Patents

Literature

37results about How to "Avoid defects such as congenital microcracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

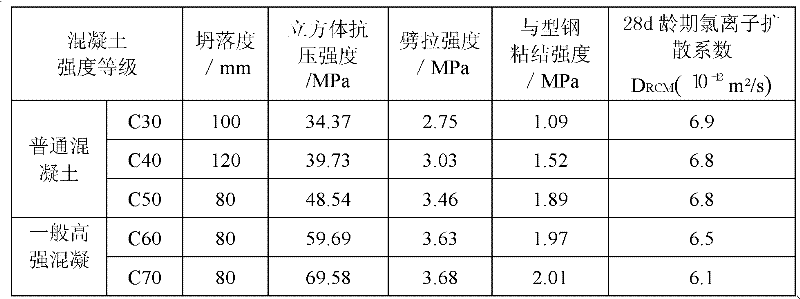

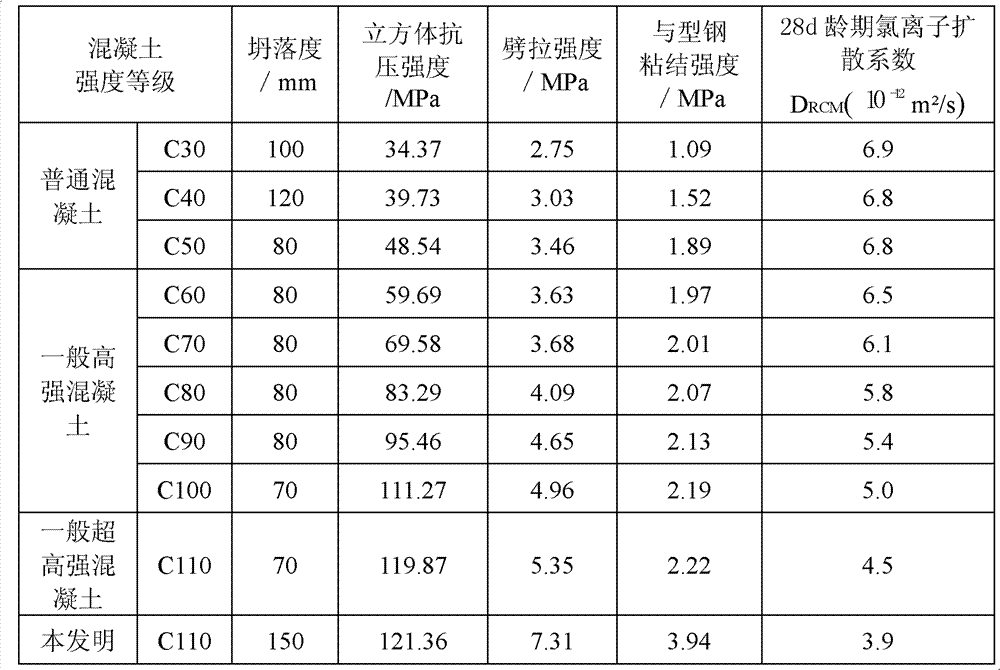

C190 strength-grade concrete for formed steel concrete composite structure

InactiveCN103553459AImprove workabilityImprove volume stabilitySolid waste managementDefoaming AgentsBond properties

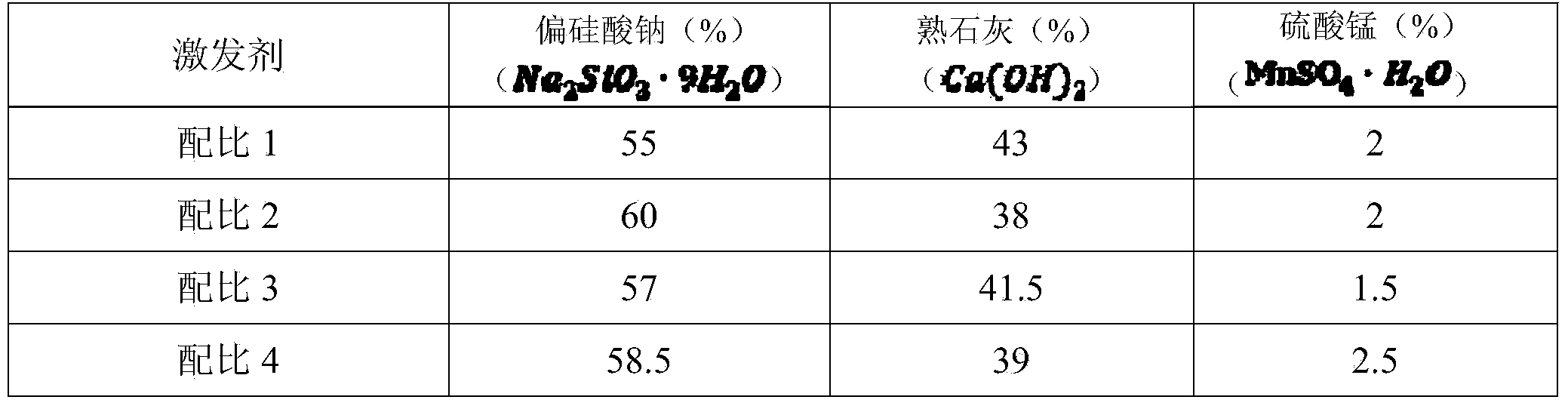

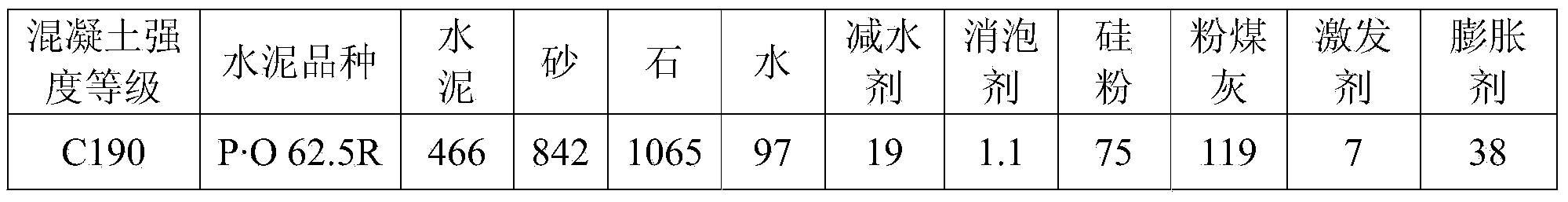

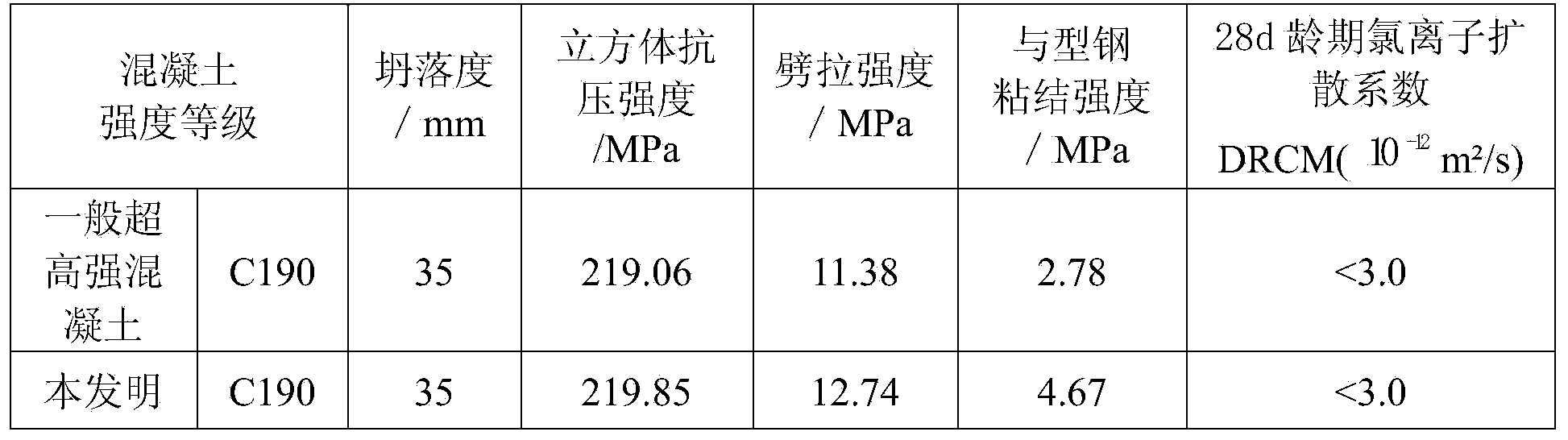

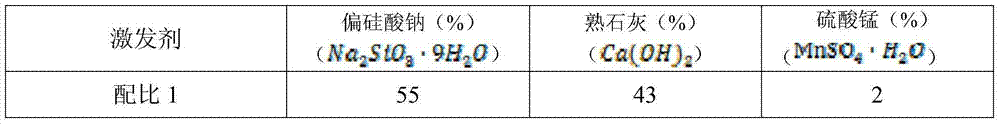

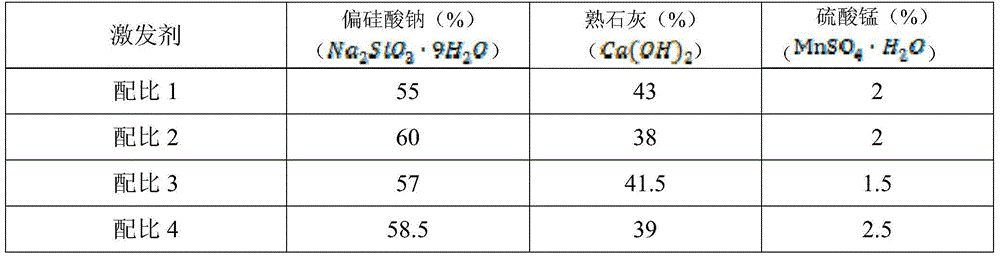

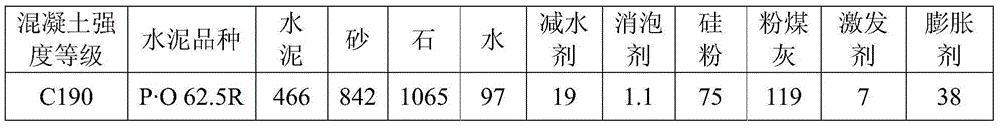

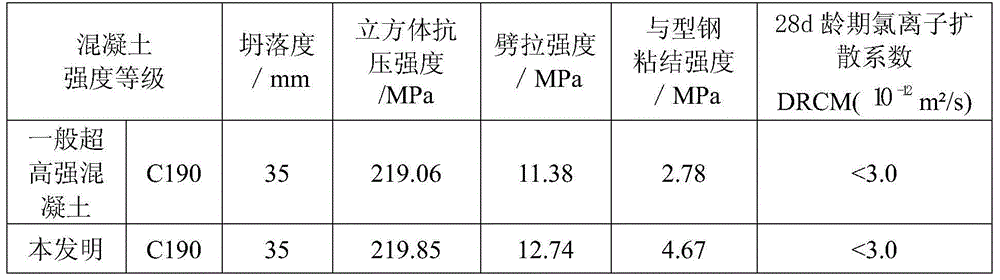

The invention discloses a C190 strength-grade concrete for a formed steel concrete composite structure, which is composed of 466 parts of cement, 842 parts of fine aggregate, 1065 parts of coarse aggregate, 97 parts of water, 19 parts of concrete superplasticizer, 1.1 parts of defoaming agent, 75 parts of silicon powder, 119 parts of expanding agent, 7 parts of activator and 38 parts of expanding agent. The preparation method comprises the following steps: blending the concrete superplasticizer and activator into weighed water to obtain a mixture, sequentially adding the fine aggregate and 1 / 3 of the mixture into a stirrer according to parts by weight, and stirring; adding the coarse aggregate and 1 / 3 of the mixture, and stirring; adding the cement, expanding agent, silicon powder and fly ash, and stirring; and adding the defoaming agent and the rest of mixture, stirring and discharging. The concrete can obviously improve the bonding property between the formed steel and the concrete in a natural state, effectively displays the respective mechanical properties and the synergic working performance of the steel and concrete, greatly enhances the loading capacity, service performance and durability of the structural member, and has high volume stability and economical efficiency.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

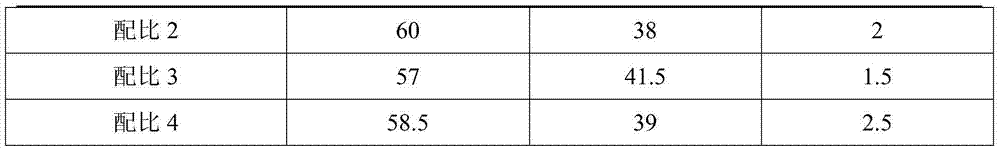

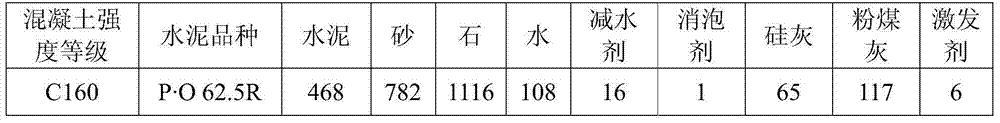

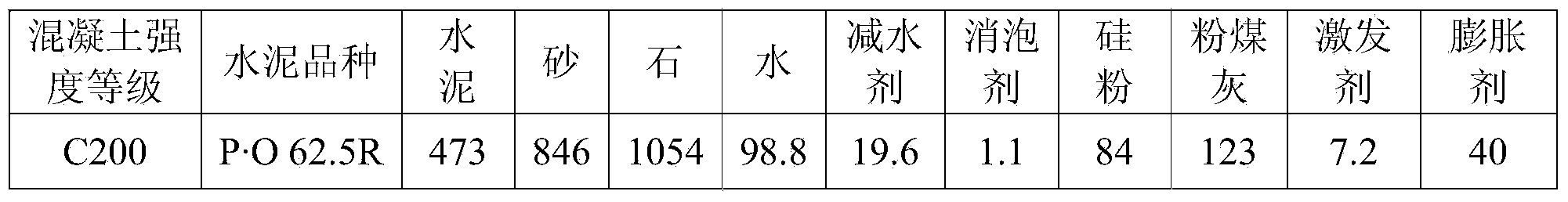

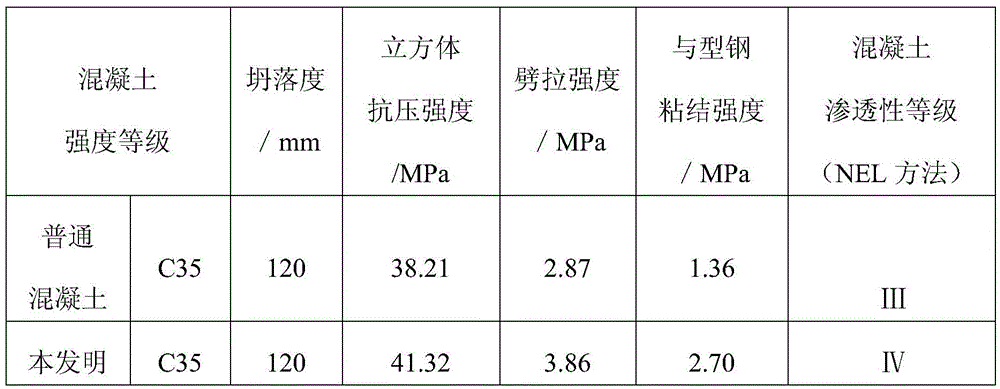

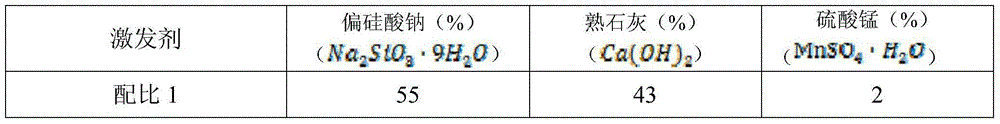

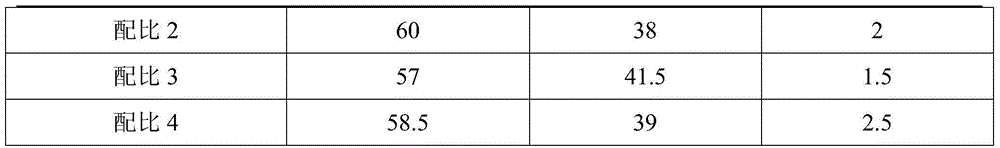

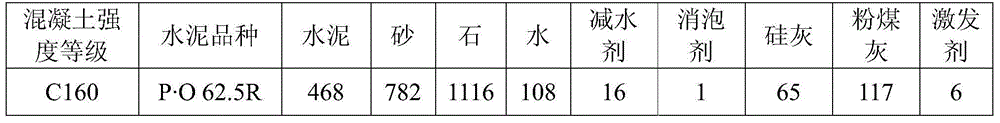

Concrete for steel reinforced concrete combined structure with C160 strength level

