[0006] 1) The process stability of the material is poor. The main molding processes of FRP composite materials include hand lay-up molding, lamination molding, RTM method,

extrusion method,

compression molding, and winding molding. Among them,

pultrusion molding and RTM method have better material stability. And

compression molding, the dispersion of material properties is relatively small, but the production process of the latter two methods is more complicated, and the production efficiency is low. At present, the main

composite material products on the market still tend to

pultrusion molding process;

[0007] 2) The dispersion of material performance is large. Since the performance of FRP composite materials is closely related to the

fiber lay-up structure, and the lay-up of fibers in FRP materials is very slow to ensure uniformity everywhere, so the mechanical properties of the material after sampling at different positions There will be deviations in performance, and the dispersion of FRP materials produced by some processes is relatively large, which leads designers to take the

lower limit of the test value of the material as much as possible when designing the structure of FRP composite materials, and its structure will lead to excessive performance in

material design. Affluence leads to a series of problems such as excessive use of materials, serious waste of materials, and high product costs;

Although the

large size solves the slowness of the hand lay-up process, the solidification and demoulding links of the winding process still exist, and these two links are the

bottleneck of production efficiency. An average set of composite poles takes 2-3 hours to solidify on average, and the

cooling time is 0.5 hours. Hours, hoisting and demoulding about 0.5 hours, so the production efficiency of GFRP single-pole tower winding is extremely low, about 6-8 hours for a pole; at the same time, because the fibers of the winding tower cannot be completely laid vertically, the laying of the fibers in the longitudinal direction cannot To maximize the strength, part of the strength will be dispersed in the circumferential direction. In this case, in order to ensure the

longitudinal strength of the composite tower, the thickness of the

fiber layer can only be increased to ensure the

longitudinal strength of the composite tower. The thickness of the tower will increase , the weight also increases, resulting in high cost of composite tower materials

The above production links, whether it is material cost, labor and production management cost are very high, and the production capacity of corresponding products is also extremely low, resulting in the cost of FRP composite pole towers being 3-4 times that of traditional steel

pipe towers, which restricts the use of FRP composite poles. Promotion and application

[0015] 2) Although the

composite material tower has a greater load-

bearing capacity than the traditional tower, due to the

low elastic modulus of the material, the modulus of the

fiber-reinforced

resin matrix composite material is 50-70GPa, which is about half of the steel material. Larger deflection occurs under heavy loads. For example, the

bending moment strength of a 10kV composite pole is 2-3 times that of a

cement pole, but its failure bending deformation can reach 3 times. The larger deformation limits the application of composite poles and towers. Conducive to the industrialization of composite poles

[0017] Due to the large

diameter of the

pipe produced by the traditional horizontal

pultrusion process, the mold is seriously eccentric from the top to the bottom, and the pultrusion process will be in contact with the air. It is easy to form air bubbles and holes between the

layers of the pultruded composite product, resulting in hollowing and eccentricity of the

pipe. In addition, due to the

gravitational force, the resin soaked in the upper layer will automatically flow downward during the pultrusion process, causing the upper

fiber layer to lack resin, and the lower

fiber layer to be rich in resin. Seriously affect the strength of the pipe, and the stability of the product is extremely low

[0018] The horizontal pultrusion mold relies on the fulcrum at one end of the mold to fix the mold, and adjusts the eccentricity of the pultruded product through the fulcrum. In the pultrusion of large-scale FRP products, the mold used is very large. Take the 110kV composite material tower as an example. The

maximum diameter of the tower can reach 1500mm, so the weight of the mold will be very large. In order to ensure that large-size FRP products can be quickly cured and bent in a short time, the curing heating device should be lengthened, and the corresponding pultrusion mold should also be lengthened, so the weight of the mold will be very high. Surprisingly, it is impossible to fix the pultrusion mold by only relying on one end of the mold to pass the

cantilever beam. If the length of the pultrusion mold is shortened, the

heat curing time of the product is not enough, and the product cannot be completely cured

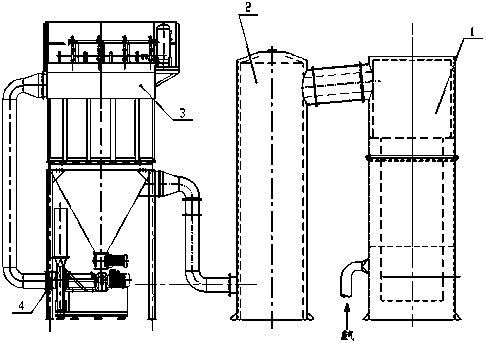

[0019] Although the insulation pole tower

production line of the vertical heavy vertical stretching method can overcome various shortcomings of the horizontal placement process, the waste gas generated in the heating and curing area is not convenient for centralized treatment

Login to View More

Login to View More  Login to View More

Login to View More