Heat-preserving and fire-proof composite plate with light weight and producing method thereof

A composite board and thermal insulation technology, which is applied to other household appliances, roofs using flat/curved panels, and tools for roofing engineering, etc., can solve the problems of life and property hazards, easy fire, heavy quality, etc., to improve work efficiency, Enhanced closed-cell performance and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

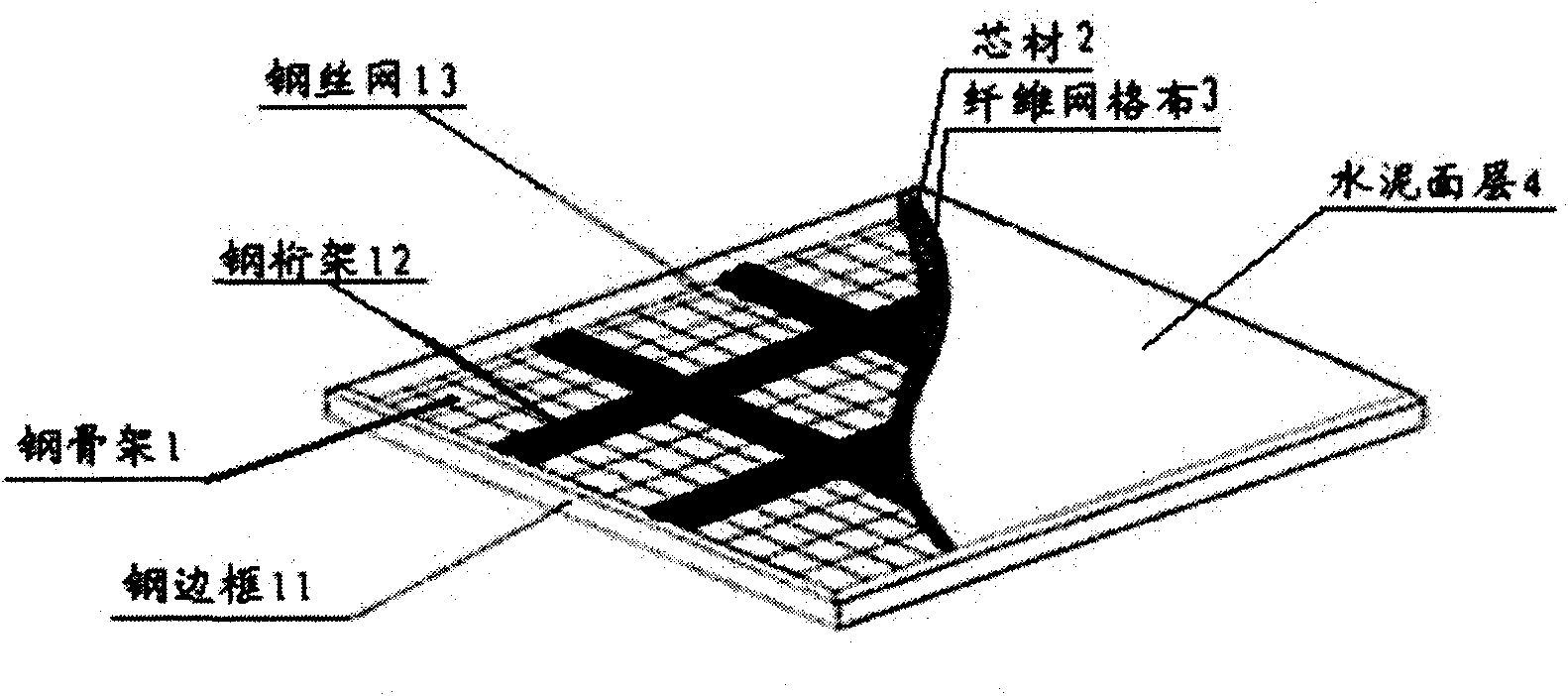

[0029] Use two 6m long (200×70×20×3) C-shaped steel and two 1.5m long (100×50×20×2.5) C-shaped steel to weld the steel frame of the steel skeleton, and weld two layers in it Steel mesh, and then welded 5 U-shaped steel as a steel truss, and put the formed steel skeleton in the mold. Blend and stir 210kg of fast-hardening sulfoaluminate cement and 90kg of fly ash, then add 150kg of water, 6120ml of hydrogen peroxide, 760ml of triethanolamine and 0.76kg of calcium stearate and continue to stir evenly. The core plate is formed by injection molding in the mold of the skeleton. After the core plate is solidified, a layer of fiber mesh cloth is laid on the surface of the core plate, and then a cement surface layer is formed on the outside of the fiber mesh cloth with self-leveling cement, that is, the light weight of the present invention is obtained. Quality insulation and fireproof composite board.