InactiveCN103539407AIncreased durabilityHigh strength and durabilityCarrying capacityReinforced concrete

The invention discloses concrete for a steel reinforced concrete combined structure with C160 strength level. The concrete is composed of cement, fine aggregate, coarse aggregate, water, a concrete super plasticizer, a defoaming agent, silica fume, fly ash and an activator according to a ratio of 468:782:1116:108:16:1:65:117:6. The preparation method is as follows: firstly, uniformly mixing the concrete super plasticizer and the activator in weighed water to obtain a mixture, sequentially adding 1 / 3 of total dosage of the fine aggregate and the mixture in a stirring machine according to a weight ratio, and stirring; adding 1 / 3 of total dosage of the coarse aggregate and the mixture and stirring; and adding the cement, the silica fume and the fly ash, and stirring; and adding the defoaming agent and the rest mixture, stirring and discharging. The concrete can greatly perfect the adhesive property between section steel and the concrete under a natural state, effectively play the respective mechanical properties and mutual cooperative working performance of the steel and the concrete and greatly improve the carrying capacity, application performance and durability of the structural member, thereby having good high-volume stability and economical efficiency.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

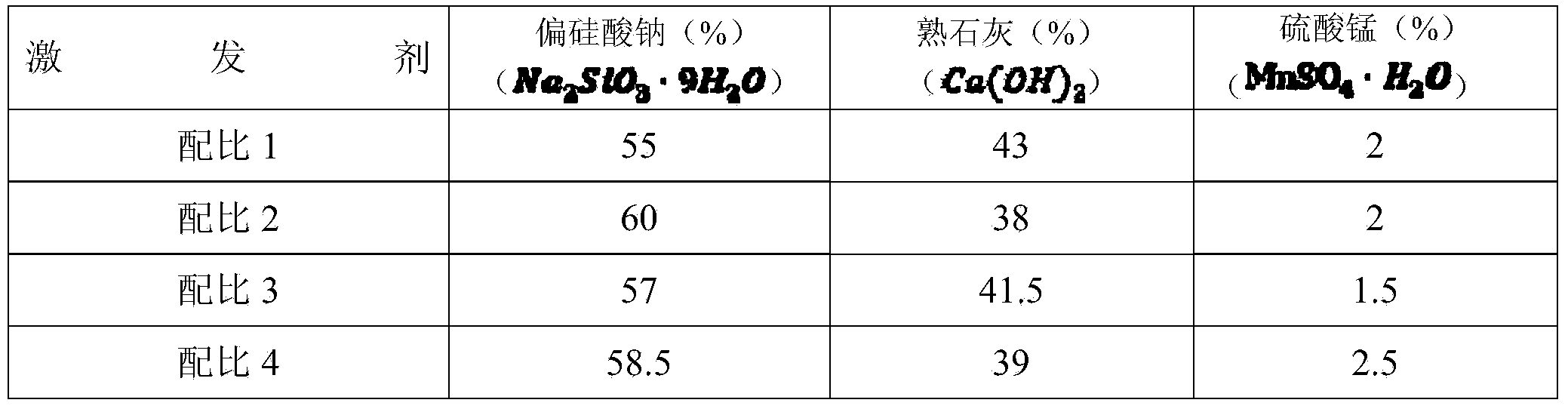

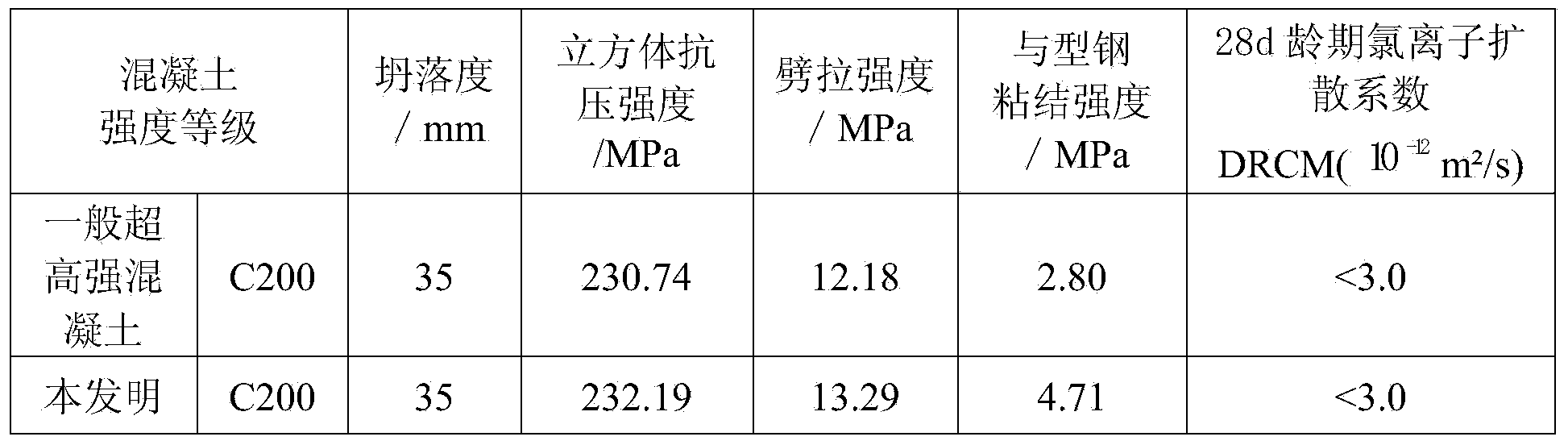

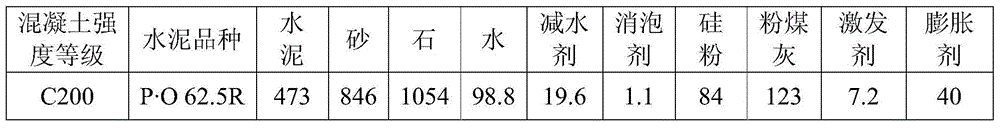

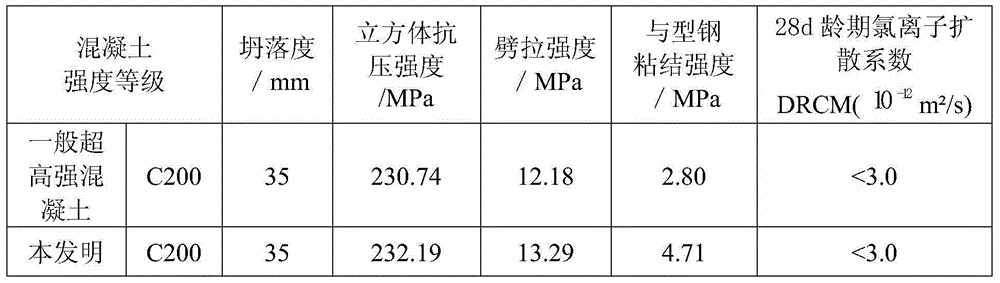

C200 strength-grade concrete for formed steel concrete composite structure

InactiveCN103553460AIncreased durabilityHigh Strength and DurabilitySolid waste managementNatural stateSuperplasticizer

The invention discloses a C200 strength-grade concrete for a formed steel concrete composite structure, which is composed of 473 parts of cement, 846 parts of fine aggregate, 1054 parts of coarse aggregate, 98.8 parts of water, 19.6 parts of concrete superplasticizer, 1.1 parts of defoaming agent, 84 parts of silicon powder, 123 parts of expanding agent, 7.2 parts of activator and 40 parts of expanding agent. The preparation method comprises the following steps: blending the concrete superplasticizer and activator into weighed water to obtain a mixture, sequentially adding the fine aggregate and 1 / 3 of the mixture into a stirrer according to parts by weight, and stirring; adding the coarse aggregate and 1 / 3 of the mixture, and stirring; adding the cement, expanding agent, silicon powder and fly ash, and stirring; and adding the defoaming agent and the rest of mixture, stirring and discharging. The concrete can obviously improve the bonding property between the formed steel and the concrete in a natural state, effectively displays the respective mechanical properties and the synergic working performance of the steel and concrete, greatly enhances the loading capacity, service performance and durability of the structural member, and has high volume stability and economical efficiency.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

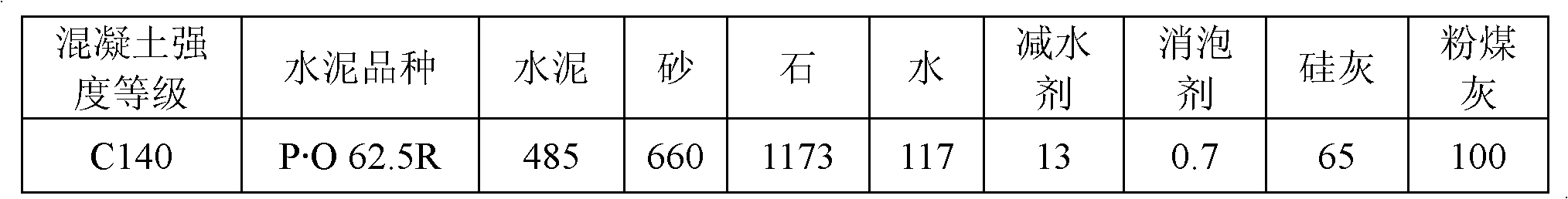

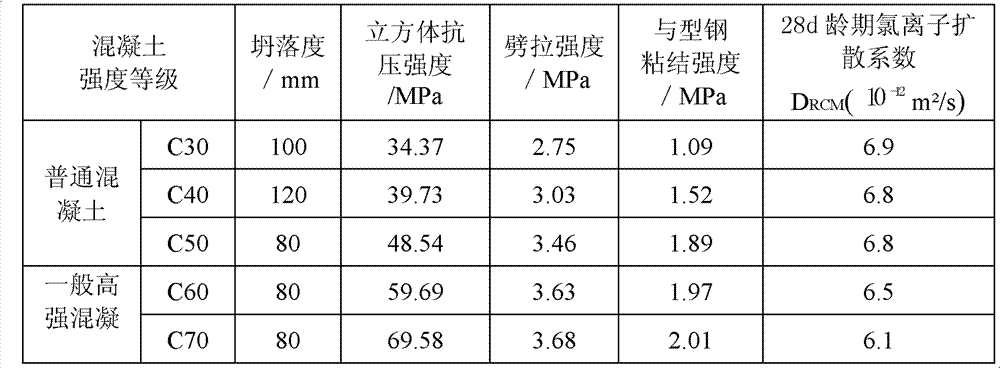

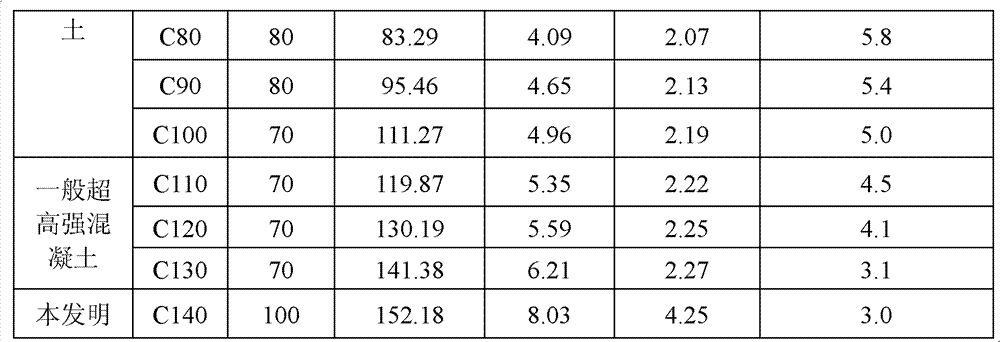

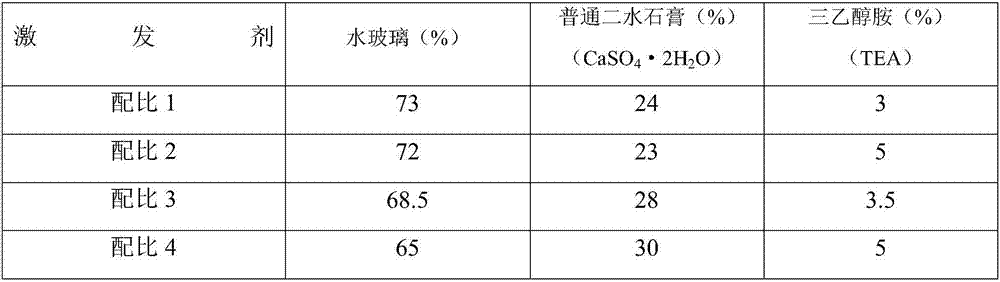

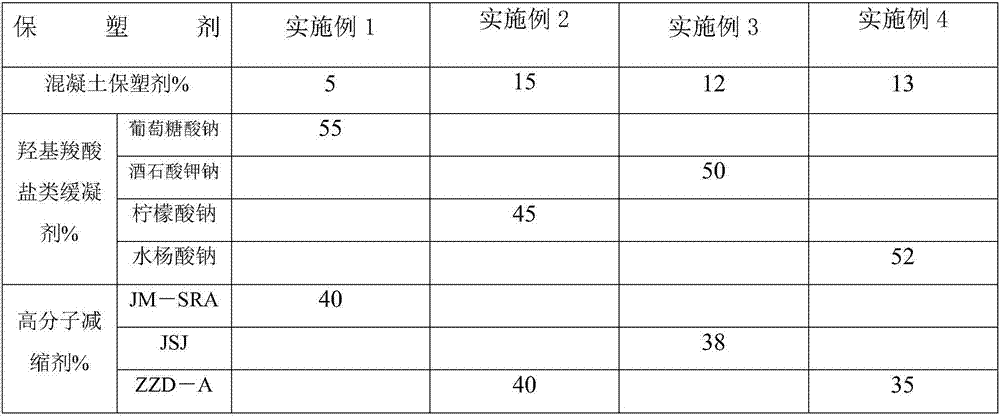

Concrete with strength grade of C140 used for profile steel-concrete composite structure

InactiveCN101913815AIncreased durabilityHigh Strength and DurabilitySolid waste managementCarrying capacityNatural state

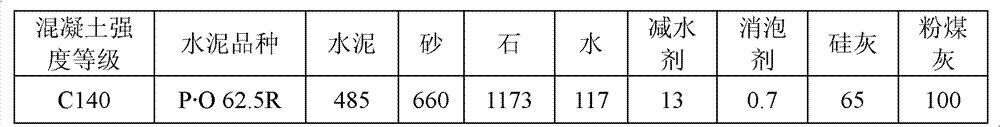

The invention discloses concrete with strength grade of C140 used for a profile steel-concrete composite structure. The concrete is characterized by being prepared from cement, fine aggregate, coarse aggregate, water, a water reducing agent, an antifoaming agent, siliceous dust, coal ash(kg / m<3>) in a mixing proportion of 485:660:1,173:117:13:0.7:65:100. A preparation method of the concrete comprises the following steps of: adding the fine aggregate and the water in an amount of which is a half based on the total weight of the used water into a forced mixer according to the weight proportion in turn; uniformly stirring for 1 to 2 minutes; adding the coarse aggregate into the mixer; uniformly stirring for 2 to 4 minutes; adding the cement, the siliceous dust and the coal ash into the mixer; uniformly stirring for 2 to 3 minutes; adding the water reducing agent, the antifoaming agent and the rest water into the mixer; uniformly stirring for 2 to 5 minutes; and discharging to obtain a concrete mixture. The concrete can obviously improve the adhesive property between profile steel and the concrete in a natural state, effectively exert respective capacity and cooperative work performance of both materials, greatly improve the carrying capacity and performance of members, and improve the durability, high volume stability and economy of the members.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

