Concrete for nuclear power station

A technology for concrete and nuclear power plants, applied in the field of concrete for nuclear power plants and concrete, can solve the problems of high cost, achieve high elastic modulus, reduce delayed ettringite phenomenon, and improve quality and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

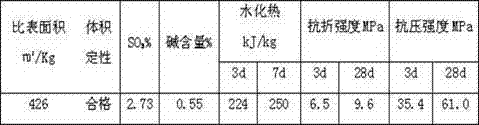

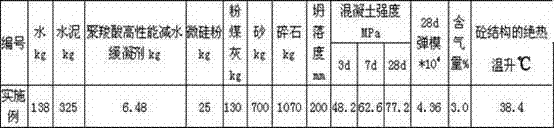

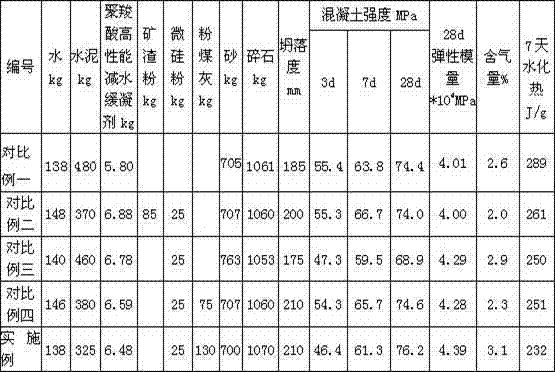

[0036] (1) Comparative test

[0037] Select different admixtures to carry out comparative experiments, and the admixtures are selected as follows:

[0038] 1) pure cement;

[0039] 2) Single doped silicon powder;

[0040] 3) Double mixing (silicon powder and slag powder, silicon powder and fly ash);

[0041] The experimental data are shown in Table 1:

[0042]Table 1 Mixing ratio of comparative test

[0043]

[0044] A large number of mix ratio exploratory tests and raw material comparison tests were carried out for the above schemes with basically the same water-cement ratio. According to the test results, most of the strengths can meet the requirements. Comparative Example 1, the concrete is too sticky, the construction performance is poor, and the heat of hydration If it is too high, comparative example 2 has poor water retention and construction performance, and comparative example 3 has a higher heat of hydration. Considering comprehensive hydration heat, mix ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com