Embodiment 2

[0031] Use two 2.5m long (100×50×20×2.5) C-shaped steel and two 2.5m long (100×50×20×2.5) C-shaped steel to weld the steel frame of the steel skeleton, and weld two A layer of steel mesh, and then welded 4 U-shaped steel as a steel truss, and put the formed steel skeleton in the mold. Blend and stir 120kg of fast-hardening sulfoaluminate cement and 80kg of fly ash, then add 110kg of water, 4250ml of hydrogen peroxide, 530ml of triethanolamine and 0.53kg of calcium stearate and continue to stir evenly. The core board is formed by injection molding in the mold of the skeleton, and a layer of fiber mesh cloth is laid on the surface of the core board after being solidified, and then a cement surface layer is formed on the outside of the fiber mesh cloth with self-leveling cement, that is, the light-weight thermal insulation material of the present invention is obtained. Fireproof composite panels.

Embodiment 3

[0033] Two 5m long (180×60×20×3) C-shaped steels and two 1.2m long (80×40×20×2.5) C-shaped steels are used to weld the steel frame of the steel skeleton, and two layers are welded in it Steel mesh, and then welded 3 U-shaped steel as a steel truss, and put the formed steel skeleton in the mold. Blend and stir 120kg of fast-hardening sulfoaluminate cement and 30kg of fly ash, then add 60kg of water, 3264ml of hydrogen peroxide, 410ml of triethanolamine and 0.41kg of calcium stearate and continue to stir evenly. The core board is formed by injection molding in the mold of the skeleton, and a layer of fiber mesh cloth is laid on the surface of the core board after being solidified, and then a cement surface layer is formed on the outside of the fiber mesh cloth with self-leveling cement, that is, the light-weight thermal insulation material of the present invention is obtained. Fireproof composite panels.

