A dynamic pressure regulating grinding type tartary buckwheat hulling machine

A tartary buckwheat shelling machine and dynamic pressure regulation technology, which is applied in grain shelling, grain processing, application, etc., can solve the problem of tartary buckwheat shelling, cracking kernels and breaking high, achieve soft and slow mechanical extrusion, and increase grinding time , The effect of high shelling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

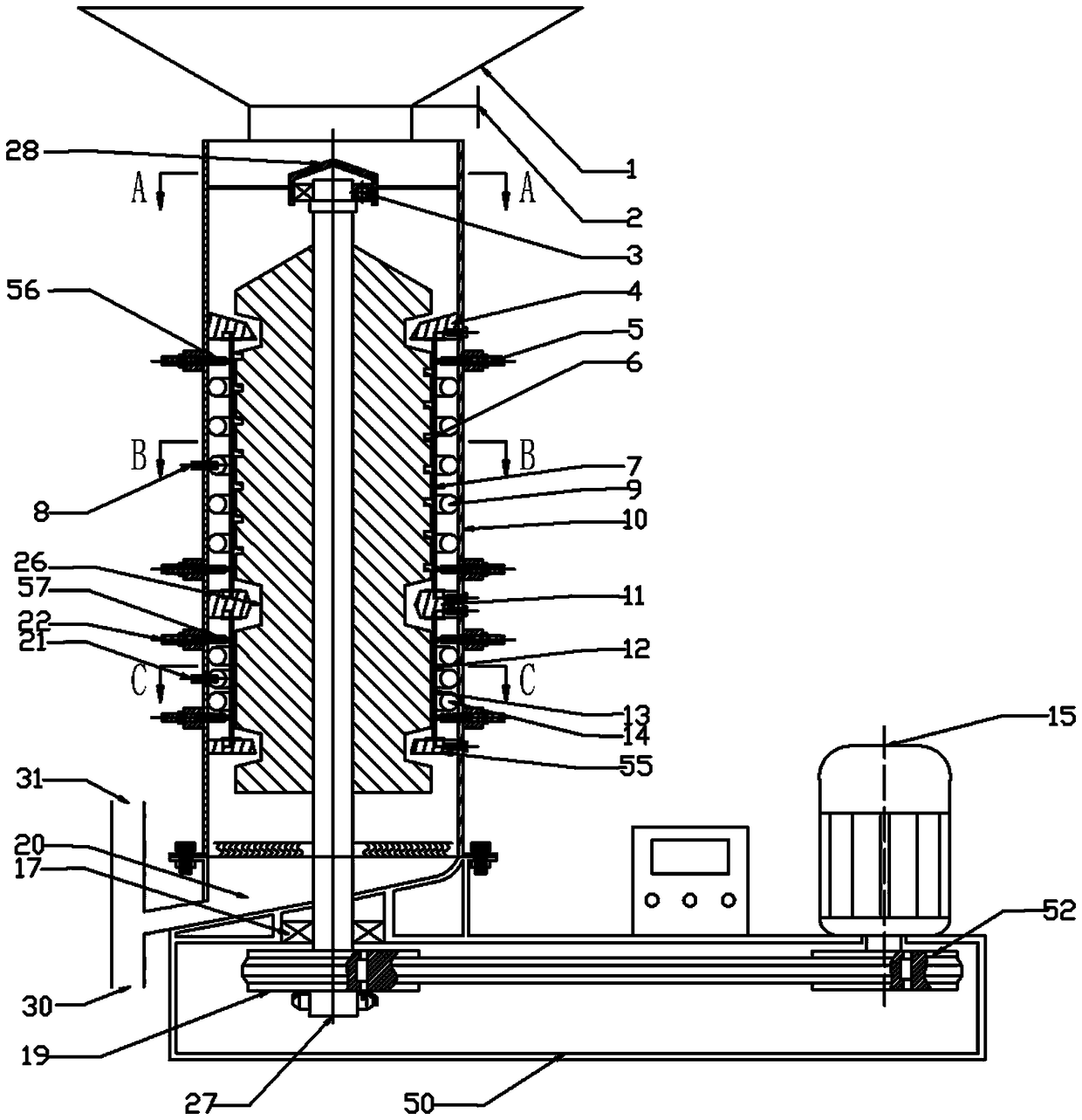

[0054] Embodiment 1: A dynamic pressure-regulating grinding type tartary buckwheat hulling machine

[0055] Such as figure 1 and figure 2 As shown, the described a kind of dynamic pressure regulating grinding type tartary buckwheat hulling machine includes a casing 10, the casing 10 is an upright cylindrical shape, and the inside of the casing 10 is concentrically equipped with a grinding cylinder 7 and a kneading circle. Cylinder 12; the grinding cylinder 7 is on the top, and the kneading cylinder 12 is on the bottom.

