Fiber-level high purity silicon tetrachloride continuous azeotropy lightness removing rectification method

A pure silicon tetrachloride and delight rectification technology, which is applied in the field of optical fiber-grade high-purity silicon tetrachloride continuous azeotropic delight rectification, can solve the problem of difficult separation, great influence on the purity of silicon tetrachloride, and unsuitable for purification. and other problems to achieve the effect of reducing system energy consumption and ensuring purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

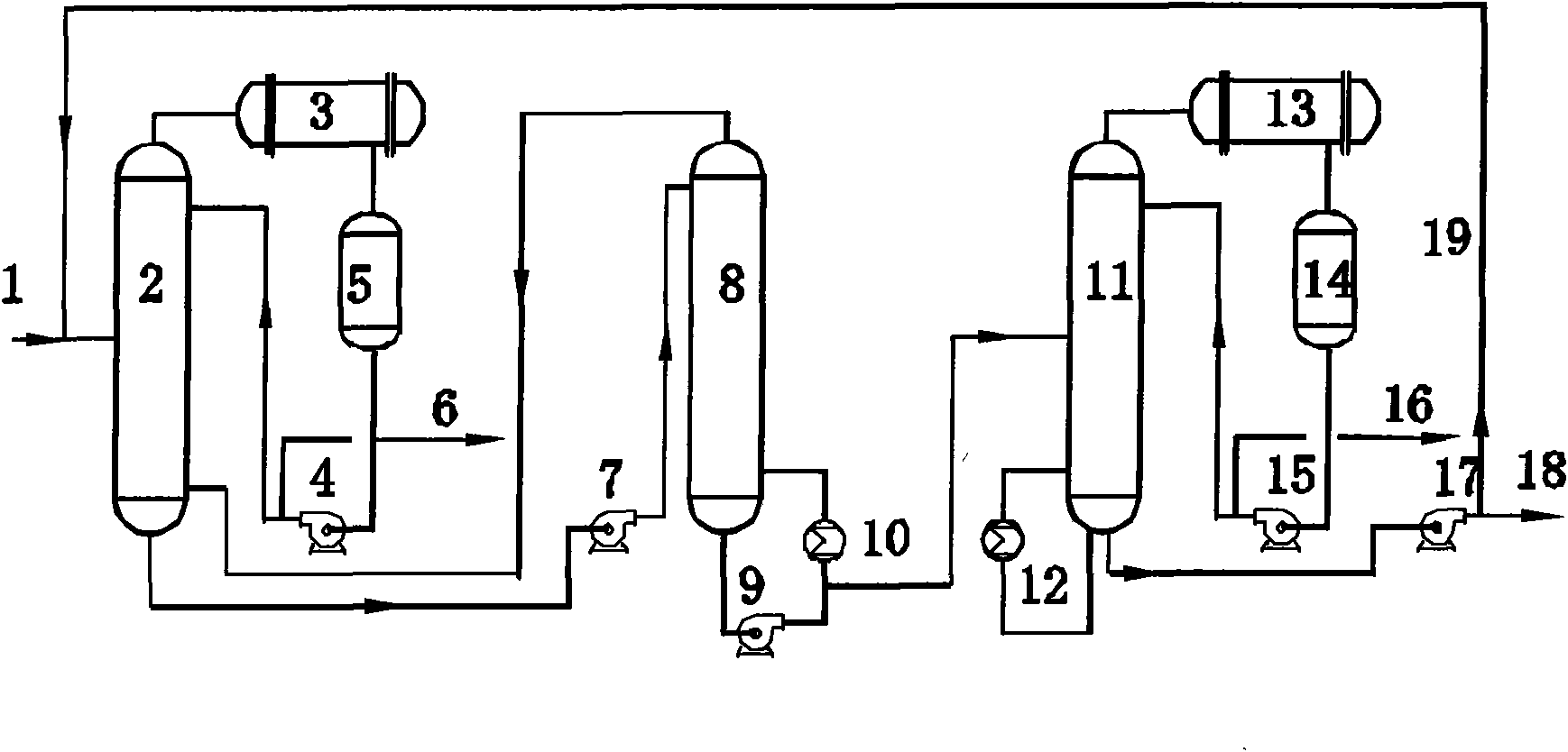

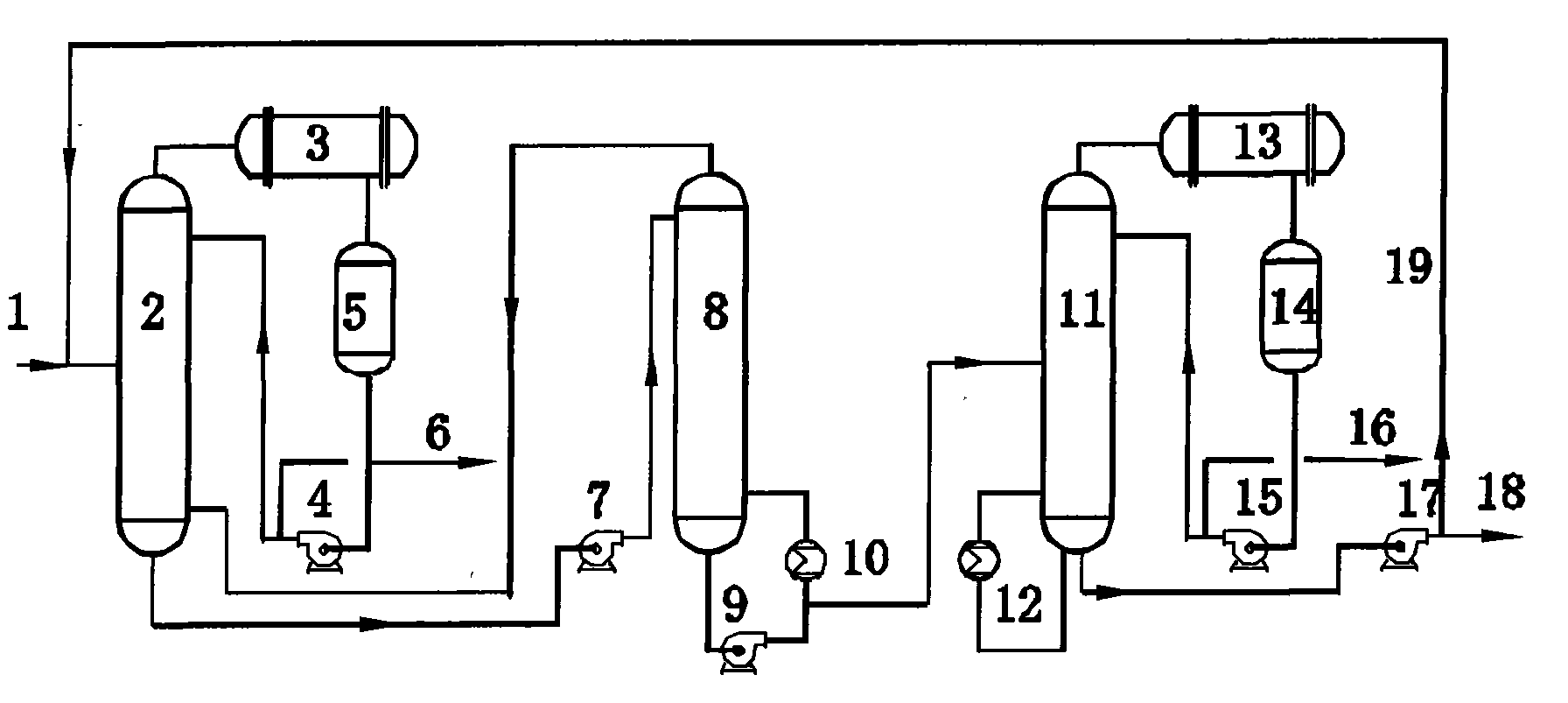

[0023] Processing 2 tons / year of silicon tetrachloride purification, the feed composition is as follows: dichlorodihydrosilane content is 0.5%; trichlorosilane content is 2%; silicon tetrachloride content is 96.95%, dimethyl dichloride The monosilane content is 0.5%, and the trimethylchlorosilane content is 0.05%.

[0024] The pressure of the upper tower of the light removal tower is controlled at 220KPa A, and the theoretical number of stages is 100 in total, and the ratio of top reflux to feed is 10; The heavy tower adopts a pressurized tower, the pressure is controlled at 250KPa A, the ratio of the reflux at the top of the tower to the feed is 15, and the theoretical number of stages is 80; a part of the bottom stream of the heavy removal tower is returned to the light removal tower for feeding, and the bottom of the heavy removal tower is returned to the stream and extracted The logistics ratio is 3:1. The impurity content is controlled at 10 in the silicon tetrachloride ...

Embodiment 2

[0026] Processing 4 tons / year of silicon tetrachloride purification, the feed composition is as follows: dichlorodihydrosilane content is 1.5%; trichlorosilane content is 18%; silicon tetrachloride content is 79.99%, dimethyl dichlorosilane The monosilane content is 0.5%, and the trimethylchlorosilane content is 0.01%.