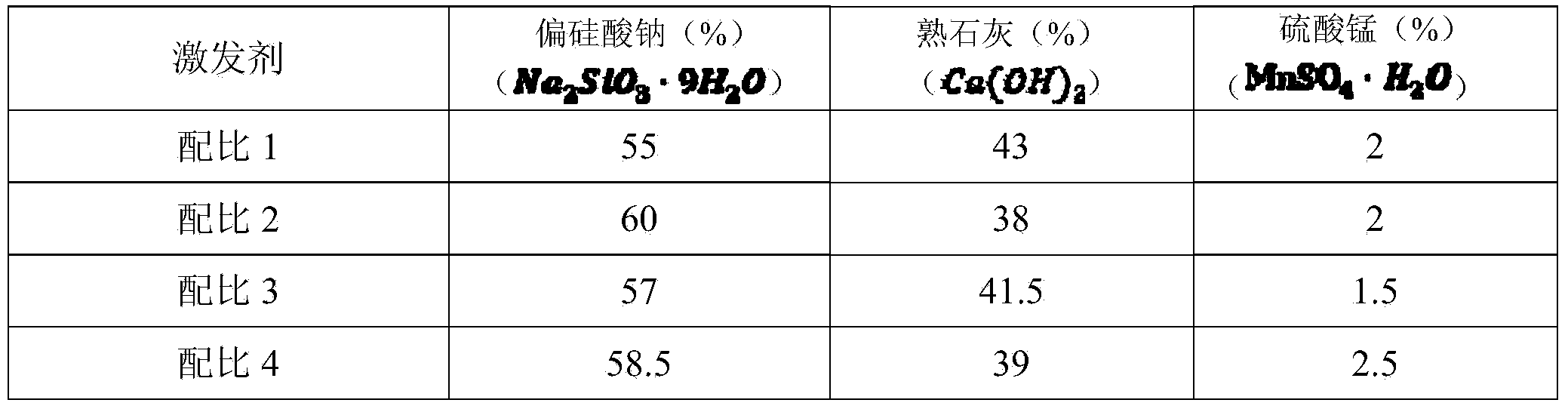

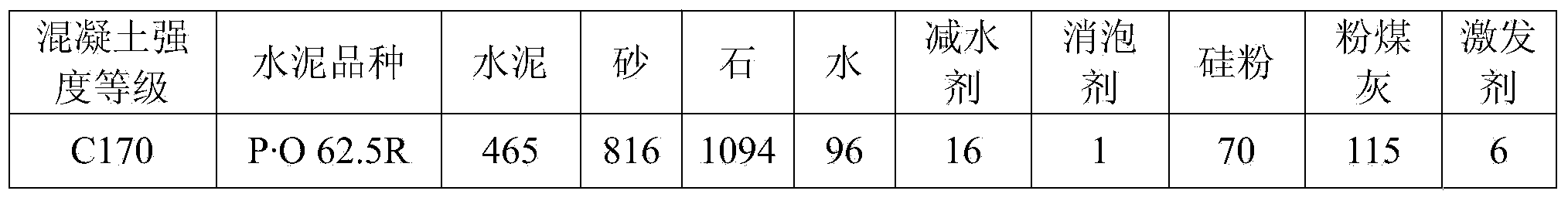

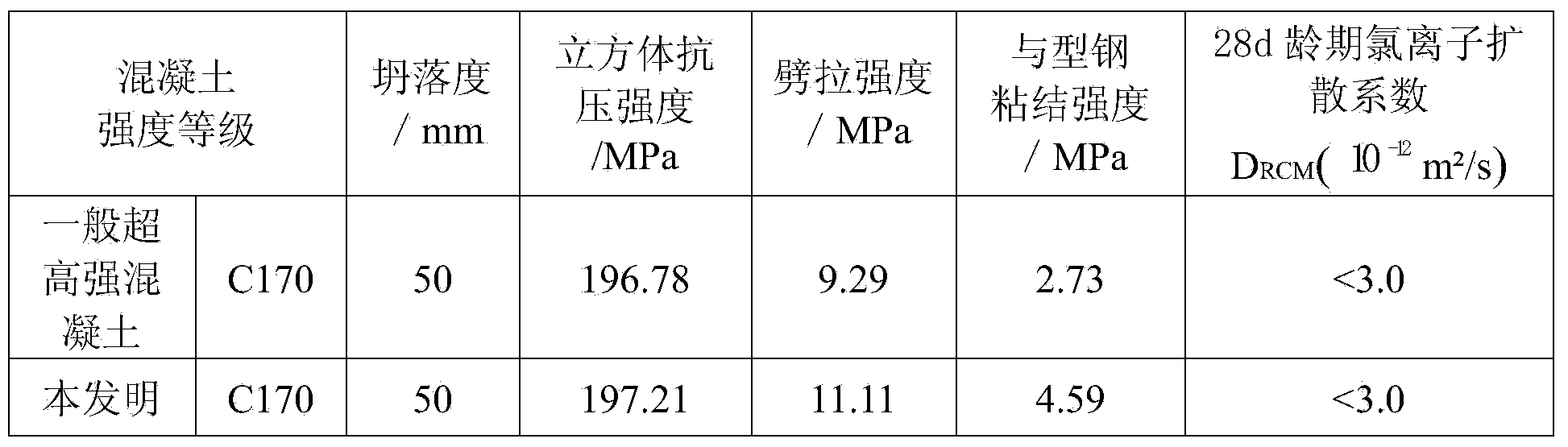

C170 strength-grade concrete for formed steel concrete composite structure

The invention discloses a C170 strength-grade concrete for a formed steel concrete composite structure, which is composed of 465 parts of cement, 816 parts of fine aggregate, 1094 parts of coarse aggregate, 96 parts of water, 16 parts of concrete superplasticizer, 1 part of defoaming agent, 70 parts of silicon powder, 115 parts of fly ash and 6 parts of activator. The preparation method comprises the following steps: blending the concrete superplasticizer and activator into weighed water to obtain a mixture, sequentially adding the fine aggregate and 1 / 3 of the mixture into a stirrer according to parts by weight, and stirring; adding the coarse aggregate and 1 / 3 of the mixture, and stirring; adding the cement, silicon powder and fly ash, and stirring; and adding the defoaming agent and the rest of mixture, stirring and discharging. The concrete can obviously improve the bonding property between the formed steel and the concrete in a natural state, effectively displays the respective mechanical properties and the synergic working performance of the steel and concrete, greatly enhances the loading capacity, service performance and durability of the structural member, and has favorable working performance and economical efficiency.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

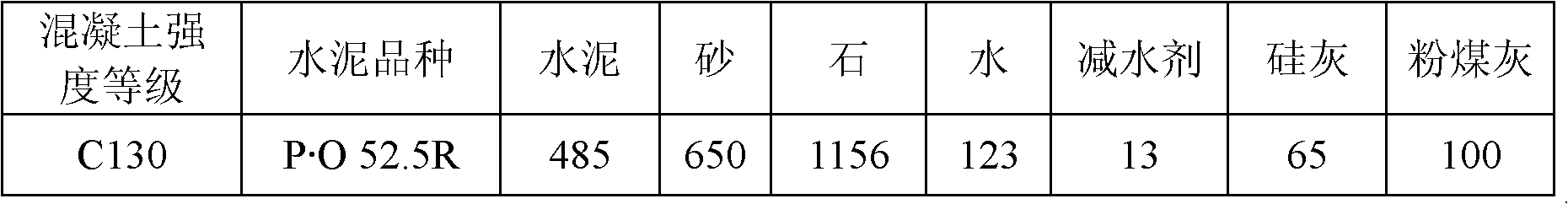

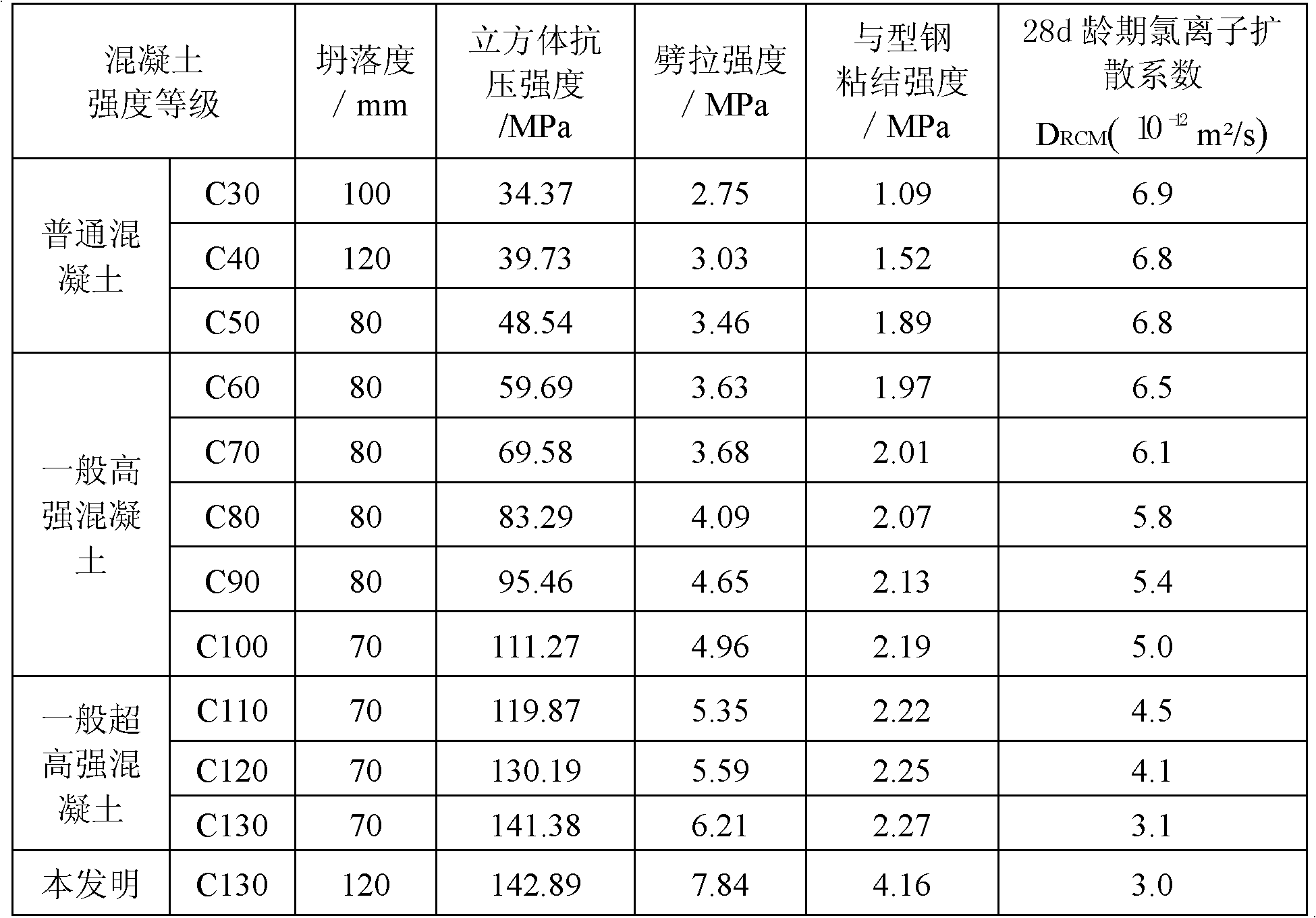

C130 (strength grade) concrete for section steel-concrete combined structure

InactiveCN101913816AIncreased durabilityHigh Strength and DurabilityNatural stateUltimate tensile strength

The invention discloses C130 (strength grade) concrete for a section steel-concrete combined structure, which is characterized by being prepared by mixing cement, fine aggregate, coarse aggregate, water, water reducer, siliceous dust and flash ash in a mass / volume ratio of 485:650:1,156:123:13:65:100. The preparation method of the concrete comprises: adding the fine aggregate and half of the total amount of water into a forceful stirrer in turn according to a weight mixing ratio, uniformly stirring for 1 to 2 minutes, and adding the coarse aggregate; uniformly stirring for 2 to 4 minutes, and adding the cement, the siliceous dust and the flash ash; uniformly stirring for 2 to 3 minutes and adding the water reducer and the rest of water; and uniformly stirring for 2 to 3 minutes, and discharging to obtain a concrete mixture. The concrete has obviously improved section steel binding performance in a natural state and capability and coordinate operation performance of the concrete and the section steel can be fully played, so that the bearing capacity and performance of a member considerably are greatly improved and the durability, high-volume stability and economy of the member are improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

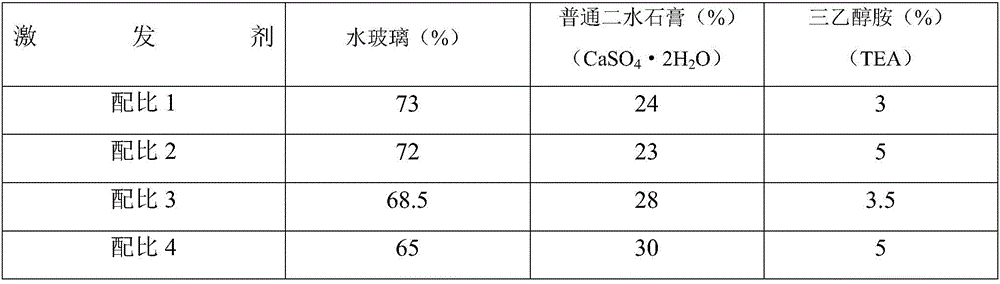

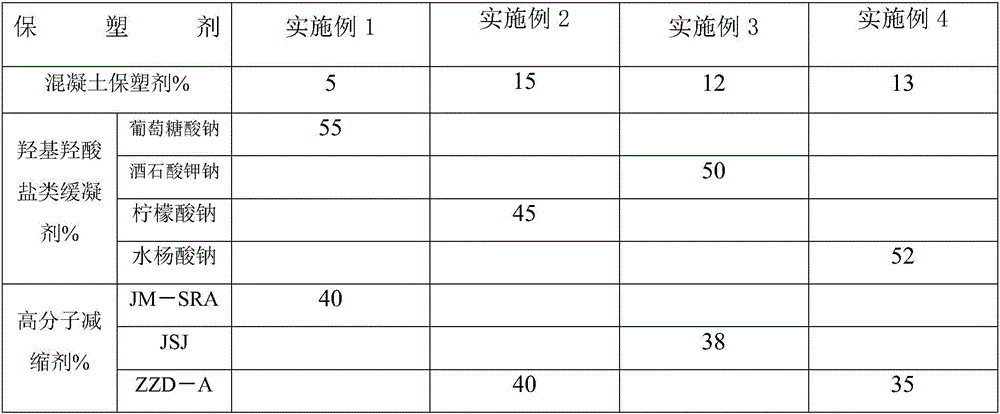

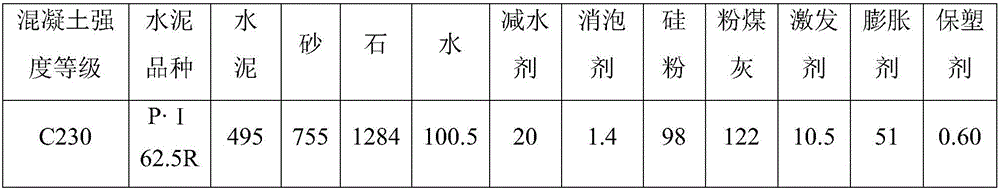

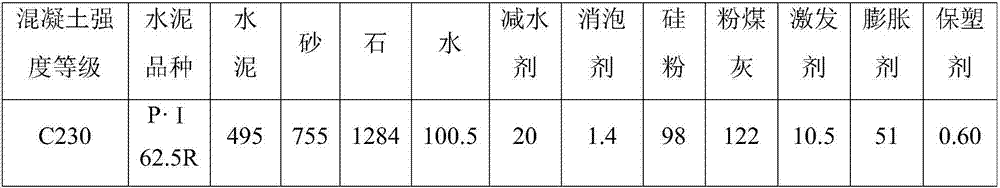

Concrete used for steel reinforced concrete composite structure and having C230 strength grade

