention aims to provide a mandrel that is easy to remove in the special-shaped pipe manufacturing process, and the mandrel is made of shape-memory material. The core mold is made of shape-memory polymer. Shape-memory polymer (SMP) is a new smart material, which can actively restore its original shape under external stimuli, and has a wide range of application scenarios.

[0038] The typical recovery process of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com