Composite high titanium and dry slag pavement concrete and preparation method thereof

A high-titanium heavy slag and concrete technology, which is applied in the field of concrete, can solve the problems of limited consumption of blast furnace slag, high utilization cost, and land occupation, and achieve the effects of reducing project cost, reducing self-weight, and rough surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

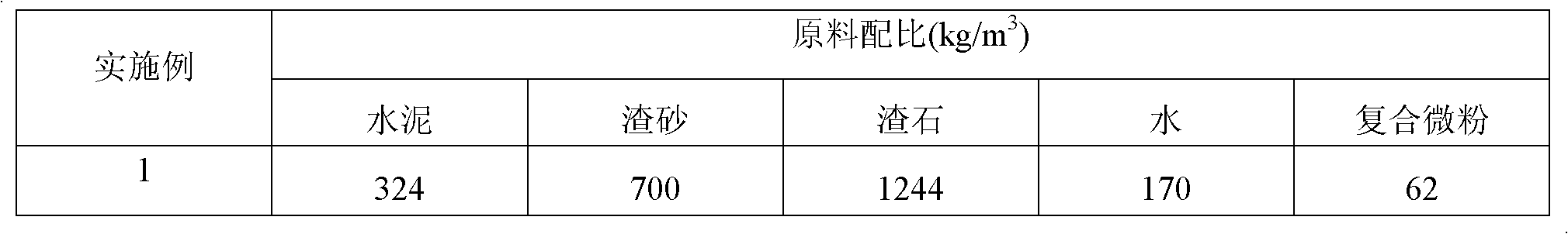

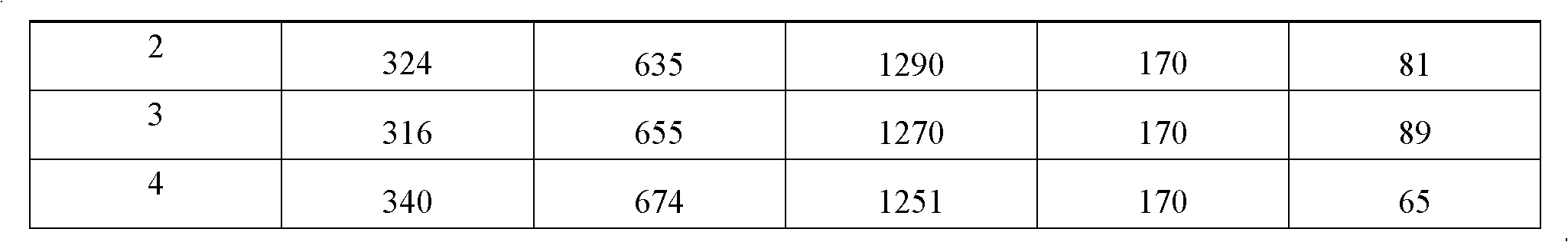

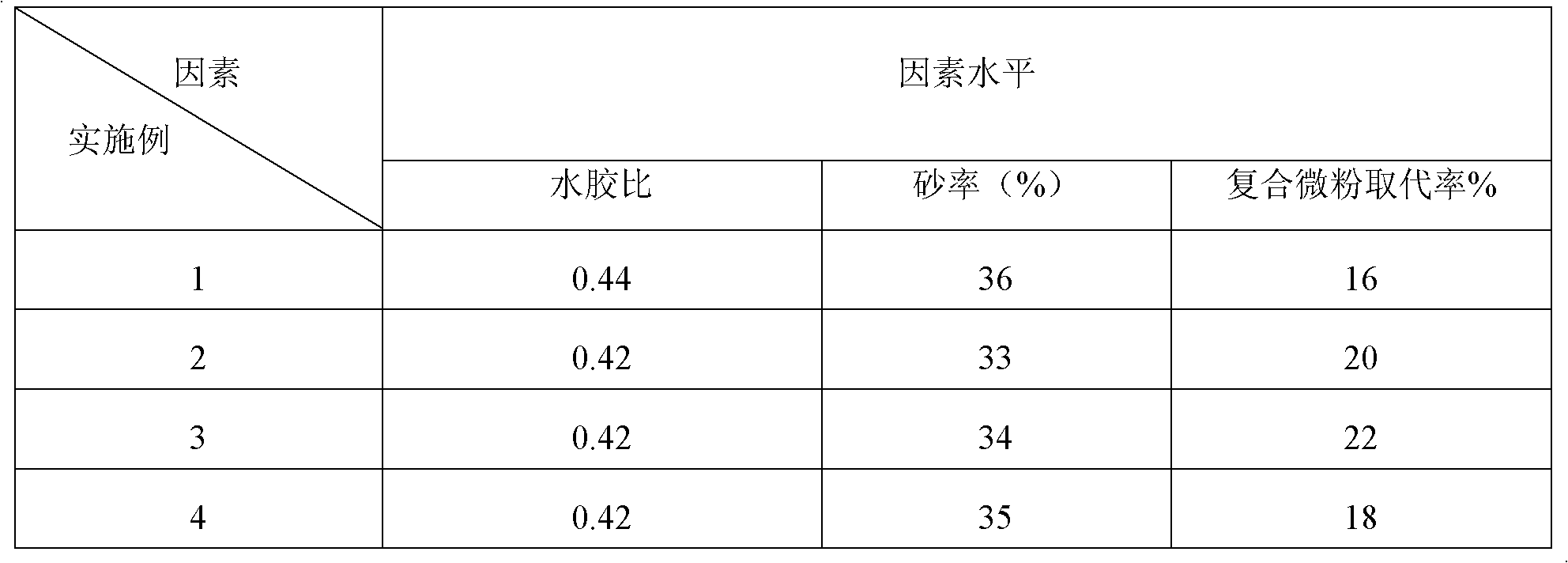

[0023] Adopt the raw material ratio of embodiment 1,2,3,4 described in the following table to obtain complex high-titanium heavy slag pavement concrete, concrete raw material ratio is shown in Table 1, other control factors are shown in Table 2, embodiment 1,2,3 , 4 The specific properties of the complex high-titanium heavy slag concrete obtained are shown in Table 3.

[0024] The concrete method of preparing high-titanium heavy slag pavement concrete in the embodiment of the present invention is:

[0025] A. Pre-wet water treatment of high-titanium heavy slag sand and high-titanium heavy slag rock, so that the moisture content of high-titanium heavy slag rock is 5%, and the moisture content of high-titanium heavy slag sand is 10%.

[0026] B According to the ratio of concrete raw materials obtained per cubic meter, determine the amount of various materials per plate, and the deviation of each plate weighing should comply with the provisions of GB50204 "Construction Quality Ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com