Patents

Literature

31results about How to "Broad requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

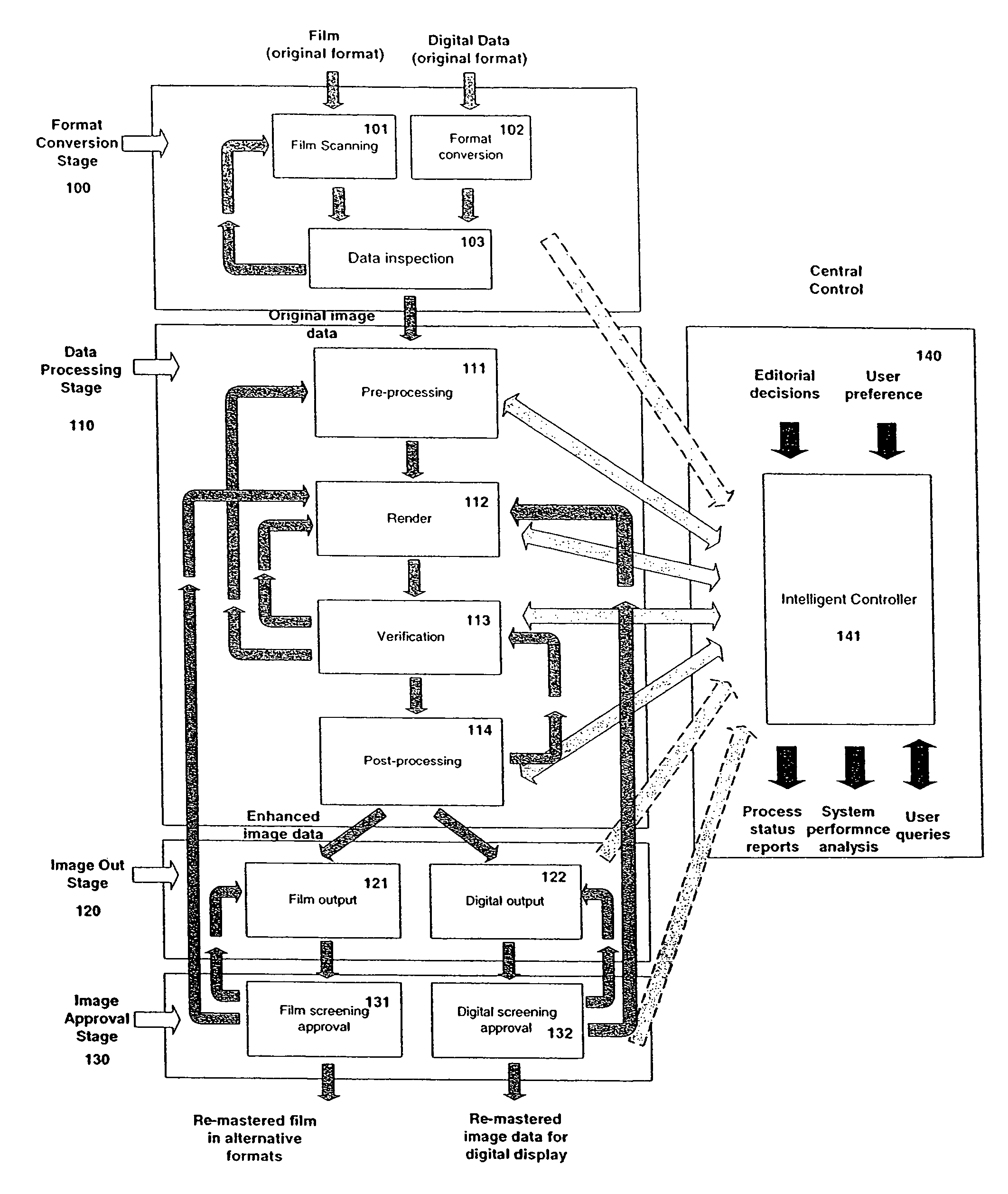

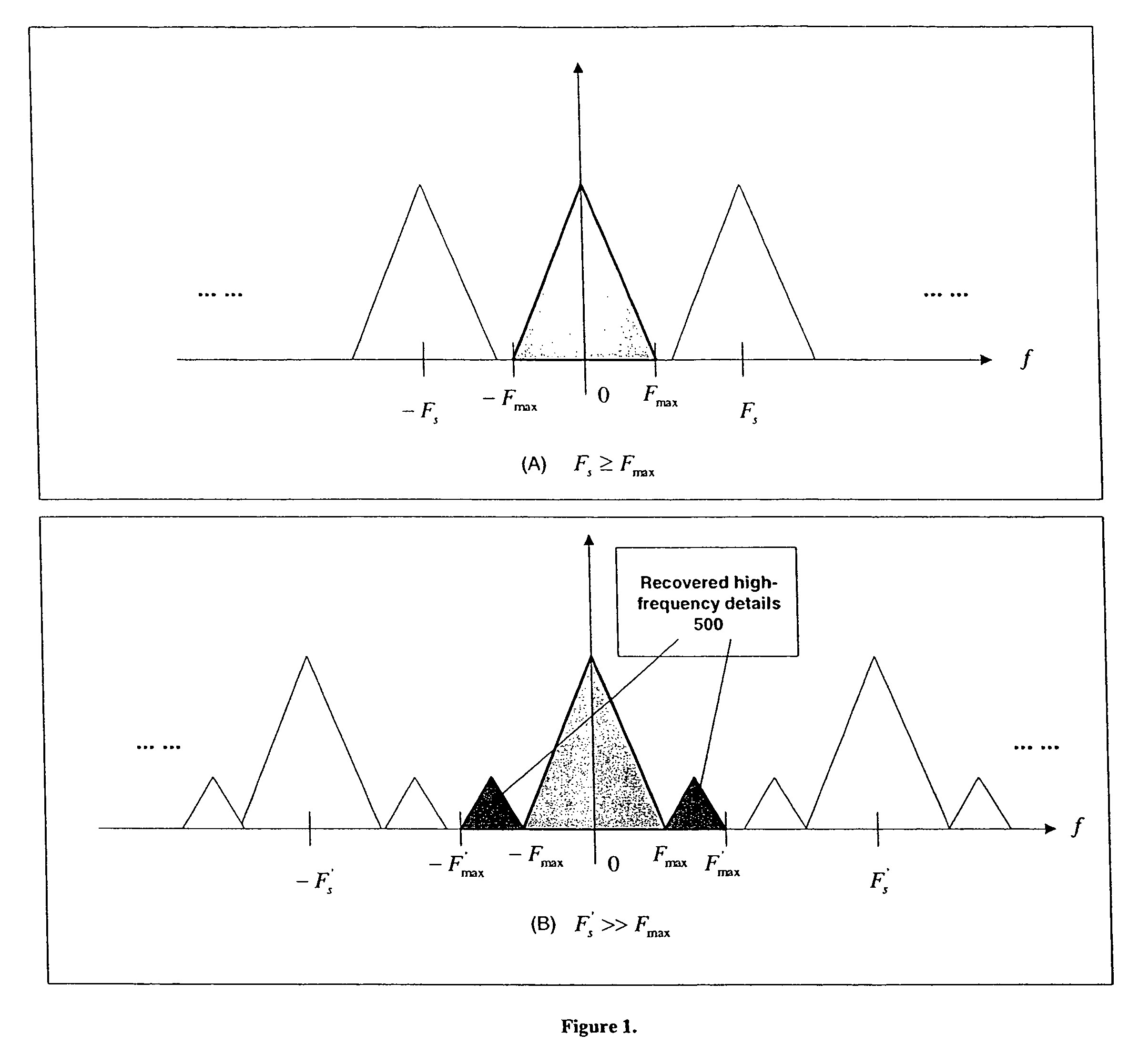

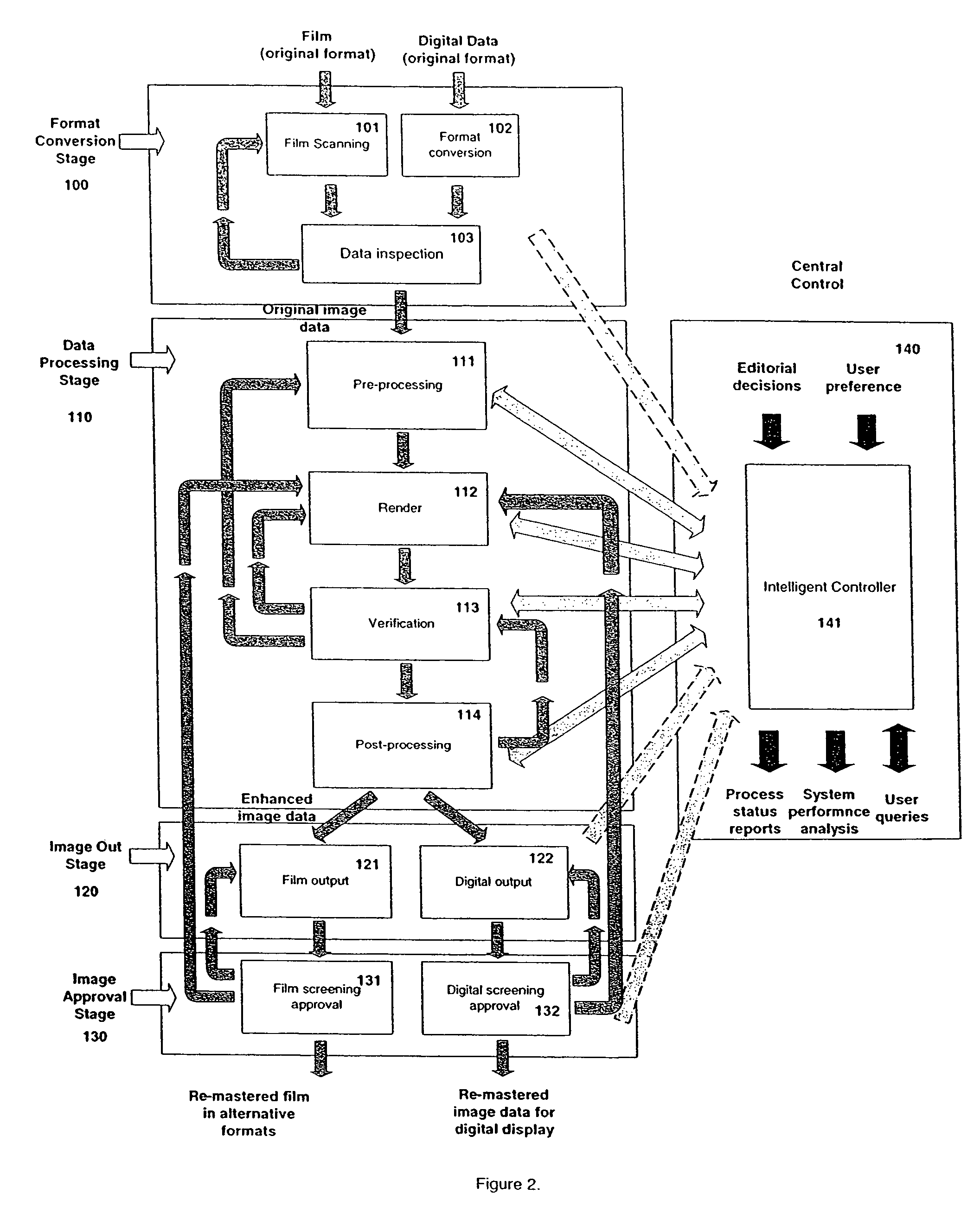

Systems and methods for digitally re-mastering or otherwise modifying motion pictures or other image sequences data

ActiveUS7856055B2Improve spatial resolutionExpands image frequency spectrumTelevision system detailsPicture reproducers using cathode ray tubesImage resolutionStatistical quality

A process and methods of digital enhancement of motion pictures and other moving image sequences for the purpose of being exhibited in an alternative display format including a large format cinema are disclosed. The invention efficiently enhances image resolution and quality through a temporal filtering process and achieves high performance using automated or interactive statistical quality evaluation methods. A system specially designed for efficient temporal computing with a parallel and distributed computing configuration equipped with a variety of optimization schemes is also disclosed. The performance of the process and the system is optimized through an intelligent controller and is scalable to support any throughput requirements demanded for concurrent motion picture releases in the original format as well as in any alternative format.

Owner:IMAX CORP

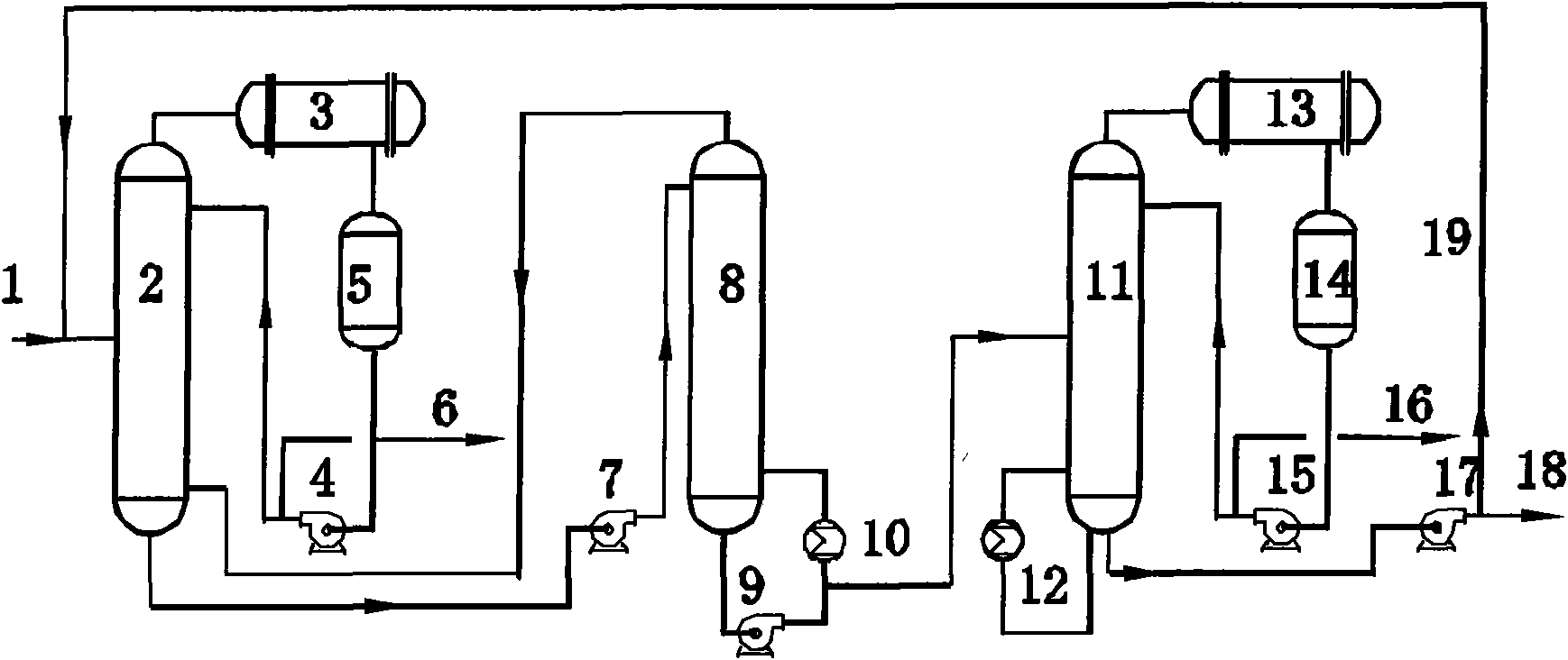

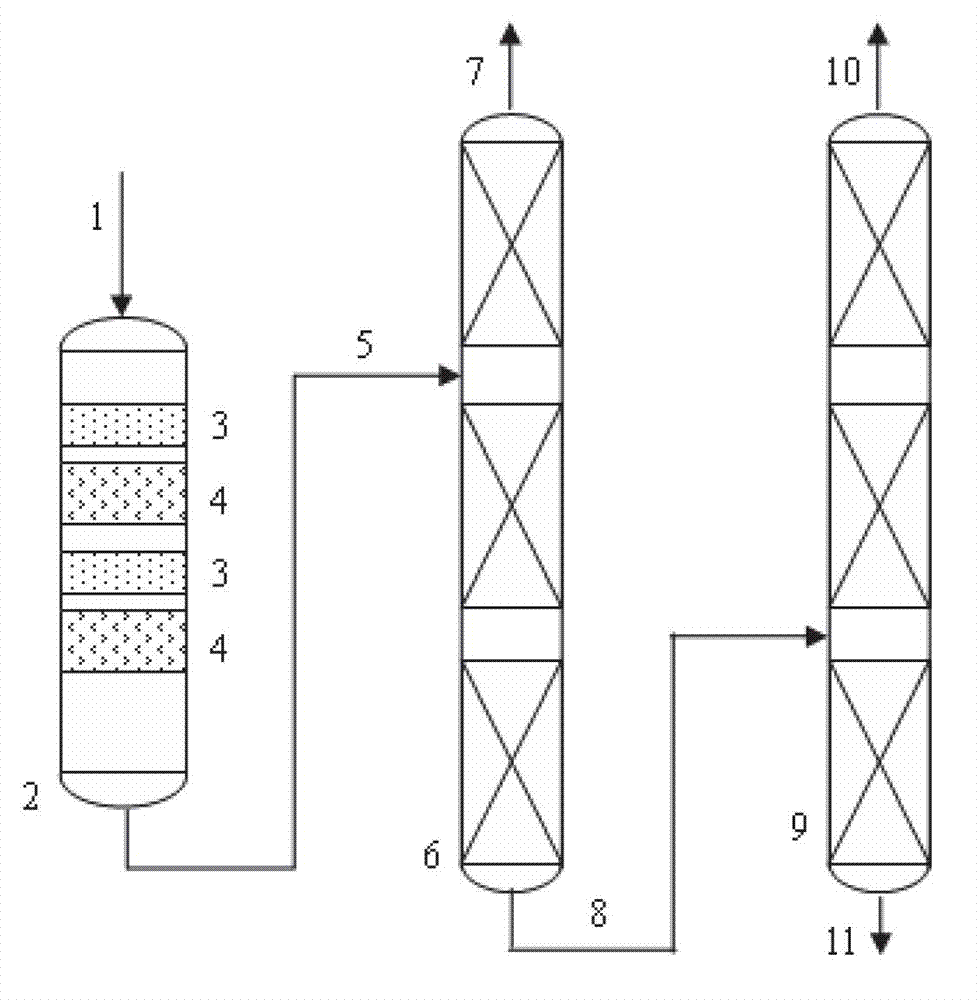

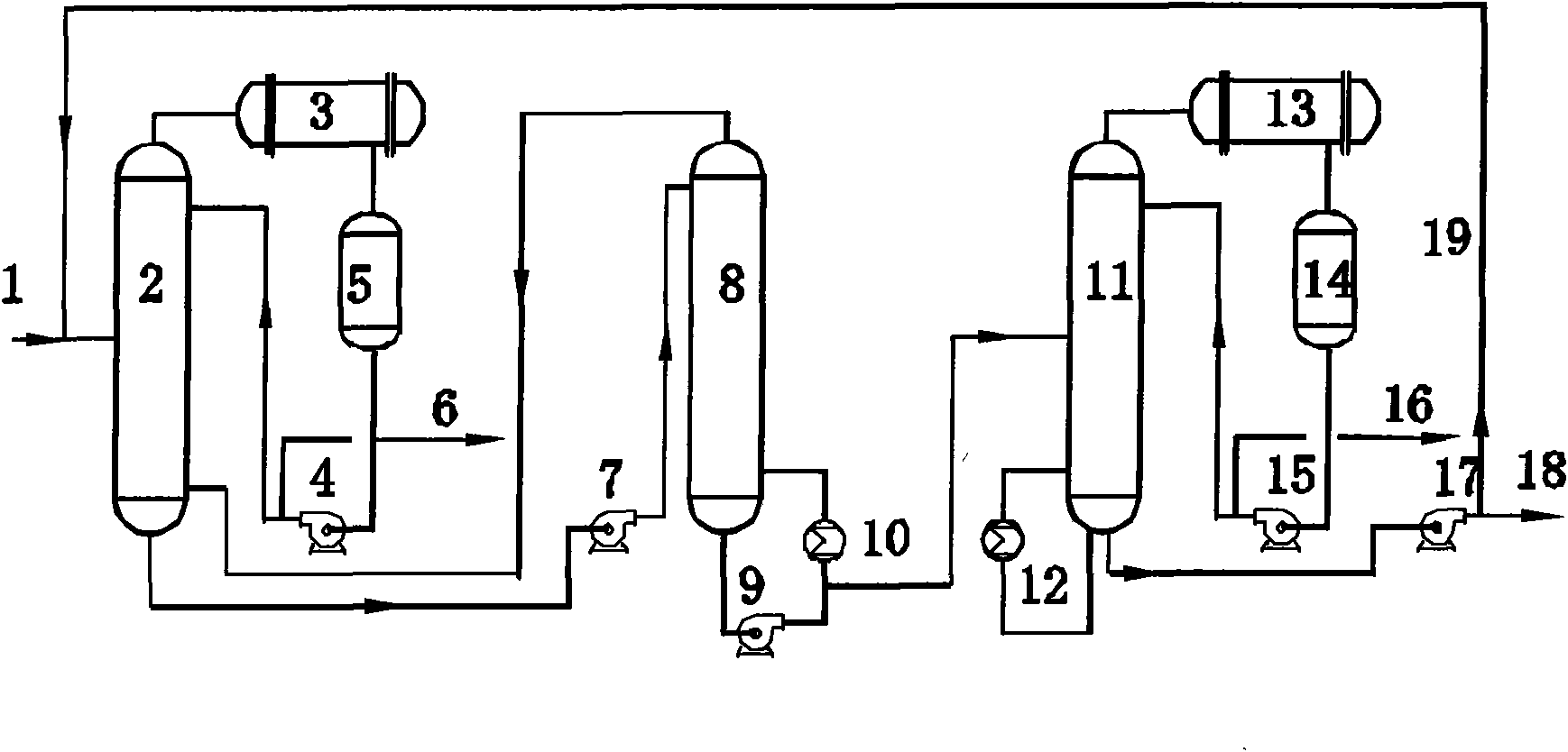

Fiber-level high purity silicon tetrachloride continuous azeotropy lightness removing rectification method

ActiveCN101564600AReduce energy consumptionSuitable for purificationFractional distillationHalogenated silanesFiberProcess engineering

The invention belongs to a fiber-level high purity silicon tetrachloride continuous azeotropy lightness removing rectification method. A lightness removing tower and a heaviness removing tower are adopted; light components and azeotropic mixtures are removed from the raw material, the material at the bottom of the lightness removing tower enters the heaviness removing tower to lead the heaviness to be removed, partial material at the bottom of the heaviness removing tower returns to the lightness removing tower as incoming stock and the fiber-level silicon tetrachloride product is obtained at the top of the heaviness removing tower. The lightness removing tower is divided into an upper lightness removing tower and a lower lightness removing tower. The upper lightness removing tower adopts a pressurizing tower with the pressure being 200-250 KPa, the total theoretical stage being 80-120, and the rate of top reflux to the incoming material being 5-12; the lower lightness removing tower adopts a pressurizing tower with the pressure being 200-250KPa, and the total theoretical stage being 80-120; and the heaviness removing tower adopts a pressurizing tower with the pressure being 200-300KPa, the rate of the top reflux to the incoming material being 8-20 and the theoretical stage being 60-100. The system adopts continuous operation, is suitable for large-scale silicon tetrachloride purification and reduces energy consumption. The method has wide requirements on the raw materials of the silicon tetrachloride and is applicable to the purification of silicon tetrachloride with the concentration range of 50-98 percent in raw materials.

