Laminar fermentation device and fermentation method thereof

A fermentation device and fermentation tank technology, which is applied in biochemical cleaning devices, biochemical equipment and methods, enzymology/microbiology devices, etc., can solve the problems of small processing capacity, substandard, inconsistent product quality, etc. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

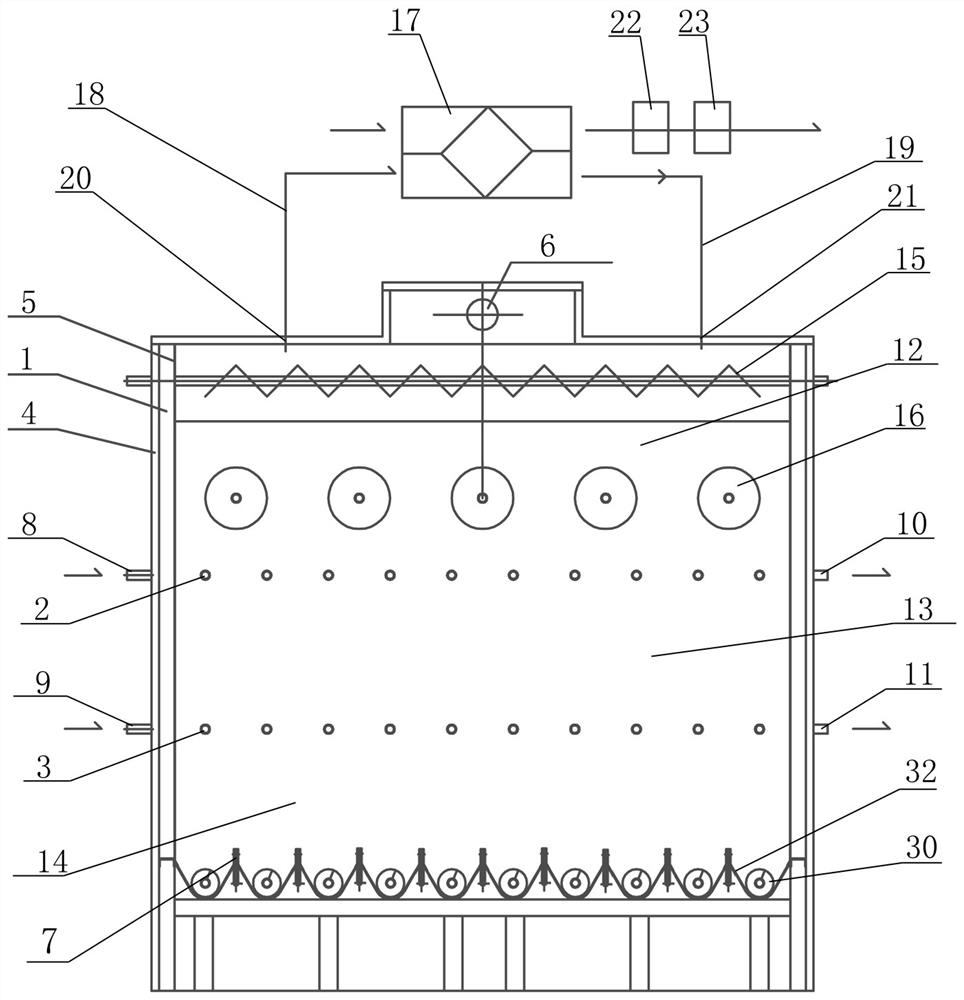

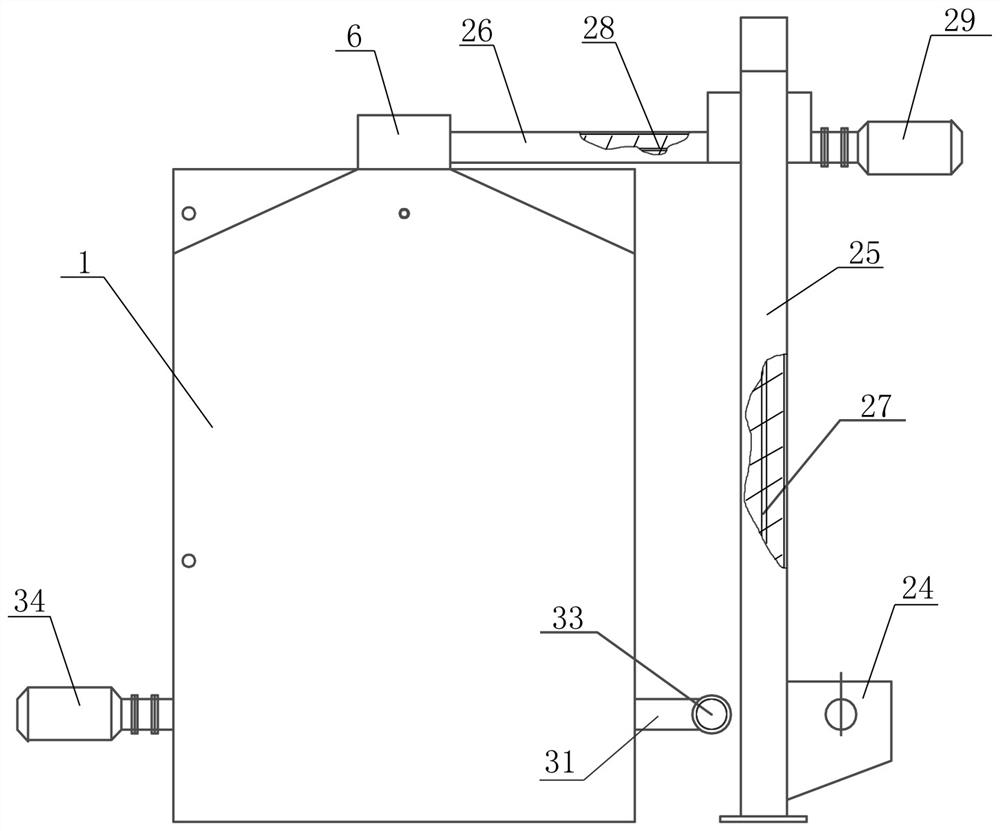

[0050]A laminar flow fermentation device, characterized in that the device includes a fermentation tank 1, a stirring mechanism in the tank, a heat recovery and aeration device, a feeding mechanism, a discharging mechanism, a heating water pipe 2 and a cooling water pipe 3, and the fermentation tank 1 is outside the tank. The end face is fixedly provided with a thermal insulation composite plate 4, and the inner end face is fixedly provided with a stainless steel plate 5. The upper cover of the fermentor 1 is provided with a feed inlet 6, and a plurality of nitrogen input pipes 7 that are passed into the fermentor 1 are provided at the bottom of the fermentor 1. A hot water inlet 8 and a cold water inlet 9 are respectively provided on the side wall of one end of the fermenter 1, and a hot water outlet 10 and a cold water outlet 11 are respectively provided on the side wall of the other end of the fermentation tank 1. The heating water pipe 2 and the cooling water pipe 3 are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com