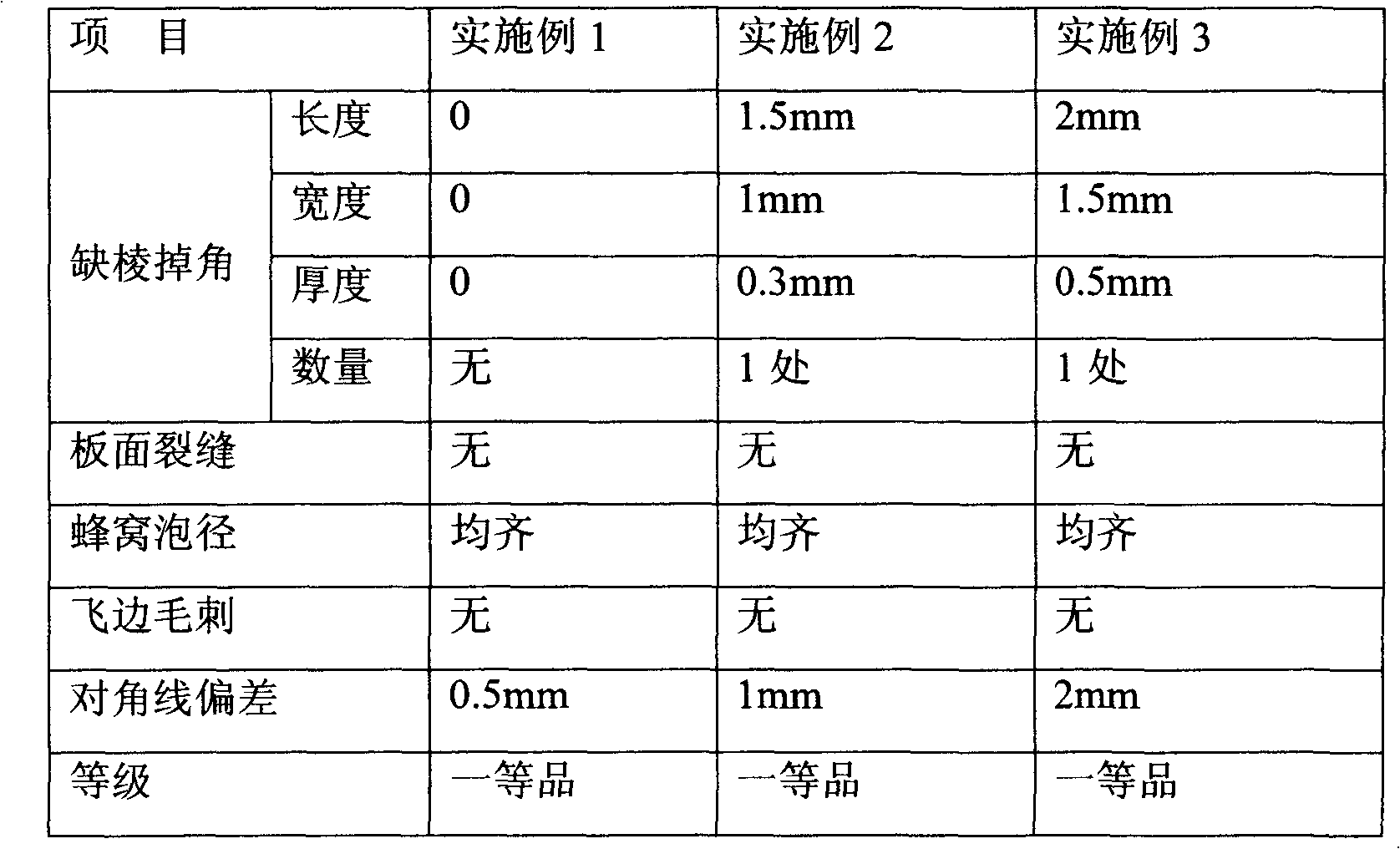

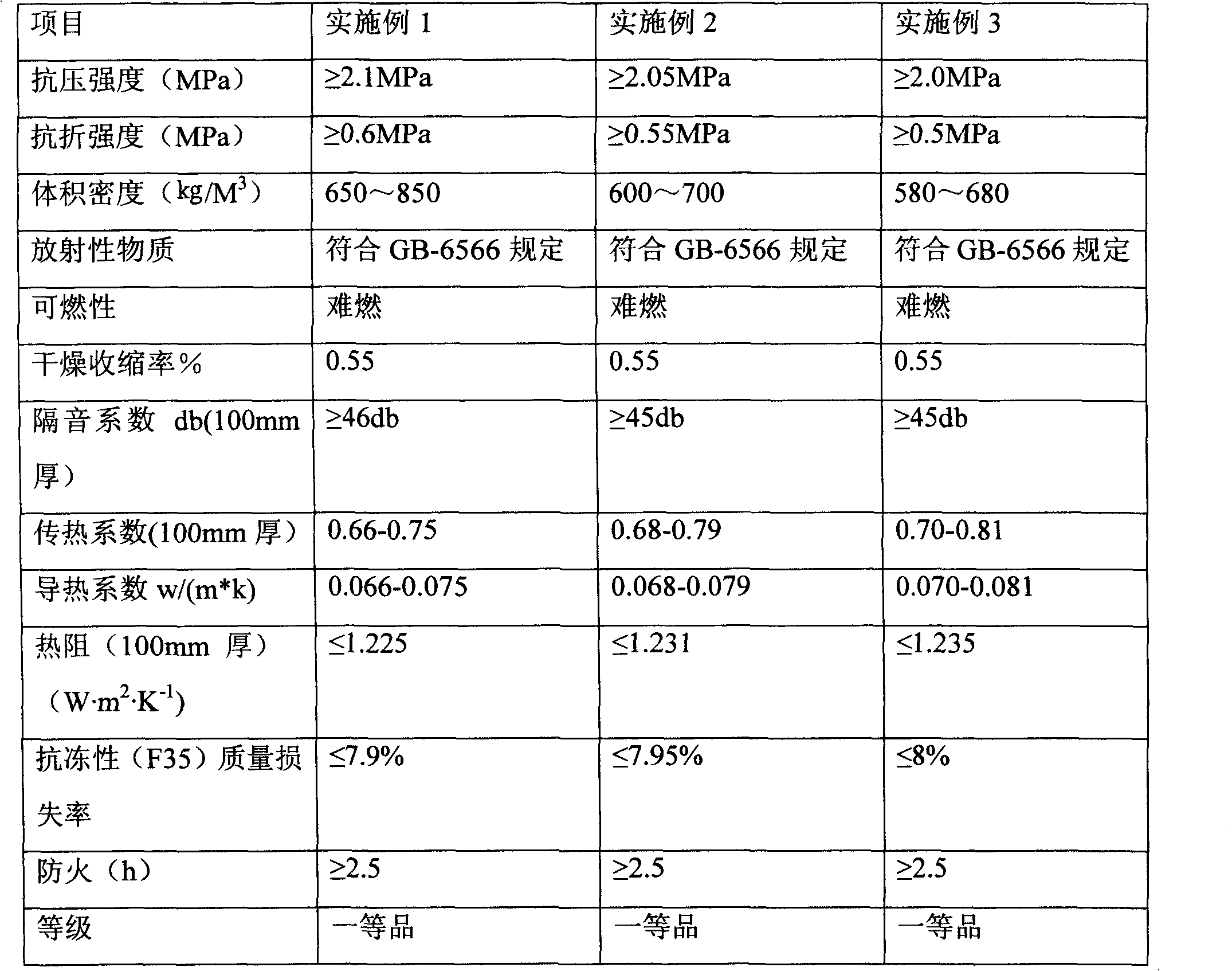

[0034] The appearance quality of the composite panels of Examples 1-3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com