Movable high-accuracy silk material ultrasonic detection system

A high-precision, ultrasonic testing technology, used in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, and measuring devices, etc. To solve the problems of large size and interference of bubble detection results, it can achieve the effect of good parameter retention performance, high reliability detection, and low bubble interference measures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

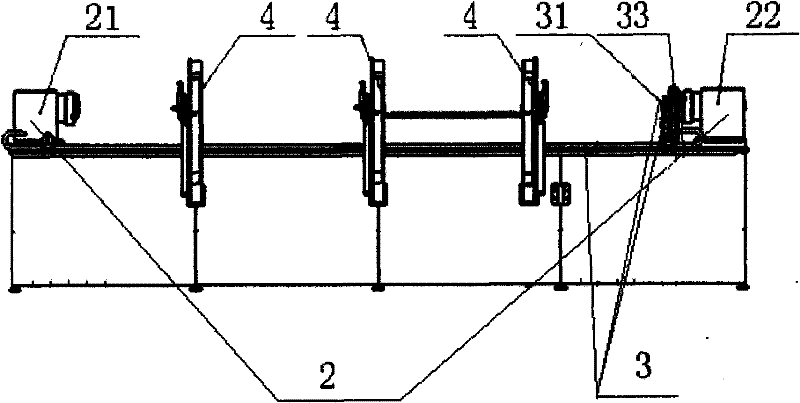

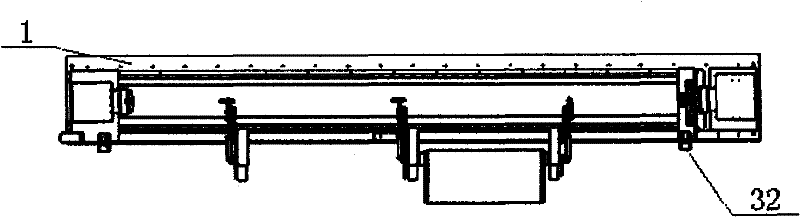

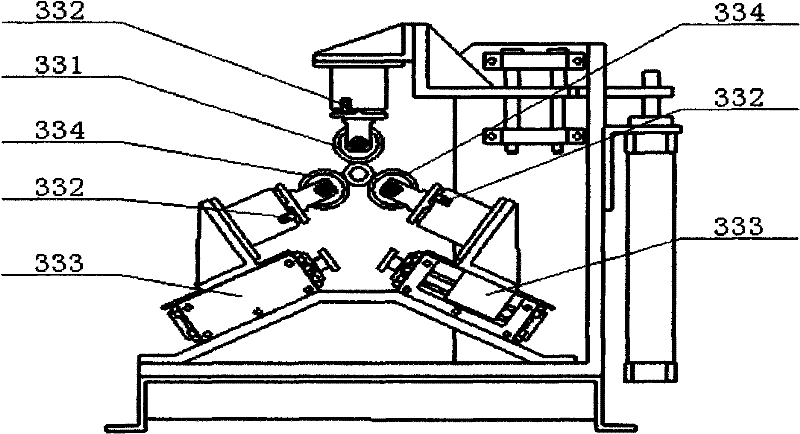

[0023] exist figure 1 , figure 2 In the shown embodiment, the moving rotation mechanism (21) and the fixed rotation mechanism (22) included in the clamping mechanism (2) are placed on the base platform (1), and the detection mechanism (3) is slidingly connected with the base platform (1) , and placed on the guide rail of the base platform (1), slides linearly on the guide rail along the detection direction, the pneumatic centering mechanism (4) is installed concentrically with the center lines of the moving and rotating mechanism (21) and the fixed rotating mechanism (22), and the moving and rotating The mechanism (21) is installed on the guide rail on one side of the base platform (1), and the fixed rotation mechanism (22) is installed on the other side of the base platform, arranged equidistantly on the rear side of the base platform; the detection unit (31) and the axial movement unit (32) flexible connection, the detection unit (31) has a degree of freedom in the radial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com