InactiveCN105837119AIncreased durabilityHigh Strength and DurabilitySolid waste managementMixing operation control apparatusNatural stateMechanical property

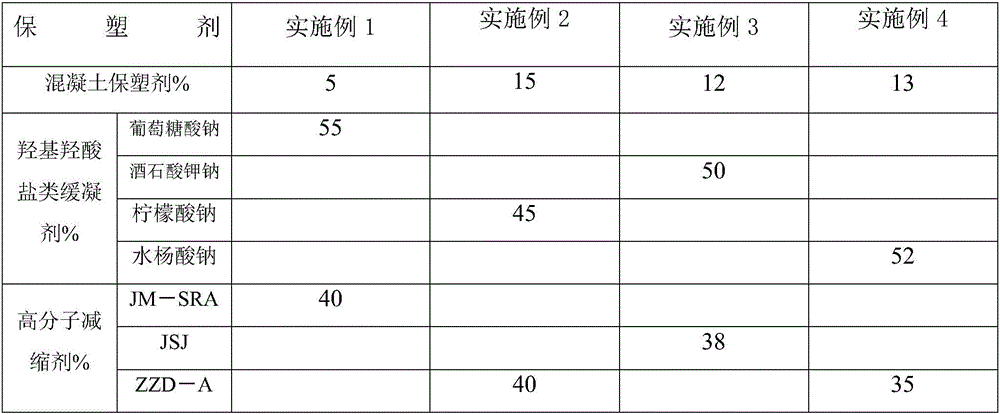

Concrete used for a steel reinforced concrete composite structure and having the C230 strength grade is disclosed. A ratio of cement, fine aggregate, coarse aggregate, water, a water reducing agent, a defoaming agent, silica fume, fly ash, an activator, an expanding agent and a composite plastic retaining agent is 495:755:1284:100.5:20:1.4:98:122:10.5:51:0.60. The preparing method includes fully mixing the water reducing agent, the activator and the composite plastic retaining agent with the water to obtain a mixture, adding the fine aggregate and one third of the mixture into a stirrer in order, fully mixing, adding the coarse aggregate one third of the mixture in order, fully stirring, adding the cement, the expanding agent, the silica fume and the fly ash, fully stirring, adding the defoaming agent and the rest of the mixture, stirring and discharging. The concrete significantly improves adhesion performance between section steel and concrete under natural states, effectively exerts mechanical properties of the steel and the concrete and synergistic properties, greatly improves bearing capacity, using performance and durability of structural components, and has good high size stability and economical performance.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Concrete for steel reinforced concrete composite structure C250 strength grade

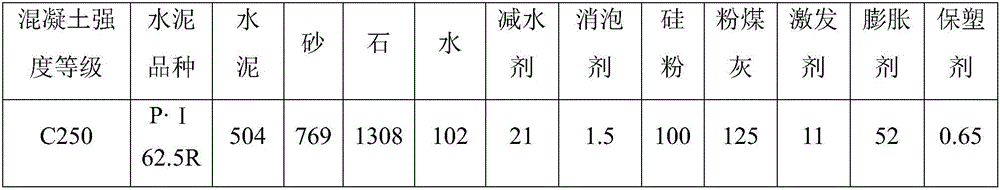

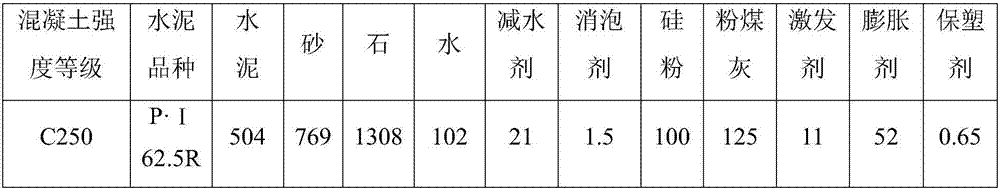

InactiveCN105777017AImprove workabilityImprove volume stabilityStructural elementReinforced concrete

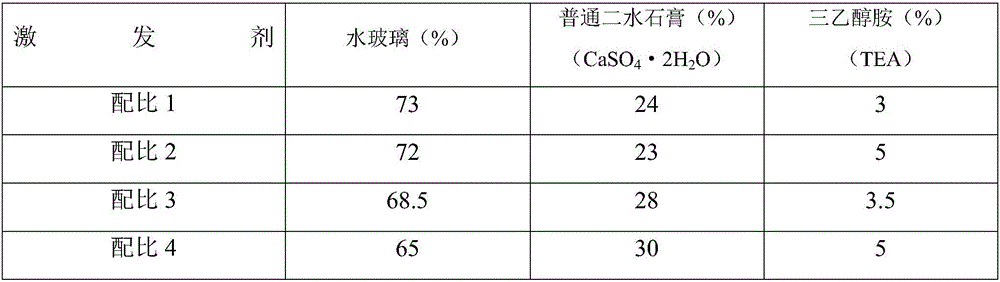

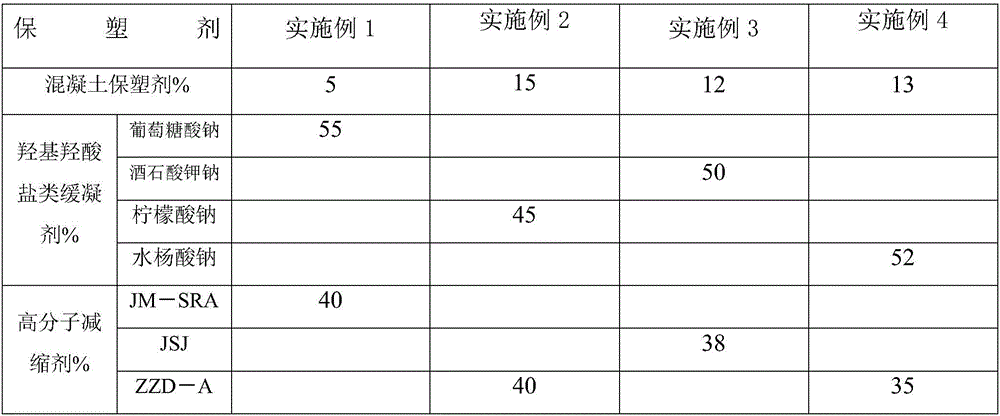

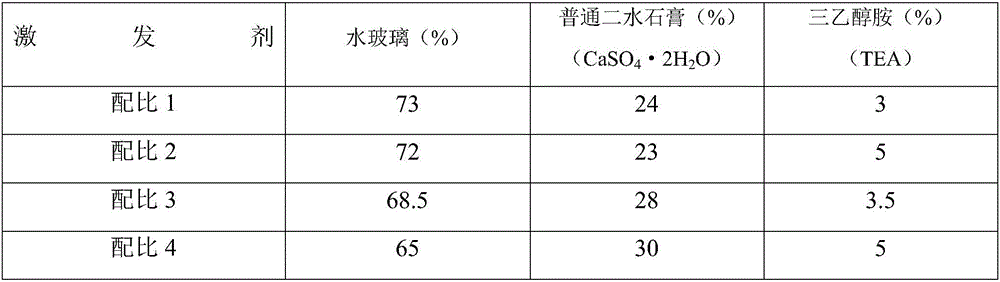

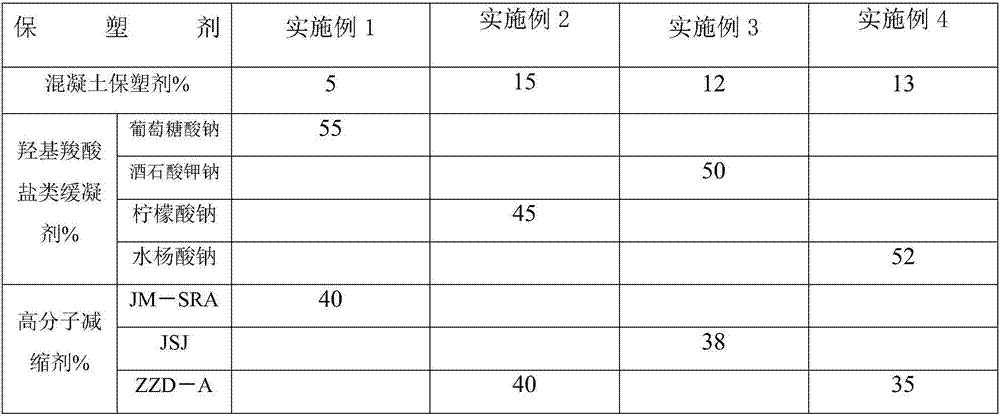

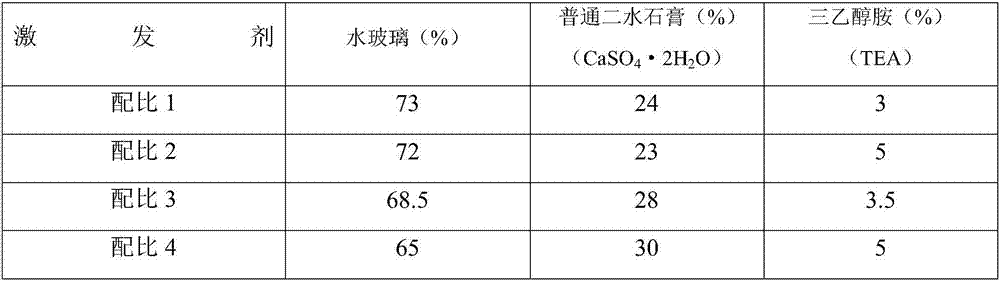

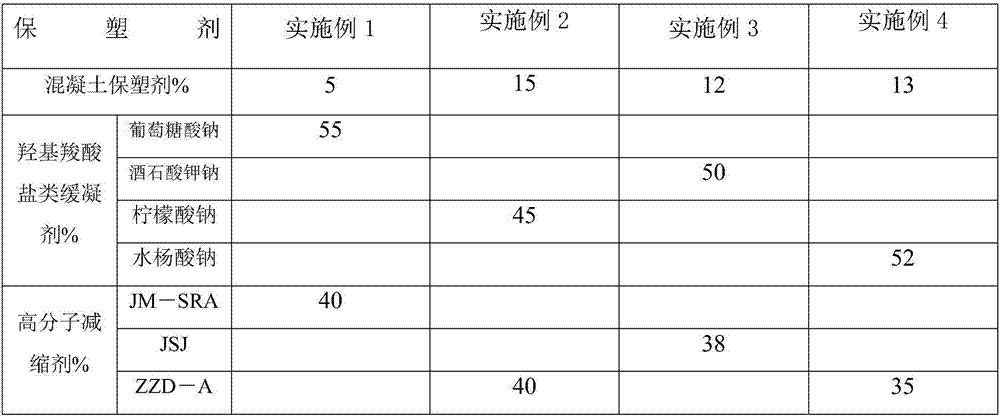

The invention discloses concrete for the steel reinforced concrete composite structure C250 strength grade. The matching ratio of cement to fine aggregate to coarse aggregate to water to water reducing agent to antifoaming agent to silica powder to coal ash to exciting agent to expanding agent to composite plastic retaining agent is 504:769:1,308:102:21:1.5:100:125:11:52:0.65. A preparing method includes the steps that the water reducing agent, the exciting agent and the composite plastic retaining agent are evenly stirred into water to obtain a mixture, and the fine aggregate and 1 / 3 of the total mixture are sequentially added into a stirring machine according to the weight ratio and stirred to be even; the coarse aggregate and 1 / 3 of the total mixture are added and stirred to be even; the cement, the expanding agent, the silica powder and the coal ash are added and stirred to be even; the antifoaming agent and the residual mixture are added, and the mixture is stirred and discharged. By means of the concrete, the bonding performance between structural steel and the concrete can be remarkably improved under the natural state, the mechanical performance and the cooperative work performance of the steel and the concrete are effectively developed, the carrying capacity, the use performance and the durability of a structural element are greatly improved, and the concrete has the good high volume stability and the good economy.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

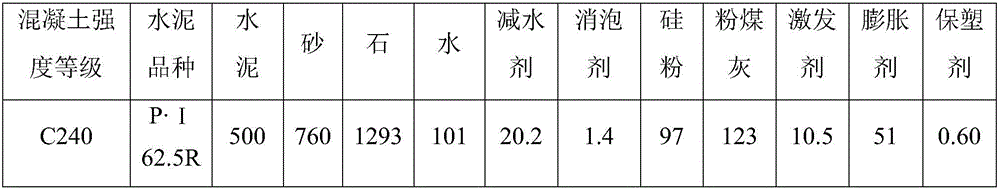

Concrete having strength grade of C240 and used for steel reinforced concrete combined structure

InactiveCN105906258AImprove workabilityImproves natural bonding propertiesCement mixing apparatusReinforced concreteStructural element

The invention discloses a concrete having a strength grade of C240 and used for a steel reinforced concrete combined structure. The concrete is prepared from cement, fine aggregate, crude aggregate, water, a water reducer, an antifoaming agent, silicon powder, fly ash, an exciting agent, an expanding agent and a composite plasticity-maintaining agent in a ratio of 500: 760: 1293: 101: 20.2: 1.4: 97: 123: 10.5: 51: 0.60. The preparation method comprises the following steps: uniformly mixing the water reducer, the exciting agent and the composite plasticity-maintaining agent with water so as to obtain a mixture, successively adding the fine aggregate and one third of the mixture into a mixer according to weight proportion and carrying out uniform mixing; adding the crude aggregate and another one third of the mixture and carrying out uniform mixing; adding the cement, expanding agent, silicon ash and fly ash and carrying out uniform mixing; and adding the antifoaming agent and the residual mixture and carrying out stirring and discharging. The concrete prepared in the invention can substantially improve bonding between section steel and concrete in a natural state, gives full play to respective mechanical properties and mutual cooperation performance of the section steel and concrete, greatly improves the bearing capability, usage performance and endurance of a structural element, and has high volume stability and economic performance.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