Owner:TIANJIN UNIV

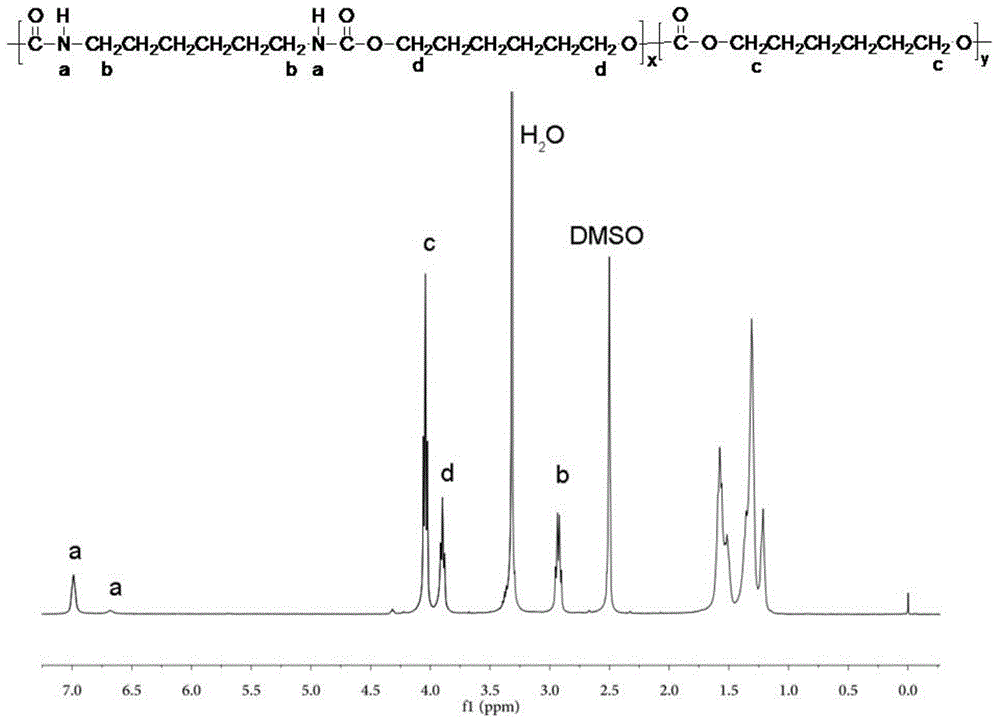

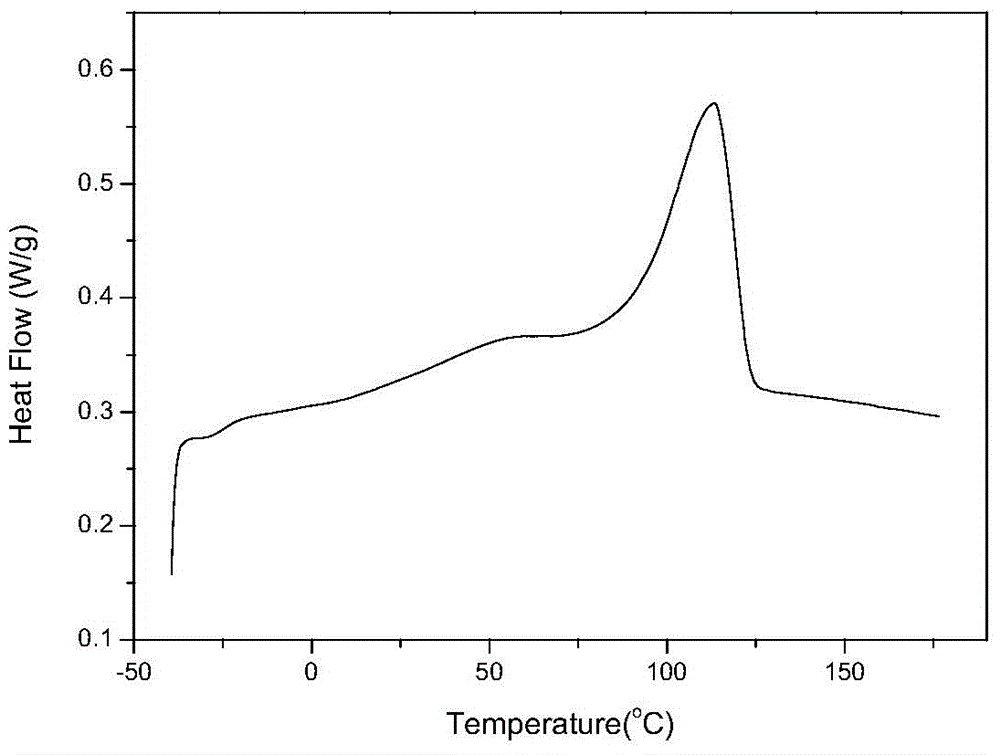

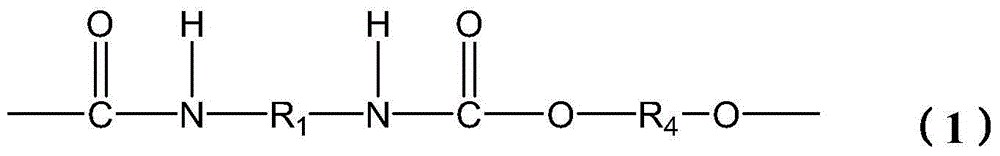

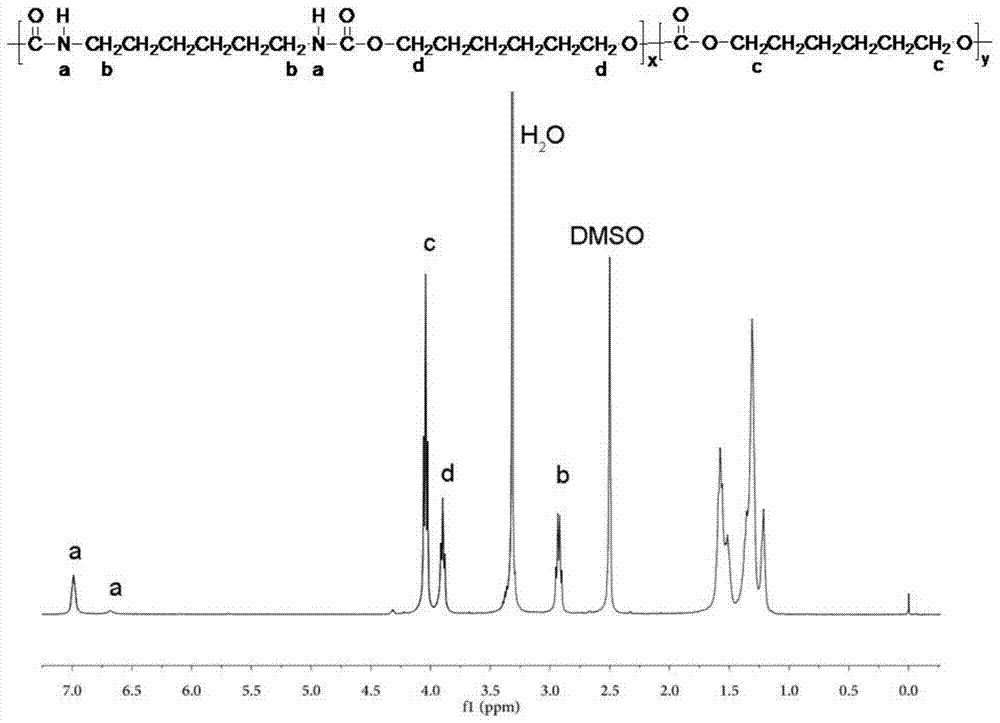

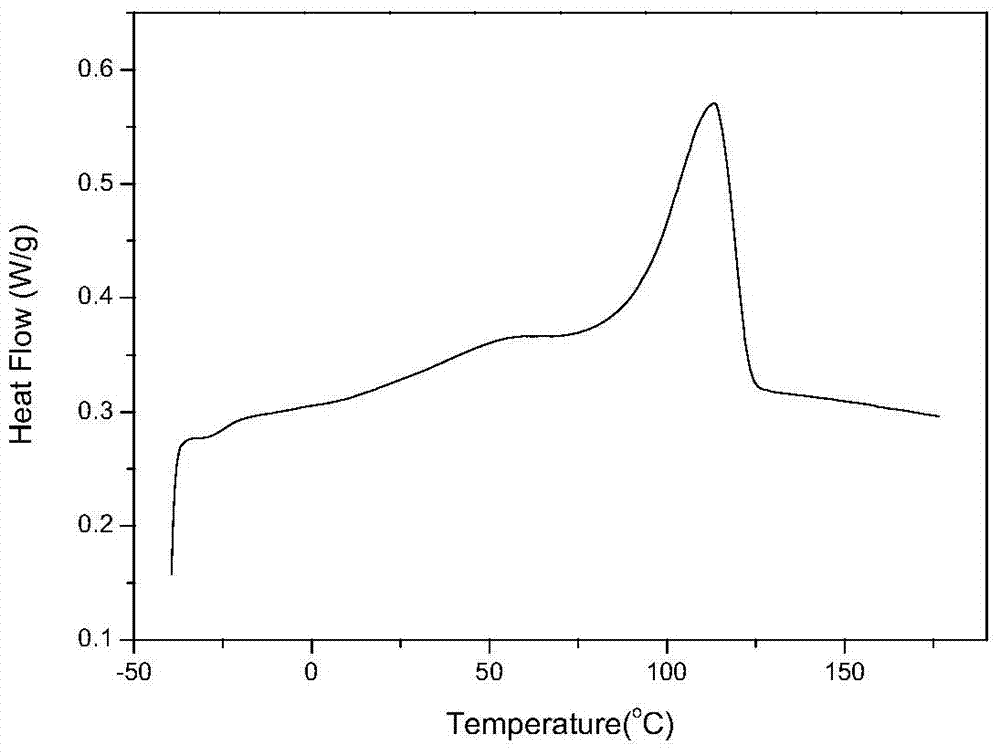

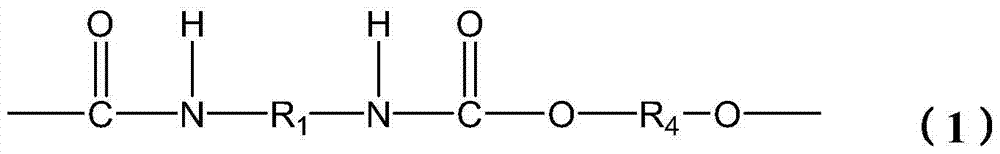

Polycarbonate polyurethane and green preparation method thereof

The invention relates to polycarbonate polyurethane and a green preparation method thereof. The polycarbonate polyurethane comprises polyurethane structural units and aliphatic polycarbonate structural units which are irregularly distributed. The polycarbonate polyurethane is successfully prepared by a nonisocyanate method, so that isocyanate and solvents are not used, and the development requirements of green chemical industry are met. In addition, the green preparation method of the polycarbonate polyurethane is relatively mild in reaction condition and low in requirement on devices; by selecting raw materials with different structures, the polycarbonate polyurethane having different linear structures and comprising two irregularly distributed structural units can be prepared, so that the structures are diverse and controllable; the prepared polycarbonate polyurethane is free of residue of isocyanate monomers, so that the application of polycarbonate polyurethane to the fields of foods and medicines is broadened.

Owner:INST OF CHEM CHINESE ACAD OF SCI

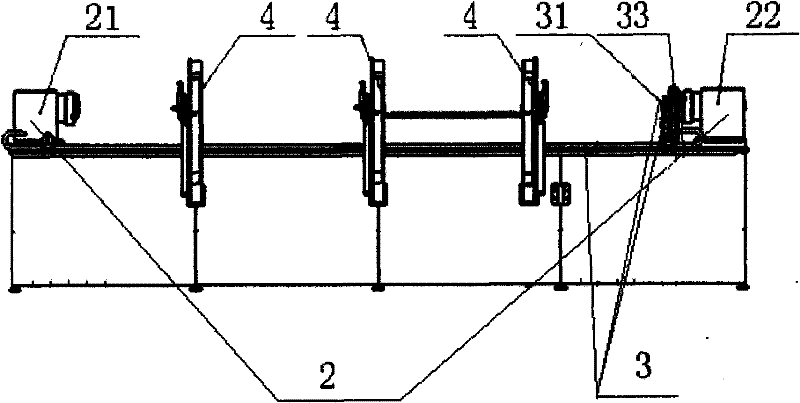

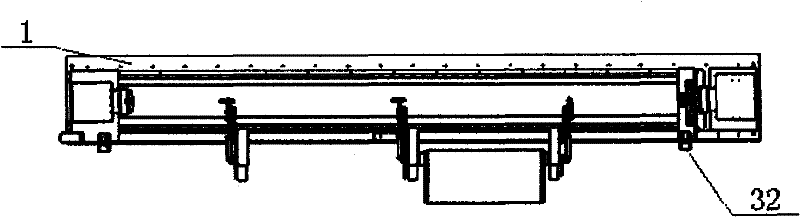

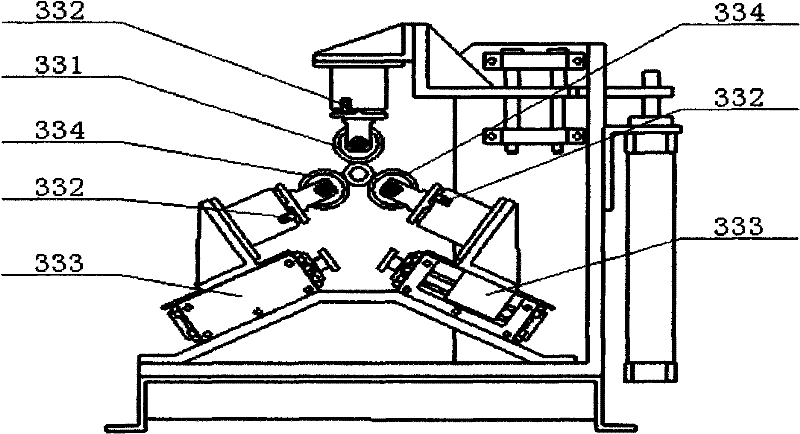

Movable high-accuracy silk material ultrasonic detection system

ActiveCN102221577AWide range of specificationsBroad requirementsAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringFalse alarm

The invention discloses a movable high-accuracy silk material ultrasonic detection system, which consists of a substrate platform (1), a clamping mechanism (2) and a detection mechanism (3), wherein the clamping mechanism (2) and the detection mechanism (3) are arranged on the substrate platform (1). The system is characterized in that: the detection mechanism (3) consists of a detection unit (31) and an axial moving unit (32); and the detection unit (31) is flexibly connected with the axial moving unit (32), has a degree of freedom in the radial direction of a silk material, and axially rigidly moves along with the radial movement of the silk material when the silk material moves radially. The movable high-accuracy silk material ultrasonic detection system changes the structural form of a conventional detection apparatus, effectively reduces a missed alarm rate and a false alarm rate, and realizes the digital operations of clamping, rotation and scanning and defect signal acquisition and processing by using private control detection software, thereby realizing the high-flexibility and high-efficiency automatic detection, recording and evaluation of internal defects, surface defects and near surface defects of the silk material.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

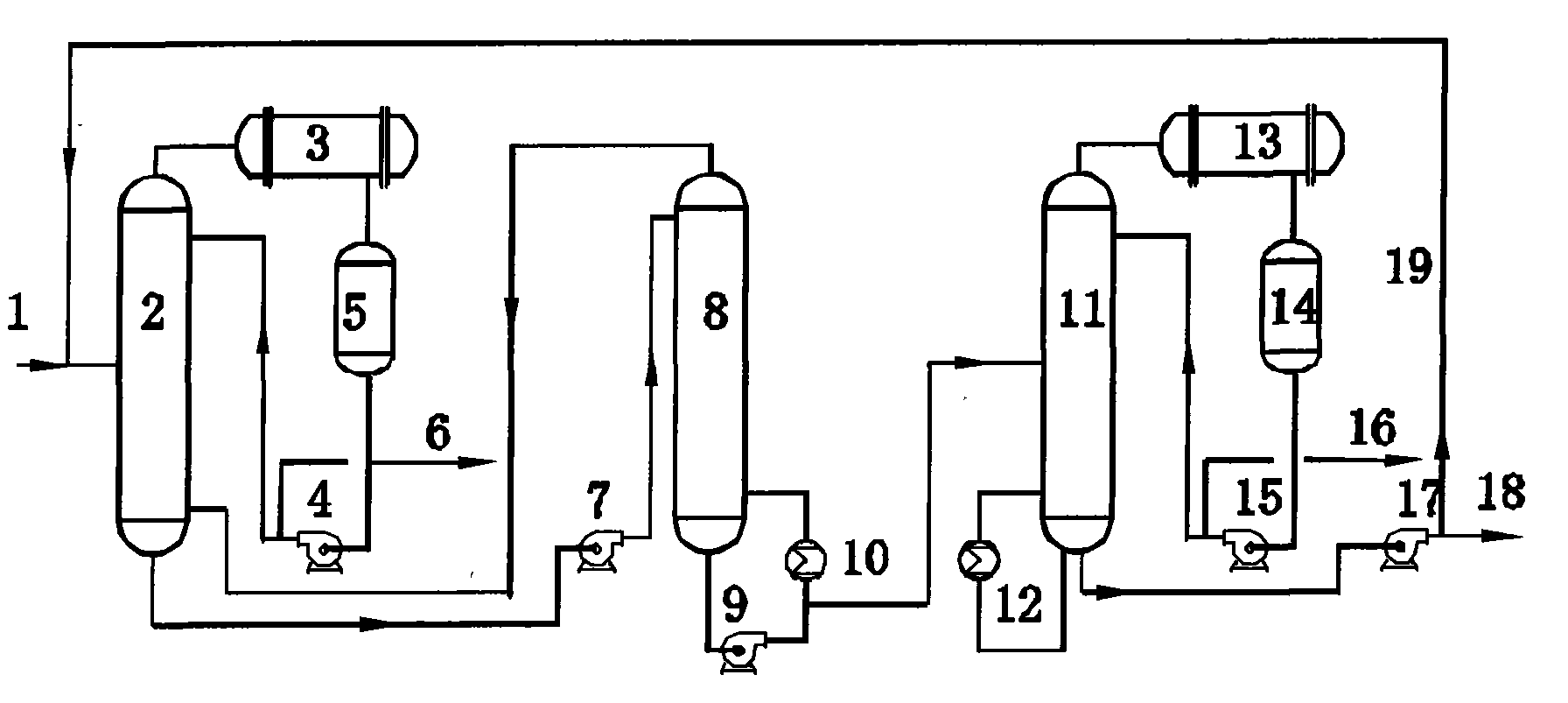

Continuous purifying method of crude product of fluoroethylene carbonate

InactiveCN102887883ABroad requirementsReduce energy consumptionOrganic chemistryDistillationProcess engineering

The invention provides a continuous purifying method of a crude product of fluoroethylene carbonate. The continuous purifying method is characterized by mainly comprising the steps as follows: processing 20-80% of fluoroethylene carbonate crude product (1) generated in the reaction between chloroethylene carbonate and fluorinating agent by virtue of a pre-processing tower (2), so as to obtain colorless decolorized fluoroethylene carbonate (5); carrying out reduced-pressure distillation to the processed crude fluoroethylene carbonate under pressure of 5-100mmHg; and respectively removing light components (7) and heavy components (1) from the top of a light component removing rectifying column (6) and the bottom of a heavy component removing rectifying column (9), so as to obtain fine fluoroethylene carbonate (10).

