Preparation method of high-strength fast-dissolving magnesium alloy material

A magnesium alloy, high-strength technology, applied in the field of preparation of high-strength fast-dissolving magnesium alloy materials, can solve the problems of long corrosion time and low strength of fast-dissolving magnesium alloys, and achieve accelerated corrosion, enhanced tensile and compressive strength, The effect of increasing the corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A method for preparing high-strength and rapidly dissolving magnesium alloy materials, preparing magnesium ingots, nickel ingots, copper ingots, aluminum ingots, iron powders, and silicon powders with a purity of ≥99.9%; magnesium ingots, nickel ingots, copper ingots and aluminum ingots are used Before surface treatment, remove surface oxides and oil stains.

[0035] In some solutions, the composition and content of the magnesium alloy material are: Ni 0.5wt%-8wt%, Cu 1wt%-3wt%, Fe 0.5wt%-4wt%, Si 0.5wt%-2wt%, Al 0.1wt% -1wt%, the first quantitative magnesium ingot is 7.5wt%-15wt%, the second quantitative magnesium ingot is 10wt%-20wt%, and the balance is the third quantitative magnesium ingot.

[0036] Preferably, the composition and content of the magnesium alloy material are: Ni 6wt%-8wt%, Cu 2wt%-3wt%, Fe2wt%-4wt%, Si 1wt%-2wt%, Al 0.1wt%-1wt%, the first The quantitative magnesium ingot is 7.5wt%-15wt%, the second quantitative magnesium ingot is 10wt%-20wt%, and th...

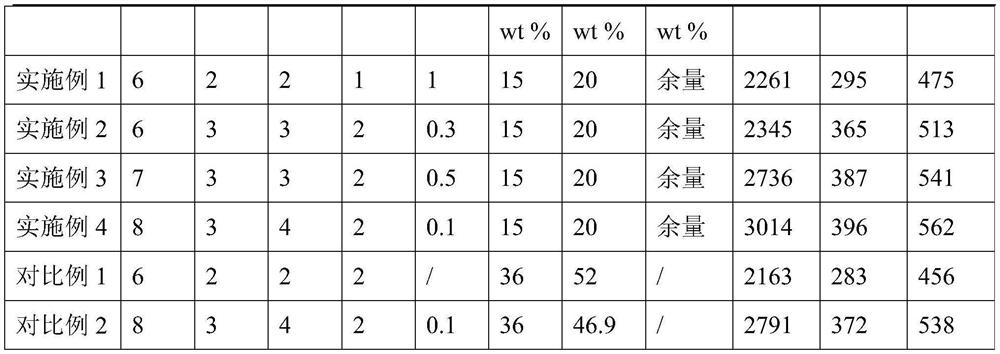

Embodiment 1

[0059] A high-strength rapidly dissolving magnesium alloy material, the chemical composition of which is (mass fraction): Ni 6wt%, Cu2wt%, Fe 2wt%, Si 1wt%, Al 1wt%, the first quantitative magnesium ingot 15wt%, the second quantitative The magnesium ingot is 20wt%, and the balance is the third quantitative magnesium ingot.

[0060] The preparation method of magnesium alloy material is:

[0061] 1, select the magnesium ingot, nickel ingot, copper ingot, aluminum ingot that purity is 99.9wt% and carry out surface treatment, remove surface oxide and oil stain, prepare the 1st magnesium alloy intermediate material;

[0062] 1-1) 15wt% 1st quantitative magnesium ingot is placed in the furnace and is warmed up to 720 ℃, insulation 20min, stirs and removes slag in the insulation process, obtains the 1st quantitative magnesium liquid;

[0063] 1-2) after adding iron powder into the 1st quantitative magnesium liquid and stirring, adding silicon powder and stirring, smelting and keepin...

Embodiment 2

[0075] A high-strength rapidly dissolving magnesium alloy material, its chemical composition is (mass fraction): Ni 6wt%, Cu3wt%, Fe 3wt%, Si 2wt%, Al 0.3wt%, the first quantitative magnesium ingot 15wt%, the second The quantitative magnesium ingot is 20wt%, and the balance is the third quantitative magnesium ingot.

[0076] The preparation method of magnesium alloy material is:

[0077] 1. Select magnesium ingots, nickel ingots, copper ingots, and aluminum ingots with a purity of 99.9wt% and carry out surface treatment to remove surface oxides and oil stains; prepare the first magnesium alloy intermediate material

[0078] 1-1) 15wt% 1st quantitative magnesium ingot is placed in the furnace and is warmed up to 720 ℃, insulation 20min, stirs and removes slag in the insulation process, obtains the 1st quantitative magnesium liquid;

[0079] 1-2) after adding iron powder into the 1st quantitative magnesium liquid and stirring, adding silicon powder and stirring, smelting and ke...

PUM

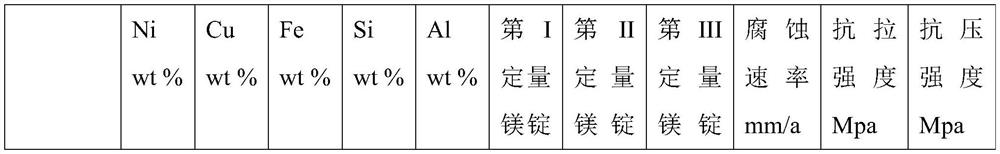

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com