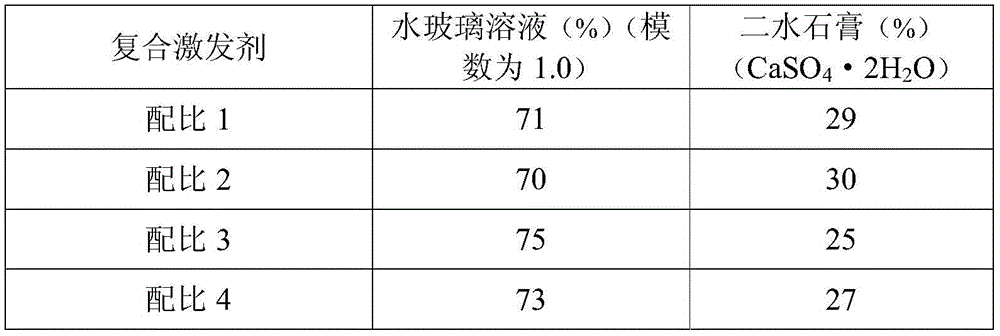

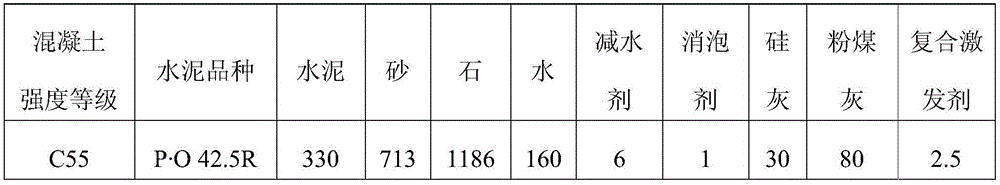

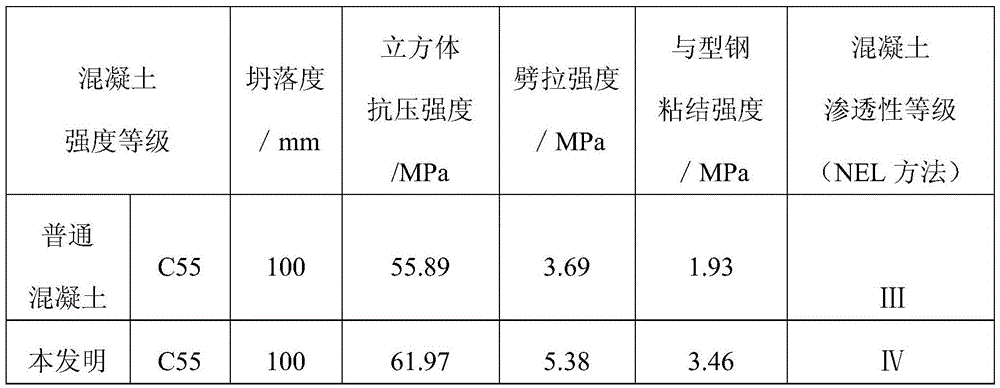

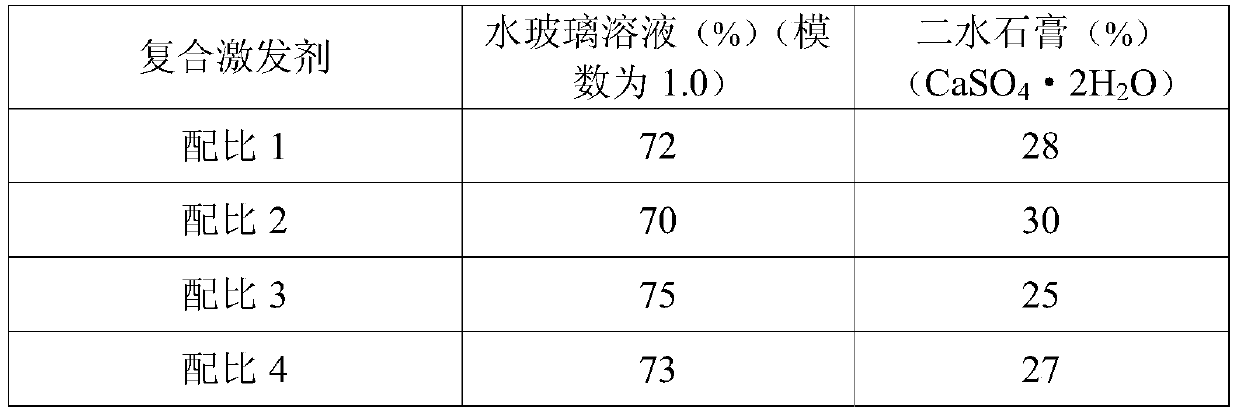

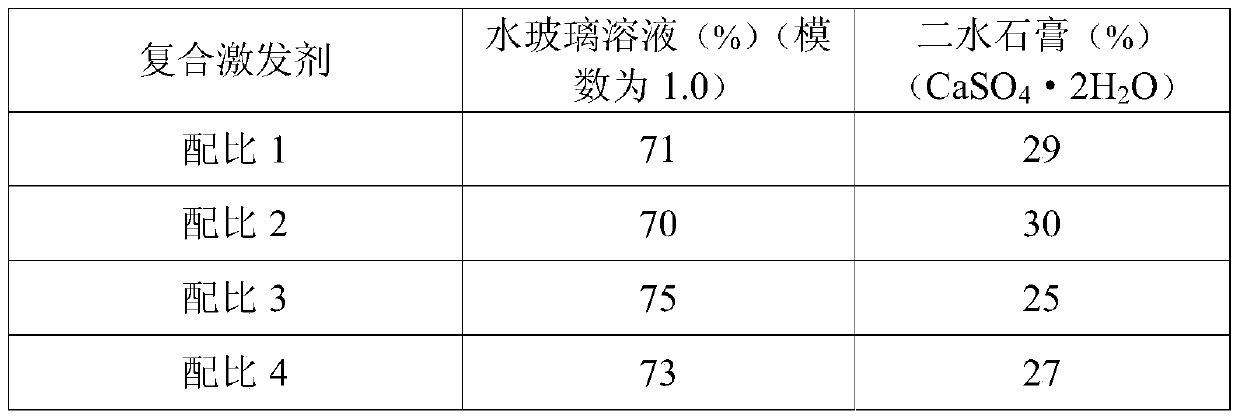

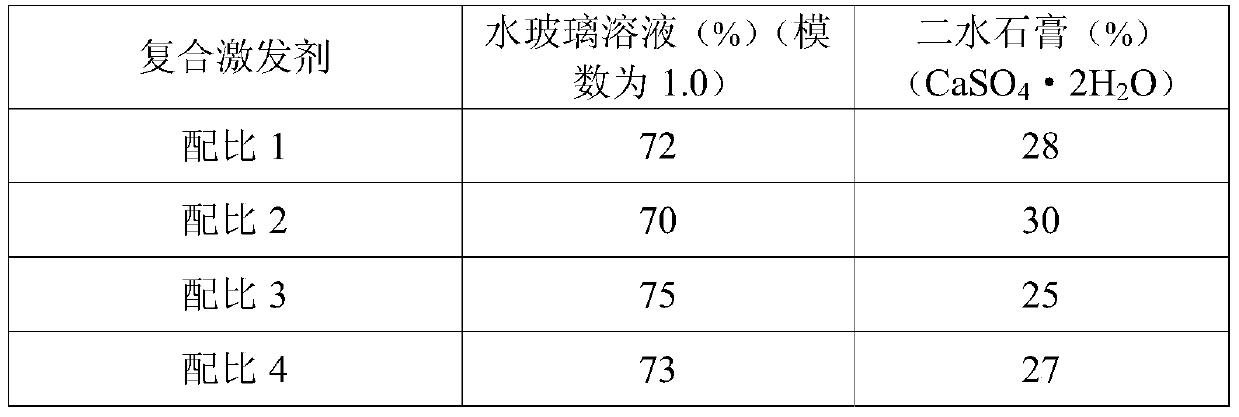

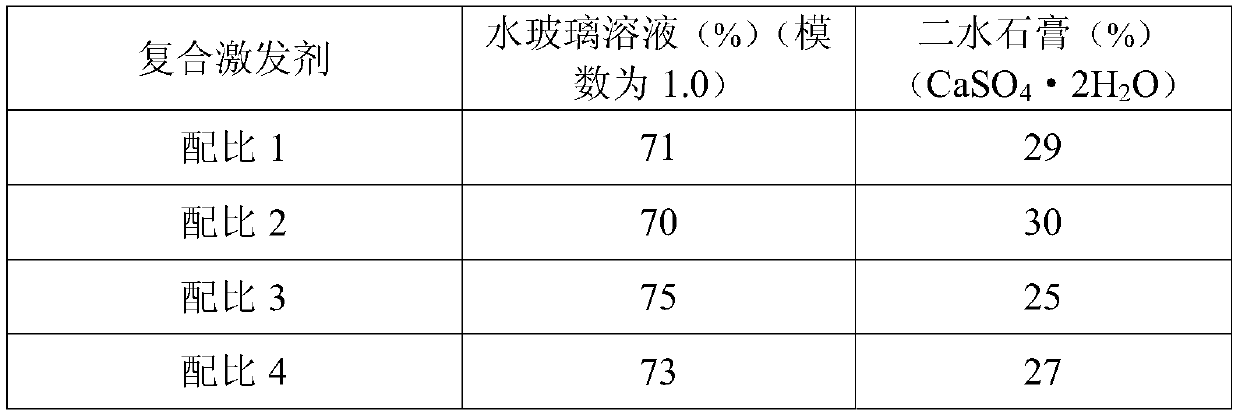

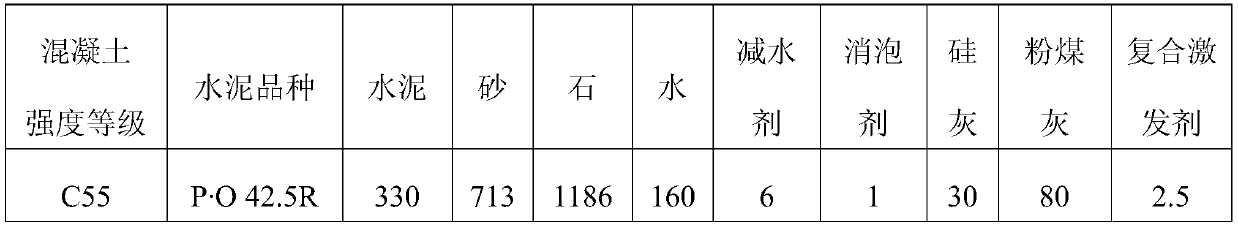

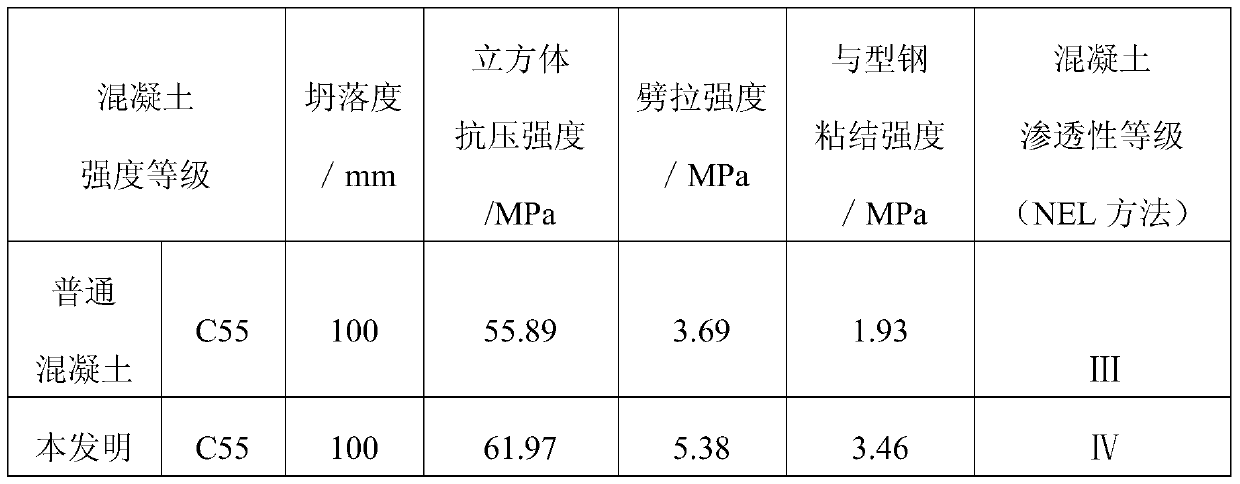

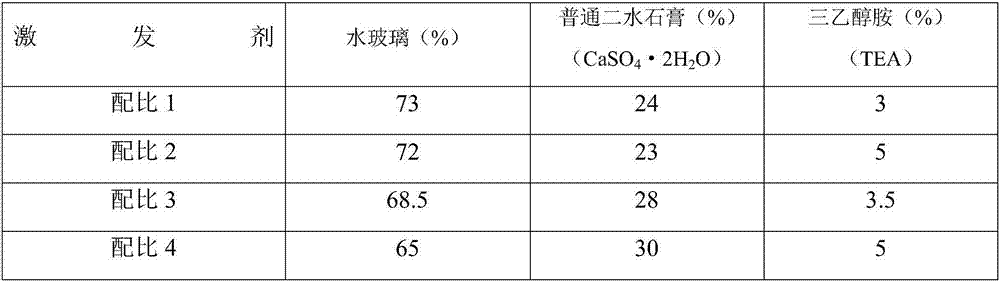

Concrete of strength grade C55 for profile steel reinforced concrete structure

The invention discloses a concrete of strength grade C55 for a profile steel reinforced concrete structure. The concrete contains the ingredients: cement, fine aggregates, coarse aggregates, water, an efficient water reducing agent, an antifoamer, silica fume, fly ash and a composite excitant, wherein the ratio (kg / m<3>) of the cement to the fine aggregates to the coarse aggregates to the water to the efficient water reducing agent to the antifoamer to the silica fume to the fly ash to the composite excitant is 330: 713: 1186: 160: 6: 1: 30: 80: 2.5. A preparation method of the concrete comprises the steps of firstly, uniformly mixing the polycarboxylic acid efficient water reducing agent and the composite excitant with the weighed water so as to obtain a mixture, sequentially adding the fine aggregates and 1 / 3 the total weight of the mixture into a stirrer according to a weight ratio, carrying out stirring, adding the coarse aggregates and 1 / 3 the total weight of the mixture into the stirrer, carrying out stirring, adding the cement, the silica fume and the fly ash into the stirrer, carrying out stirring, adding the antifoamer and the remaining mixture into the stirrer, carrying out stirring, and carrying out discharging. The concrete can be used for remarkably improving the bonding property between profile steel and the concrete in a state of nature, and respective mechanical properties and mutual cooperated working performance of two kinds of materials, i.e., the steel and the concrete are effectively exerted, so that the bearing capacity and use performance of structural elements are substantially improved, and the durability of structures is improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

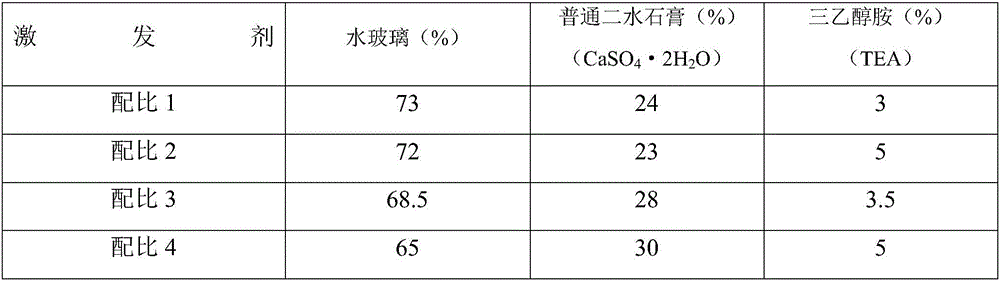

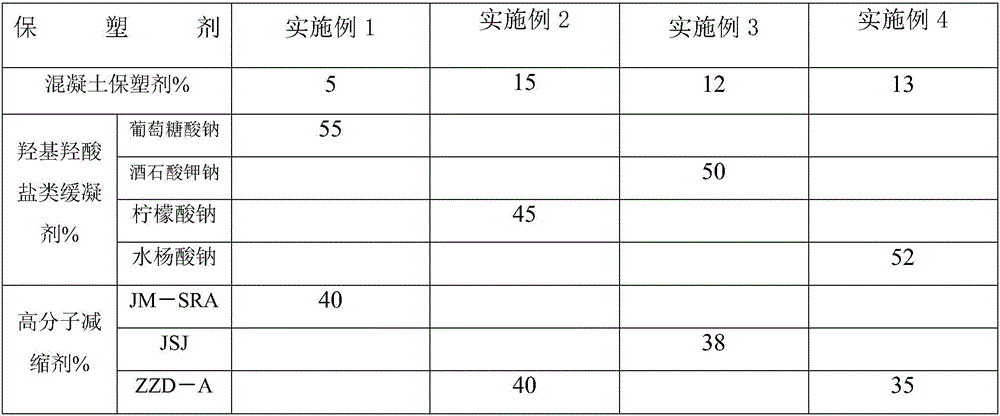

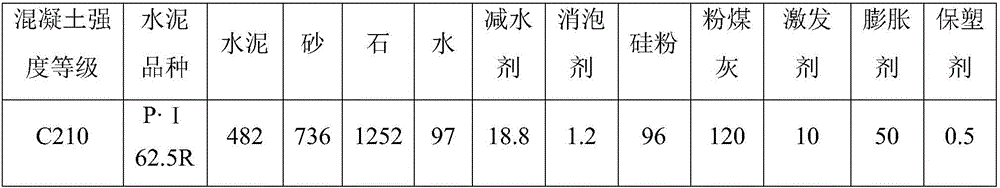

C210-strength-level concrete for steel reinforced concrete composite structures

The invention discloses a C210-strength-level concrete for steel reinforced concrete composite structures. The concrete is composed of 482 parts of cement, 736 parts of fine aggregate, 1252 parts of coarse aggregate, 97 parts of water, 18.8 parts of high-performance water reducing agent, 1.2 parts of defoaming agent, 96 parts of silicon powder, 120 parts of fly ash, 10 parts of excitant, 50 parts of excitant and 0.50 part of composite plastic retaining agent. The preparation method comprises the following steps: uniformly mixing the water reducing agent, excitant and composite plastic retaining agent in the water to obtain a mixture, and sequentially adding the fine aggregate and 1 / 3 of the mixture into a stirrer according to the weight ratio; adding coarse aggregate and 1 / 3 of the mixture, and uniformly mixing; adding the cement, expanding agent, silica fume and fly ash, and uniformly mixing; and adding the defoaming agent and the rest mixture, stirring and discharging. The concrete can obviously improve the bonding property between the steel bar and concrete in a natural state, effectively displays the respective mechanical properties and synergic working properties of the steel and concrete, greatly enhances the carrying capacity, service performance and durability of the structural member, and has high volume stability and favorable economical efficiency.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