Owner:CHINA NAT OFFSHORE OIL CORP +2

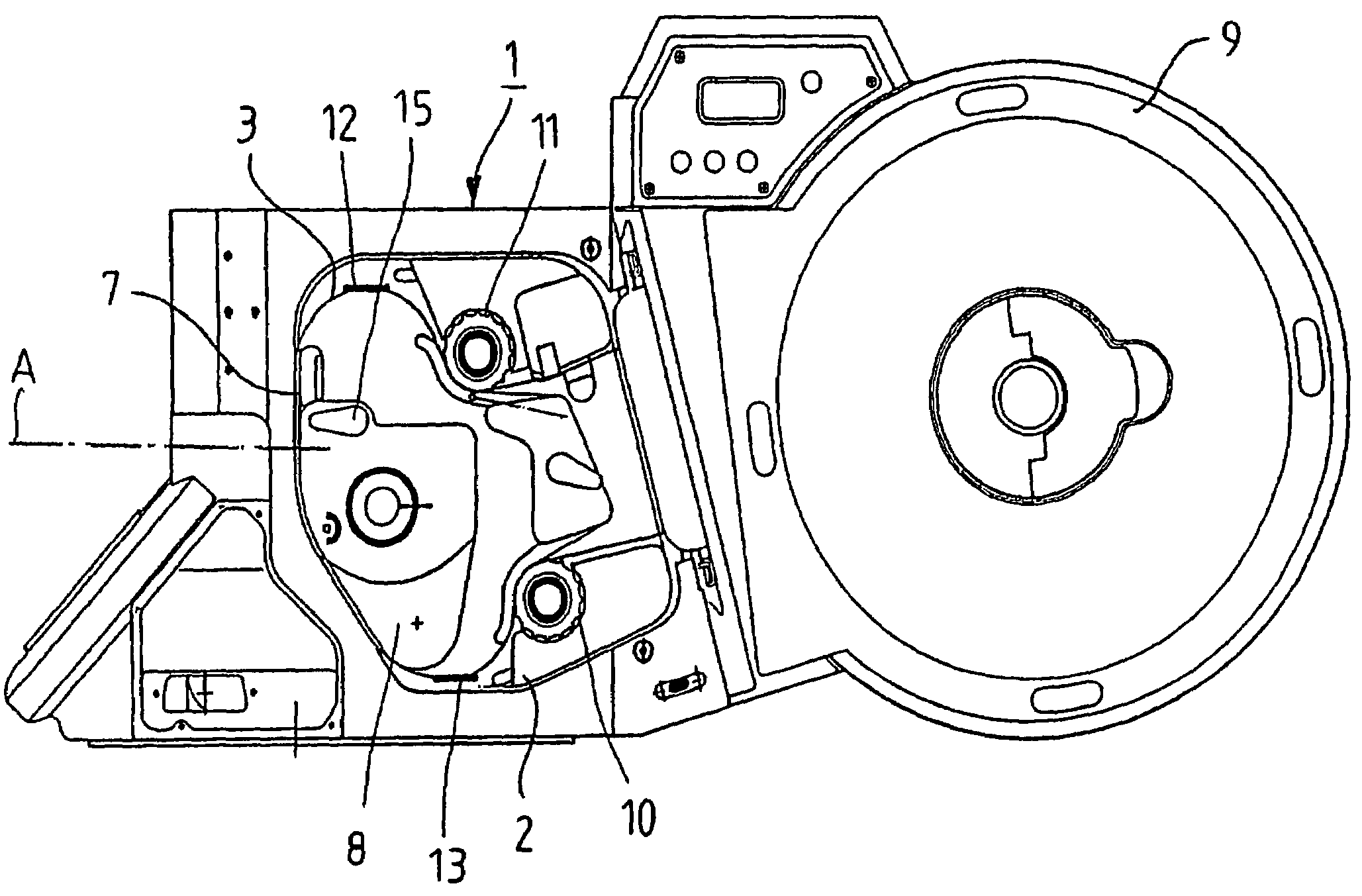

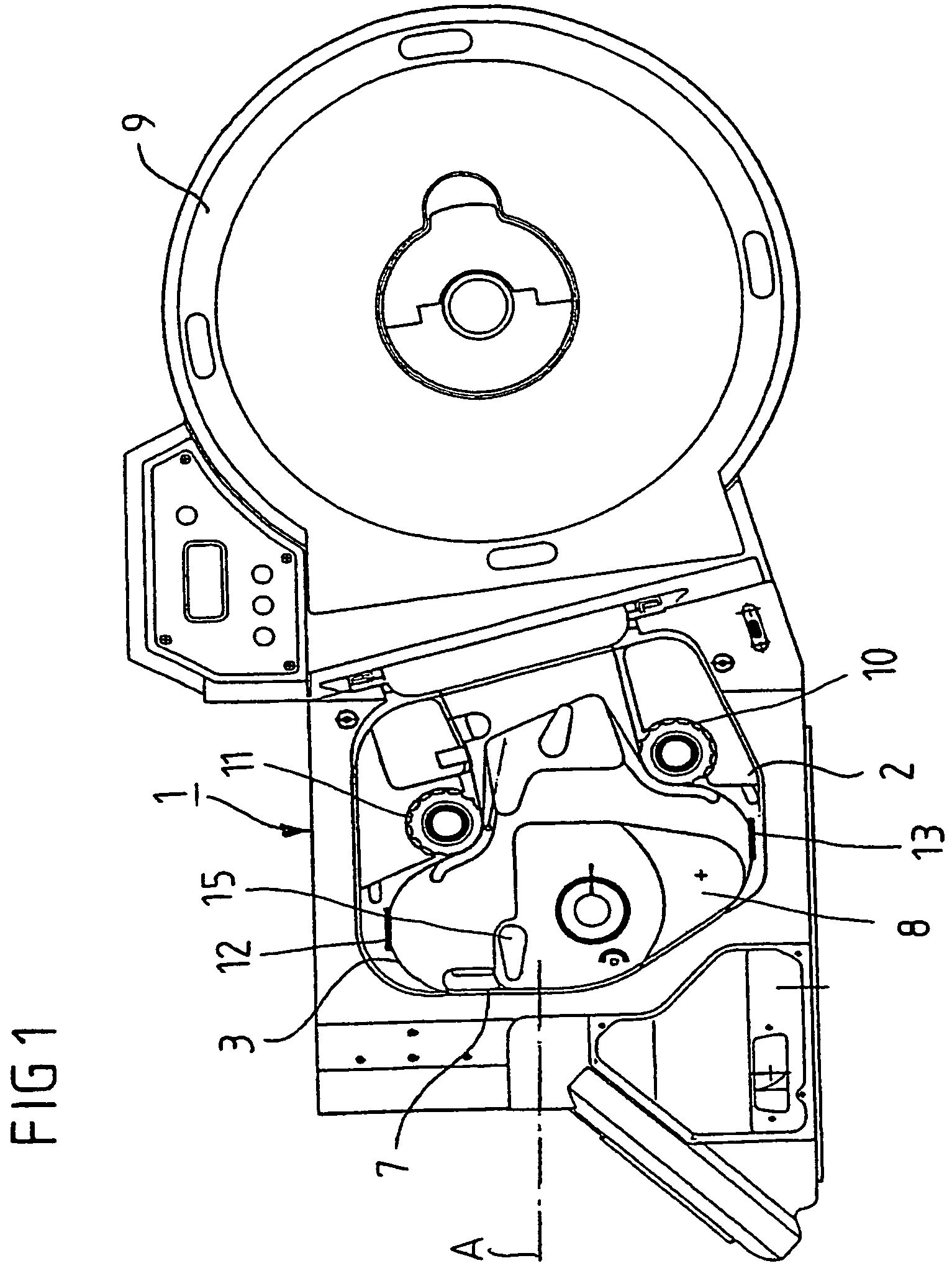

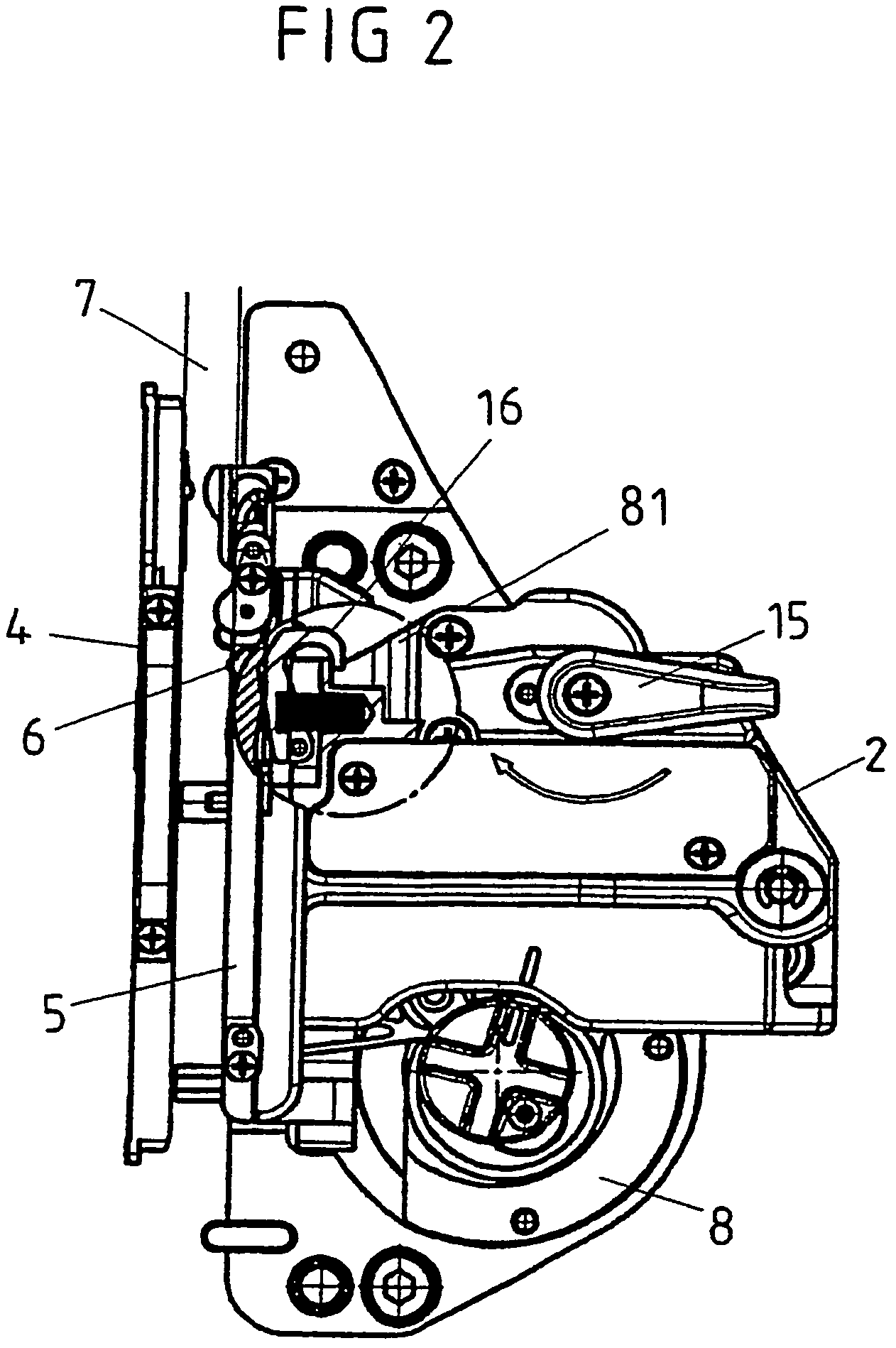

Film guide for a movie camera

InactiveUS7393105B2Wide tolerance requirementLow production costProjector film strip handlingCamera film strip handlingFilm planeEngineering

A film guide for a movie camera having an image window which is arranged in a recording beam path of the movie camera, a gripper platform which is supported on the image window, between whose mutually facing film planes a film channel is formed through which a movie film is moved by a film transport mechanism, and a spacing window which is connected to the gripper platform. The spacing window is supported on the image window in such a manner that the film channel narrows to form a film gap between the mutually facing film planes of the image window and the spacing window.

Owner:ARNOLD & RICHTER CINE TECHN & BETRIEBS

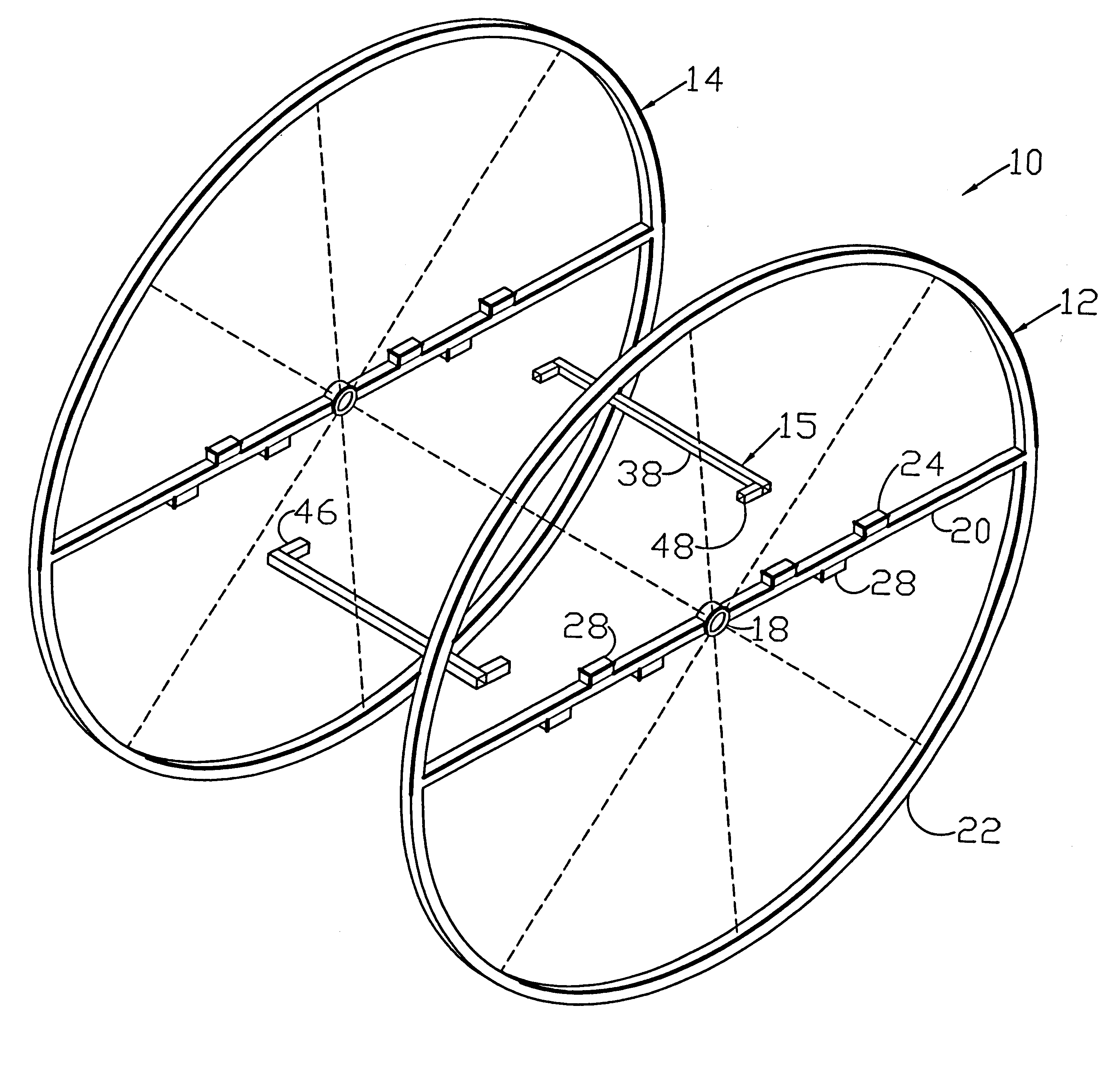

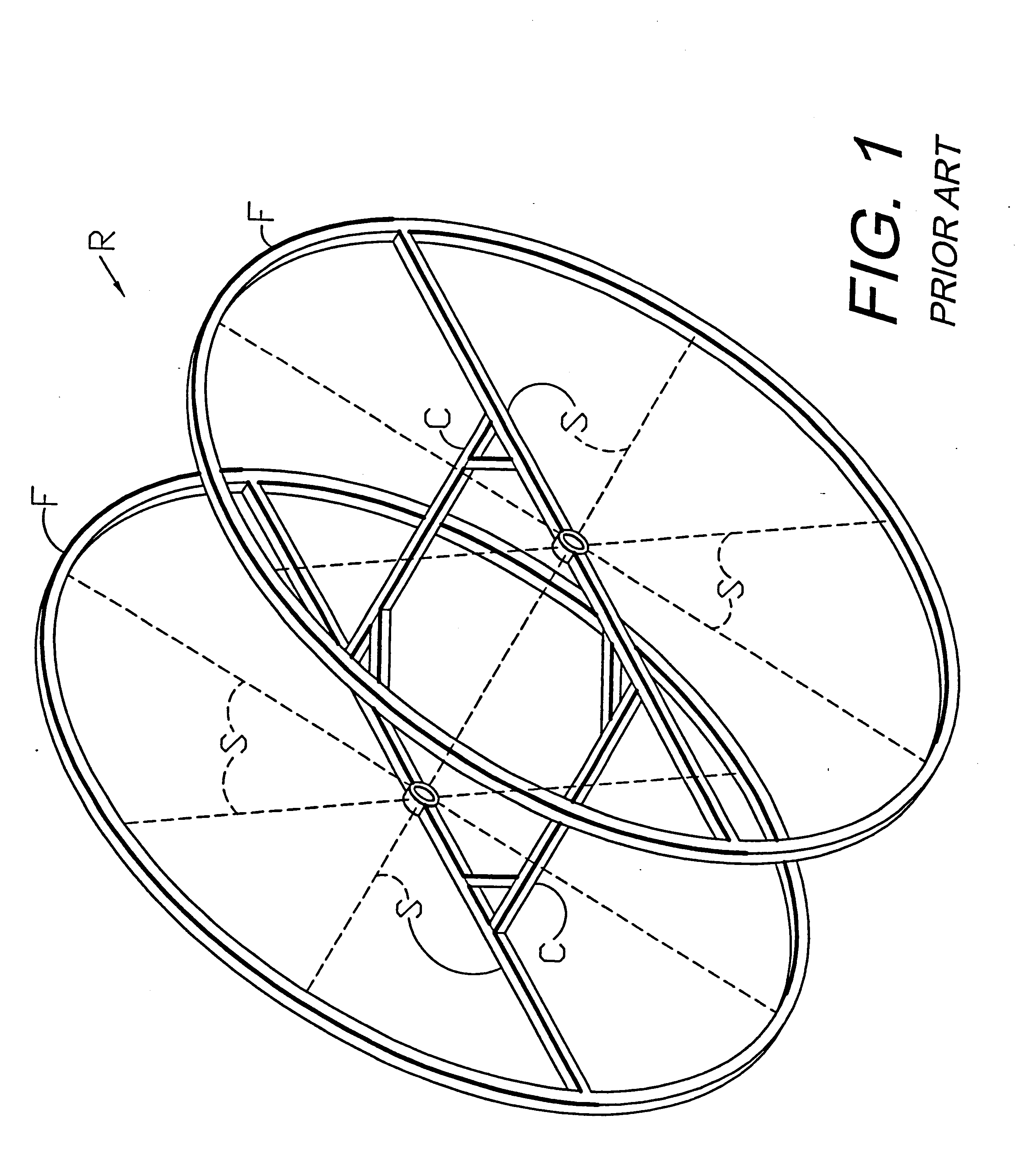

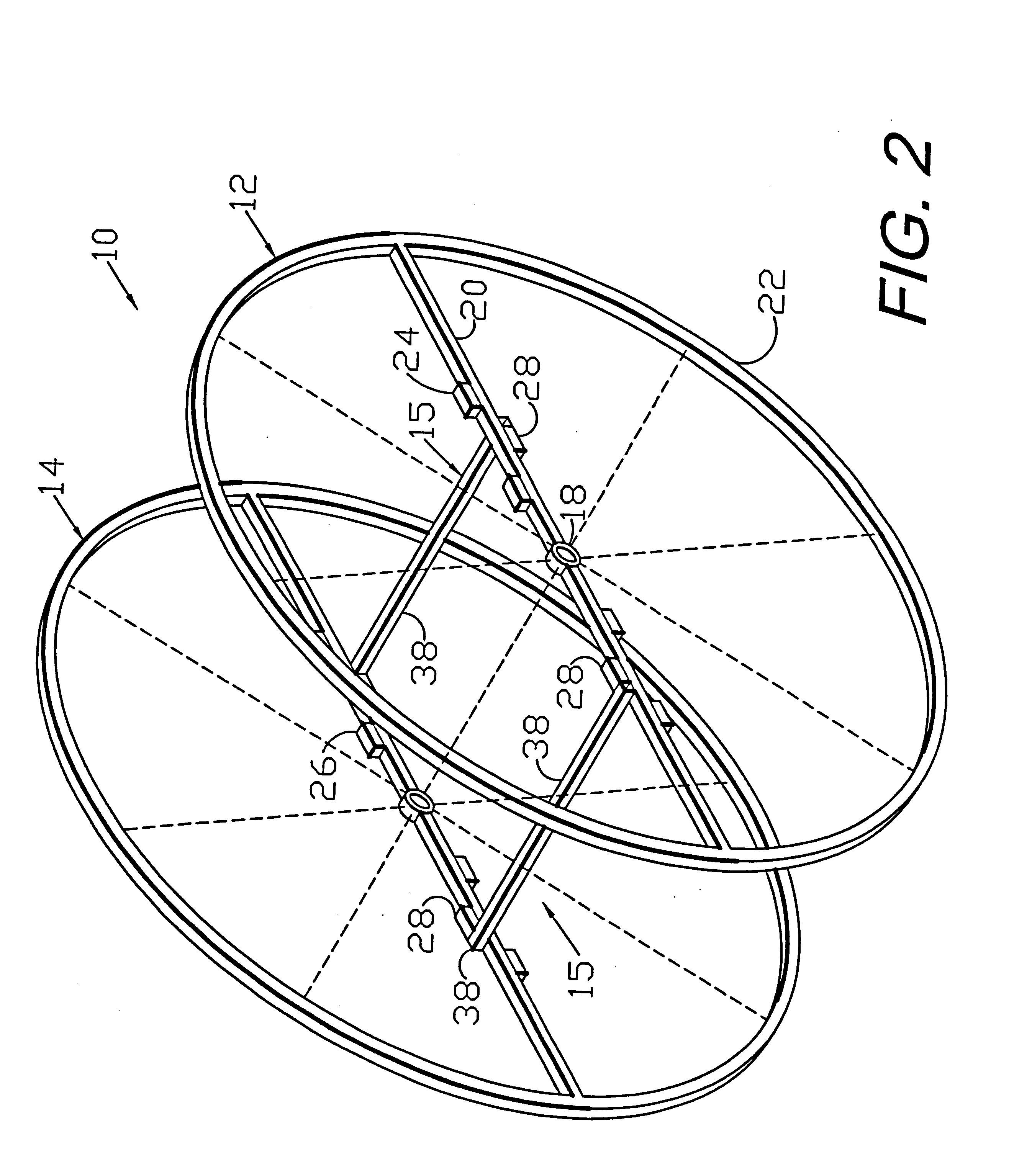

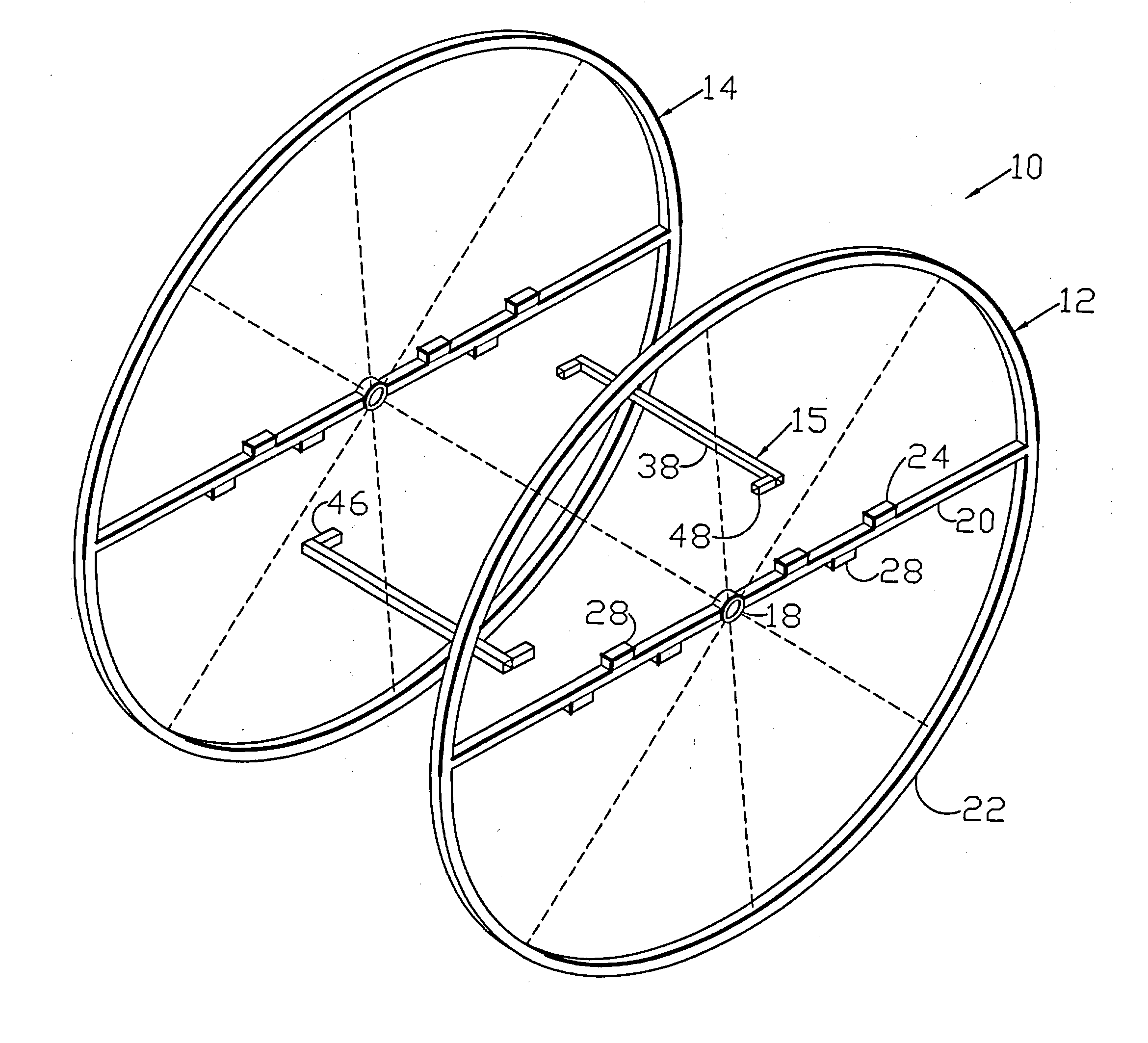

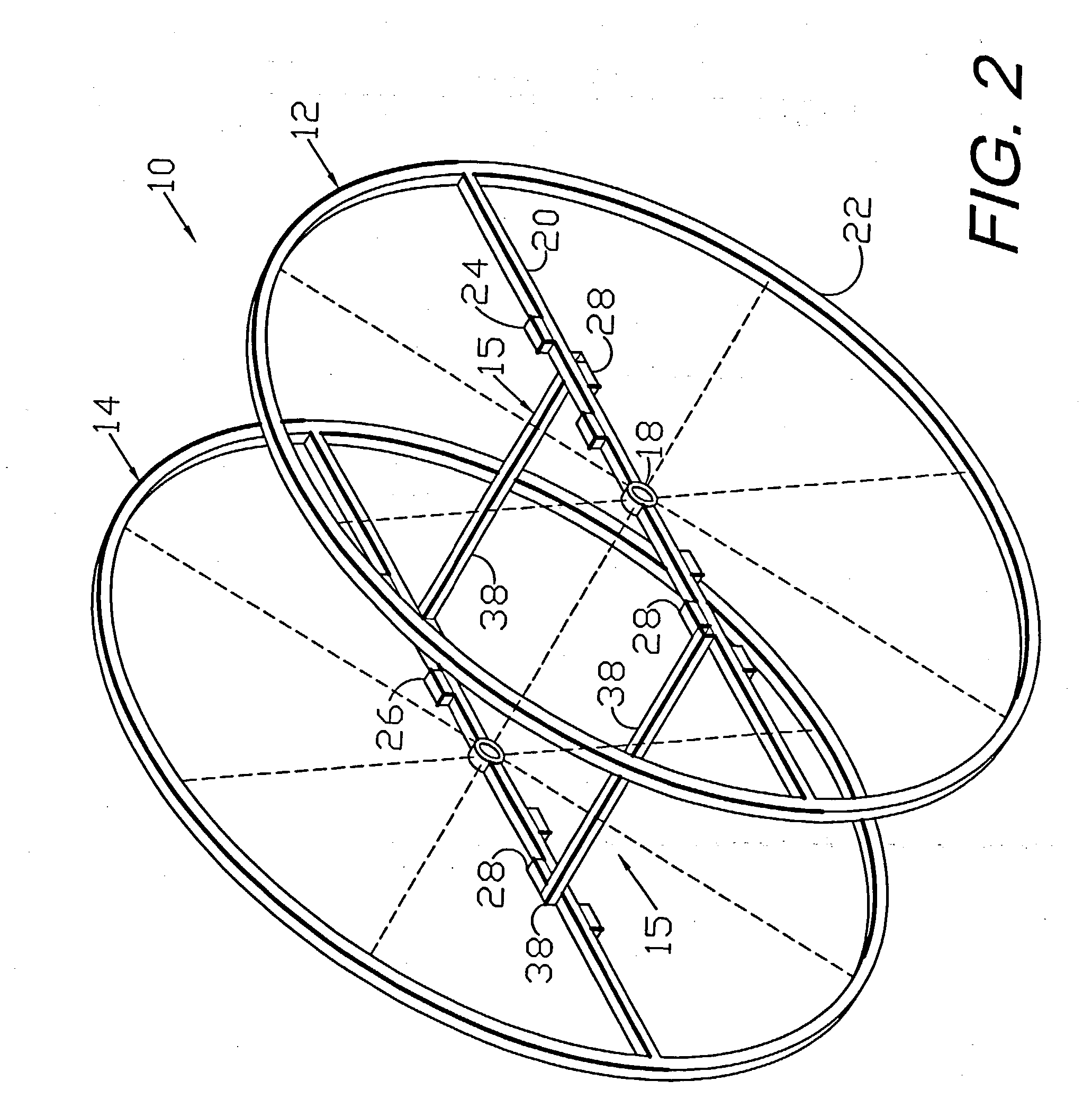

Knockdown, changeable reel system and method

InactiveUS6722607B2Efficient removalLarge amount of materialFilament handlingWebs handlingEngineeringFlange

