Recycled aggregate surface treating agent and use method thereof

A technology of surface treatment agent and recycled aggregate, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc. Micro-cracks and other problems to achieve the effect of improving interface structure and porosity, increasing strength and reducing water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

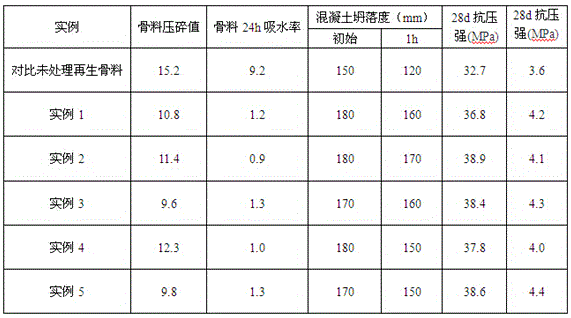

Examples

Embodiment 1

[0031] The ratio of recycled aggregate surface treatment agent is: calcium acrylate 4%, sodium persulfate 0.2%, triethanolamine 0.4%, bisacrylamide 5%, γ-glycidyl etheroxypropyl trimethoxysilane 3%, wood Calcium 0.5%, water 91.85%

[0032] The preparation of recycled aggregate surface agent and the treatment of recycled aggregate include the following process steps:

[0033] 1) Dissolving acrylate in water to obtain an acrylate solution, and then adding persulfate, triethanolamine, and a crosslinking agent to the acrylate solution to obtain an acrylate polymer solution;

[0034] 2) Add wood calcium and silane coupling agent to the acrylate polymer solution and stir for 2-5 minutes to prepare the surface treatment agent;

[0035] 3) Put the recycled aggregate into the surface treatment agent and soak for 5-10 minutes. The liquid level of the surface treatment agent should be slightly higher than the recycled aggregate, then take out the recycled aggregate and let it stand for ...

Embodiment 2

[0039] The ratio of recycled aggregate surface treatment agent is: 4% magnesium acrylate, 0.4% potassium persulfate, 0.2% triethanolamine, 3% butyl acrylate, 3% γ-aminopropyl triethoxysilane, 1% wood calcium, Water 88.4%;

[0040] All the other are with embodiment 1.

Embodiment 3

[0042] The mixing ratio of recycled aggregate surface treatment agent is: 5% calcium acrylate, 0.5% ammonium persulfate, 0.4% triethanolamine, 4% butyl acrylate, 2% acryloyloxysilane, 0.7% wood calcium, 87.4% water %;

[0043] All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com