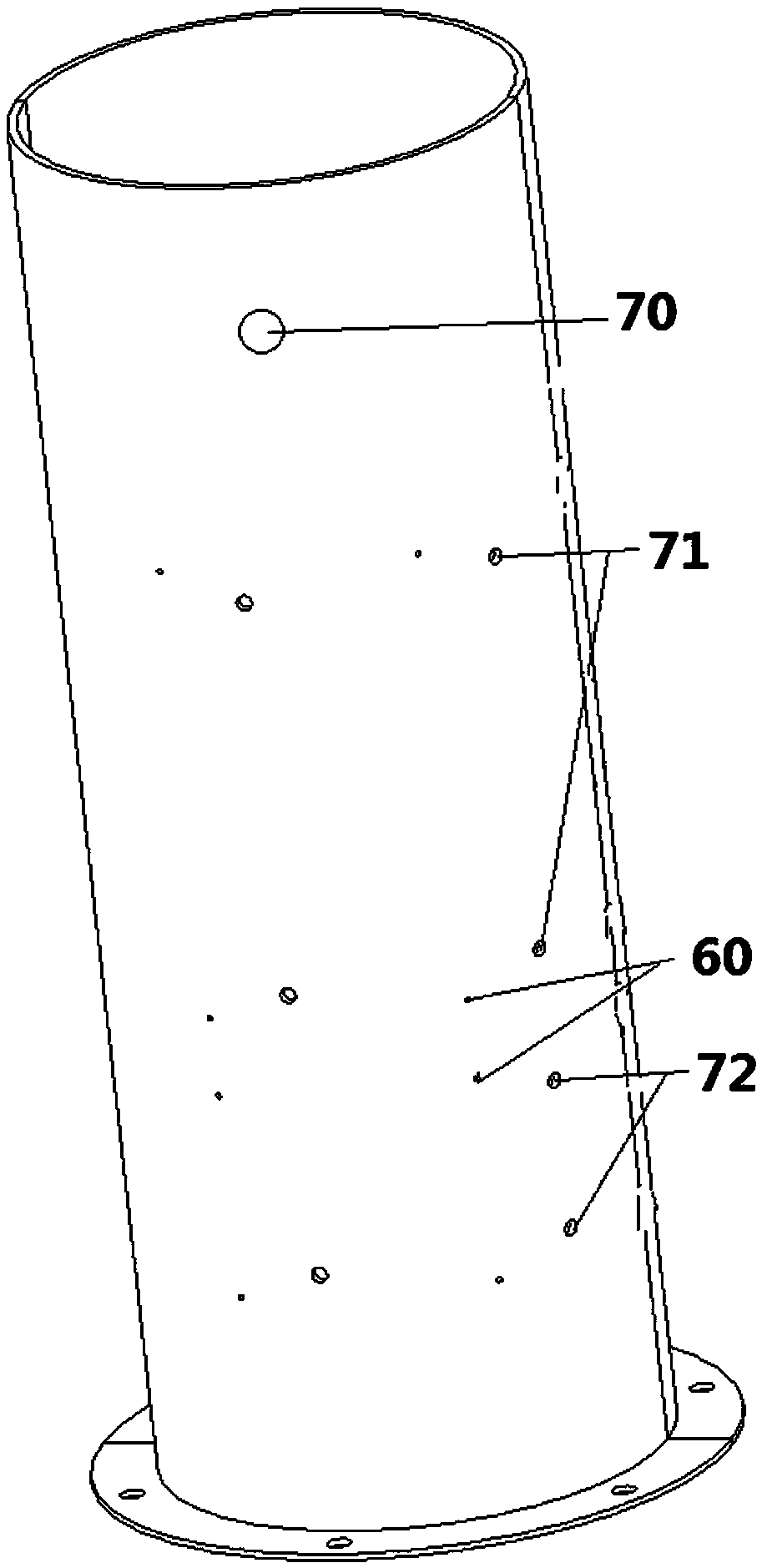

[0056] Such as figure 1 , Figure 9 and Figure 10 As shown, on the inner wall of the casing 10 corresponding to the upper end position of the grinding cylinder 7, an upper annular retaining ring 4 is fixed by bolts, and the gap position between the lower end of the grinding cylinder 7 and the upper end of the kneading cylinder 12 is fixed by bolts. The inner wall of the casing 10 is fixedly equipped with a middle annular retaining ring 11, and the inner...

Embodiment approach 2

[0076] Embodiment 2: A method of using a dynamic pressure-adjusting grinding type tartary buckwheat hulling machine

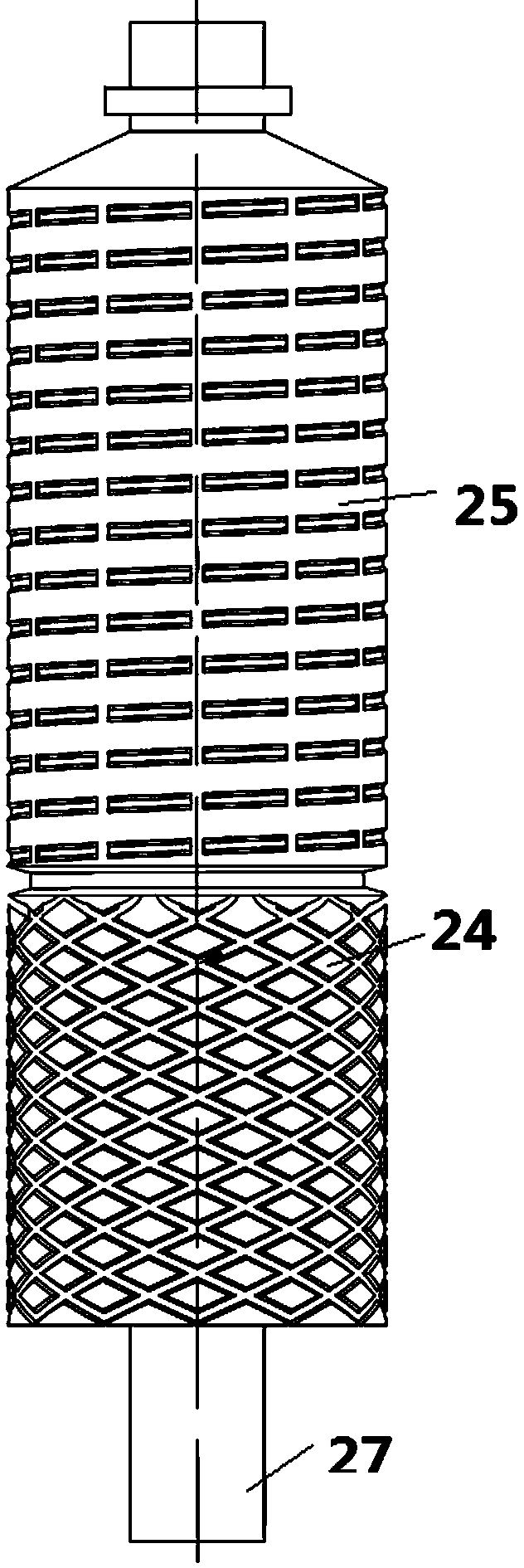

[0077] The tartary buckwheat grains with appropriate moisture content are poured from the feed hopper 1, and the feed flow is controlled by the feed valve 2, and the grains fall to the conical sliding cover 28 by the feed valve 2 and slide into the grinding chamber 6, because The high-speed operation of the grinding roller 26 and the helical arrangement of the grinding discs 53 in the vertical direction make the grains form a certain accumulation in the grinding chamber 6 and fall as a whole under the action of gravity; during the falling process of the grains, the grinding The corundum abrasive on the surface of the cylinder 7 and the grinding roller 26 grinds the husks of the grains so that the husks at the corners are worn off, and the kernels at the corners gradually leak out, and the bonding strength of the husks is greatly reduced. During the grinding pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com