Owner:PETROFLEX N A

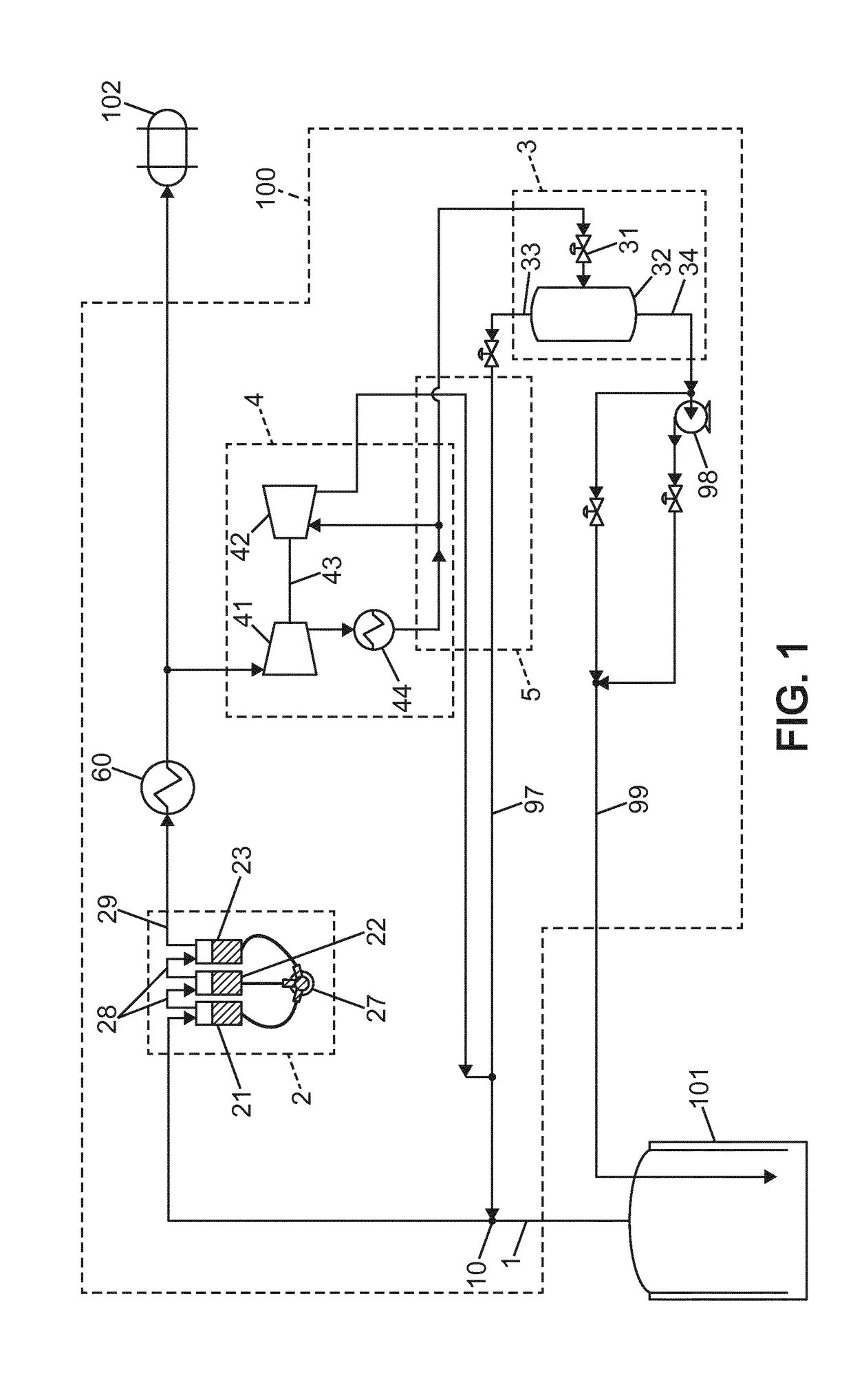

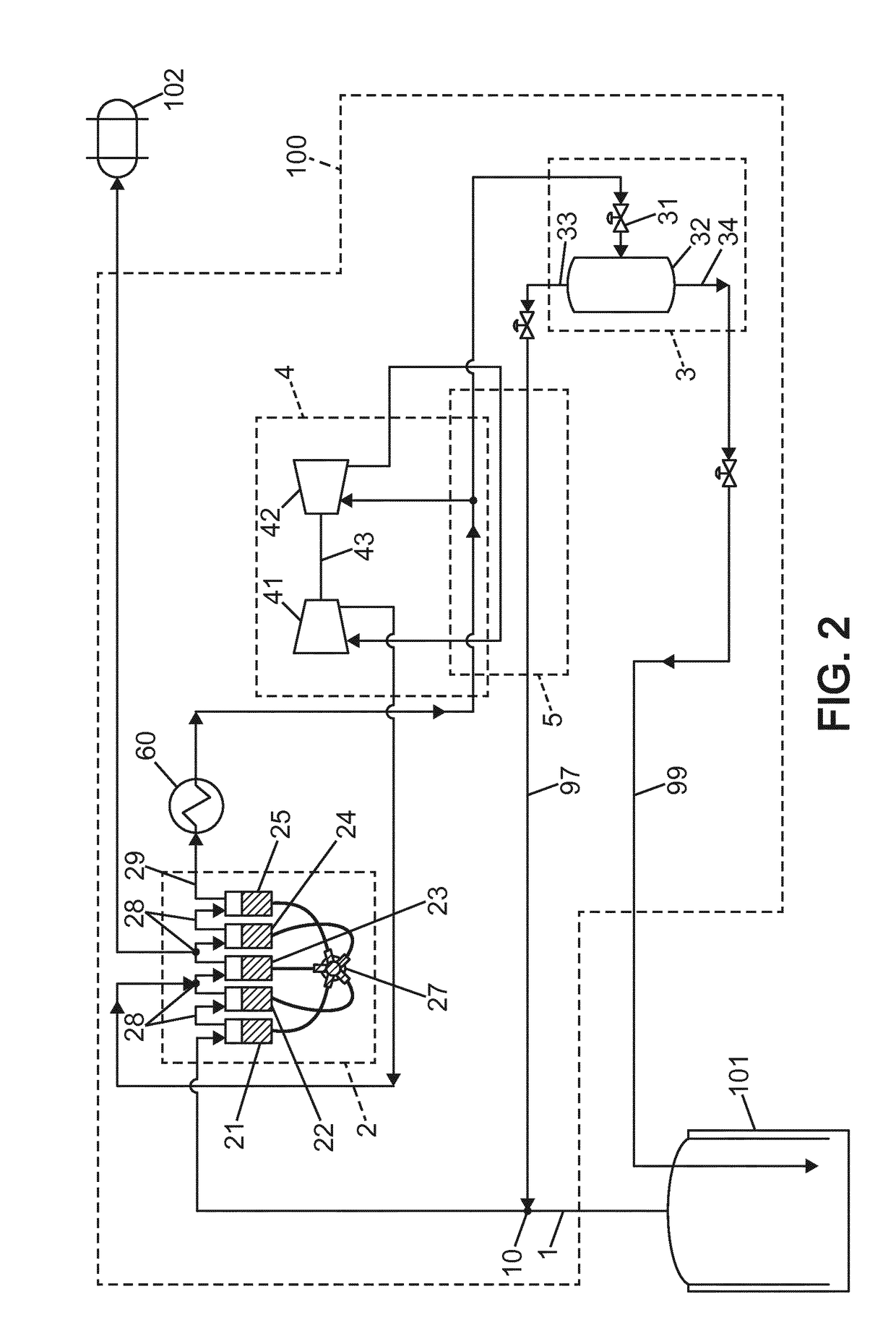

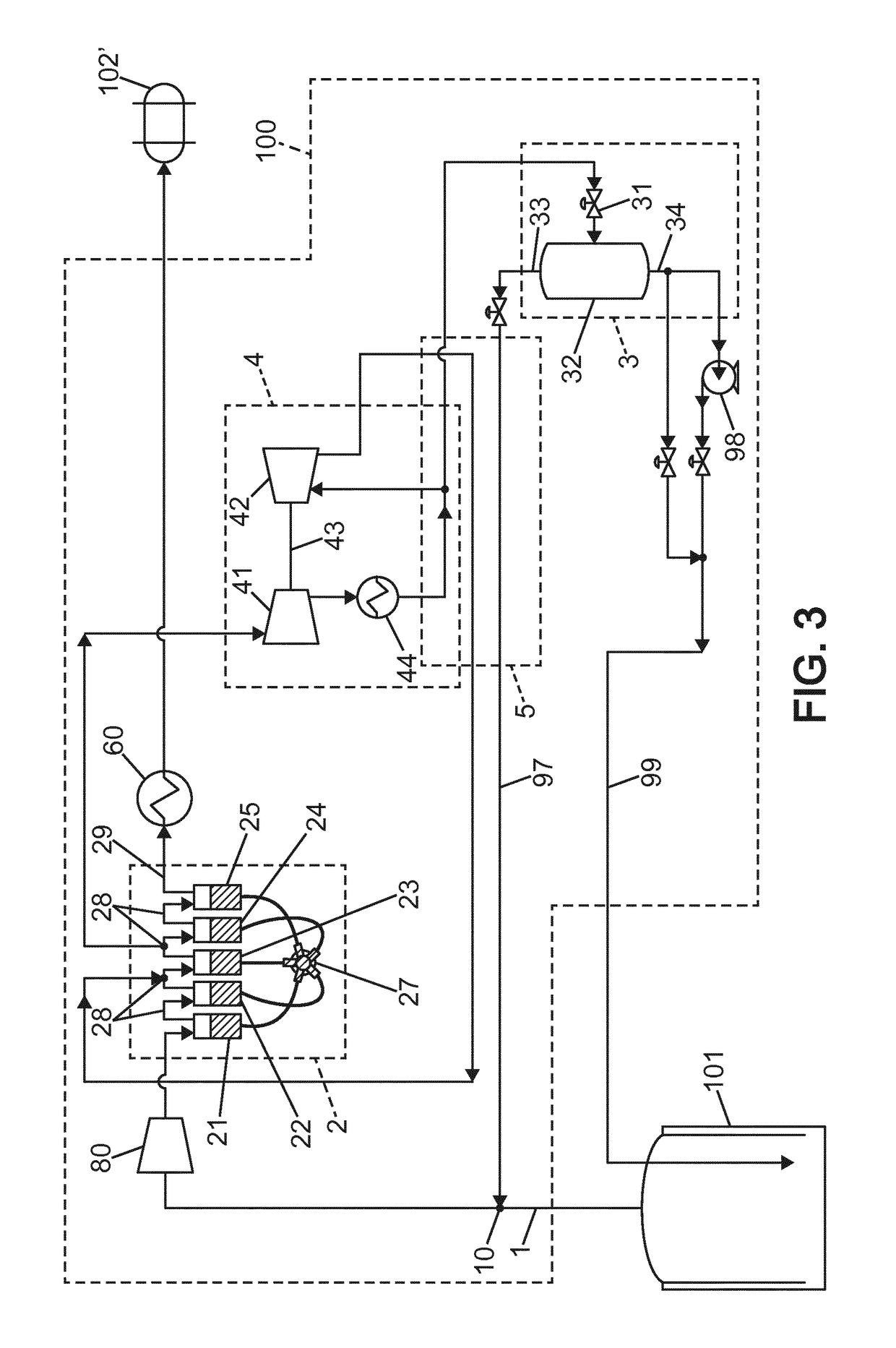

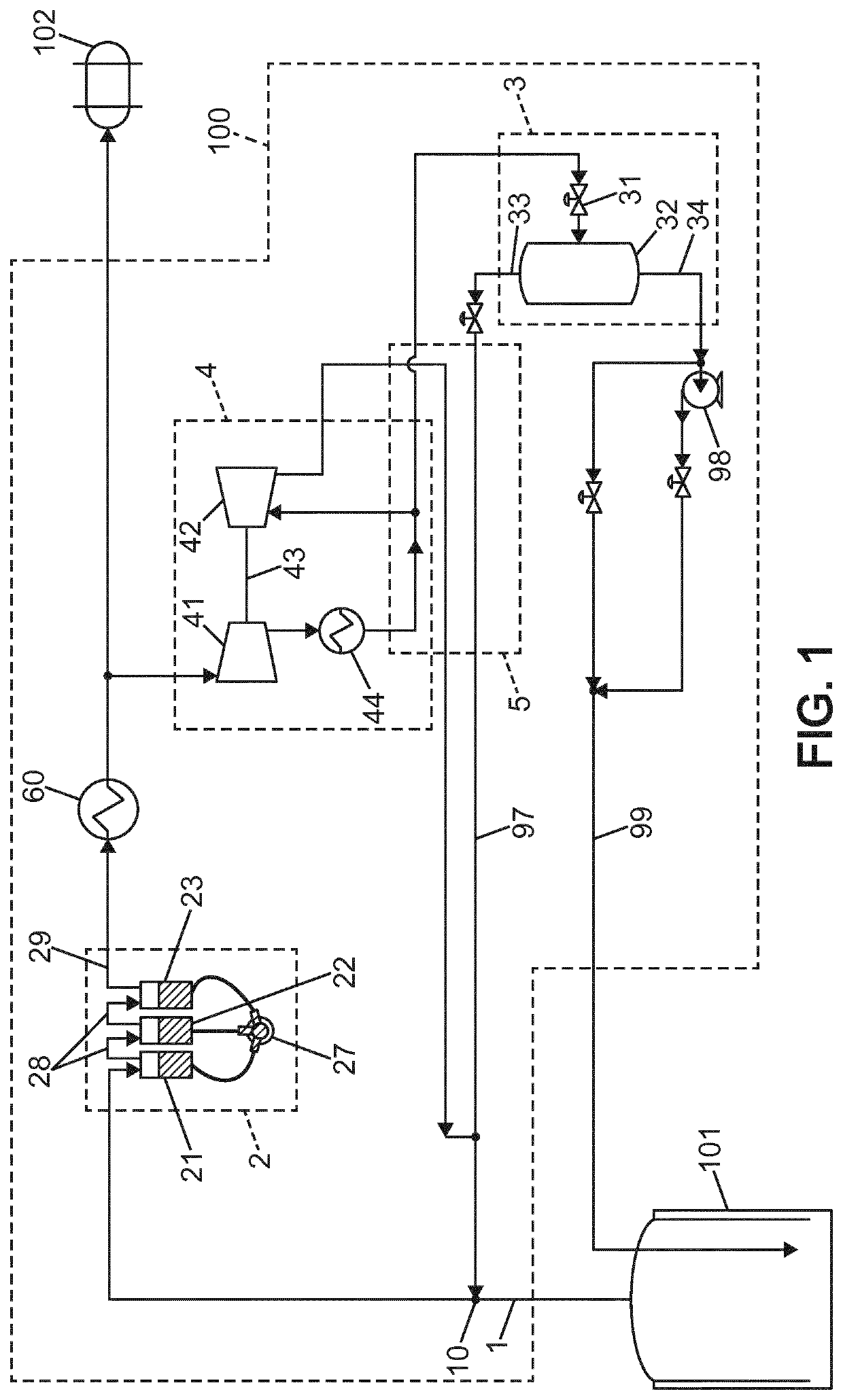

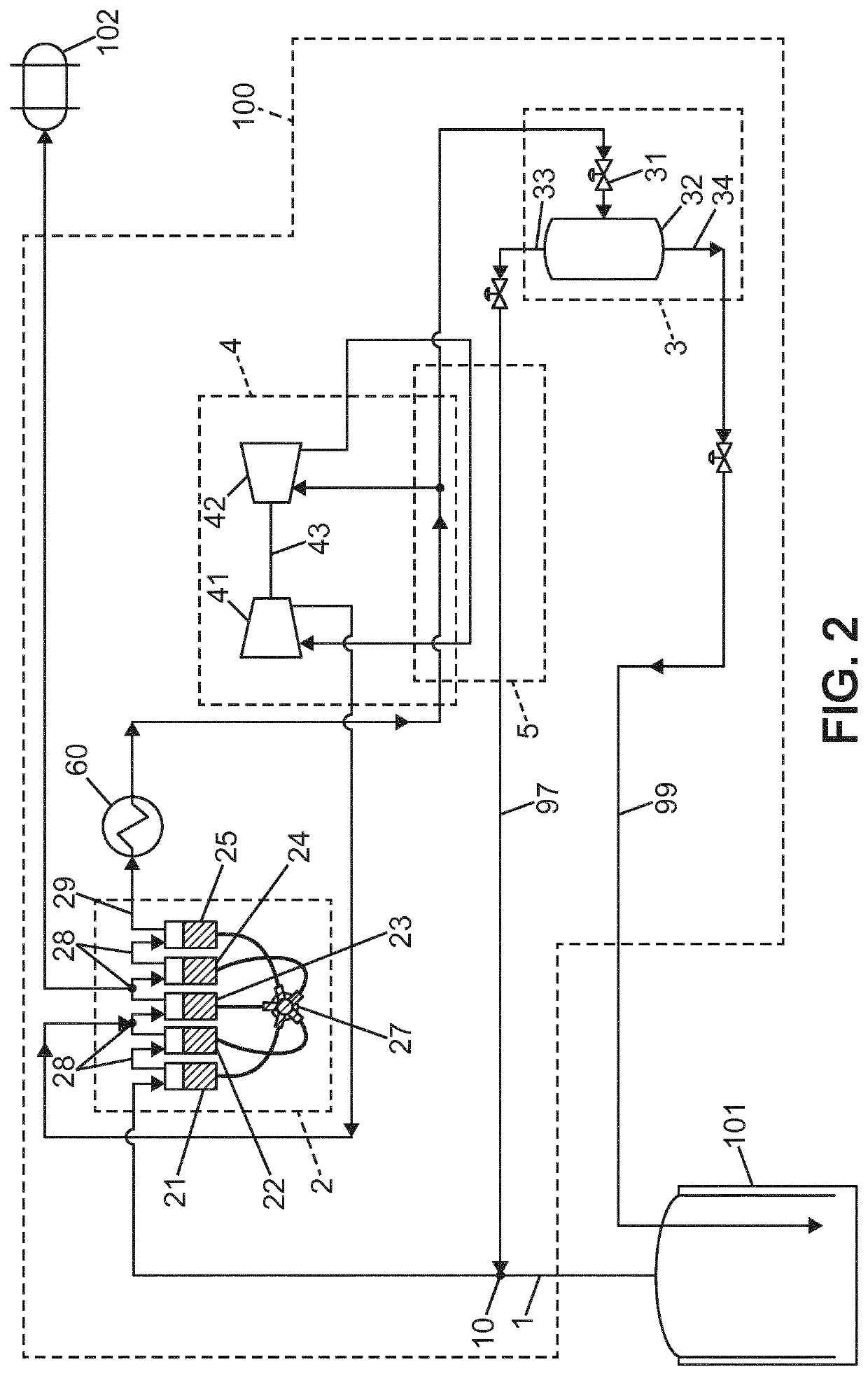

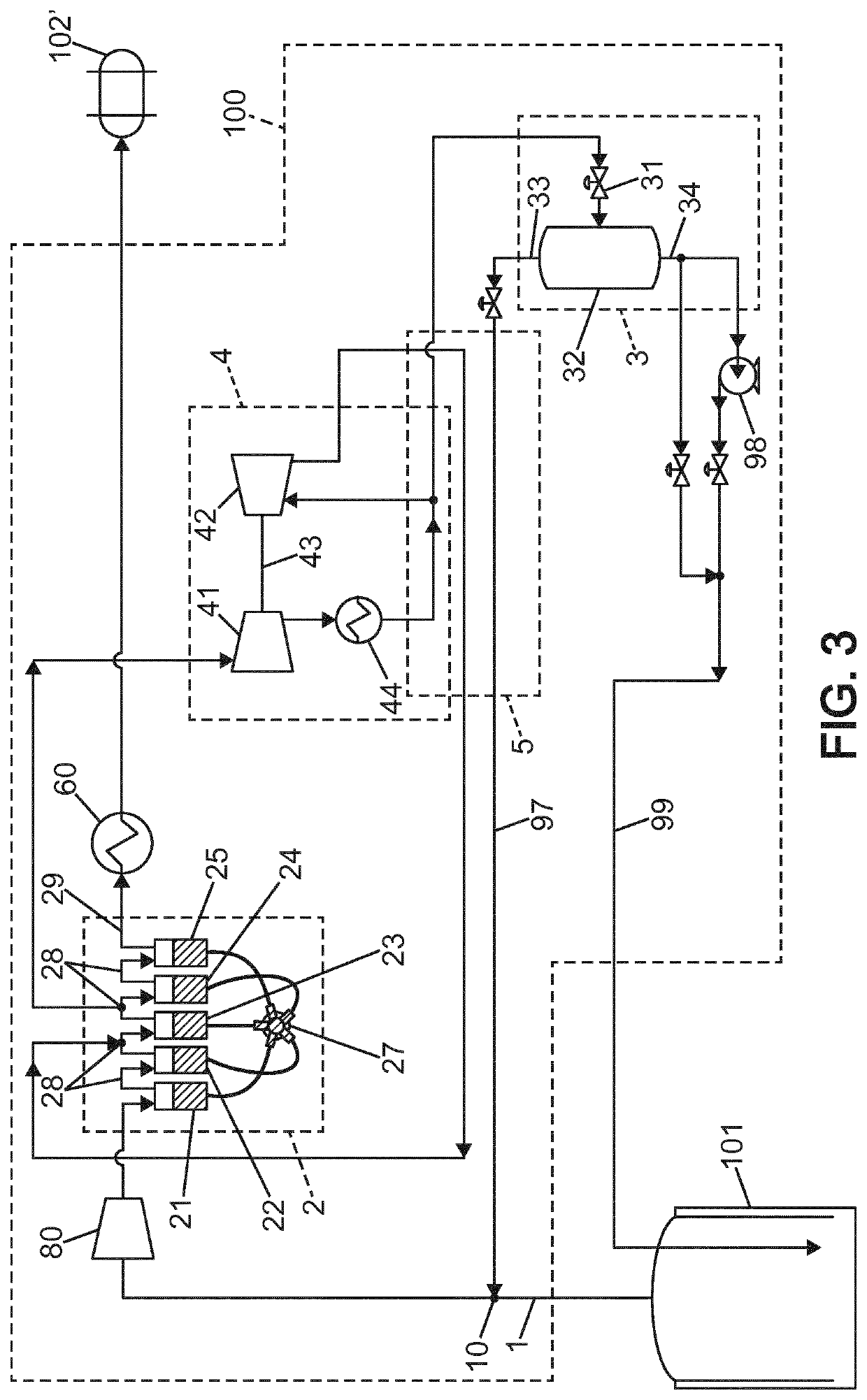

System for liquefying a gas

ActiveUS20190056174A1Easy to matchEasy to adjustSolidificationLiquefactionAutomotive engineeringProduct gas

A system (100) for liquefying a gas comprises a liquid piston gas multistage compressor (2). It can be arranged on-board a liquefied gas carrier for recycling boil-off gas. Such system may be easily adapted or controlled for matching wide requirement ranges for variations of the liquefaction capacity. In addition, at least part of the liquid piston gas multistage compressor can be shared between the gas liquefying system and an extra gas-fed device. Such extra gas-fed device may be in particular a gas-fuelled or hybrid fuel propulsion engine of the vessel.

