Core Structure of 4-Cavity Hose Forming Mold

A technology for forming molds and hoses, which is applied to tubular objects, household appliances, and other household appliances. It can solve problems that affect product quality, affect product appearance, and products are easy to collapse and damage, so as to achieve beautiful appearance and not easy to collapse. And damage, reduce the effect of tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

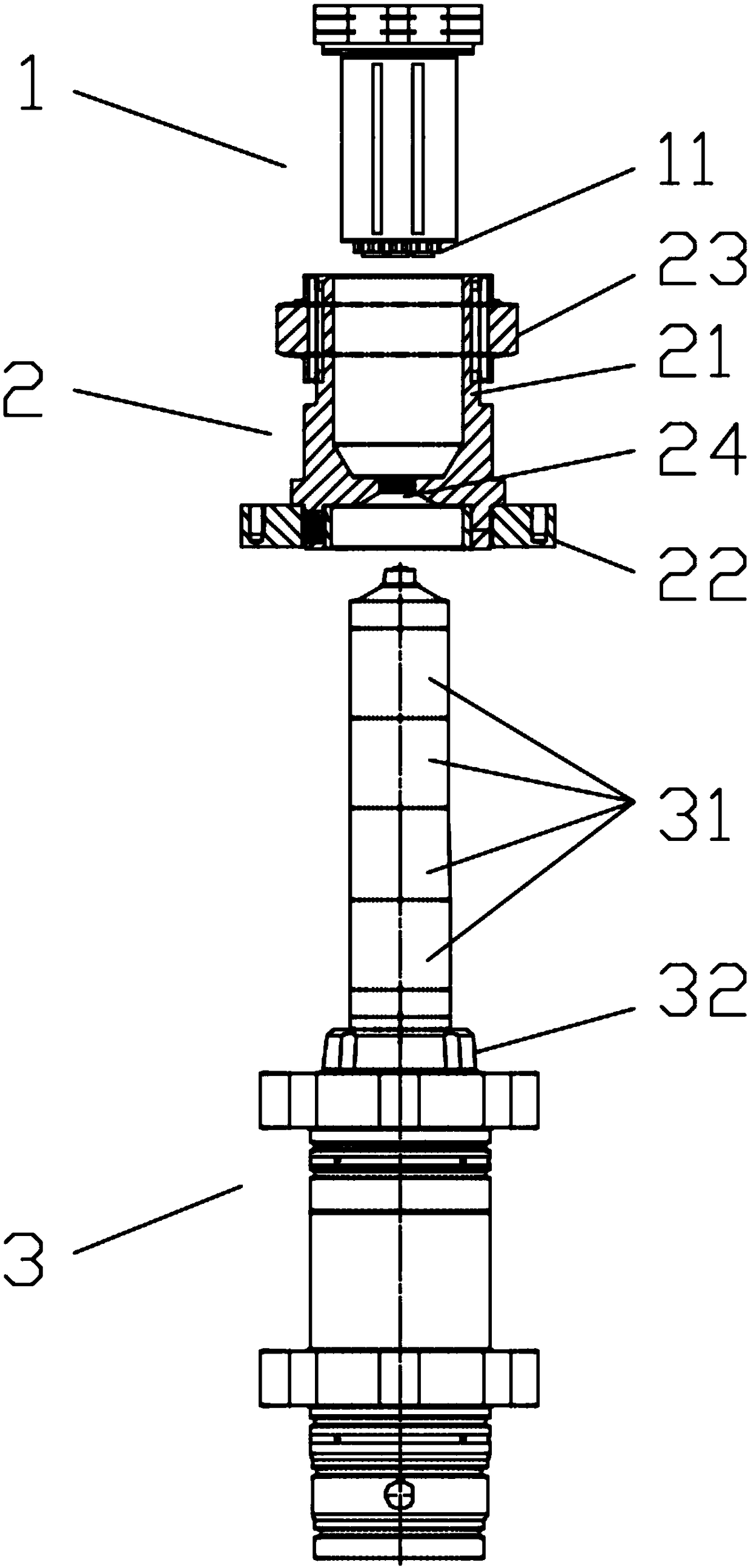

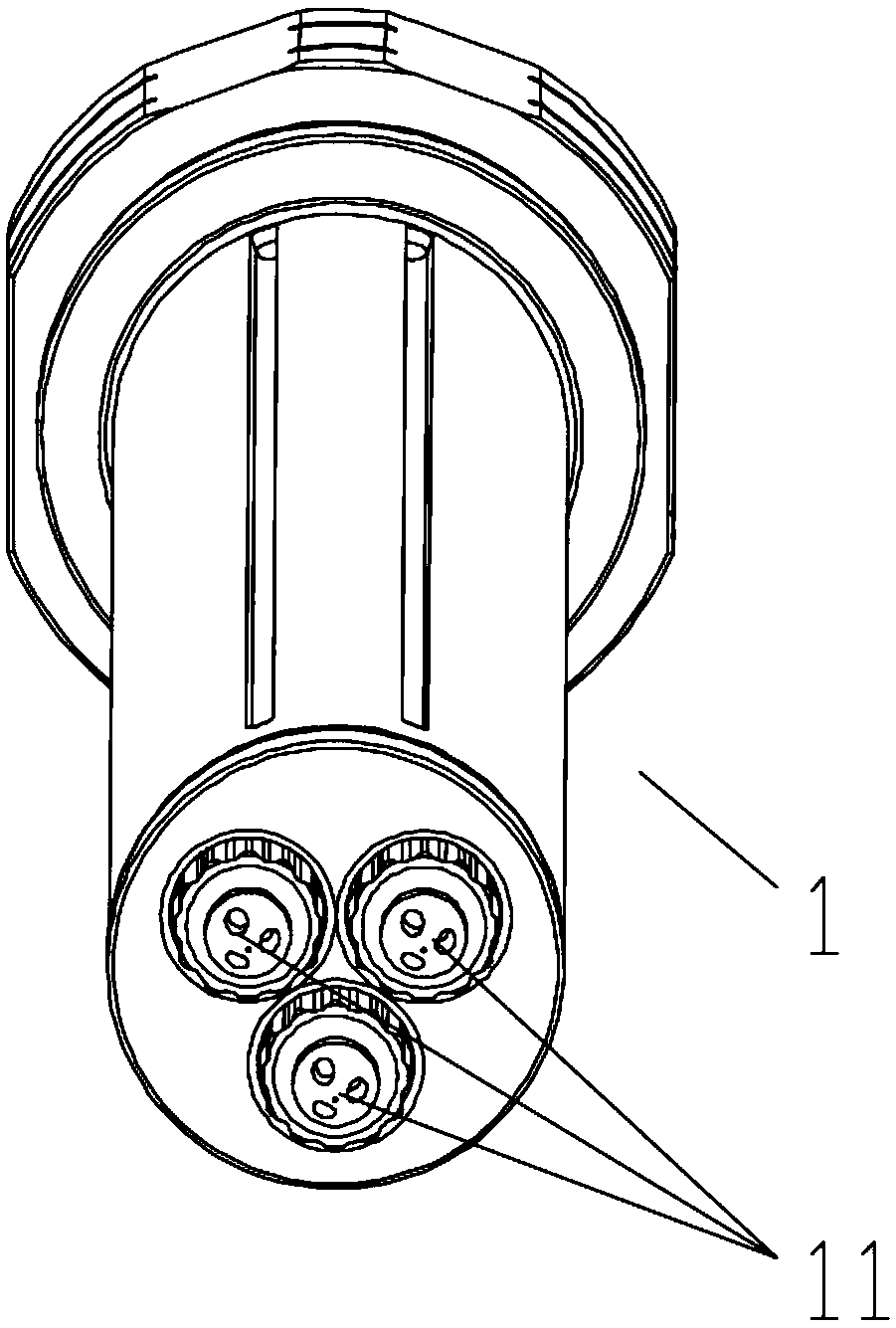

