Circulating water aquaculture system

A technology of aquaculture and circulating water, applied in fish farming, application, animal husbandry, etc., can solve the problems of oxygen affecting the growth of aquaculture objects, the increase of suspended particle concentration, and affecting the growth of aquaculture objects, so as to avoid instantaneous hypoxia and turbidity Excessively high, to achieve recycling, to achieve the effect of resource

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

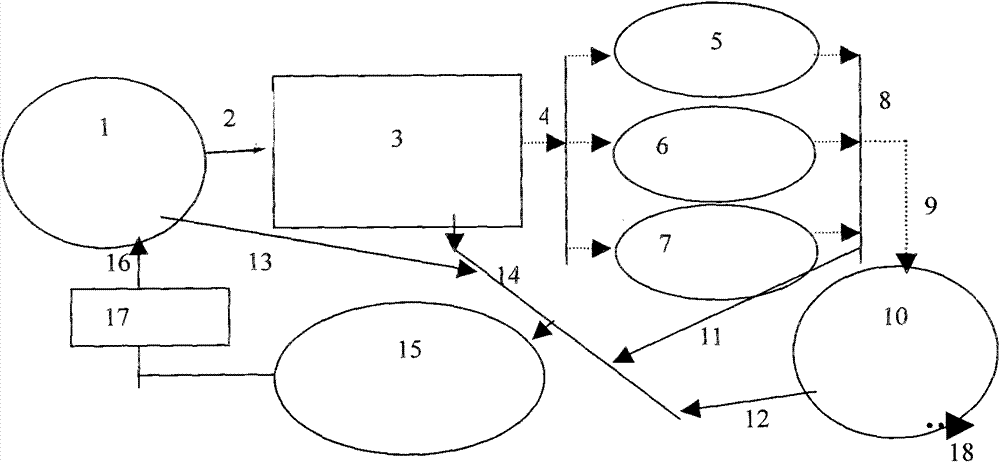

[0011] The present invention (referring to accompanying drawing) adopts cultivation pond 1, three flocculation reactors 5,6,7, biofilter 15, sedimentation tank 3, floc collection device 10 and deployment pond 17, and described cultivation pond is shallow conical Type glass fiber reinforced plastic breeding pond with a diameter of 6m, a depth of 2m and a volume of 50m 3 , the bottom is inclined at 30 degrees, the center of the bottom of the pond is provided with a sewage outlet to connect to the sewage pipe 2, and the breeding pond is equipped with oxygenation and temperature control equipment; the sedimentation tank is 10m long and 2m wide, and it is an advection sedimentation tank, and the sedimentation tank is connected with the flocculation reactor An adjustable on-off valve 4 is set at the bottom of the sedimentation tank, and a sludge pump is installed at the bottom of the sedimentation tank, and a sloping plate with an inclination angle of 60° is placed in the sedimentati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com