Owner:CRYOSTAR

Rotary hearth furnace brown coal drying method and device

InactiveCN102829607AObvious beneficial effectIncrease the exhaust forceDrying solid materials with heatDrying gas arrangementsBrown coalFlue gas

The invention discloses a rotary hearth furnace brown coal drying method and a rotary hearth furnace brown coal drying device which can dry the brown coal at high efficiency and low consumption. The method comprises the following step of: taking overheated steam and high temperature flue gas as a brown coal drying heat source; taking equipment which takes a rotary hearth furnace as a core as a drying device, uniformly distributing the dried brown coal at the furnace bottom of the rotary hearth furnace through a reflection plate distributor; turning the brown coal layer through a turning mechanism in the process of rotating the furnace bottom, obtaining heat of the brown coal through heat exchange, and heating the brown coal. The device comprises a charging system, a feeding hole, a rotary hearth furnace bottom, a furnace wall, a furnace top, a high temperature flue gas and overheated steam inlet, a turning and flue gas injection system, an exhaust gas outlet, a furnace bottom driving system, a furnace bottom supporting roller, a furnace bottom centering roller, a discharging hole and a discharging system, wherein the turning and flue gas injection system comprises a fixing beam, an adjusting mechanism, a plough-shaped turning plate and a high temperature flue gas nozzle. The brown coal with wide particle size range can be directly dried, and large-scale, rapid and low-energy-consumption drying production of the brown coal is realized.

Owner:UNIV OF SCI & TECH LIAONING

New method for recycling polyethylene product

The invention discloses a new method for recycling a polyethylene product. The new method comprises the following operation steps: crushing polyethylene, and then placing polyethylene into a water pool, wherein a water friction extrusion flushing machine is arranged in the water pool; driving a material to enter into a material cleaning pool by using rolling motors, and further flushing and cleaning a fragment, wherein one rolling motor is arranged in the material cleaning pool at an interval of 3 meters; spin-drying the cleaned polyethylene fragment, or directly drying in the sun on a sunny day; granulating the dried polyethylene fragment by using a special extruder, setting the temperature of a feed opening to be lower than 170-190 DEG C, medium extruder temperature to be 210-230 DEG C and mould orifice temperature to be 210 DEG C, and filtering by using a 80-mesh filter screen; dicing in cold water, then spreading, standing for 30-50 minutes, and then bagging and sealing. A polyethylene granule produced by adopting the new method disclosed by the invention is low in impurity content and proper in process parameter and can be granulated again without the addition of new materials, such as an antioxidant, a compatilizer and an elastomer.

Owner:贵州枫叶管业有限公司

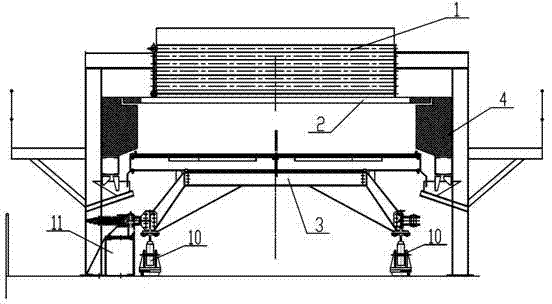

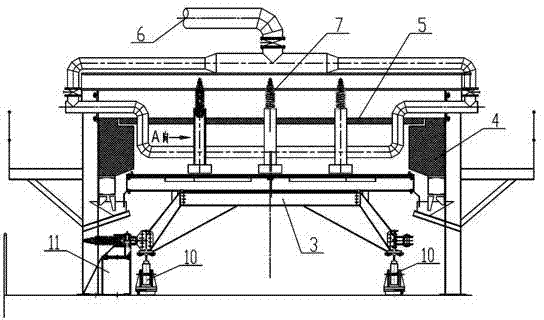

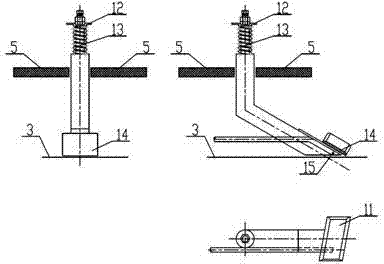

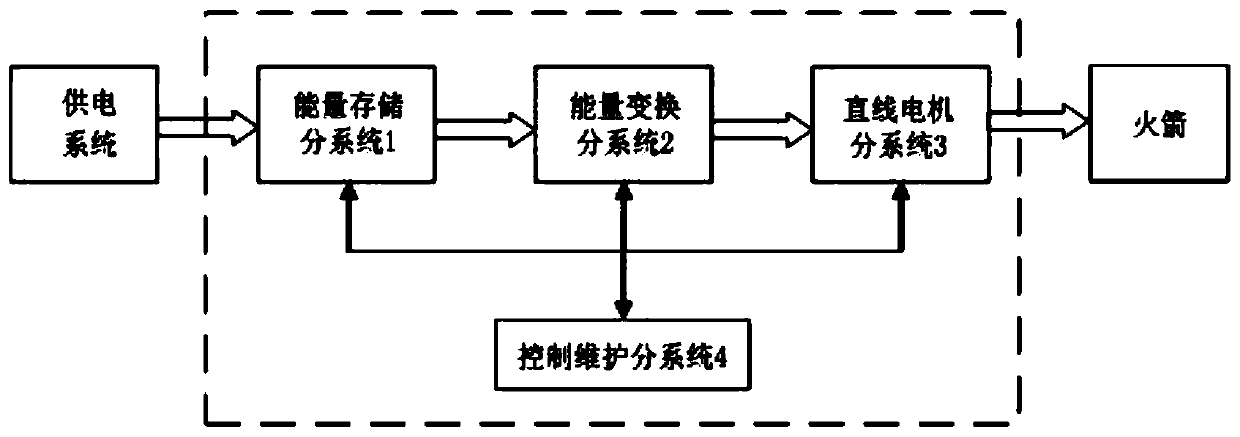

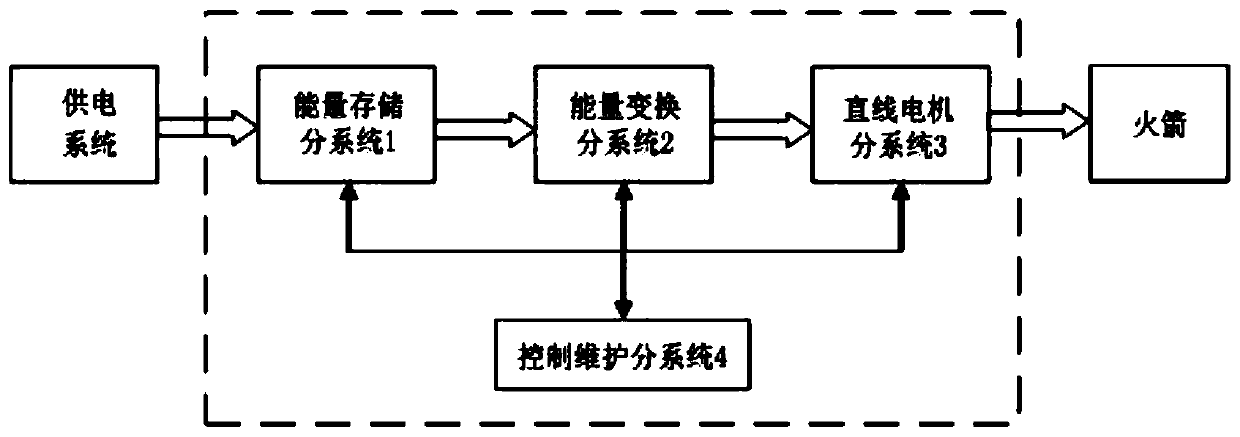

Space launch system and method based on electromagnetic pushing launch

ActiveCN110406698ASolve the problem of high-frequency continuous transmissionZero damageElectromagnetic launchersElectric devicesElectromagnetic launchRocket launch

The invention discloses a space launch system and method based on electromagnetic pushing launch. Electric energy is converted into an electromagnetic force; through the electromagnetic force, a rocket is pushed to be accelerated to a certain speed along an electromagnetic launching track to realize the launching of the rocket. According to the space launch system and method based on electromagnetic pushing launch, space launch vehicles such as the rocket are accelerated to several Mach numbers within a certain distance through the electromagnetic force; and therefore, a primary engine of an existing traditional rocket can be replaced, and the rocket can be ignited after being launched to the high attitude; the space launch system and method based on electromagnetic pushing launch has theoutstanding advantages of short preparation time, high launching frequency, low launching and maintenance cost, flexible and convenient launching mode and the like; and problems that traditional rocket launching cannot satisfy high frequency continuous launching, the rocket launching cost is high, the launching flexibility is not enough and so on are solved.

Owner:NAVAL UNIV OF ENG PLA

Breeding method of arma chinensis

InactiveCN112385608ABreeding facilities are easily accessibleEasy accessAnimal husbandryBiotechnologyVermin

The invention relates to a breeding method of arma chinensis, and belongs to the technical field of insect breeding and biological pest control. According to the method, a time relation of growth anddevelopment of food-borne plants, prey insects and the arma chinensis is combined, the modern agricultural science and technology are adopted according to biology and ecology habits of the food-borneplants, the prey insects and the arma chinensis, coordinated development of the food-borne plants, the prey insects and the arma chinensis is achieved, manual operation is reduced as much as possible,and rolling feeding of the arma chinensis is achieved. The method has the advantages of being easy to operate, low in cost, high in survival rate, high in intensification degree, capable of facilitating large-scale breeding and easy to popularize.

Owner:云南省烟草公司大理州公司 +1

Template sealing strip used in road and bridge foundation engineering bulkhead wall and used for preventing foundations from being destroyed

InactiveCN105780817ASimple structureNovel structureArtificial islandsUnderwater structuresReinforced concreteEngineering

The invention relates to a template sealing strip used in a road and bridge foundation engineering bulkhead wall and used for preventing foundations from being destroyed. The template sealing strip consists of flexible pipe-like bodies, springs, conical cylinder bodies, column cone cylinder magnets and an adhesive body, wherein the springs are uniformly distributed in the flexible pipe-like bodies; the lower ends of the springs are spliced to the conical cylinder bodies; the conical cylinder bodies are spliced to the flexible pipe-like bodies; the upper ends of the springs are spliced to the conical cylinder magnets; the conical cylinder magnets are spliced to the flexible pipe-like bodies; the adhesive body is spliced on the flexible pipe-like bodies. The template sealing strip disclosed by the invention is simple in structure, novel and reasonable, easy to manufacture, convenient to operate, and high in practicability, so that the common failing that the foundations of the reinforced concrete bulkhead wall are destroyed can be avoided, and the purposes that the reinforced concrete bulkhead wall is good in appearance effect, high in quality, and long in service life can be realized.

Owner:曹玉芝

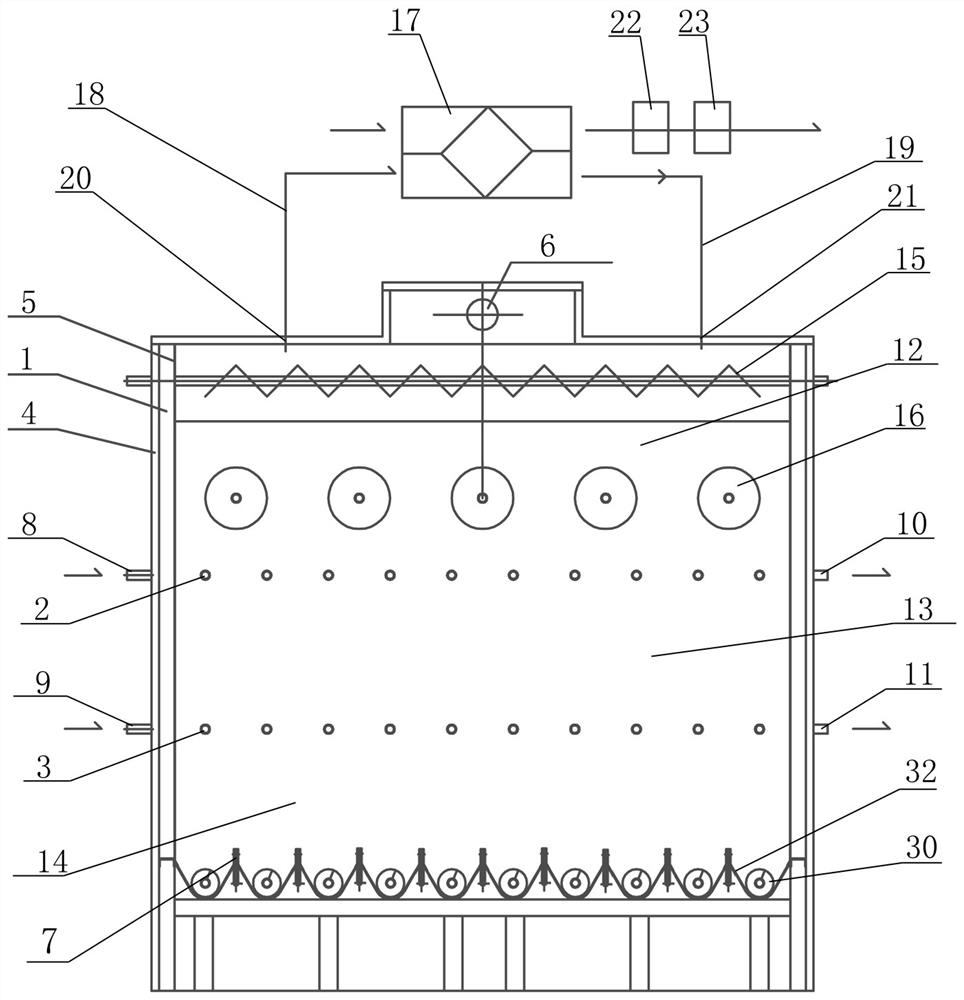

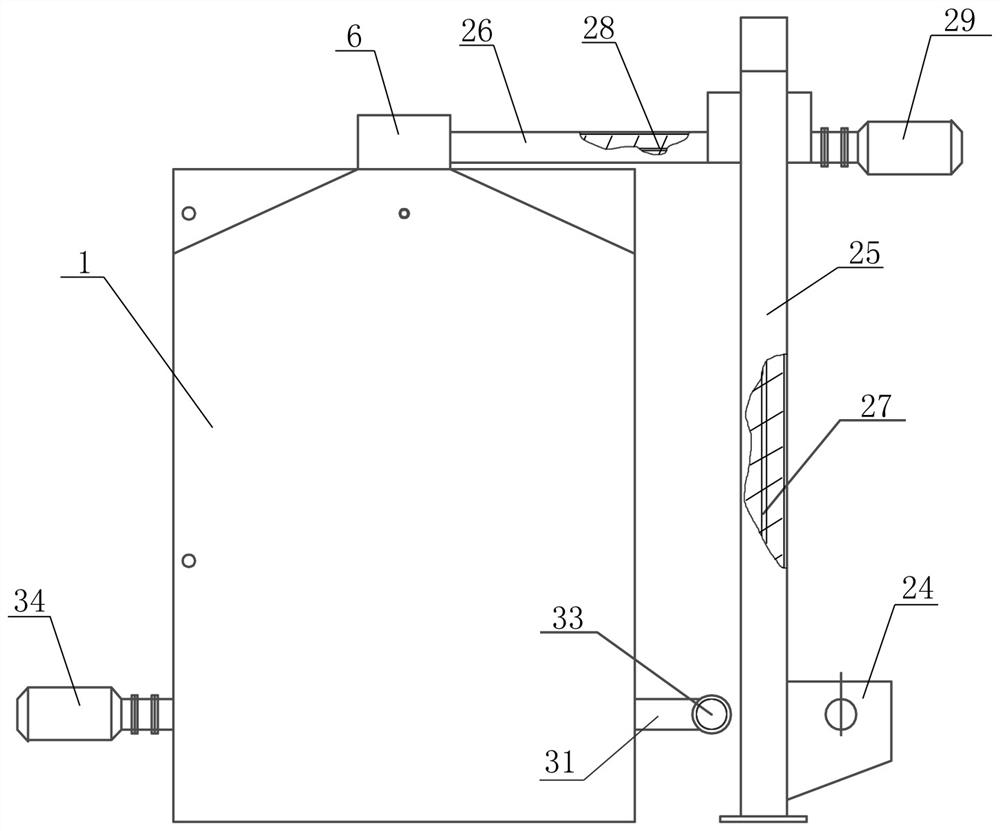

Laminar fermentation device and fermentation method thereof

PendingCN112410174ARealize zero pollution dischargeTo overcome the characteristics of different qualityBioreactor/fermenter combinationsBiological substance pretreatmentsProcess engineeringWater pipe

A laminar flow fermentation device is characterized by comprising a fermentation tank, an in-tank stirring mechanism, a heat recovery and air exchange device, a feeding mechanism, a discharging mechanism, a heating water pipe and a cooling water pipe, and the heating water pipe and the cooling water pipe are respectively coiled in the fermentation tank which is divided into three equal sections, namely an aerobic fermentation section, a facultative fermentation section and an anaerobic fermentation section. The in-tank stirring mechanism comprises a plurality of material homogenizing stirringcages and a plurality of turning stirring cages and a heat recovery air interchanger comprises a heat recovery air interchanger, an exhaust pipe and an air inlet pipe and a feeding mechanism comprisesa feeding funnel, a vertical conveying pipe and a transverse conveying pipe, and the discharging mechanism comprises a plurality of laminar flow discharging stirring cages and an external conveying pipe. The fermentation property and the sufficient fermentation environment meet the necessary conditions for completing complete fermentation, materials in the bin move at the same time from top to bottom, the top of the bin is filled with the same amount of materials as discharged materials, and the dynamic full-bin state in the bin is guaranteed all the time.

