Reverse design device and method for gasification process

A design method and process technology, applied in the field of reverse design devices of gasification processes, can solve problems such as difficult sorting rules, and achieve the effects of reducing workload, reducing workload and comprehensive design variables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

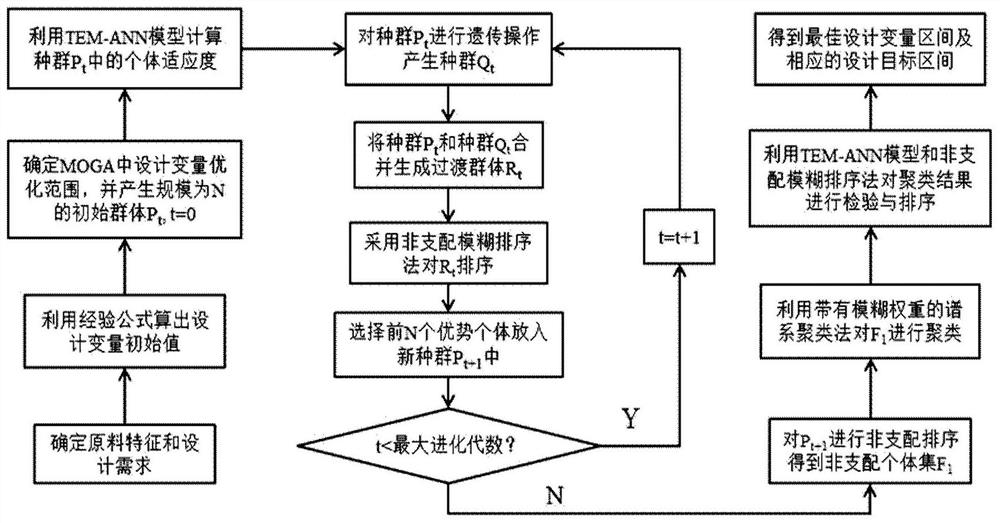

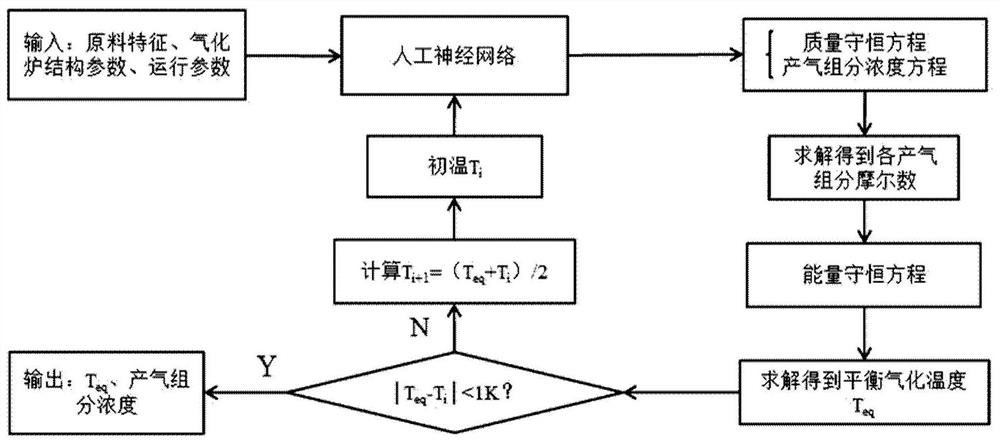

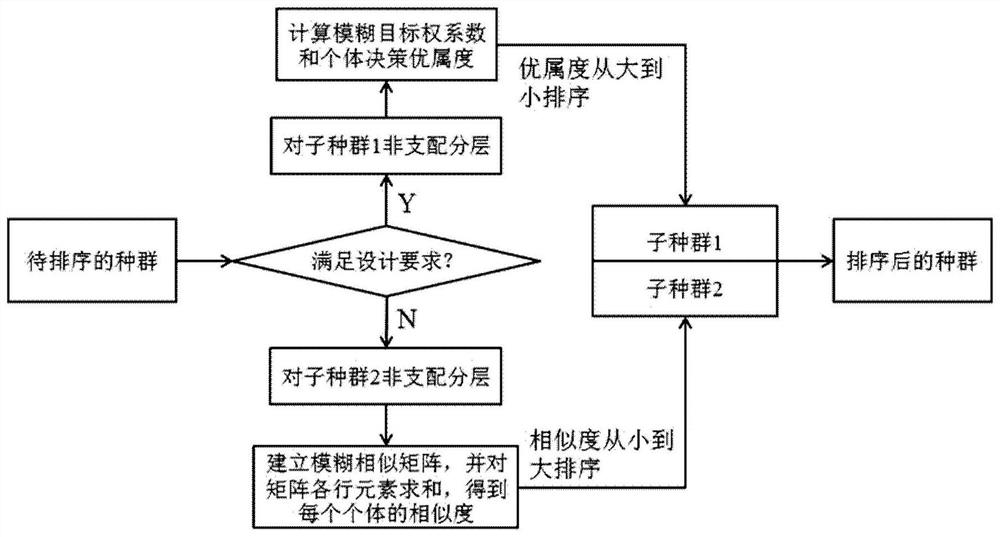

[0069] The invention proposes a gasification process reverse design method, in which the gasification parameters are reversely designed according to the designer's requirements on the gas production index, and the best design scheme meeting the design target is obtained. Reverse design flow chart such as figure 1 shown.

[0070] The invention also discloses a device for the reverse design of the gasification process. The device includes a product prediction module, a parameter optimization module, and a cluster analysis module. The product prediction module ensures the accuracy of the design, and the parameter optimization module improves the design accuracy. quality and reduce the workload, the cluster analysis module improves the practicality of the design. Compared with the traditional design method, the reverse design method has broader requirements for design variables and design goals, the design process is more directional, and the design results are more in line with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com