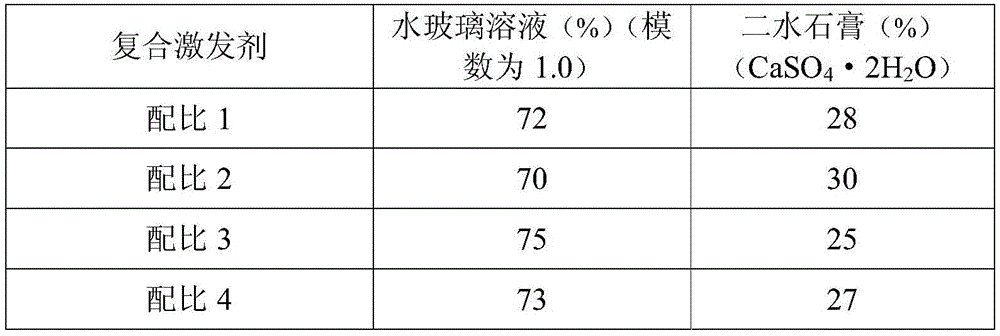

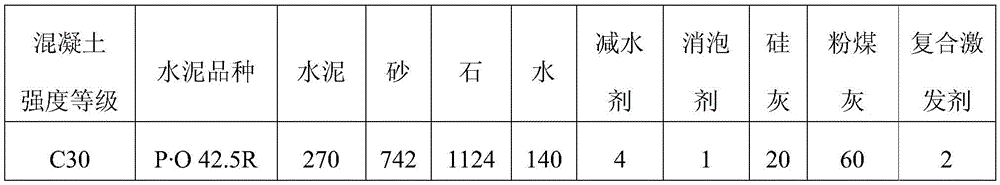

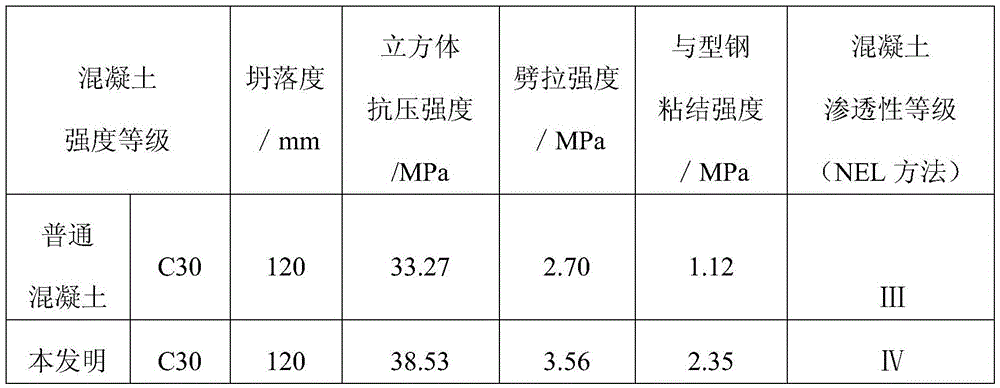

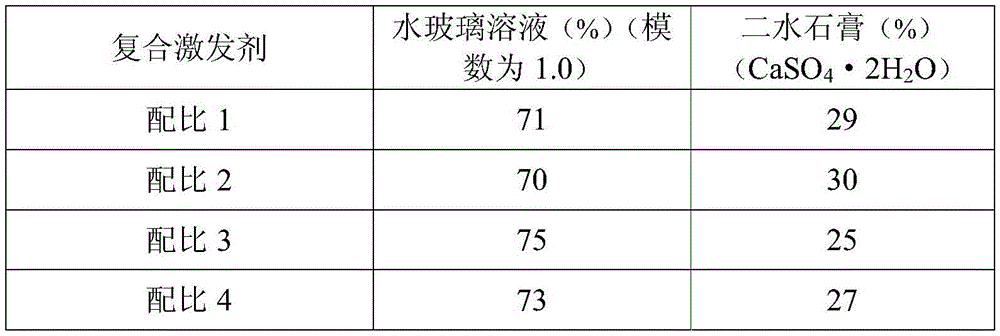

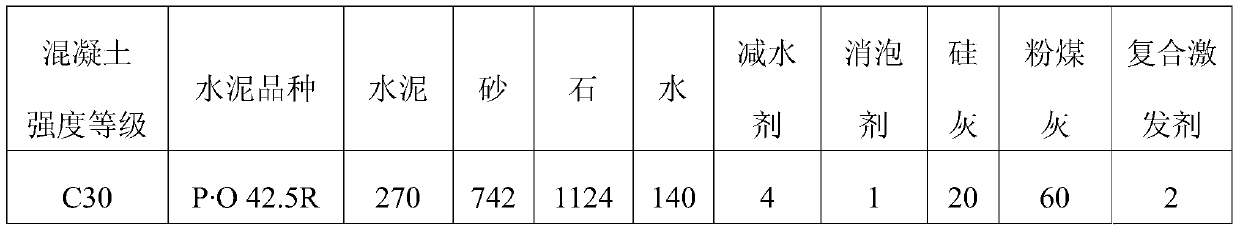

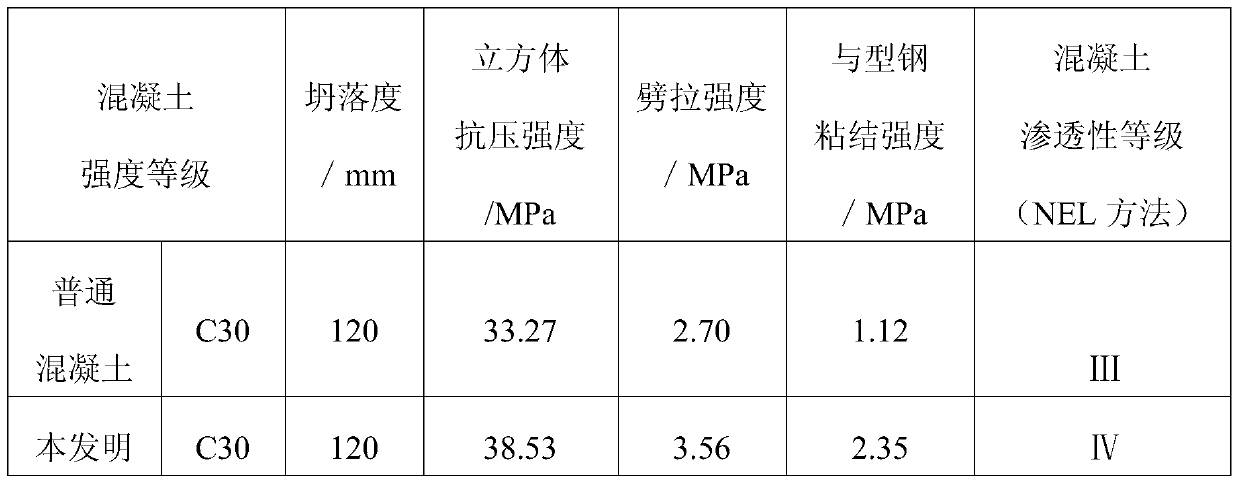

Concrete with strength grade C30 for steel reinforced concrete composite structure

InactiveCN105621995AIncreased durabilityImprove work performanceSolid waste managementNatural stateSuperplasticizer

The invention discloses concrete with a strength grade C30 for a steel reinforced concrete composite structure. The mixture ratio of cement to fine aggregate to coarse aggregate to water to an efficient slushing agent to an antifoaming agent to silica fume to coal ash to a composite catalyst (kg / m<3>) is 270:742:1124:140:4:1:20:60:2. A preparation method of the concrete comprises the steps that the polycarboxylate-type efficient slushing agent and the composite catalyst are firstly stirred into the weighed water evenly to obtain a mixture, 1 / 3 of the total quantity of the fine aggregate and the mixture is sequentially added to a stirrer according to the weight ratio, stirring is carried out, 1 / 3 of the total quantity of the coarse aggregate and the mixture is added, and stirring is carried out; the cement, the silica fume and the coal ash are added, and stirring is carried out; the antifoaming agent and the residual mixture are added, and stirring and discharging are carried out. By means of the concrete, the bonding performance between profile steel and the concrete can be remarkably improved in a natural state, the respective mechanical properties and the cooperative working property of the steel and the concrete can be effectively achieved, and therefore the bearing capacity and use performance of a structural member are greatly improved, and the durability of the structure is improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Concrete at strength grade of C50 for steel reinforced concrete composite structure

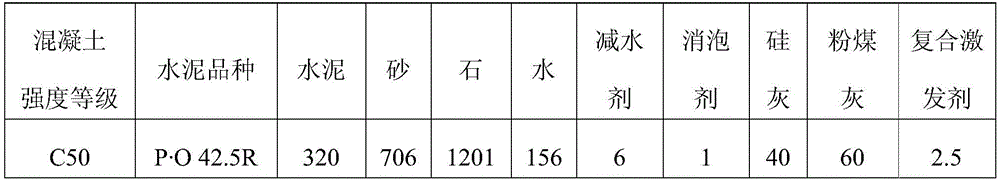

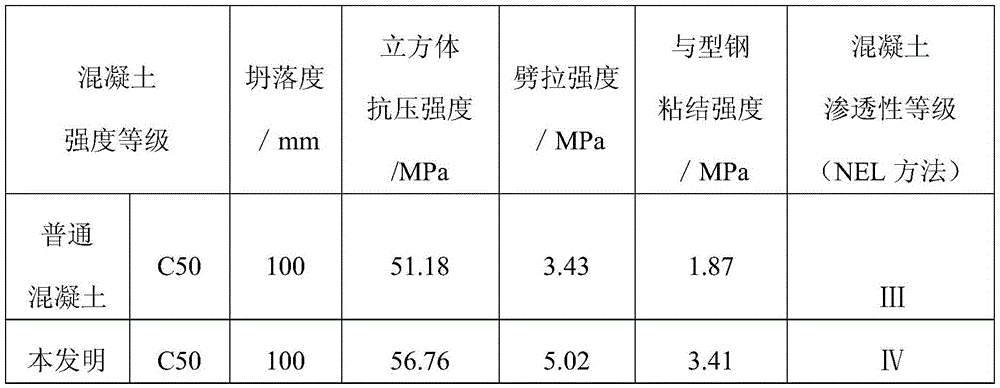

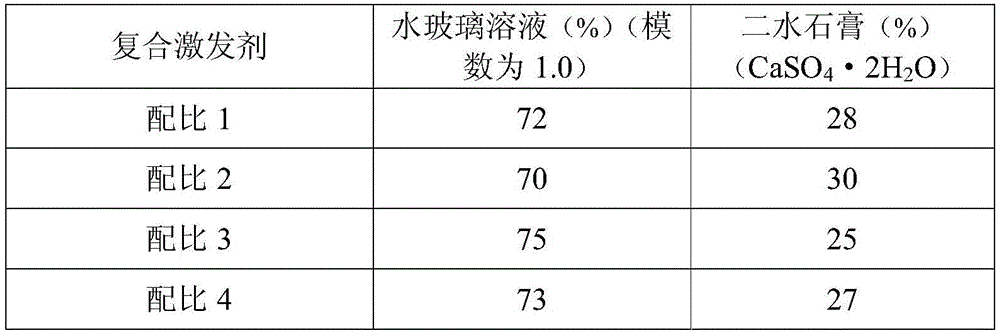

InactiveCN105481317AIncreased durabilityImprove work performanceSolid waste managementReinforced concretePlasticizer

The invention discloses concrete at a strength grade of C50 for a steel reinforced concrete composite structure. Cement:fine aggregate:coarse aggregate:water:super plasticizer:antifoaming agent:silica fume:fly ash:composite activator (kg / m<3>) is 320:706:1,201:156:6:1:40:60:2.5. A preparation method comprises the following steps of uniformly mixing the polycarboxylate type super plasticizer and the composite activator into weighed water to obtain a mixture, sequentially mixing the fine aggregate and 1 / 3 of the total amount of the mixture into a stirrer according to a weight ratio, adding the course aggregate and 1 / 3 of the total amount of the mixture, performing stirring, adding the cement, the silica fume and the fly ash, performing stirring, adding the antifoaming agent and the residual mixture, and performing stirring and discharging. According to the concrete, bonding performance between structural steel and the concrete can be remarkably improved in a natural state, and respective mechanical performance and cooperative working performance of the steel and the concrete can be effectively utilized, thereby greatly improving bearing capacity and application performance of a structural component and improving durability of the structure.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

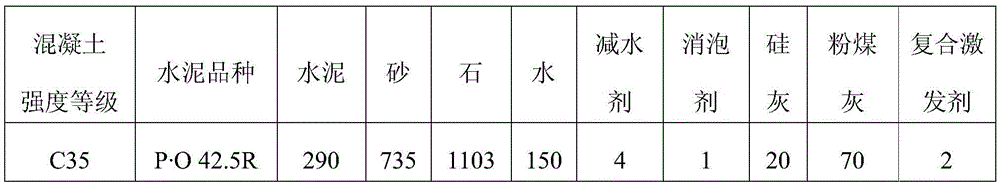

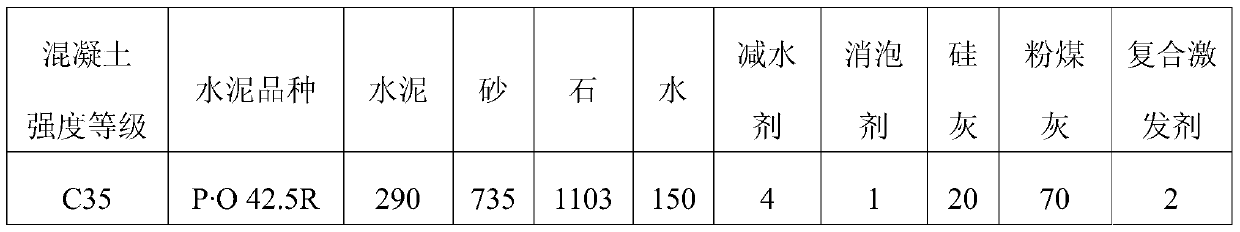

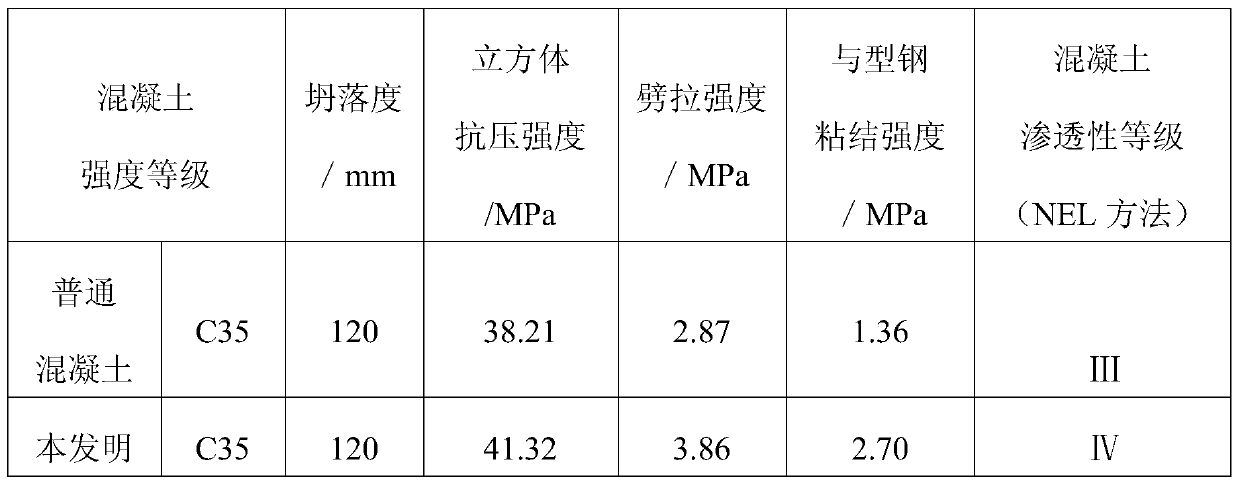

Concrete with strength grade of C35 for steel reinforced concrete composite structures