Owner:王天浩 +1

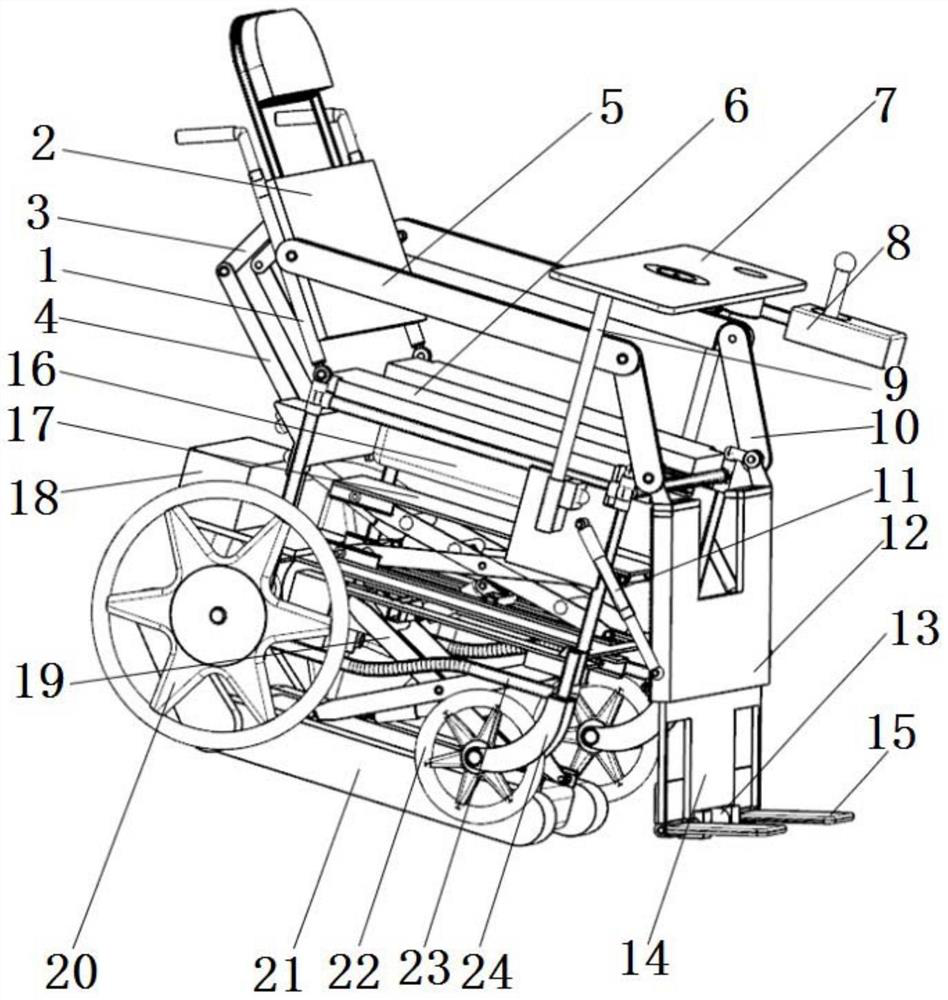

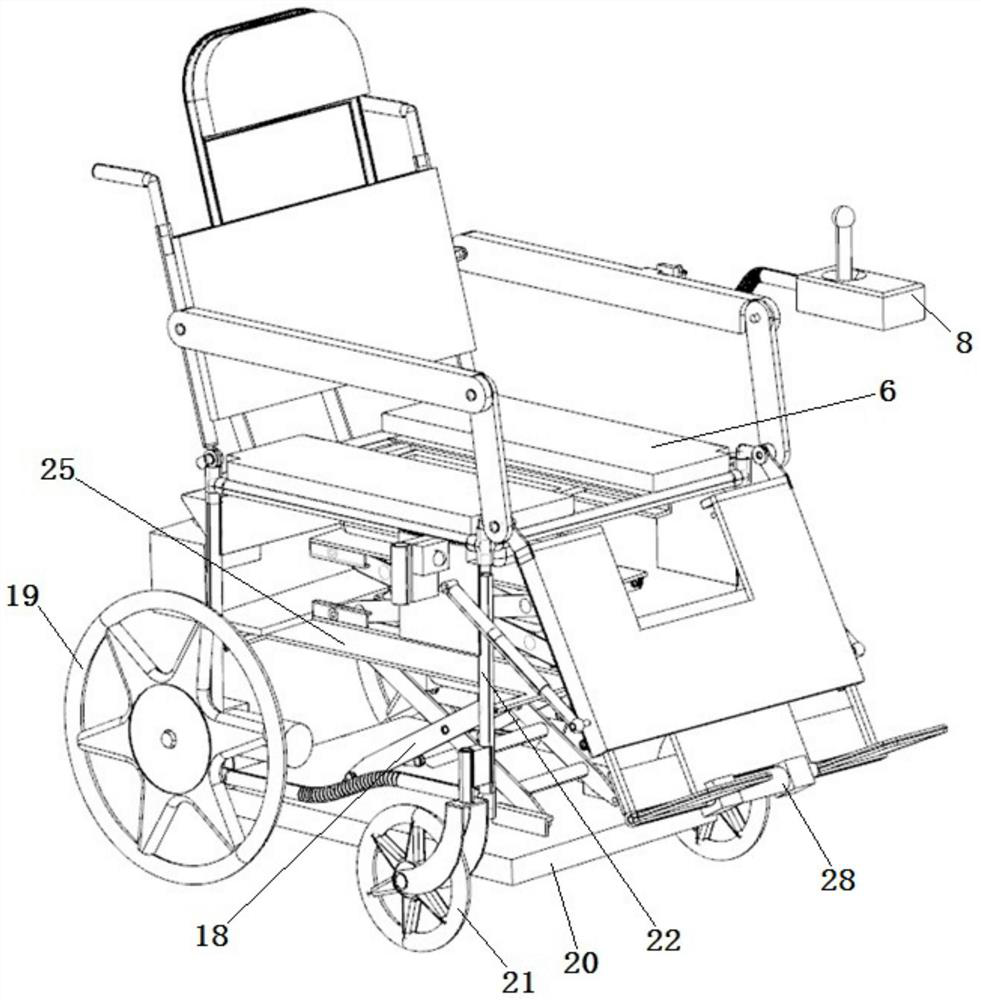

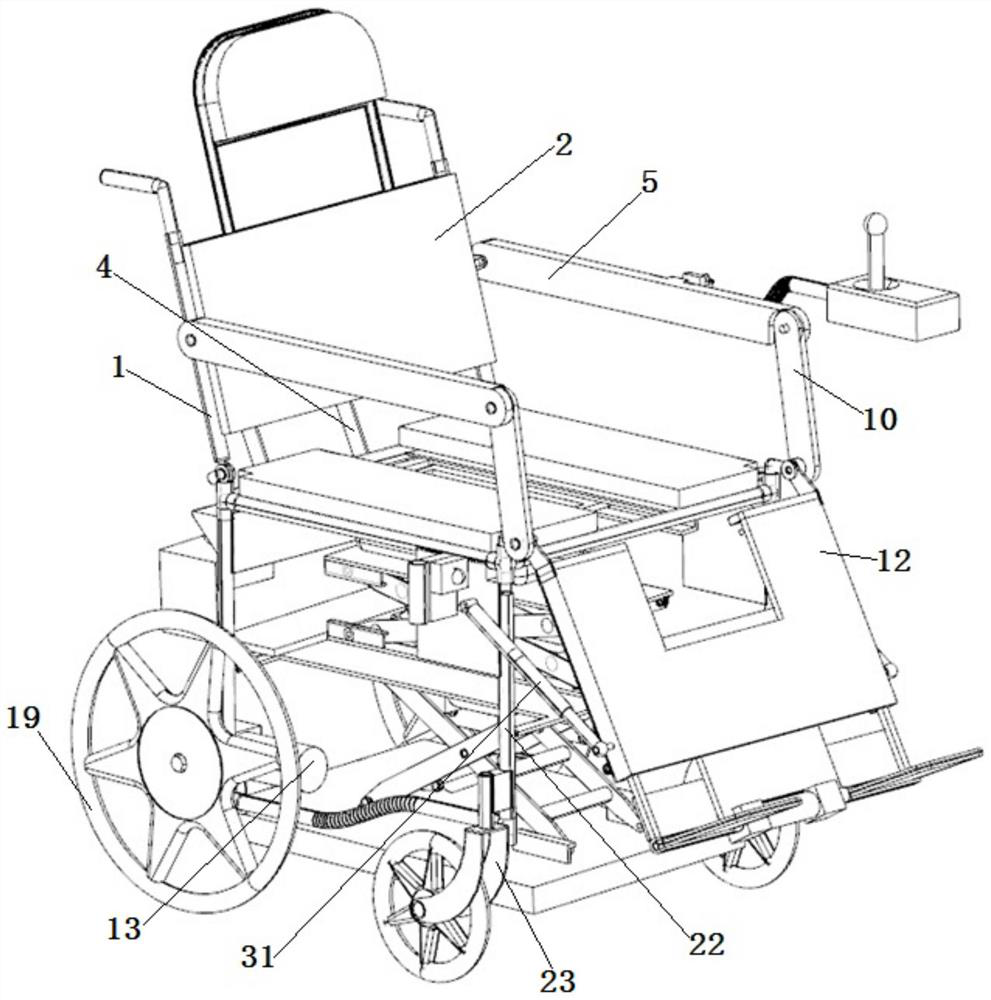

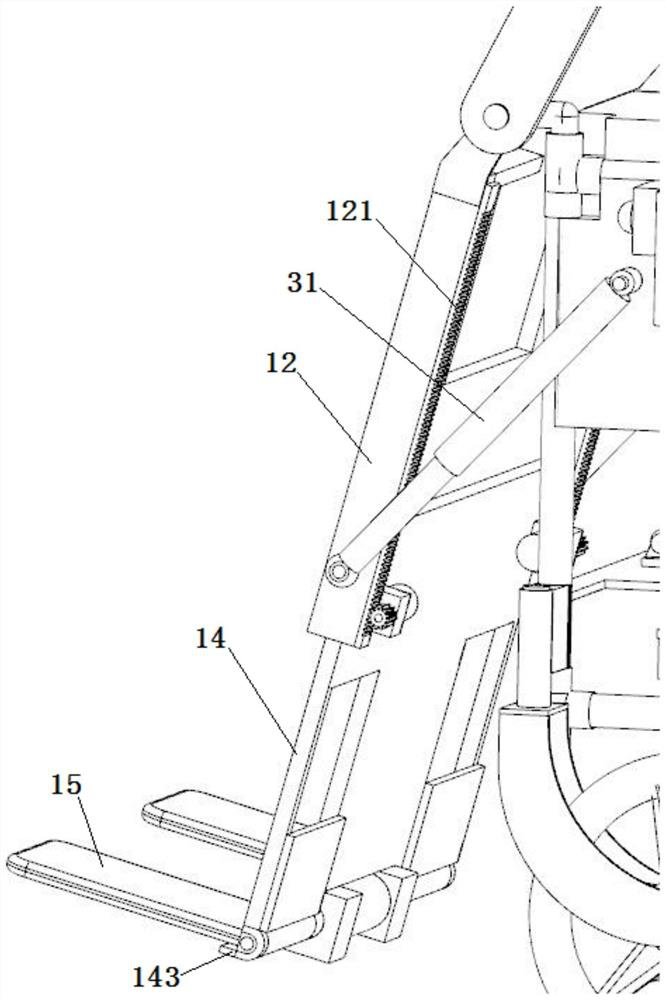

Multifunctional electric wheelchair

PendingCN112704607AMeet various needsProtect healthWheelchairs/patient conveyanceWheelchairEngineering

The invention discloses a multifunctional electric wheelchair. The multifunctional electric wheelchair comprises a frame; first supports are hinged to the two ends of one edge of the frame; a backup plate is arranged between the two first supports; one ends of at least two first movable rods are hinged to the opposite surface of the back surface of the backup plate; the other ends of the first movable rods are further hinged to one end of a second movable rod; the other end of the second movable rod is in shaft connection with the same rotating shaft; the rotating shaft is connected with the frame; the rotating shaft can rotate on the frame; the rotating shaft is connected with a third movable rod; the third movable rod is further hinged to the output end of a first electric push rod; the mounting end of the first electric push rod is arranged on a first supporting plate; the first supporting plate is fixed in an inner cavity of the frame; the first support is further hinged to a first handrail; the first handrail is further hinged to a second handrail; the second handrail is hinged to one end of a leg supporting plate; the side edge of the leg supporting plate is hinged to the frame through a second electric push rod; and one end of the leg supporting plate is further hinged to the frame. According to the invention, the sitting posture and the lying state can be adjusted; and operation is simple and easy.

Owner:SHAANXI UNIV OF SCI & TECH

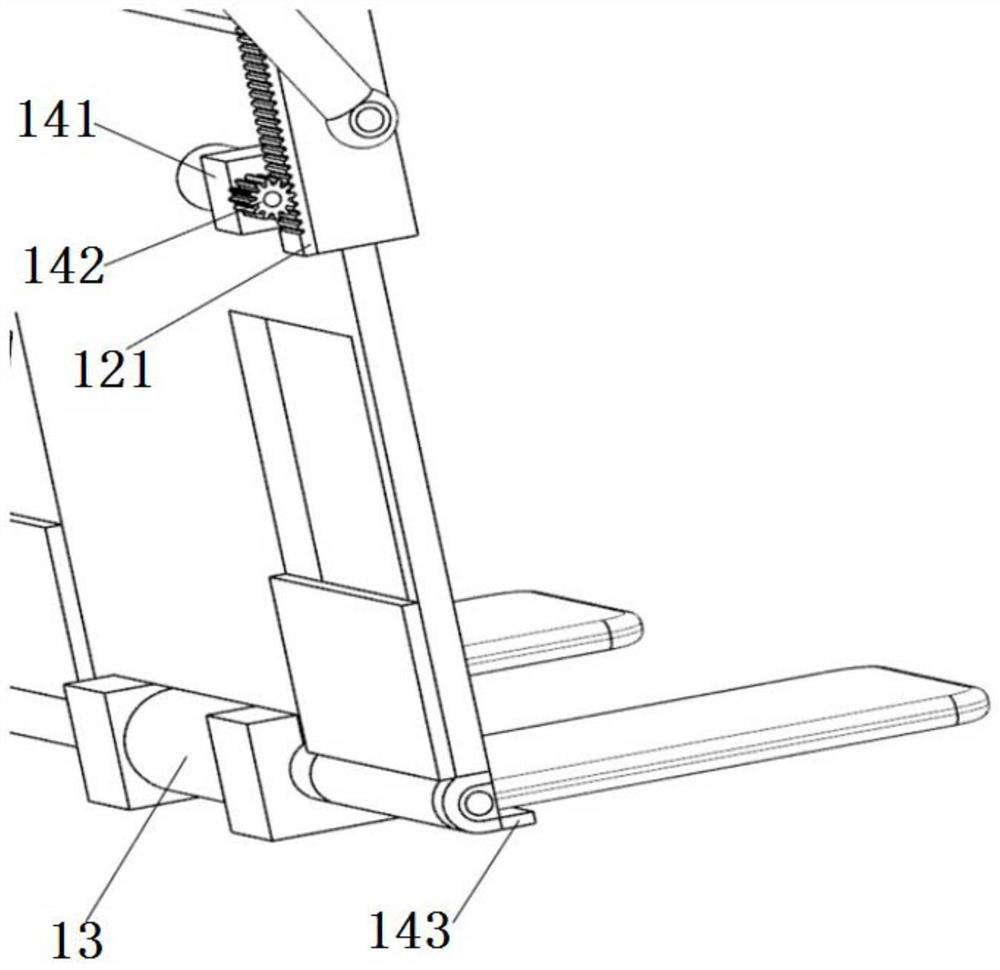

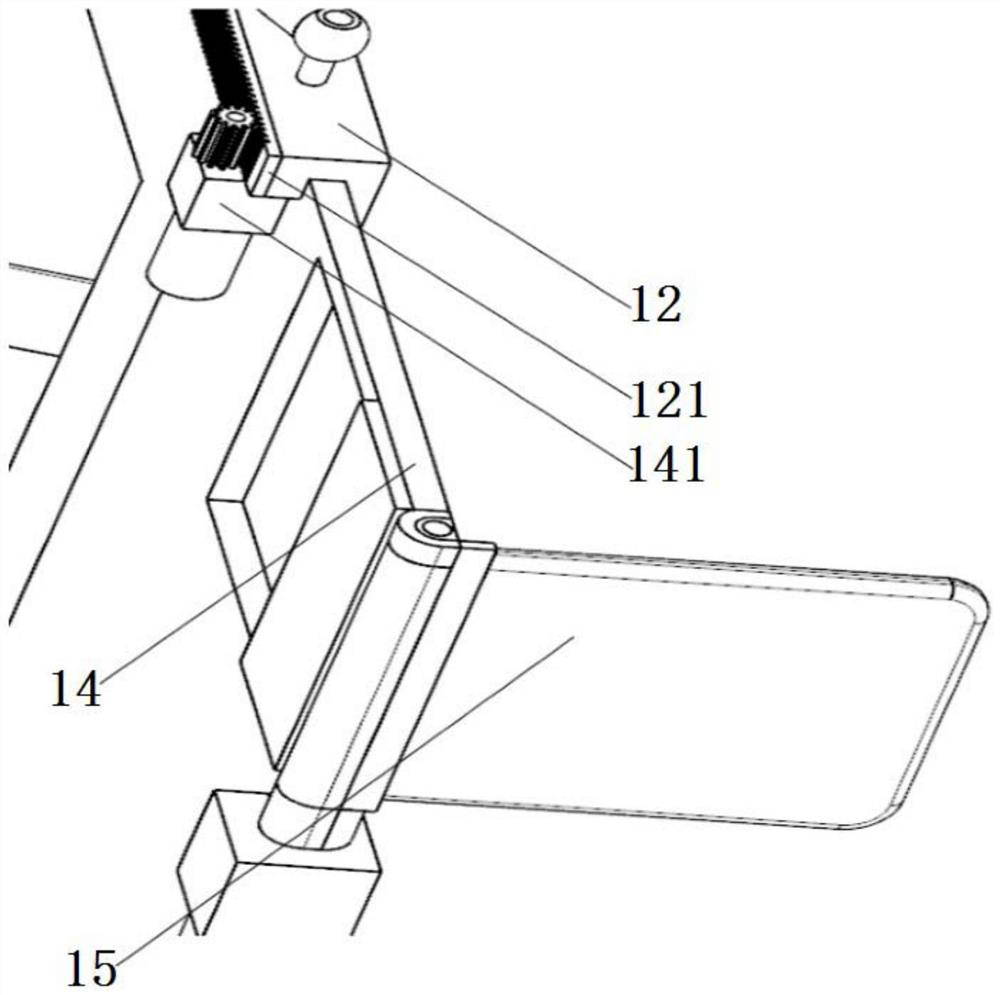

Lifting type nursing wheelchair

PendingCN112618181AReduce careImprove convenienceWheelchairs/patient conveyancePhysical medicine and rehabilitationWheelchair user

The invention discloses a lifting type nursing wheelchair. The lifting type nursing wheelchair comprises a square frame and first wheels arranged on two sides of a bottom surface of the square frame, second wheels are further arranged on the two sides of the bottom surface of the square frame, the first wheels are arranged at a rear end of a pushing direction of the lifting type nursing wheelchair, the second wheels are arranged at a front end of the pushing direction of the lifting type nursing wheelchair, a first supporting plate is arranged in an inner cavity of the square frame and parallel to a bottom surface of the square frame, and one end of a first telescopic mechanism is hinged to one surface of the first supporting plate; a supporting seat is hinged to the other end of the first telescopic mechanism and the first telescopic mechanism is used for pushing or lifting the supporting seat to make contact with or be lifted away from the ground; when contraction of the first telescopic mechanism is completed, the first wheels and the second wheels make contact with the ground; and when expansion of the first telescopic mechanism is completed, the first wheels and the second wheels do not make contact with the ground and the supporting seat makes contact with the ground. The convenience of the wheelchair user is improved.

