Continuous purifying method of crude product of fluoroethylene carbonate

A technology of fluoroethylene carbonate and chloroethylene carbonate, which is applied in the field of continuous purification of fluoroethylene carbonate crude products, can solve the problems of non-continuous process, low production efficiency, unstable product quality and yield, etc. Achieve the effects of reducing energy consumption, ensuring purity, and improving product quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

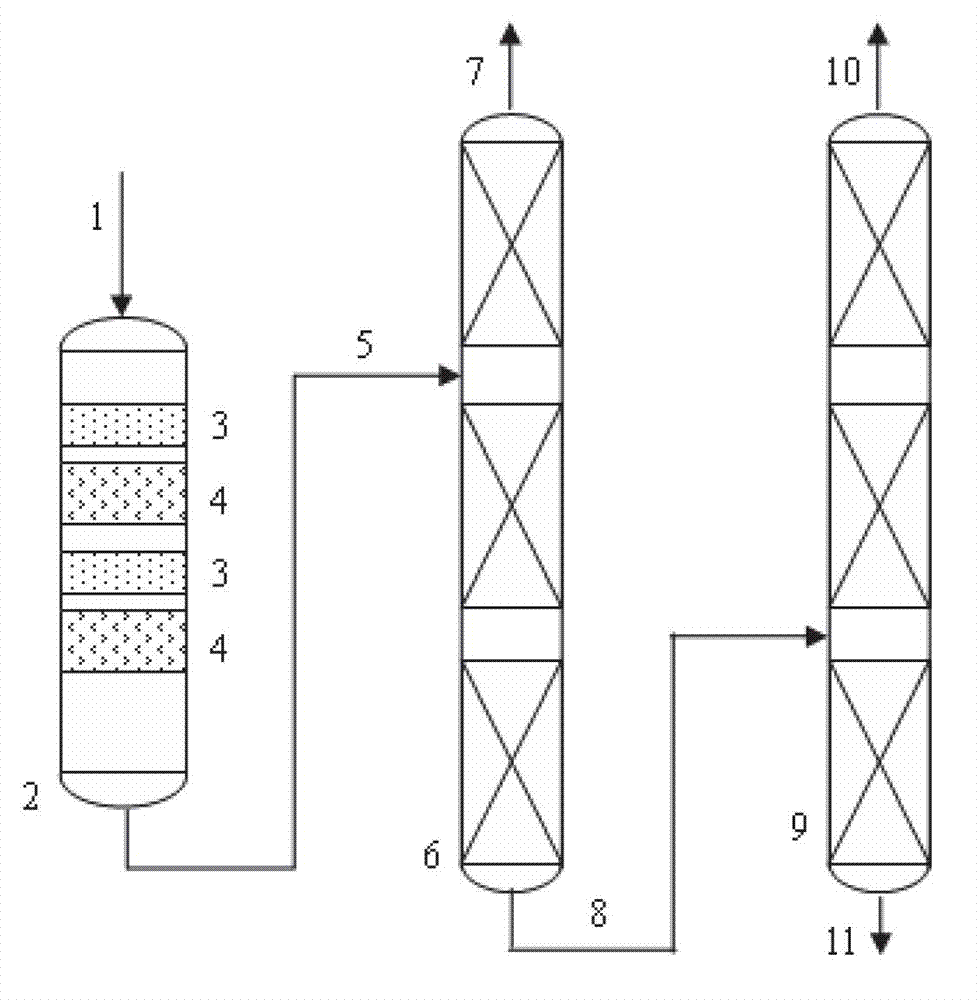

Embodiment 1

[0022] To process 100 tons / year of high-purity fluoroethylene carbonate, the feed composition is as follows: the content of fluoroethylene carbonate is 23%, the content of solvent is 73%, the content of impurities in light components is 1.5%, and the content of impurities in heavy components is 2.5%.

[0023] Two layers of sodium carbonate adsorption layers and zeolite adsorption layers are alternately installed in the pretreatment tower. The sodium carbonate adsorption layer provides a retention time of 20 minutes, and the zeolite adsorption layer provides a residence time of 30 minutes; The number is 30, the feed is located on the 10th plate (from top to bottom, the same below), the reflux ratio is 5, and the temperature at the top of the tower is controlled at 18 o C; the pressure at the top of the weight-removing rectification tower is 5 mmHg, the number of trays is 30, the feed is located at the 20th plate, the reflux ratio is 10, and the temperature at the top of th...

Embodiment 2

[0025] Processing 500 tons / year of high-purity fluoroethylene carbonate, the feed composition is as follows: the content of fluoroethylene carbonate is 77%, the content of solvent is 20%, the content of impurities in light components is 1.5%, and the content of impurities in heavy components is 1.5%.

[0026] In the pretreatment tower, five layers of potassium hydroxide adsorption layers and five activated carbon adsorption layers are alternately installed. The potassium hydroxide adsorption layer provides a retention time of 60 minutes, and the activated carbon adsorption layer provides a residence time of 80 minutes; the top pressure of the light removal rectification tower is 100 mmHg, The number of trays is 80, the feed is located at the 25th plate, the reflux ratio is 40, and the temperature at the top of the tower is controlled at 34 o C; The pressure at the top of the weight-removing rectification tower is 100 mmHg, the number of trays is 100, the feed is located a...

Embodiment 3

[0028] Processing 350 tons / year of high-purity fluoroethylene carbonate, the feed composition is as follows: the content of fluoroethylene carbonate is 45%, the content of solvent is 53%, the content of impurities in light components is 1.5%, and the content of impurities in heavy components is 0.5%.

[0029] Three layers of calcium bicarbonate adsorption layers and activated clay particle adsorption layers are installed alternately in the pretreatment tower. The calcium bicarbonate adsorption layer provides a retention time of 45 minutes, and the activated clay particle adsorption layer provides a residence time of 55 minutes; The pressure is 50 mmHg, the number of trays is 60, the feed is located at the 20th plate, the reflux ratio is 30, and the temperature at the top of the tower is controlled at 28 o C; The pressure at the top of the weight-removing rectification tower is 60 mmHg, the number of trays is 80, the feed is located at the 65th plate, the reflux ratio is 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com