[0027] The pressure of the upper tower of the light removal tower is controlled at 200KPa A, and the theoretical number of stages is 80 in total, and the ratio of reflux to feed at the top of the tower is 5; The heavy tower adopts a pressurized tower, the pressure is controlled at 200KPa A, the ratio of reflux to feed at the top of the tower is 8, and the theoretical number of stages is 60; a part of the bottom stream of the de-heavy tower returns to the de-light tower to feed, and the return stream changes elastically according to the concentration range of the raw material. The ratio of the return stream to the output stream at the bottom of the de-weighting...

Embodiment 3

[0029] Processing 4 tons / year of silicon tetrachloride purification, the feed composition is as follows: dichlorodihydrosilane content is 0.05%; trichlorosilane content is 1%; silicon tetrachloride content is 98.4%, dimethyl dichlorosilane The monosilane content is 0.5%, and the trimethylchlorosilane content is 0.05%.

[0030] The upper tower of the light removal tower adopts a pressurized tower, the pressure is controlled at 250KPa A, the theoretical number of stages is 120, and the ratio of top reflux to feed is 12; the lower tower of the light removal tower adopts a pressurized tower, the pressure is controlled at 250KPa A, and the theoretical number of stages is total The weight removal tower adopts a pressurized tower, the pressure is controlled at 300KPa A, the tower top reflux to feed ratio is 20, and the theoretical number of stages is 100; a part of the weight removal tower bottom stream is returned to the light removal tower to feed, and the return flow is based on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com