Owner:SHAANXI UNIV OF SCI & TECH

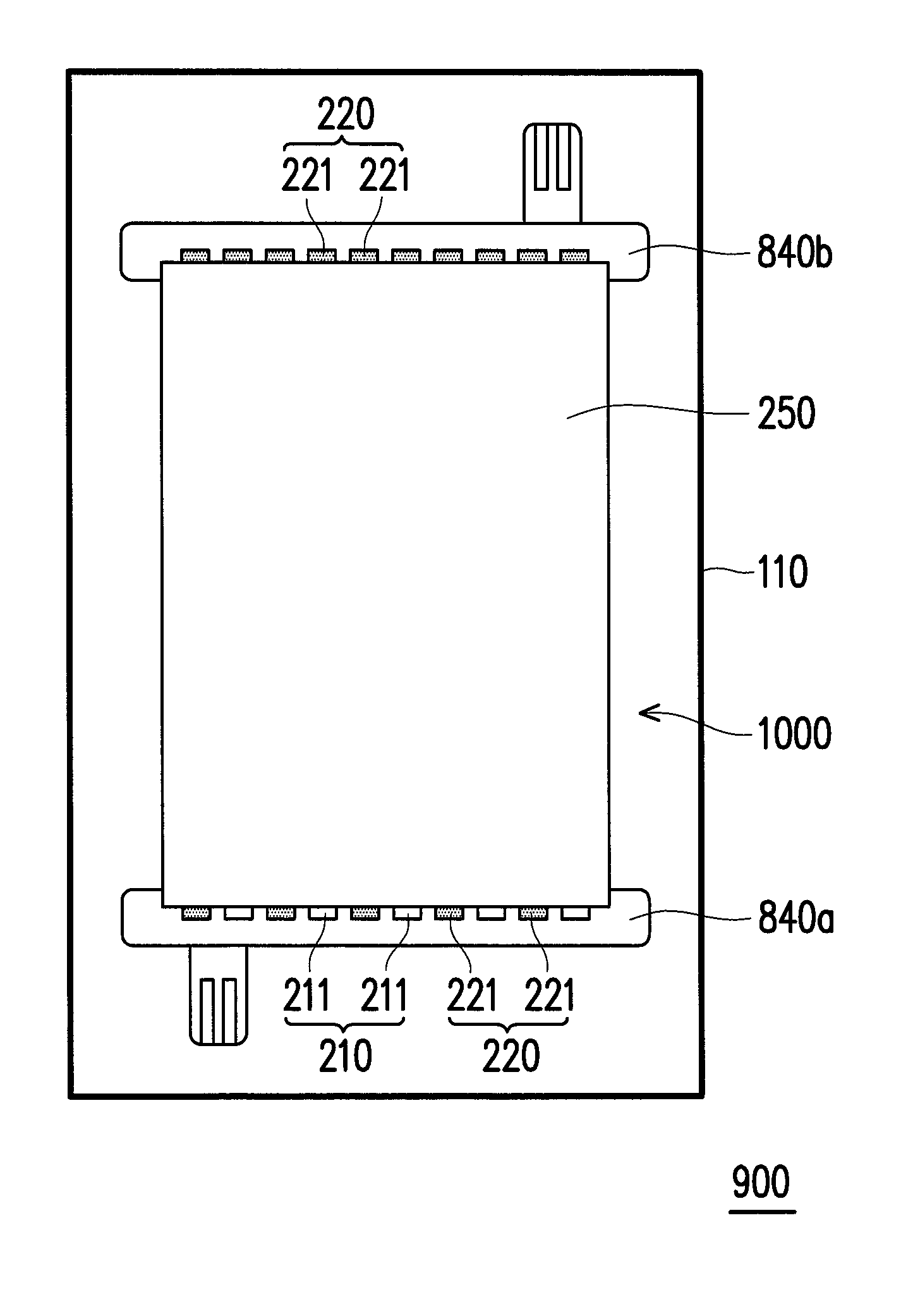

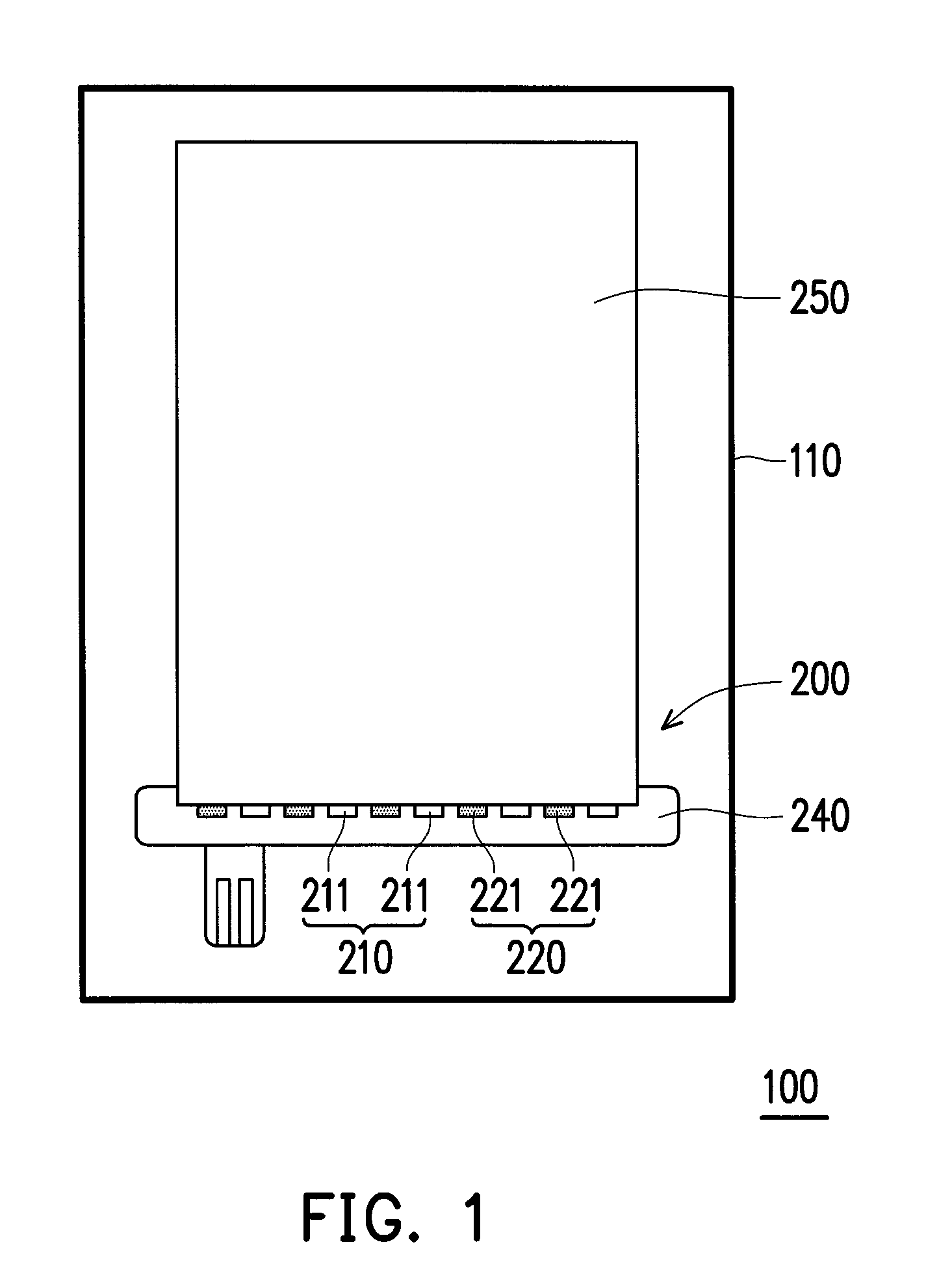

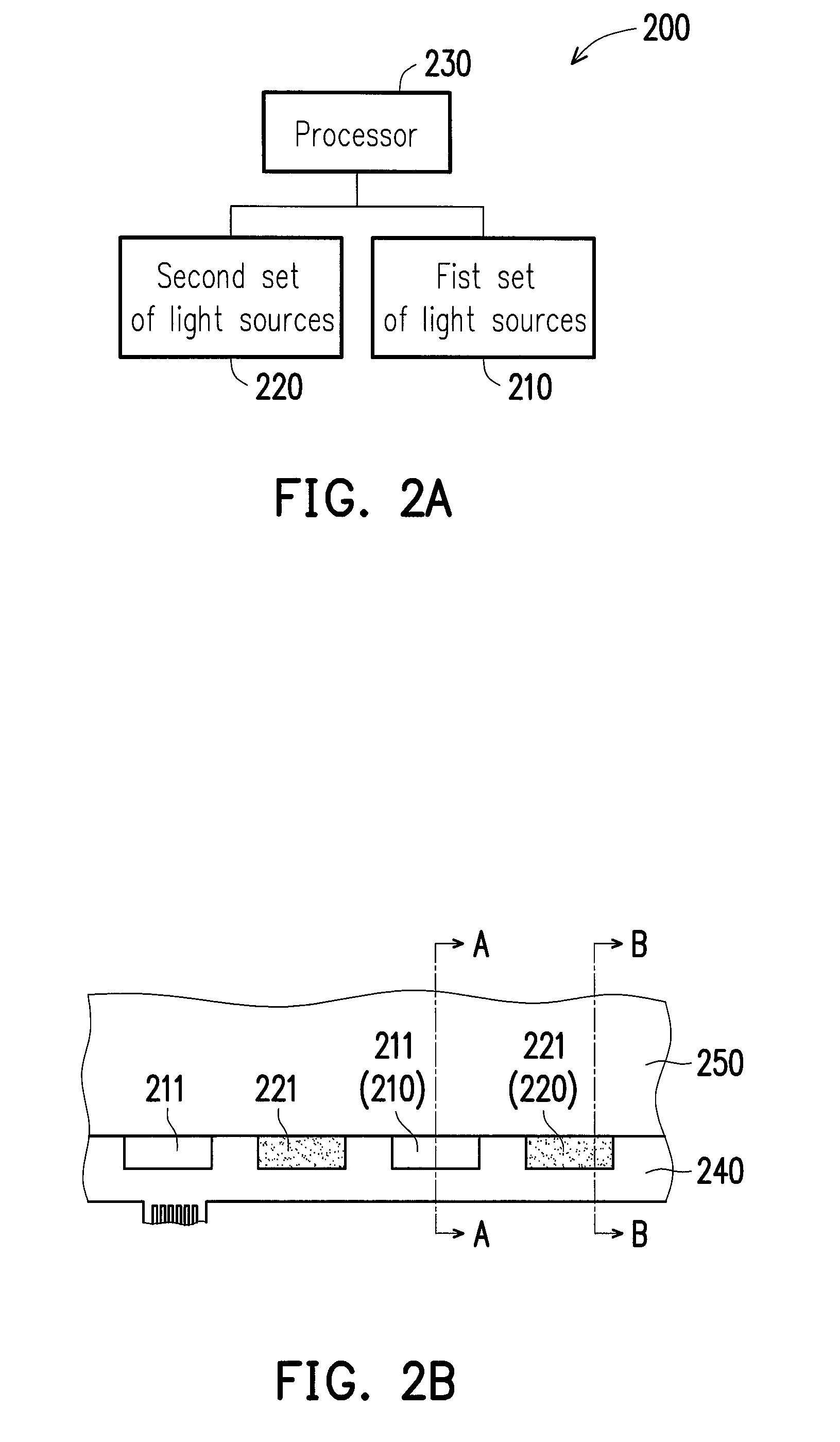

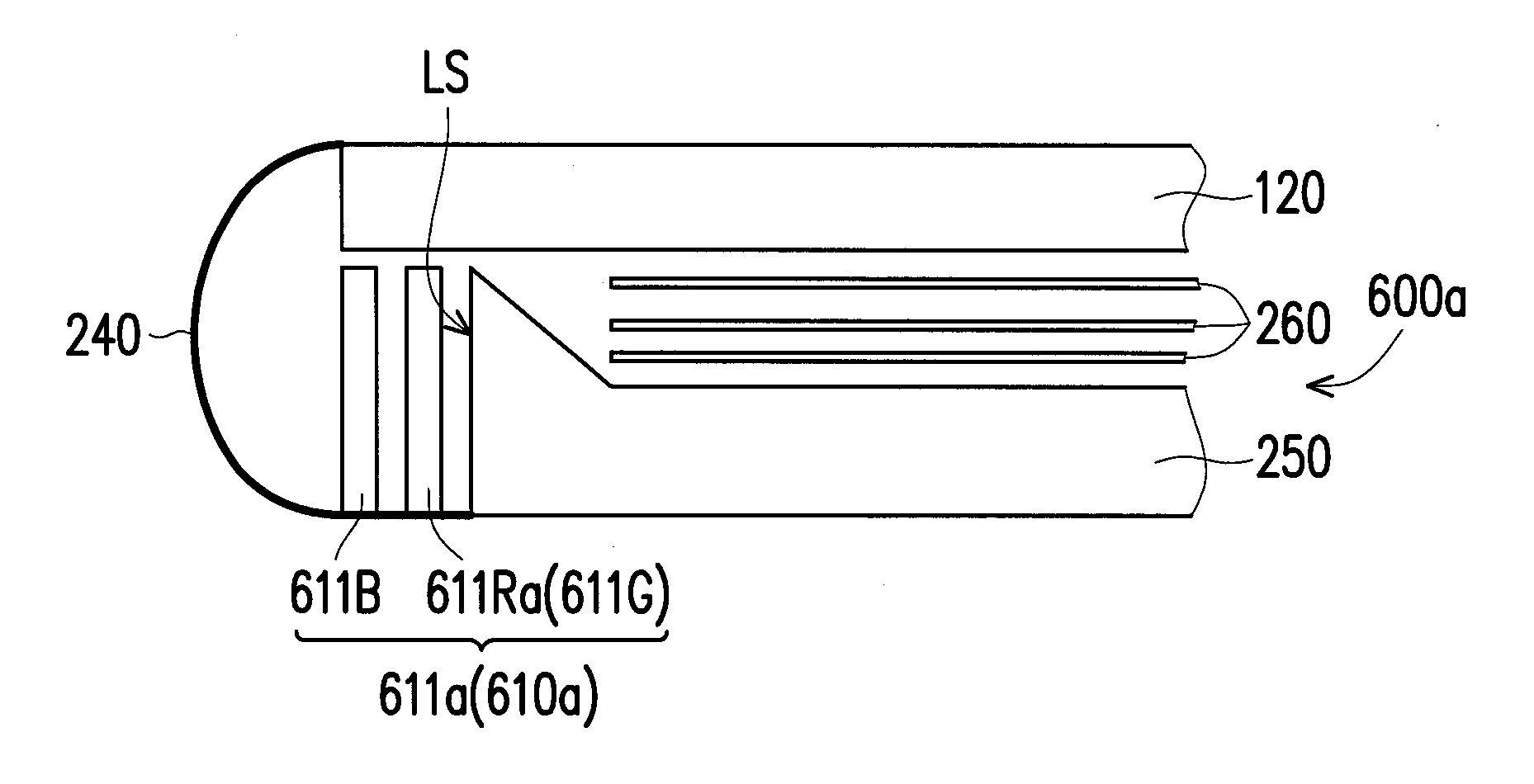

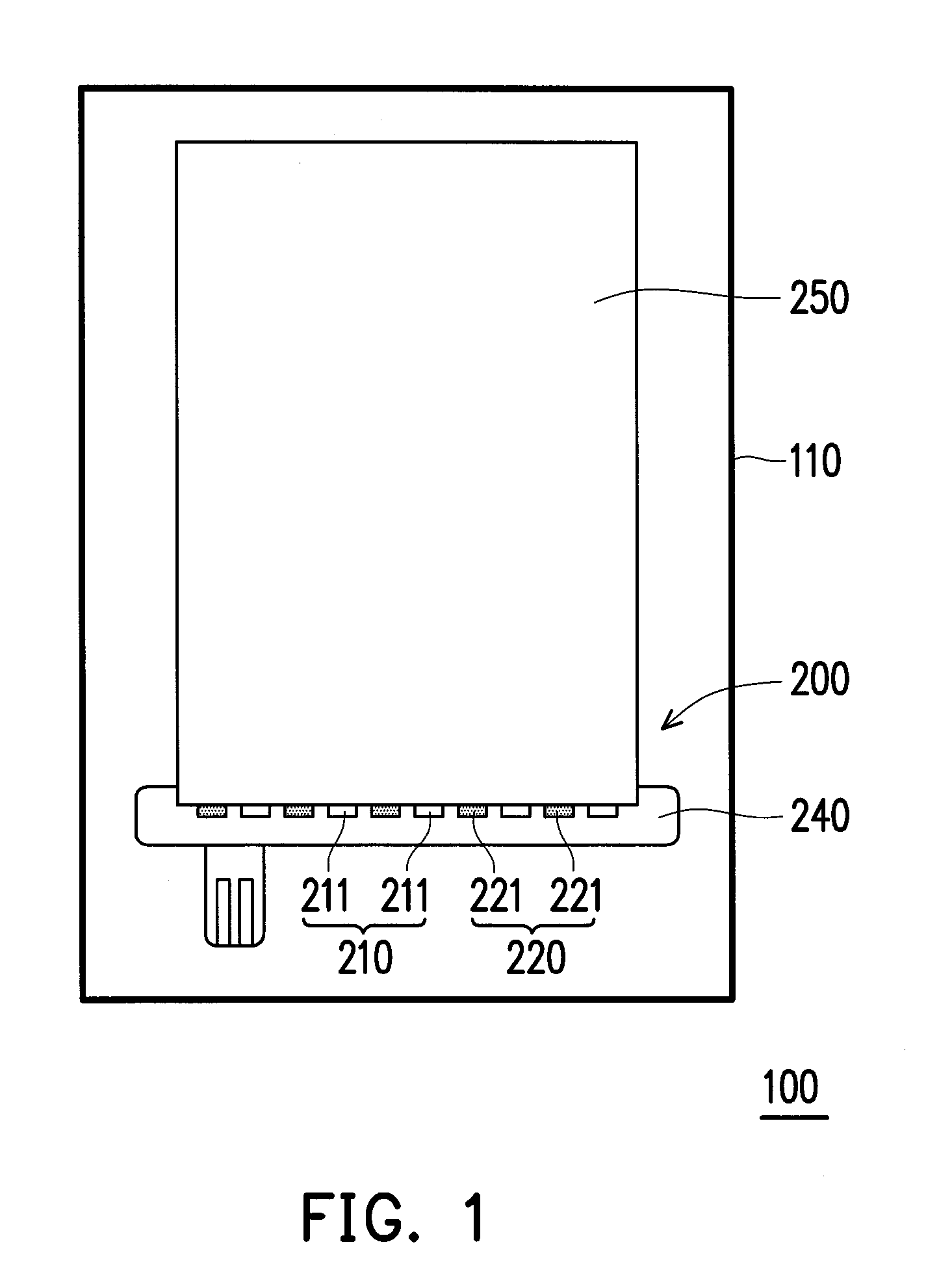

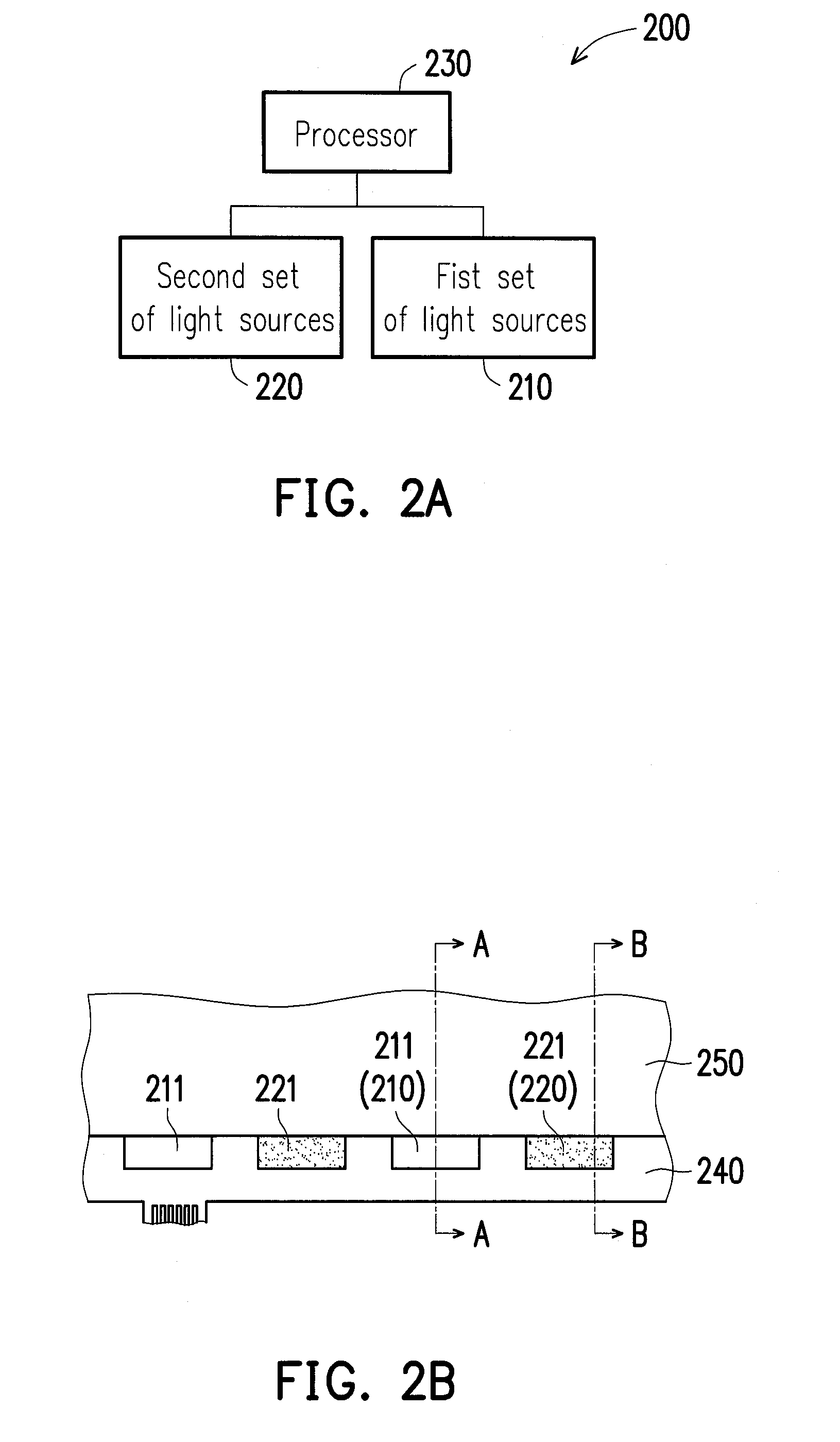

Image adjusting method, light source module and electronic device

ActiveUS9570044B2Extended service lifeHigh quality imagingCathode-ray tube indicatorsGamutComputer science

Owner:HTC CORP

System for liquefying a gas

ActiveUS10801775B2Easy to adjustBroad requirementsSolidificationLiquefactionEngineeringLiquid piston

Owner:CRYOSTAR

Image adjusting method, light source module and electronic device

ActiveUS20140333679A1Extended service lifeHigh quality imagingCathode-ray tube indicatorsInput/output processes for data processingGamutComputer module

An image adjusting method, a light source module, and an electronic device are provided. The image adjusting method includes the following steps. A first set of light source and a second set of light source of the light source module are driven independently by corresponding driving intensity respectively. An image display command is received. The driving intensity corresponding to the first set of light sources and the second set of light sources respectively are adjusted according to the image display command, wherein a gamut of the first set of light sources is wider than that of the second set of light sources, and luminous efficacy of the second set of light sources is higher than that of the first set of light sources.