The invention discloses concrete with the strength grade of C35 for steel reinforced concrete composite structures. The concrete comprises cement, fine aggregate, coarse aggregate, water, a high-efficiency water reducing agent, a defoaming agent, silicon ash, coal ash and a composite excitant (kg / m<3>) in a proportioning ratio of 290:735:1103:150:4:1:20:70:2. A preparation method of the concrete comprises the following steps: firstly, uniformly mixing a polycarboxylic acid high-efficiency water reducing agent and the composite excitant into weighed water so as to obtain a mixture, sequentially adding fine aggregate and 1 / 3 of the mixture into a stirring machine according to the weight proportioning ratio, adding coarse aggregate and 1 / 3 of the mixture, stirring, adding cement, silicon ash and coal ash, stirring, adding the defoaming agent and the rest mixture, stirring, and discharging. According to the concrete, the bonding property of steel and concrete can be greatly improved in a natural state, and respective mechanical properties and mutual cooperative working performance of the two materials, namely, steel and concrete, can be effectively brought into play, so that the bearing property and the use performance of a structural part can be greatly improved, and the structural durability can be improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Concrete for steel reinforced concrete combined structure with C160 strength level

InactiveCN103539407BIncreased durabilityHigh strength and durabilityReinforced concreteCarrying capacity

The invention discloses concrete for a steel reinforced concrete combined structure with C160 strength level. The concrete is composed of cement, fine aggregate, coarse aggregate, water, a concrete super plasticizer, a defoaming agent, silica fume, fly ash and an activator according to a ratio of 468:782:1116:108:16:1:65:117:6. The preparation method is as follows: firstly, uniformly mixing the concrete super plasticizer and the activator in weighed water to obtain a mixture, sequentially adding 1 / 3 of total dosage of the fine aggregate and the mixture in a stirring machine according to a weight ratio, and stirring; adding 1 / 3 of total dosage of the coarse aggregate and the mixture and stirring; and adding the cement, the silica fume and the fly ash, and stirring; and adding the defoaming agent and the rest mixture, stirring and discharging. The concrete can greatly perfect the adhesive property between section steel and the concrete under a natural state, effectively play the respective mechanical properties and mutual cooperative working performance of the steel and the concrete and greatly improve the carrying capacity, application performance and durability of the structural member, thereby having good high-volume stability and economical efficiency.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

C190 strength-grade concrete for formed steel concrete composite structure

InactiveCN103553459BIncreased durabilityHigh strength and durabilitySolid waste managementAggregate (composite)Plasticizer

The invention discloses a C190 strength-grade concrete for a formed steel concrete composite structure, which is composed of 466 parts of cement, 842 parts of fine aggregate, 1065 parts of coarse aggregate, 97 parts of water, 19 parts of concrete superplasticizer, 1.1 parts of defoaming agent, 75 parts of silicon powder, 119 parts of expanding agent, 7 parts of activator and 38 parts of expanding agent. The preparation method comprises the following steps: blending the concrete superplasticizer and activator into weighed water to obtain a mixture, sequentially adding the fine aggregate and 1 / 3 of the mixture into a stirrer according to parts by weight, and stirring; adding the coarse aggregate and 1 / 3 of the mixture, and stirring; adding the cement, expanding agent, silicon powder and fly ash, and stirring; and adding the defoaming agent and the rest of mixture, stirring and discharging. The concrete can obviously improve the bonding property between the formed steel and the concrete in a natural state, effectively displays the respective mechanical properties and the synergic working performance of the steel and concrete, greatly enhances the loading capacity, service performance and durability of the structural member, and has high volume stability and economical efficiency.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Concrete with strength grade of C140 used for profile steel-concrete composite structure

InactiveCN101913815BIncreased durabilityHigh strength and durabilitySolid waste managementCarrying capacityNatural state

The invention discloses concrete with strength grade of C140 used for a profile steel-concrete composite structure. The concrete is characterized by being prepared from cement, fine aggregate, coarse aggregate, water, a water reducing agent, an antifoaming agent, siliceous dust, coal ash(kg / m<3>) in a mixing proportion of 485:660:1,173:117:13:0.7:65:100. A preparation method of the concrete comprises the following steps of: adding the fine aggregate and the water in an amount of which is a half based on the total weight of the used water into a forced mixer according to the weight proportion in turn; uniformly stirring for 1 to 2 minutes; adding the coarse aggregate into the mixer; uniformly stirring for 2 to 4 minutes; adding the cement, the siliceous dust and the coal ash into the mixer; uniformly stirring for 2 to 3 minutes; adding the water reducing agent, the antifoaming agent and the rest water into the mixer; uniformly stirring for 2 to 5 minutes; and discharging to obtain a concrete mixture. The concrete can obviously improve the adhesive property between profile steel and the concrete in a natural state, effectively exert respective capacity and cooperative work performance of both materials, greatly improve the carrying capacity and performance of members, and improve the durability, high volume stability and economy of the members.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A kind of concrete with c230 strength grade for steel-concrete composite structure

InactiveCN105837119BIncreased durabilityHigh strength and durabilitySolid waste managementMixing operation control apparatusReinforced concreteNatural state

Concrete used for a steel reinforced concrete composite structure and having the C230 strength grade is disclosed. A ratio of cement, fine aggregate, coarse aggregate, water, a water reducing agent, a defoaming agent, silica fume, fly ash, an activator, an expanding agent and a composite plastic retaining agent is 495:755:1284:100.5:20:1.4:98:122:10.5:51:0.60. The preparing method includes fully mixing the water reducing agent, the activator and the composite plastic retaining agent with the water to obtain a mixture, adding the fine aggregate and one third of the mixture into a stirrer in order, fully mixing, adding the coarse aggregate one third of the mixture in order, fully stirring, adding the cement, the expanding agent, the silica fume and the fly ash, fully stirring, adding the defoaming agent and the rest of the mixture, stirring and discharging. The concrete significantly improves adhesion performance between section steel and concrete under natural states, effectively exerts mechanical properties of the steel and the concrete and synergistic properties, greatly improves bearing capacity, using performance and durability of structural components, and has good high size stability and economical performance.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

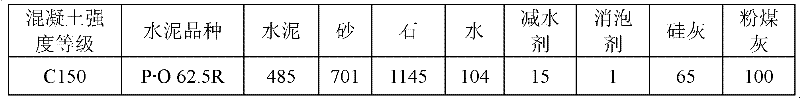

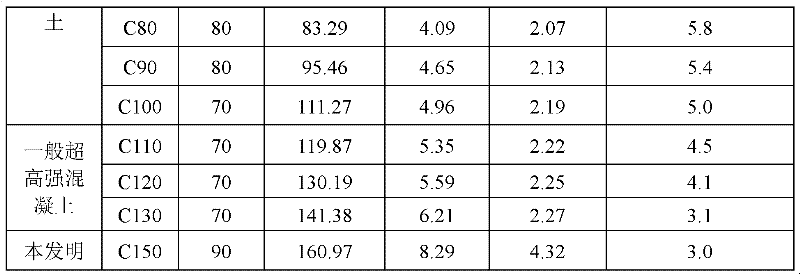

C150 (strength grade) concrete for section steel-concrete combined structure

InactiveCN101913822BIncreased durabilityHigh strength and durabilitySolid waste managementCement mixing apparatusNatural stateUltimate tensile strength

The invention discloses C150 (strength grade) concrete for a section steel-concrete combined structure, which is characterized by being prepared by mixing cement, fine aggregate, coarse aggregate, water, water reducer, defoaming agent, siliceous dust and flash ash in a mass / volume ratio of 485:701:1,145:104:15:1:65:100. The preparation method of the concrete comprises: adding the fine aggregate and half of the total amount of water into a forceful stirrer in turn according to a weight mixing ratio, uniformly stirring for 1 to 2 minutes, adding the coarse aggregate, uniformly stirring for 2 to4 minutes, adding the cement, the siliceous dust and the flash ash, uniformly stirring for 2 to 3 minutes, adding the water reducer, the defoaming agent and the rest of water, uniformly stirring for 2 to 5 minutes, and discharging to obtain a concrete mixture. The concrete has obviously improved section steel binding performance in a natural state and can effectively play respective capability and coordinate operation performance with the section steel, thereby improving the bearing capacity and performance of a member considerably and improving the durability, high-volume stability and economy of the member.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A kind of concrete with c30 strength grade for steel-concrete composite structure

InactiveCN105621995BIncreased durabilityImprove work performanceSolid waste managementNatural stateSuperplasticizer

The invention discloses concrete with a strength grade C30 for a steel reinforced concrete composite structure. The mixture ratio of cement to fine aggregate to coarse aggregate to water to an efficient slushing agent to an antifoaming agent to silica fume to coal ash to a composite catalyst (kg / m<3>) is 270:742:1124:140:4:1:20:60:2. A preparation method of the concrete comprises the steps that the polycarboxylate-type efficient slushing agent and the composite catalyst are firstly stirred into the weighed water evenly to obtain a mixture, 1 / 3 of the total quantity of the fine aggregate and the mixture is sequentially added to a stirrer according to the weight ratio, stirring is carried out, 1 / 3 of the total quantity of the coarse aggregate and the mixture is added, and stirring is carried out; the cement, the silica fume and the coal ash are added, and stirring is carried out; the antifoaming agent and the residual mixture are added, and stirring and discharging are carried out. By means of the concrete, the bonding performance between profile steel and the concrete can be remarkably improved in a natural state, the respective mechanical properties and the cooperative working property of the steel and the concrete can be effectively achieved, and therefore the bearing capacity and use performance of a structural member are greatly improved, and the durability of the structure is improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

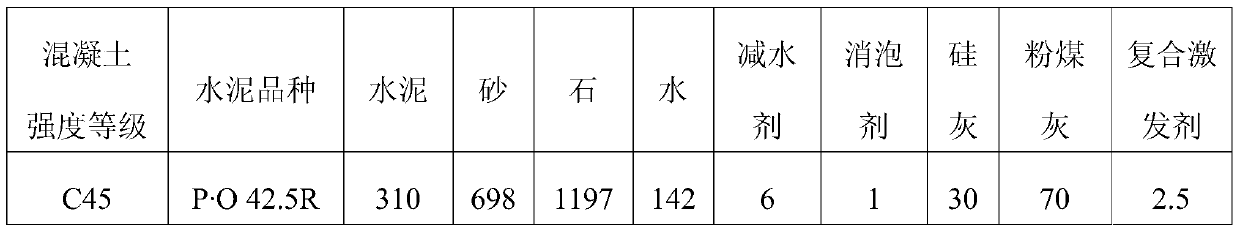

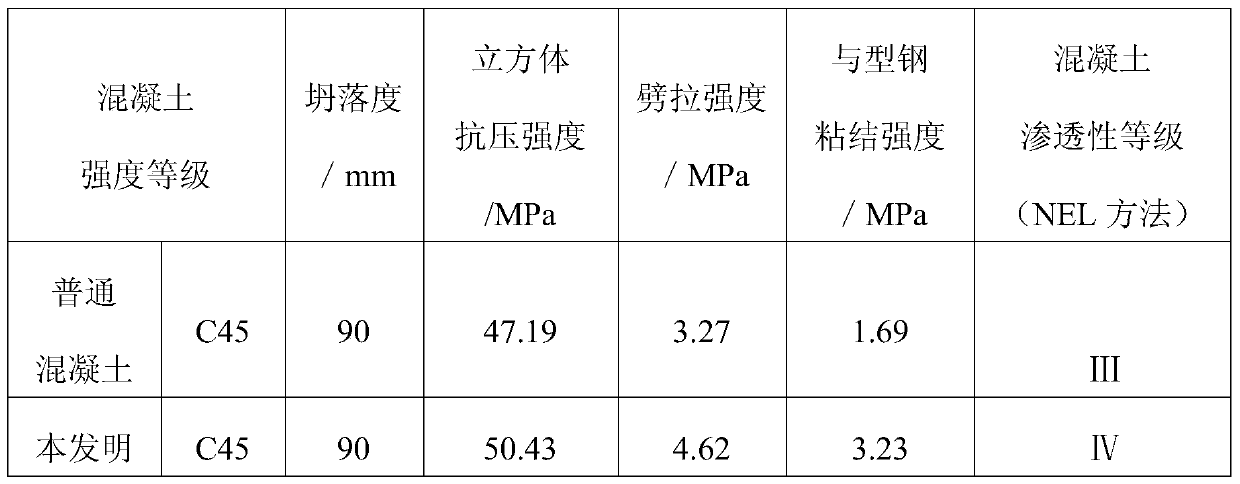

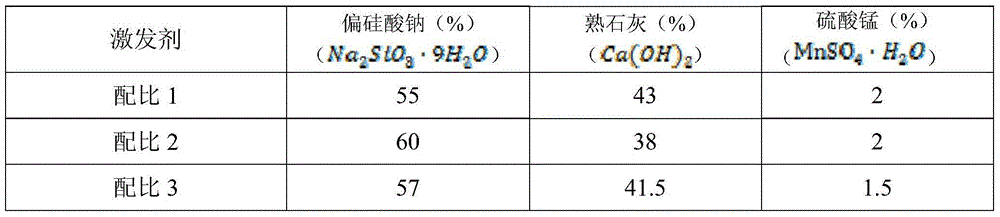

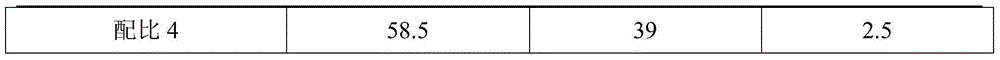

A kind of concrete for C45 strength grade of steel-concrete composite structure

InactiveCN105439517BIncreased durabilityImprove work performanceSolid waste managementReinforced concreteSuperplasticizer

The invention discloses C45 strength level concrete for a steel section-concrete combined structure, which is prepared from cement, fine aggregate, coarse aggregate, water, an efficient water reducer, a defoaming agent, silica fume, fly ash, and a composite booster in a ratio of 310:698:1197:142:6:1:30:70:2.5 (kg / m<3>). A preparation method comprises the steps of: uniformly mixing polycarboxylic acidefficient water reducer and the composite booster with weighed water to obtain a mixture, adding 1 / 3 of the total amount of the fine aggregate and the coarse aggregate according to the weight ratio to a stirrer, stirring, adding 1 / 3 of the total amount of the coarse aggregate and the mixture, stirring, adding the cement,silica fume, and fly ash, stirring, adding the defoaming agent and the rest mixture, stirring, and discharging. According to the concrete, the adhesion property between the steel section and concrete is significantly improved in natural state, and the respective mechanical property and synergic working property of the steel and concrete materials are effectively exerted, so that the bearing capability and use performance of a structural element are greatly improved and the structure durability is improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

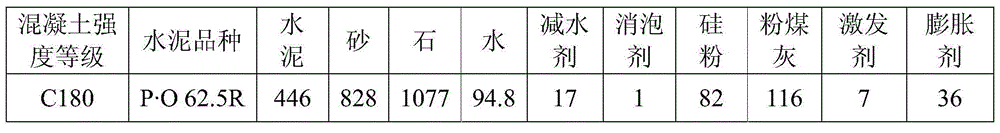

C180 strength-grade concrete for formed steel concrete composite structure

The invention discloses a C180 strength-grade concrete for a formed steel concrete composite structure, which is composed of 446 parts of cement, 828 parts of fine aggregate, 1077 parts of coarse aggregate, 94.8 parts of water, 17 parts of concrete superplasticizer, 1 part of defoaming agent, 82 parts of silicon powder, 116 parts of expanding agent, 7 parts of activator and 36 parts of expanding agent. The preparation method comprises the following steps: blending the concrete superplasticizer and activator into weighed water to obtain a mixture, sequentially adding the fine aggregate and 1 / 3 of the mixture into a stirrer according to parts by weight, and stirring; adding the coarse aggregate and 1 / 3 of the mixture, and stirring; adding the cement, expanding agent, silicon powder and fly ash, and stirring; and adding the defoaming agent and the rest of mixture, stirring and discharging. The concrete can obviously improve the bonding property between the formed steel and the concrete in a natural state, effectively displays the respective mechanical properties and the synergic working performance of the steel and concrete, greatly enhances the loading capacity, service performance and durability of the structural member, and has high volume stability and economical efficiency.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