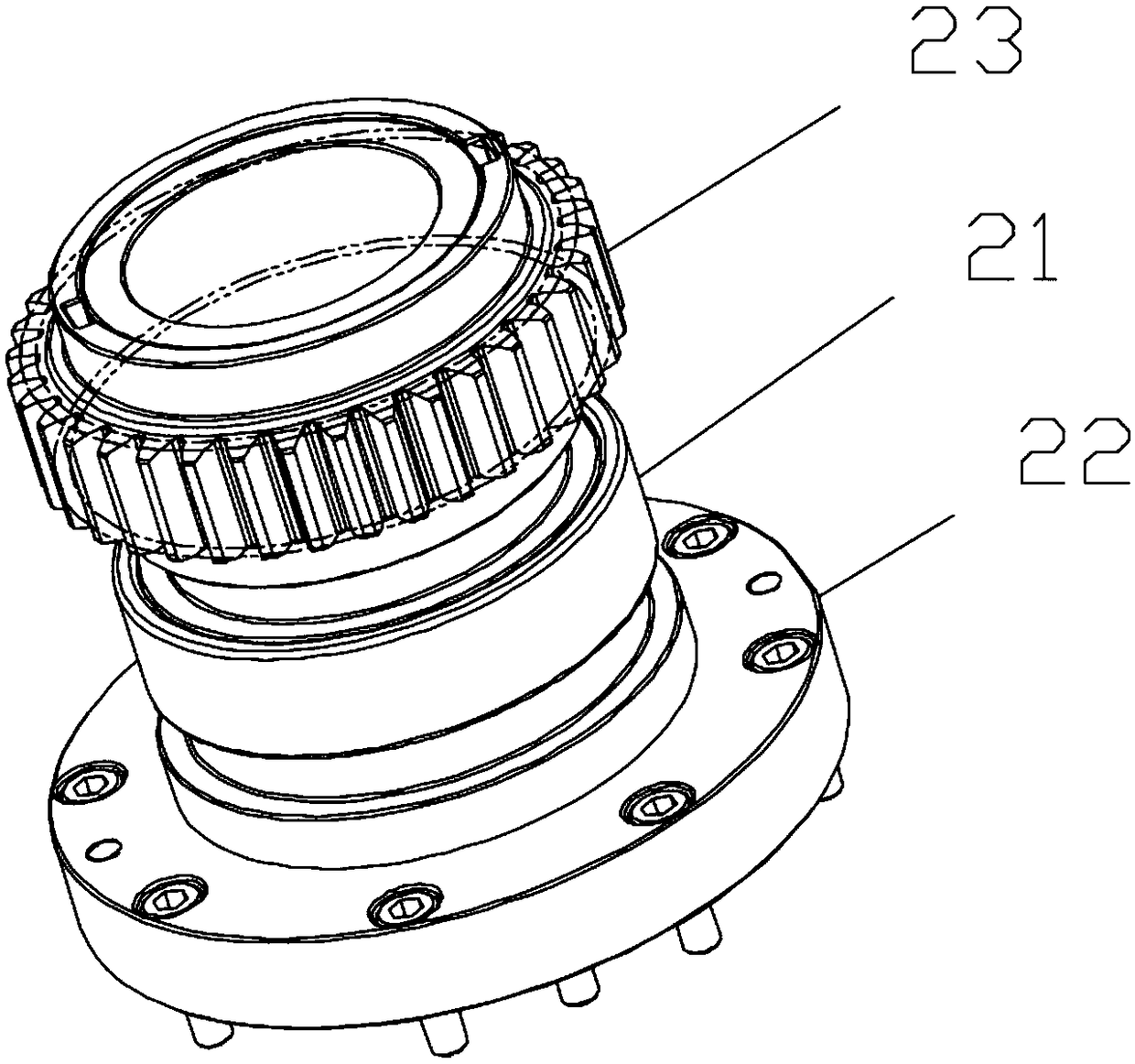

[0013] Such as Figure 1 to Figure 3 As shown, the mold core structure of the 4-cavity hose forming mold includes a glue injection head 1, a front mold core 2 and a rear mold core 3; the end of the glue injection head 1 is provided with three nozzles 11 arranged in an equilateral triangle; The front mold core 2 includes a threaded core 21, a fixed screw cap 22 and a gear 23 connected to the upper end of the threaded core 21; the threaded core 21 is threaded with the screw cap 22; the threaded core 21 Below is the cavity 24; the rear core 3 includes a plurality of ring assemblies 31 and push sleeves 32 at the head; the ring assemblies 31 are used to communicate with the blowing system; the gear 23 is driven by a hydraulic motor; The nozzle 11 of the injection head 1 is inserted into the threaded core 21 of the front core 2 and is located above the cavity 24, and the rear core 3 is located below the cavity 24 and together with the cavity 24 forms a soft Tube injection cavity. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com