Owner:HTC CORP

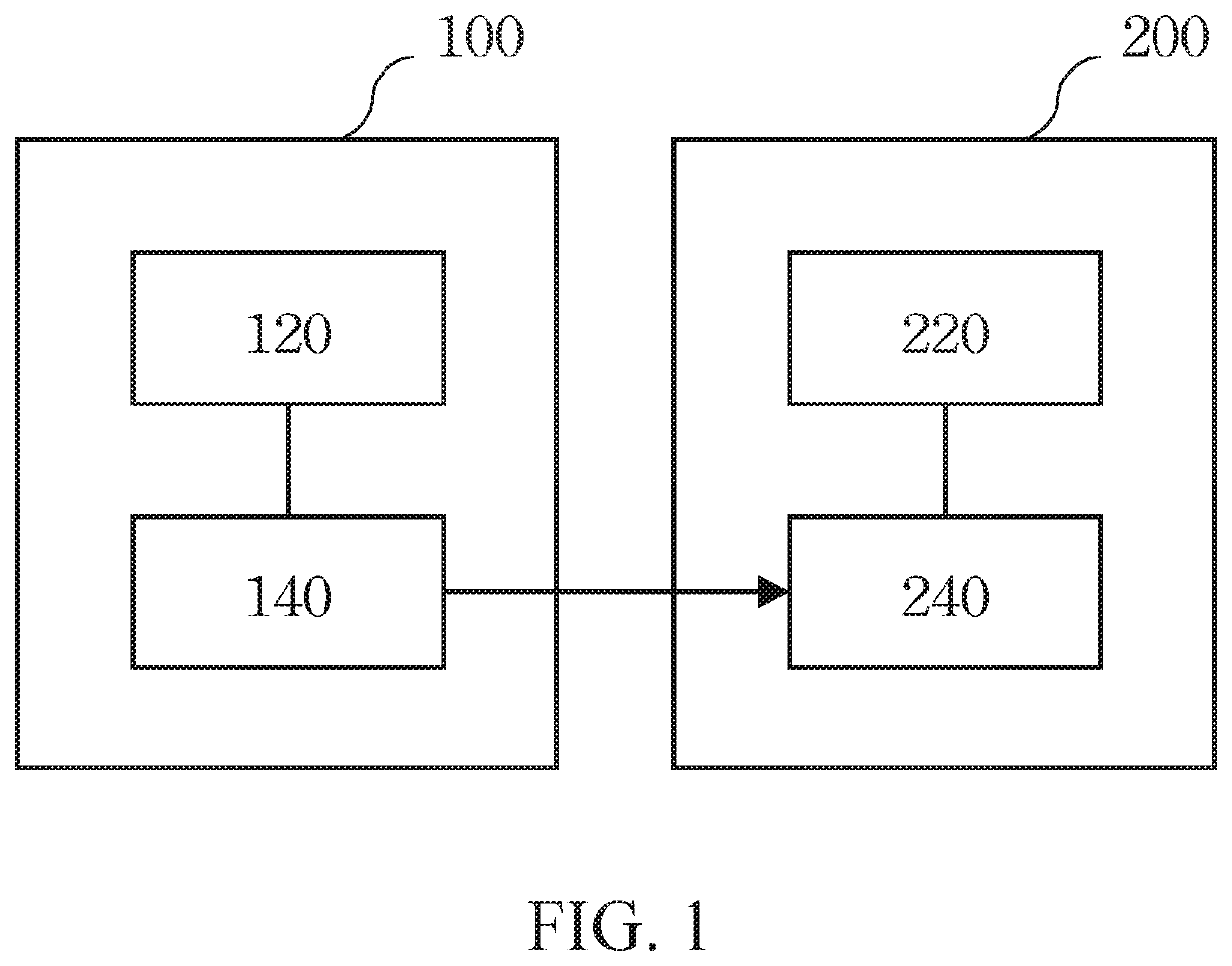

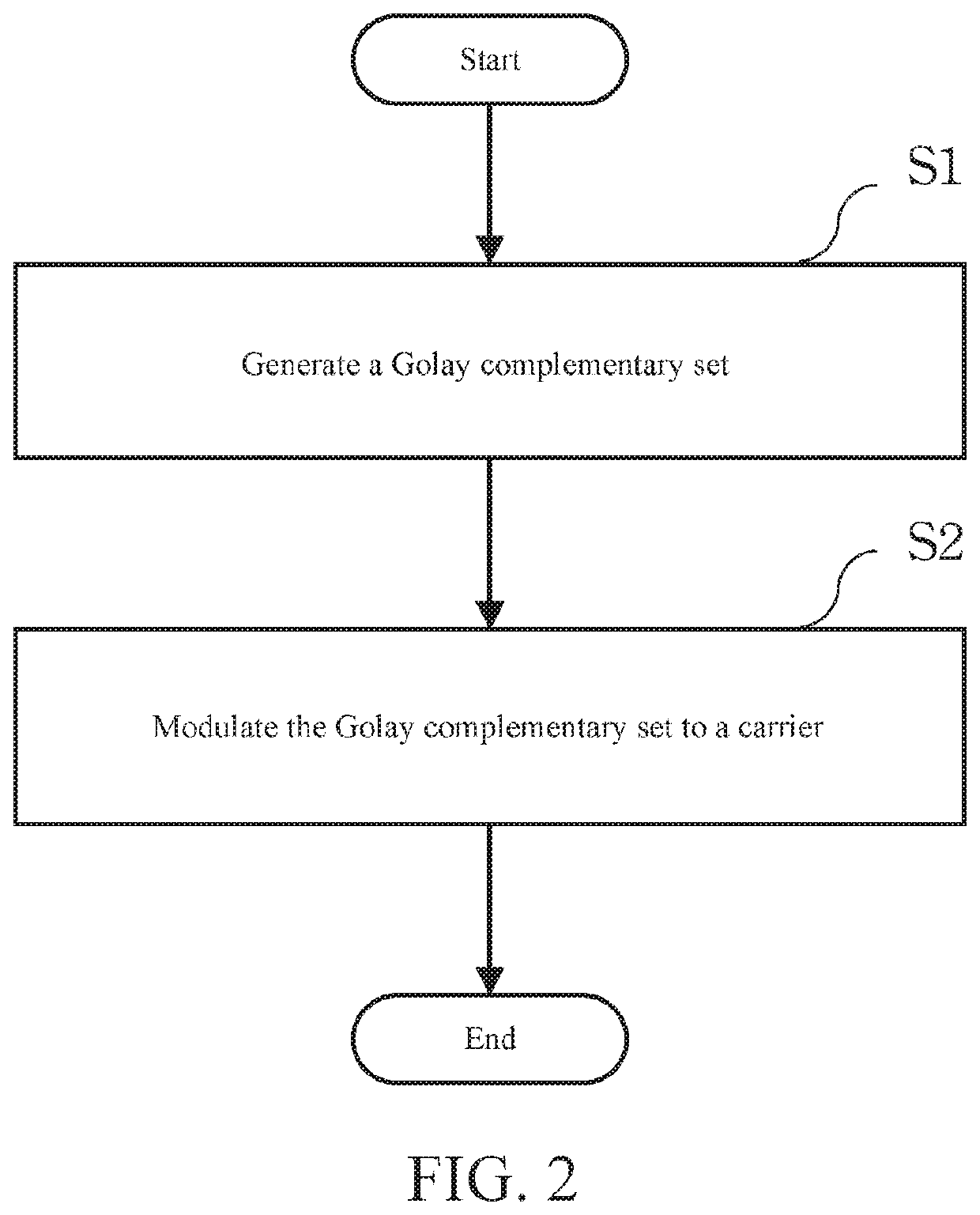

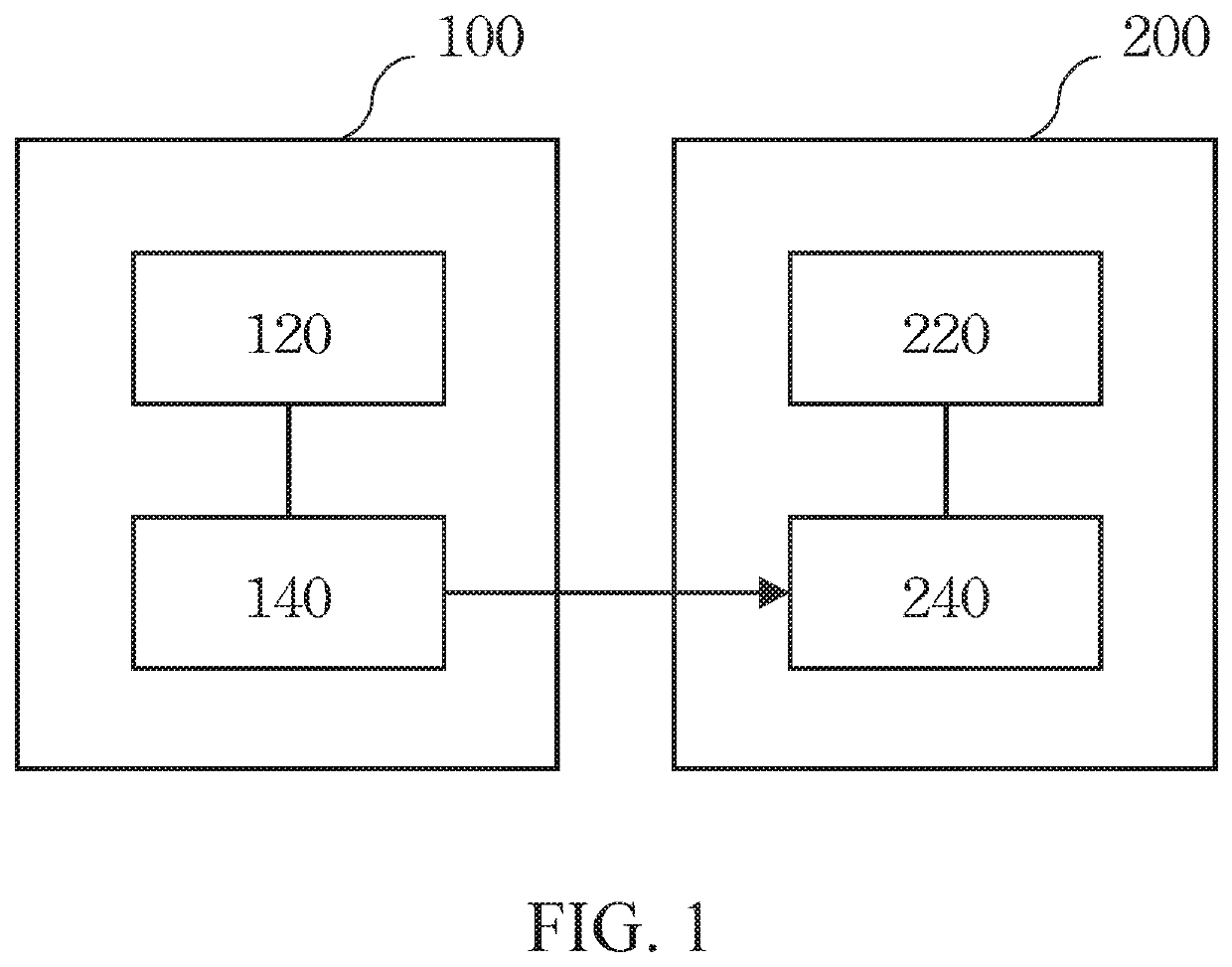

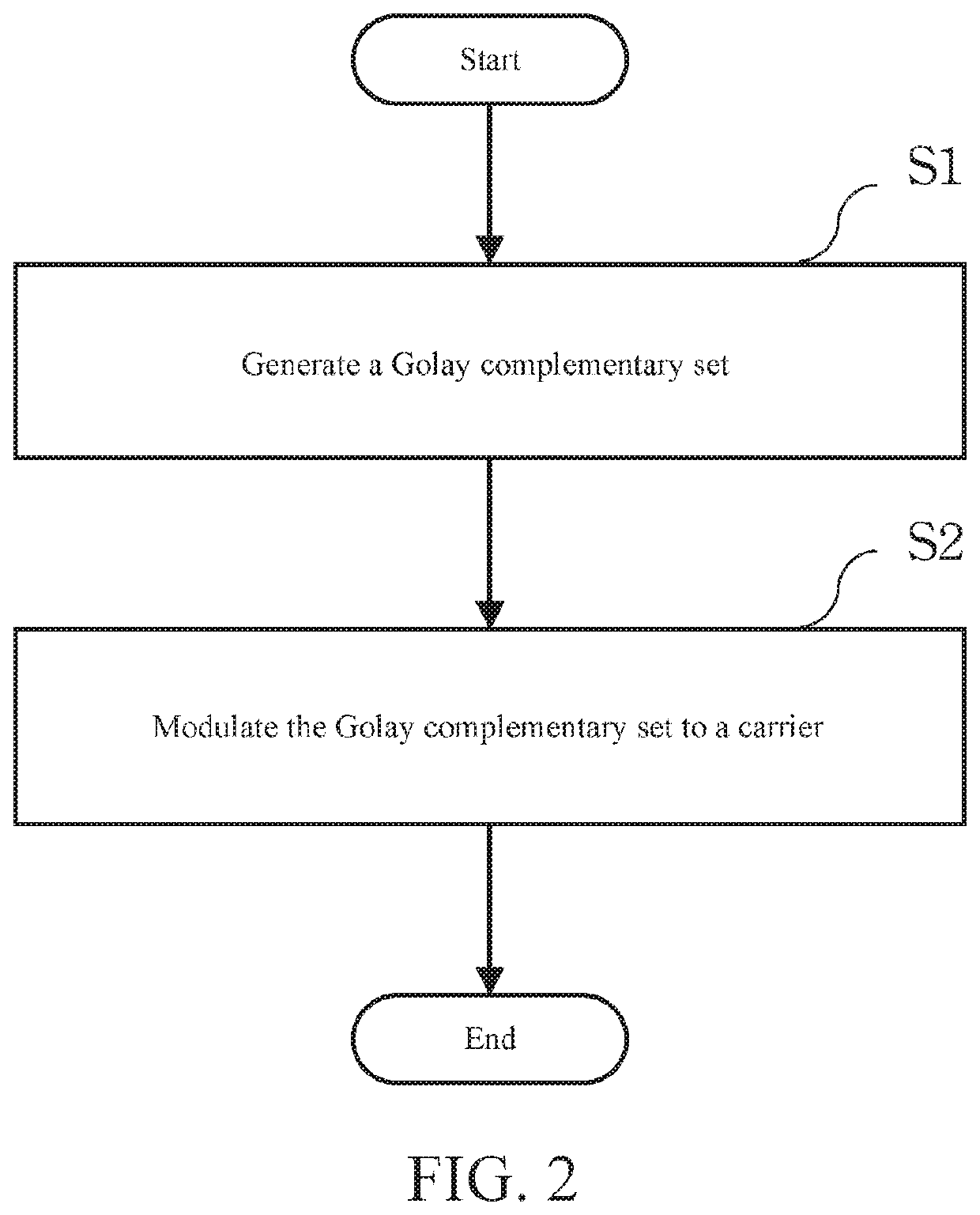

Communication device and communication method

ActiveUS20200177297A1Broad requirementsReduce hardware costsMultiplex code generationChannel estimationTelecommunicationsCarrier signal

A communication device and a communication method are provided. The communication device includes: a processor configured to generate a Golay complementary set, and a modulator configured to modulate the Golay complementary set to a carrier. Herein, the generated Golay complementary set is generated by using an algebraic structure and has an elastic length, and is adapted to communication application such as channel estimation or signal synchronization.

Owner:NAT CHENG KUNG UNIV

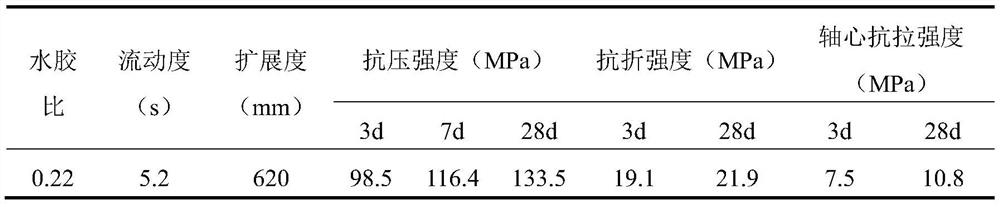

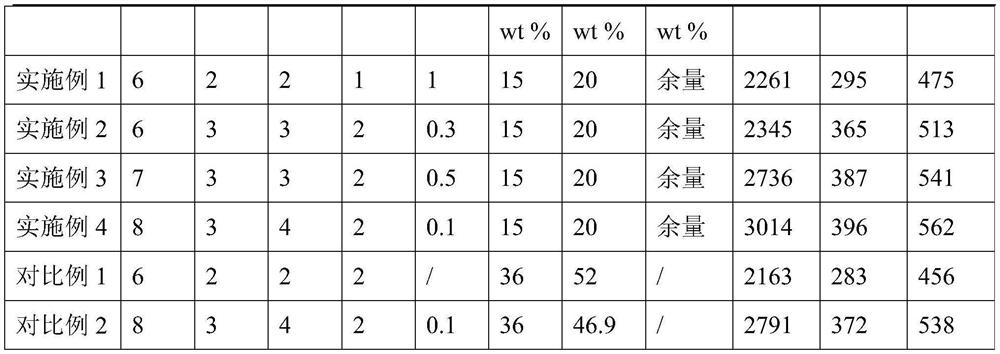

A kind of self-compacting C120 ready-mixed dry concrete and its preparation method

ActiveCN112209683BHigh strength and durabilityAddressing Reunion's FlawsBridge erection/assemblyBuilding material handlingPortland cementFlexural strength

The invention provides a self-compacting C120 ready-mixed dry concrete and a preparation method thereof, belonging to the technical field of concrete materials. The self-compacting C120 ready-mixed dry concrete comprises, in parts by weight, 480-550 parts of Portland cement, 40-55 parts of coarse aggregates, 70-80 parts of steel fibers, 470-550 parts of fine aggregates, and admixtures. 11-15 parts, mineral admixtures 145-190 parts. The ready-mixed dry concrete prepared by the present invention has a compressive strength of not less than 120 MPa after 28 days, a flexural strength of not less than 20 MPa and an axial tensile strength of not less than 8 MPa. After being transported to the construction site and directly mixed with water, the material is discharged It can realize self-compacting, free from vibration, and has the function of high strength and durability.

Owner:YICHUN UNIVERSITY

A space launch system and method based on electromagnetic propulsion

ActiveCN110406698BSolve the problem of high-frequency continuous transmissionZero damageElectromagnetic launchersElectric devicesElectromagnetic launchRocket launch

The invention discloses a space launch system and method based on electromagnetic propulsion. It converts electrical energy into electromagnetic force, propels the rocket through electromagnetic force, accelerates the rocket to a certain speed along the electromagnetic launch track, and realizes the launch of the rocket. The invention accelerates rockets and other aerospace vehicles within a certain distance to several Machs by electromagnetic force, can replace the first-stage engine of traditional rockets, and can launch the rocket into the sky and then ignite it, and has the advantages of short preparation time, high launch frequency, The outstanding advantages of low launch and maintenance costs, flexible and convenient launch methods, etc. solve the problems that traditional rocket launches cannot meet high-frequency continuous launches, high rocket launch costs, and insufficient launch flexibility.

Owner:NAVAL UNIV OF ENG PLA

Knockdown, changeable reel system and method

InactiveUS20030136872A1Efficient transportEfficient storageFilament handlingWebs handlingEngineeringFlange

Owner:PETROFLEX N A

A kind of polycarbonate polyurethane and its green preparation method

The invention relates to polycarbonate polyurethane and a green preparation method thereof. The polycarbonate polyurethane comprises polyurethane structural units and aliphatic polycarbonate structural units which are irregularly distributed. The polycarbonate polyurethane is successfully prepared by a nonisocyanate method, so that isocyanate and solvents are not used, and the development requirements of green chemical industry are met. In addition, the green preparation method of the polycarbonate polyurethane is relatively mild in reaction condition and low in requirement on devices; by selecting raw materials with different structures, the polycarbonate polyurethane having different linear structures and comprising two irregularly distributed structural units can be prepared, so that the structures are diverse and controllable; the prepared polycarbonate polyurethane is free of residue of isocyanate monomers, so that the application of polycarbonate polyurethane to the fields of foods and medicines is broadened.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Fiber-level high purity silicon tetrachloride continuous azeotropy lightness removing rectification method

ActiveCN101564600BBroad requirementsReduce energy consumptionHalogenated silanesFractional distillationFiberProcess engineering

Owner:TIANJIN UNIV

Communication device and communication method

ActiveUS10862608B2Broad requirementsReduce hardware costsMultiplex code generationChannel estimationTelecommunicationsCarrier signal

A communication device and a communication method are provided. The communication device includes: a processor configured to generate a Golay complementary set, and a modulator configured to modulate the Golay complementary set to a carrier. Herein, the generated Golay complementary set is generated by using an algebraic structure and has an elastic length, and is adapted to communication application such as channel estimation or signal synchronization.

Owner:NAT CHENG KUNG UNIV

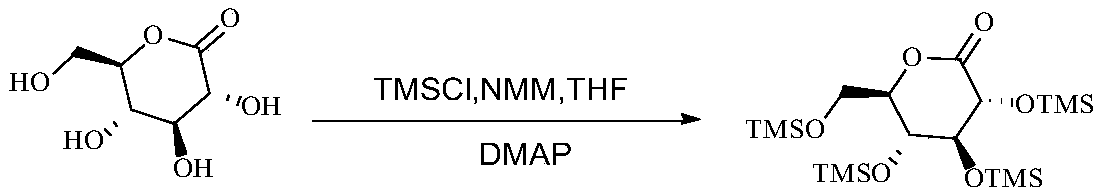

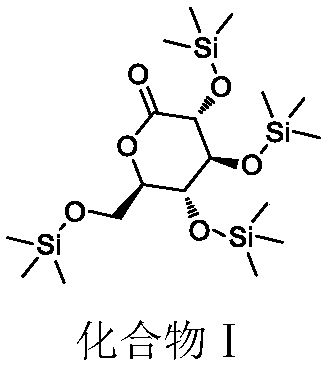

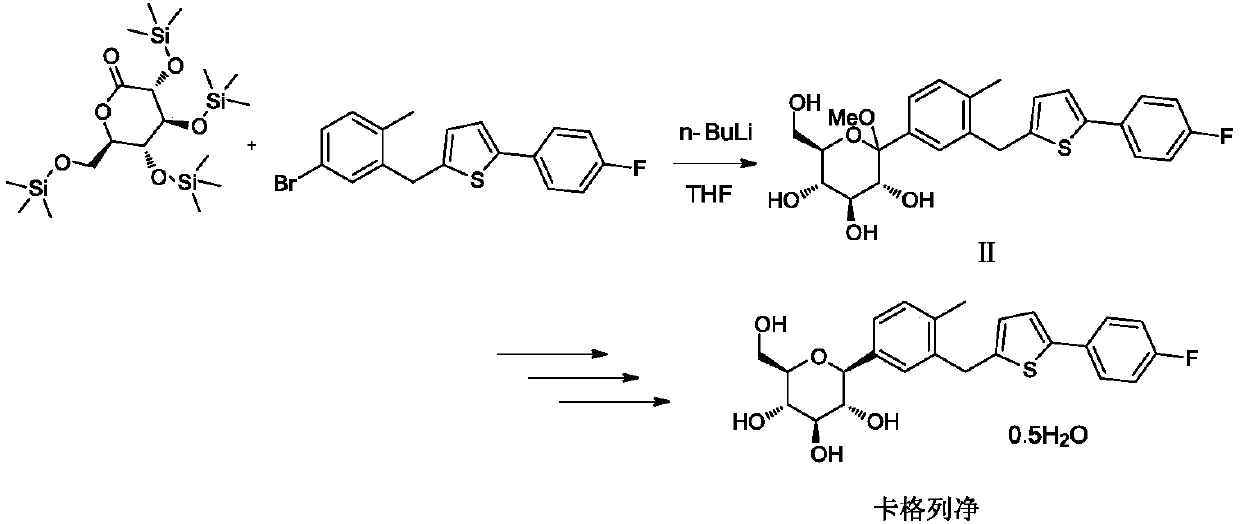

Preparation method of 2, 3, 4, 6-tetra-O-trimethylsilyl-D-glucolactone

ActiveCN111233915AReduced cooling efficiency requirementsWide temperatureGroup 4/14 element organic compoundsOrganic chemistry methodsTrimethylsilyl chlorideMethylpyridinium

The present invention provides a preparation method of 2, 3, 4, 6-tetra-O-trimethylsilyl-D-glucolactone. The method comprises the following steps: dropwise adding trimethylchlorosilane into a system of tetrahydrofuran and N-methylmorpholine, adding glucolactone in batches after dropwise adding of the trimethylchlorosilane, and then adding 4-dimethyl pyridine for reaction so as to obtain the 2, 3,4, 6-tetra-O-trimethylsilyl-D-glucolactone. Compared with the prior art, the preparation method disclosed by the invention has the advantages that the requirements on the feeding temperature and the feeding time during reaction are wider, the quality controllable range is widened, the process repeatability is good, the requirement on the cooling of production equipment is reduced, and the preparation method has great advantages in the aspects of product purity and impurity compound IV control.

Owner:SHANGHAI SYNCORES TECH INC +1

A kind of preparation method of special foliage fertilizer for organic agricultural product crops

The invention relates to a method for preparing a special foliar fertilizer for organic agricultural crops. The method comprises the following steps: by taking wheat germ oil residue as a raw material, firstly, decomposing grease in oil residue by using a lipase preparation, and then decomposing protein by using a protease preparation, so as to produce amino acids and plant active substances; filtering, reserving liquid for later use, and decomposing an organic phosphorus compound in a solid part by using a phytase preparation, so as to generate available phosphorus; filtering and reserving liquid for later use; finally, mixing two parts of liquid, so as to prepare the foliar fertilizer with high amino acid content and abundant available phosphorus nutrition. The foliar fertilizer prepared by the method obtains a good yield-increasing effect by a field experiment.

Owner:SHANDONG ZOETICLAND BIOLOGICAL TECH

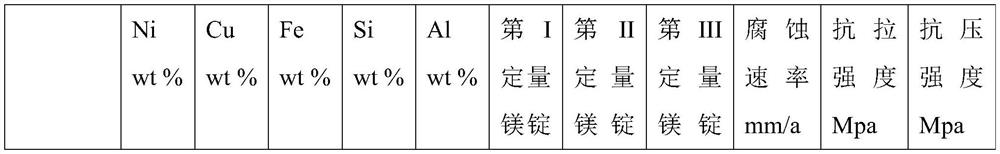

Preparation method of high-strength fast-dissolving magnesium alloy material

PendingCN114855007ASolve the problem of slow anode corrosionHigh strengthProcess efficiency improvementMetallic materialsIngot

Owner:有研金属复材(忻州)有限公司

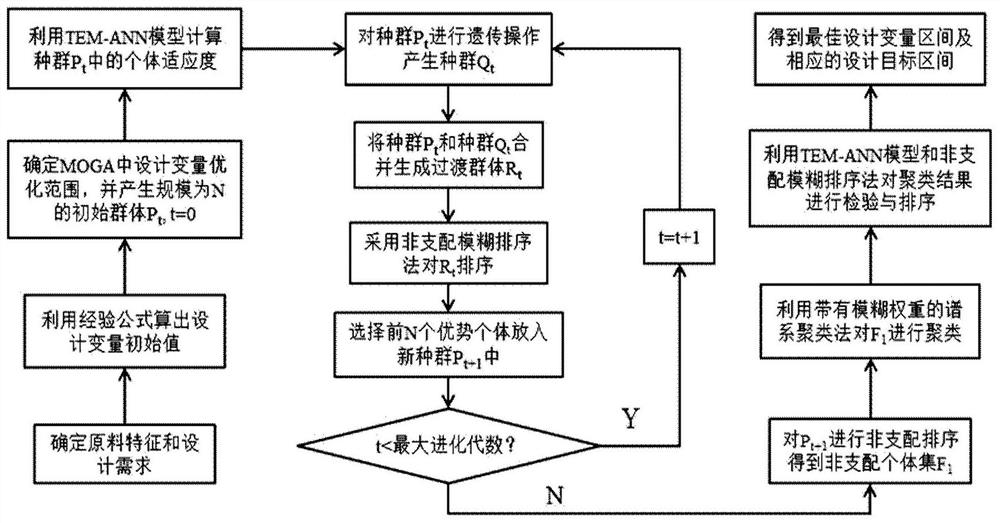

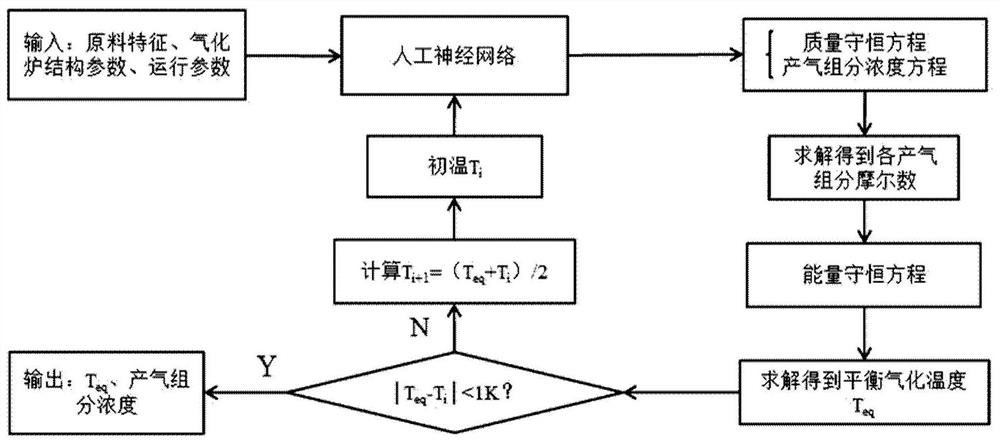

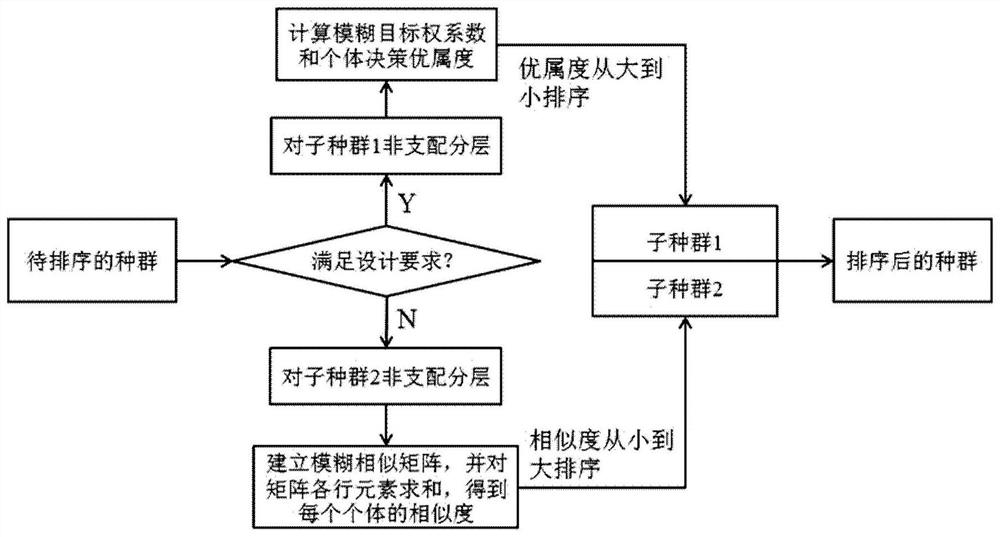

Reverse design device and method for gasification process

ActiveCN112825103ABroad requirementsComprehensive design variablesDesign optimisation/simulationProcess engineeringWorkload

A design method of a gasification process comprises the following steps: determining raw material characteristics and design requirements, and the design requirements being design target value ranges; according to the raw material characteristics and the design requirements, giving an assumed value of a design variable, and calculating by utilizing the assumed value and an empirical formula to obtain an initial value of the design variable; determining a design variable optimization range of reverse design according to the obtained design variable initial value; sorting the individuals in the obtained initial population through a non-dominated fuzzy sorting method; clustering all non-dominated individuals by adopting a pedigree clustering method with a fuzzy target weight coefficient, and finally, sorting different classes by utilizing a non-dominated fuzzy sorting method, so that a design variable and a design target interval which most meet design requirements are obtained. According to the reverse design, the requirement for a design target is wider, design variables are more comprehensive, the design process has clearer directivity, the design result better meets the design requirement, the workload is greatly reduced, and a designer is not required to have rich experience.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com