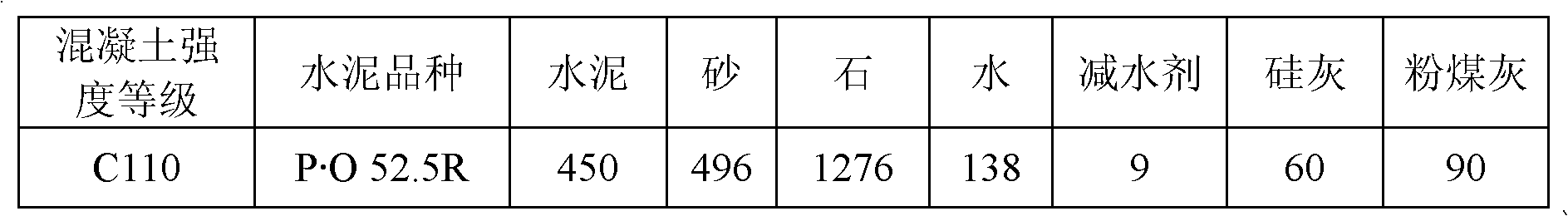

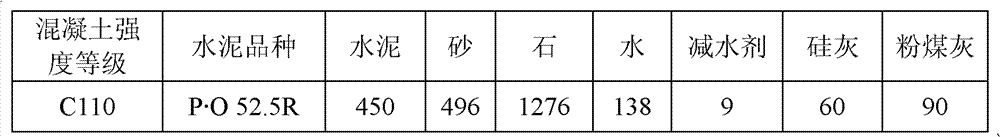

Concrete for profiled steel concrete composite structure with C110 in strength grade

InactiveCN101921092AIncreased durabilityHigh Strength and DurabilityCement mixing apparatusNatural stateUltimate tensile strength

The invention discloses a concrete for a profiled steel concrete composite structure with C110 in strength grade and is characterized in that the concrete mix ratio to fine aggregate to coarse aggregate to water to water reducer to siliceous dust to coal ash (kg / m<3>) is 450:496:1276:138:9:60:90. A preparation method of the concrete comprises the following steps: adding the fine aggregate and thewater to a forced mixer in proportion by weight, wherein the water accounts for 50% of the total water consumption; evenly stirring the mixture for 1-2min, adding the coarse aggregate for evenly stirring for 2-4min, adding the concrete, the siliceous dust and the coal ash for stirring for 2-3min, and adding the water reducer and the rest of the water; and finally evenly stirring the mixture for 2-3min and discharging to obtain the concrete mixture. The concrete can obviously improve the adhesive property between the profiled steel and the concrete under the natural condition and effectively exert individual capacity and cooperative work performance of the two materials, thereby greatly improving bearing capacity and performance of construction members and enhancing durability, high-volumestability and economy thereof.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

C200 strength-grade concrete for formed steel concrete composite structure

InactiveCN103553460BIncreased durabilityHigh strength and durabilitySolid waste managementAggregate (composite)Plasticizer

The invention discloses a C200 strength-grade concrete for a formed steel concrete composite structure, which is composed of 473 parts of cement, 846 parts of fine aggregate, 1054 parts of coarse aggregate, 98.8 parts of water, 19.6 parts of concrete superplasticizer, 1.1 parts of defoaming agent, 84 parts of silicon powder, 123 parts of expanding agent, 7.2 parts of activator and 40 parts of expanding agent. The preparation method comprises the following steps: blending the concrete superplasticizer and activator into weighed water to obtain a mixture, sequentially adding the fine aggregate and 1 / 3 of the mixture into a stirrer according to parts by weight, and stirring; adding the coarse aggregate and 1 / 3 of the mixture, and stirring; adding the cement, expanding agent, silicon powder and fly ash, and stirring; and adding the defoaming agent and the rest of mixture, stirring and discharging. The concrete can obviously improve the bonding property between the formed steel and the concrete in a natural state, effectively displays the respective mechanical properties and the synergic working performance of the steel and concrete, greatly enhances the loading capacity, service performance and durability of the structural member, and has high volume stability and economical efficiency.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A kind of concrete with c35 strength grade for steel-concrete composite structure

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

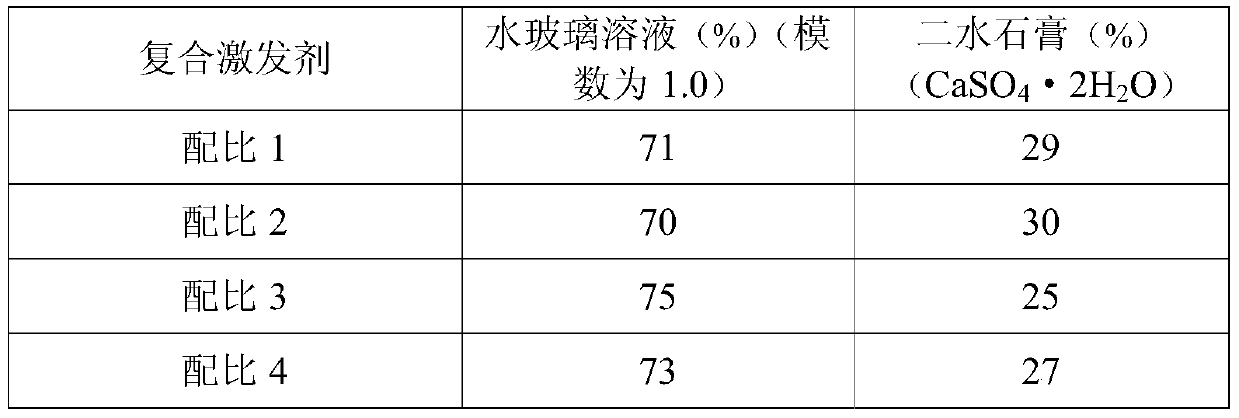

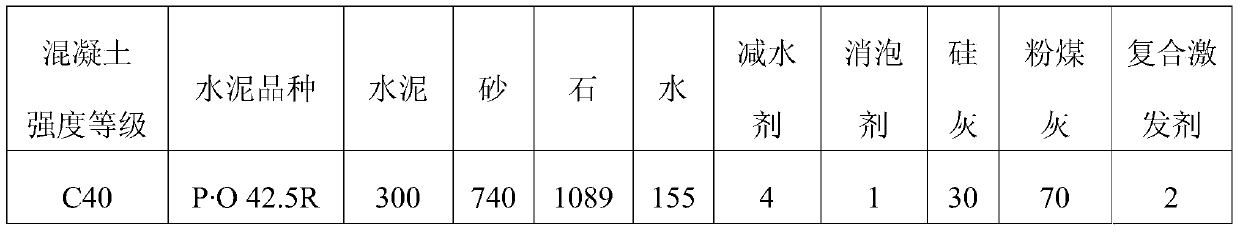

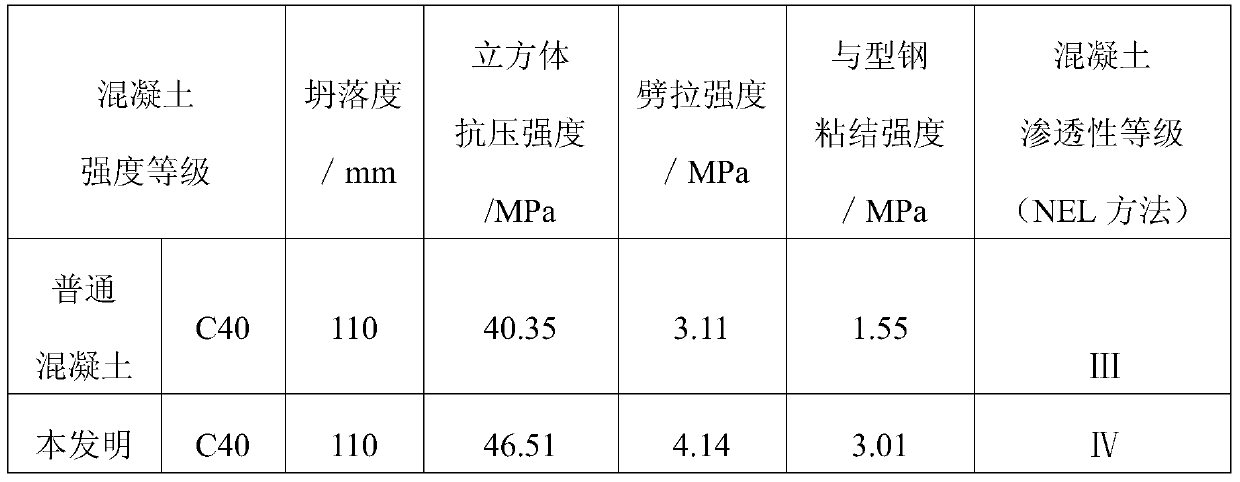

A kind of concrete with c40 strength grade for steel-concrete composite structure

InactiveCN105481318BIncreased durabilityImprove work performanceSolid waste managementSuperplasticizerNatural state

The invention discloses concrete at a strength grade of C40 for a steel reinforced concrete composite structure. Cement:fine aggregate:coarse aggregate:water:super plasticizer:antifoaming agent:silica fume:fly ash:composite activator (kg / m<3>) is 300:740:1,089:155:4:1:30:70:2. A preparation method comprises the following steps of uniformly mixing the polycarboxylate type super plasticizer and the composite activator into weighed water to obtain a mixture, sequentially mixing the fine aggregate and 1 / 3 of the total amount of the mixture into a stirrer according to a weight ratio, adding the course aggregate and 1 / 3 of the total amount of the mixture, performing stirring, adding the cement, the silica fume and the fly ash, performing stirring, adding the antifoaming agent and the residual mixture, and performing stirring and discharging. According to the concrete, bonding performance between structural steel and the concrete can be remarkably improved in a natural state, and respective mechanical performance and cooperative working performance of the steel and the concrete can be effectively utilized, thereby greatly improving bearing capacity and application performance of a structural component and improving durability of the structure.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A kind of concrete with c55 strength grade for steel-concrete composite structure

The invention discloses a concrete of strength grade C55 for a profile steel reinforced concrete structure. The concrete contains the ingredients: cement, fine aggregates, coarse aggregates, water, an efficient water reducing agent, an antifoamer, silica fume, fly ash and a composite excitant, wherein the ratio (kg / m<3>) of the cement to the fine aggregates to the coarse aggregates to the water to the efficient water reducing agent to the antifoamer to the silica fume to the fly ash to the composite excitant is 330: 713: 1186: 160: 6: 1: 30: 80: 2.5. A preparation method of the concrete comprises the steps of firstly, uniformly mixing the polycarboxylic acid efficient water reducing agent and the composite excitant with the weighed water so as to obtain a mixture, sequentially adding the fine aggregates and 1 / 3 the total weight of the mixture into a stirrer according to a weight ratio, carrying out stirring, adding the coarse aggregates and 1 / 3 the total weight of the mixture into the stirrer, carrying out stirring, adding the cement, the silica fume and the fly ash into the stirrer, carrying out stirring, adding the antifoamer and the remaining mixture into the stirrer, carrying out stirring, and carrying out discharging. The concrete can be used for remarkably improving the bonding property between profile steel and the concrete in a state of nature, and respective mechanical properties and mutual cooperated working performance of two kinds of materials, i.e., the steel and the concrete are effectively exerted, so that the bearing capacity and use performance of structural elements are substantially improved, and the durability of structures is improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A kind of concrete with c250 strength grade for steel-concrete composite structure

InactiveCN105777017BIncreased durabilityHigh strength and durabilityCarrying capacityReinforced concrete

The invention discloses concrete for the steel reinforced concrete composite structure C250 strength grade. The matching ratio of cement to fine aggregate to coarse aggregate to water to water reducing agent to antifoaming agent to silica powder to coal ash to exciting agent to expanding agent to composite plastic retaining agent is 504:769:1,308:102:21:1.5:100:125:11:52:0.65. A preparing method includes the steps that the water reducing agent, the exciting agent and the composite plastic retaining agent are evenly stirred into water to obtain a mixture, and the fine aggregate and 1 / 3 of the total mixture are sequentially added into a stirring machine according to the weight ratio and stirred to be even; the coarse aggregate and 1 / 3 of the total mixture are added and stirred to be even; the cement, the expanding agent, the silica powder and the coal ash are added and stirred to be even; the antifoaming agent and the residual mixture are added, and the mixture is stirred and discharged. By means of the concrete, the bonding performance between structural steel and the concrete can be remarkably improved under the natural state, the mechanical performance and the cooperative work performance of the steel and the concrete are effectively developed, the carrying capacity, the use performance and the durability of a structural element are greatly improved, and the concrete has the good high volume stability and the good economy.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

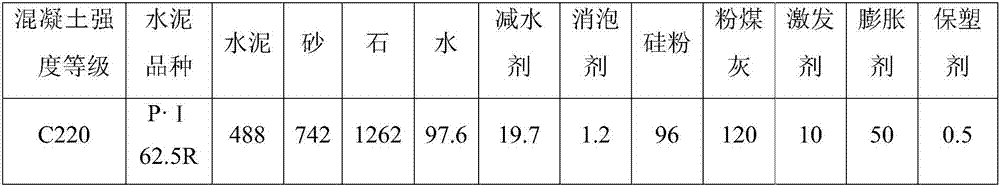

A kind of concrete with c220 strength grade for steel-concrete composite structure

The invention discloses concrete of a strength grade C220 for a steel reinforced concrete combined structure. The concrete comprises cement, fine aggregate, coarse aggregate, water, a water reducing agent, a defoaming agent, silicon powder, coal ash, an excitant, an expanding agent and a composite plastic retaining agent in a ratio of 488:742:1262:97.6:19.7:1.2:96:120:10:50:0.50. A preparation method comprises the following steps: firstly, uniformly mixing the water reducing agent, the excitant and the composite plastic retaining agent with water so as to obtain a mixture, sequentially adding the fine aggregate, the coarse aggregate and 1 / 3 of the mixture into a stirrer according to a weight ratio, adding the coarse aggregate and 1 / 3 of the mixture, uniformly mixing, adding the cement, the expanding agent, the silicon ash and the coal ash, uniformly mixing, adding the defoaming agent and the rest mixture, stirring, and discharging, thereby obtaining the concrete. By adopting the concrete, the bonding property of steel and concrete can be remarkably improved in a natural state, respective mechanical properties and mutual synergetic working properties of the steel and the concrete can be effectively taken into play, the bearing property, the use performance and the durability of a structural component can be greatly improved, and good volume stability and economy can be achieved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Concrete for profiled steel concrete composite structure with C110 in strength grade

InactiveCN101921092BIncreased durabilityHigh strength and durabilityCement mixing apparatusAggregate (composite)Water use

The invention discloses a concrete for a profiled steel concrete composite structure with C110 in strength grade and is characterized in that the concrete mix ratio to fine aggregate to coarse aggregate to water to water reducer to siliceous dust to coal ash (kg / m<3>) is 450:496:1276:138:9:60:90. A preparation method of the concrete comprises the following steps: adding the fine aggregate and thewater to a forced mixer in proportion by weight, wherein the water accounts for 50% of the total water consumption; evenly stirring the mixture for 1-2min, adding the coarse aggregate for evenly stirring for 2-4min, adding the concrete, the siliceous dust and the coal ash for stirring for 2-3min, and adding the water reducer and the rest of the water; and finally evenly stirring the mixture for 2-3min and discharging to obtain the concrete mixture. The concrete can obviously improve the adhesive property between the profiled steel and the concrete under the natural condition and effectively exert individual capacity and cooperative work performance of the two materials, thereby greatly improving bearing capacity and performance of construction members and enhancing durability, high-volumestability and economy thereof.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com