Rotary hearth furnace brown coal drying method and device

A drying method and technology of a rotary hearth furnace, applied in the directions of drying gas arrangement, heating device, drying solid materials, etc., can solve the problems of small heat exchange area, high manufacturing precision requirements, and huge equipment, so as to achieve simple equipment manufacturing, Controlling the effect of flexible, low-energy drying production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

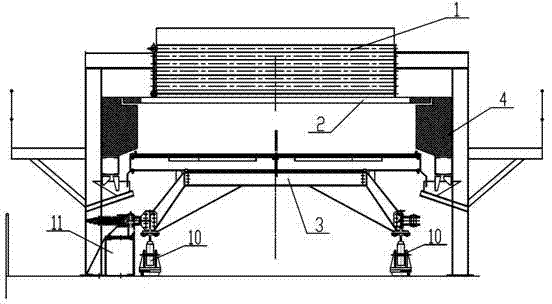

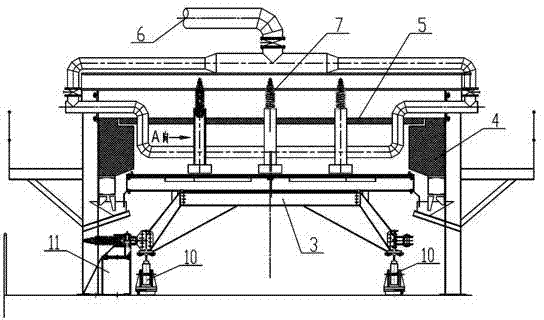

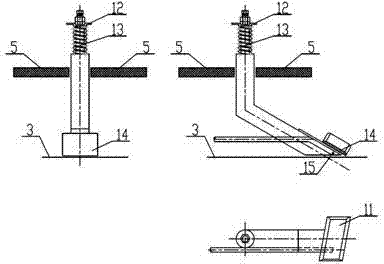

[0030] A method and device for drying lignite in a rotary hearth furnace, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the lignite drying heat source adopts superheated steam and high-temperature flue gas. 3 / h. Superheated steam and high-temperature flue gas are supplied in sections, divided into a heating section, a second heating section, a third heating section, a drying section and a heat preservation section. The temperature of each section: the first heating section is 180-200°C; The three heating sections are 150-180°C; the drying section is 180°C; the holding section is 150°C. The exhaust gas temperature is 130-150°C.

[0031]The drying device consists of charging system 1, feeding port 2, rotating furnace bottom 3, furnace wall 4, furnace roof 5, high temperature flue gas and superheated steam inlet 6, material turning and flue gas injection system 7, exhaust gas outlet 8, Furnace bottom driving system 9, furnace bottom support rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com