A kind of concrete with c230 strength grade for steel-concrete composite structure

A technology of strength grade and combined structure, applied in the directions of hybrid operation control, hybrid operation control device, ceramic molding machine, etc., can solve problems such as poor natural bonding performance, improve construction efficiency, avoid congenital micro-cracks, high work efficiency sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

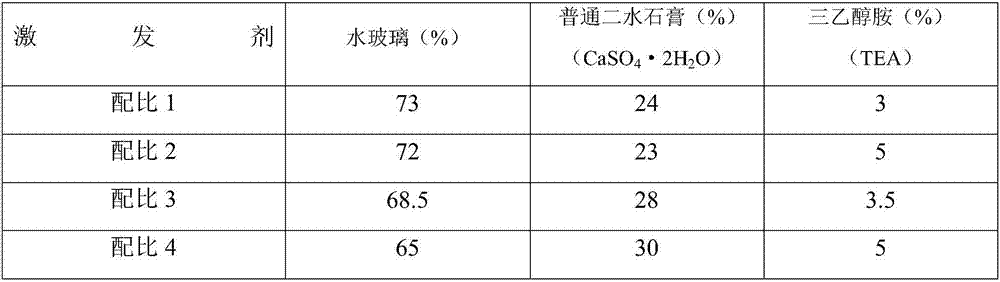

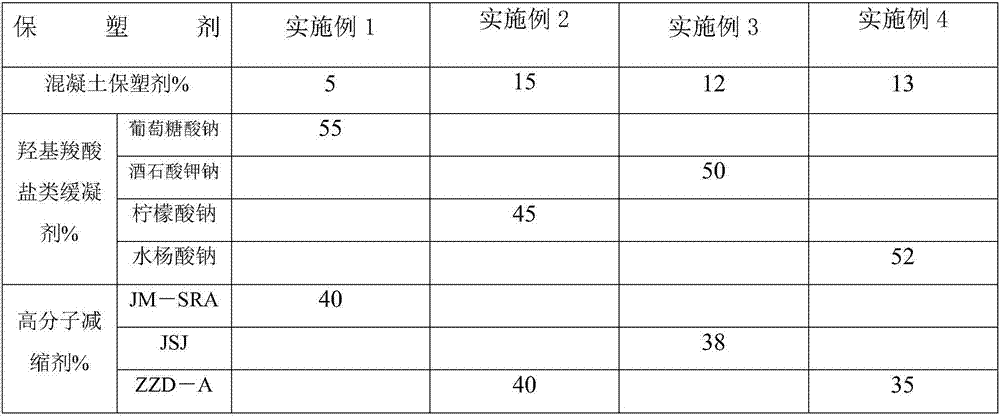

Method used

Image

Examples

Embodiment

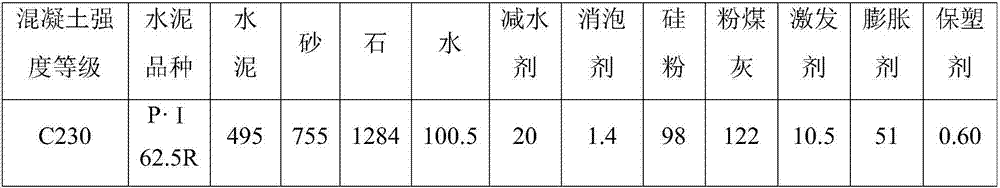

[0069] (1) Raw materials

[0070] 1. Cement

[0071] Choose Qinling brand P·I 62.5R cement with stable quality and good performance, and conduct an adaptability test between the two with polycarboxylic acid concrete high-performance water reducing agent before use. The test method adopts the current building materials industry standard "Cement and The method in "Test Method for Compatibility of Water Reducer" JC / T 1083-2008 has good compatibility with polycarboxylate concrete high performance water reducer. The performance indicators of the selected cement meet the requirements of the current relevant national standards such as "Portland Cement, Ordinary Portland Cement" GB175-2007, and its alkali content is low, the heat of hydration is low, and the water demand is also low.

[0072] 2. Aggregate

[0073] Use sand and quartz sand with a mass ratio of 8:2.

[0074] The sand is medium-to-coarse and Bahe sand with smooth particles, hard texture and good gradation. The quality of the san...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com