Self-compacting C120 premixed dry concrete and preparation method thereof

A concrete and self-compacting technology, which is applied in bridge materials, building materials processing, construction, etc., can solve the problems of steel fiber agglomeration and other problems, and achieve the effect of broad requirements, broad application range, and simple and practical preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A self-compacting C120 ready-mixed dry concrete is composed of the following components by weight fraction:

[0040] P.Ⅰ52.5 Portland cement 520 parts, mineral powder 100 parts, fly ash 50 parts, silica fume 40 parts, fine stone 50 parts, quartz sand 350 parts, artificial sand 200 parts, steel fiber 80 parts, 8.5 parts of water agent, 5 parts of defoamer;

[0041] The preparation method of the above-mentioned C120 ready-mixed dry concrete is as follows:

[0042] (1) Weigh the above raw materials according to the weight fraction, pour Portland cement, fine stone, quartz sand, artificial sand, mineral powder, fly ash and silica fume into the mixer in sequence, then add water reducing agent and defoaming agent agent, start dry mixing;

[0043] (2) During the mixing process, sieve the steel fibers into the mixture of the mixer in batches, and stir while adding. The stirring lasts for about 300s. After the mixing is uniform, the ready-mixed dry concrete is obtained and dis...

Embodiment 2

[0051] A C120 ready-mixed dry concrete, which consists of the following components in parts by weight: 500 parts of Portland cement of P.I52.5, 100 parts of mineral powder, 50 parts of fly ash, 40 parts of silica fume, fine stone 55 parts, 350 parts of quartz sand, 190 parts of artificial sand, 70 parts of steel fiber, 8 parts of powder water reducer, 5 parts of defoamer;

[0052] The preparation process of the concrete is the same as in Example 1.

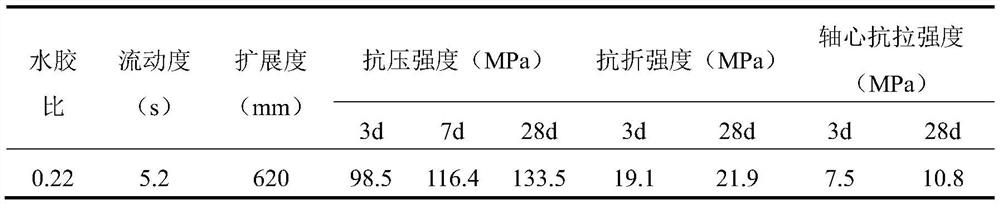

[0053] Regarding the performance of C120 ready-mixed dry concrete, the test results are shown in Table 2:

[0054] Table 2 Measured values of concrete mechanical indexes

[0055]

example 1

[0059] The first construction and application of the UHPC concrete of the present invention on domestic high-speed railway bridges was carried out on the Lanzhou-Zhangye high-speed railway Shibalibao Super Bridge. The UHPC structure is lighter in size and its own weight is greatly reduced. The weight of the UHPC composite beam is about 72% of that of ordinary concrete beams. The width is 6m, the girder height at the lowest point is 5.3m, the thickness of the box girder web is 25cm-45cm, the thickness of the bottom plate is 25cm-55cm, the thickness of the roof is 30cm, and the width is 90cm-110cm. It is a typical long-span bridge with light weight, high strength and thin wall structure. Design requirements: the measured value of compressive strength is not less than 120Mpa, the flexural strength is not less than 14MPa, the axial ultimate tensile strength is not less than 6.0MPa, and the volume ratio of steel fiber is not less than 2%. The design requirements need to meet the ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com