Core structure of lithium ion battery

A lithium-ion battery and cell technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as difficult to control tightness, safety hazards, short circuits, etc., to improve cycle performance and rate discharge performance, and prevent safety hazards , The effect of simple structure and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

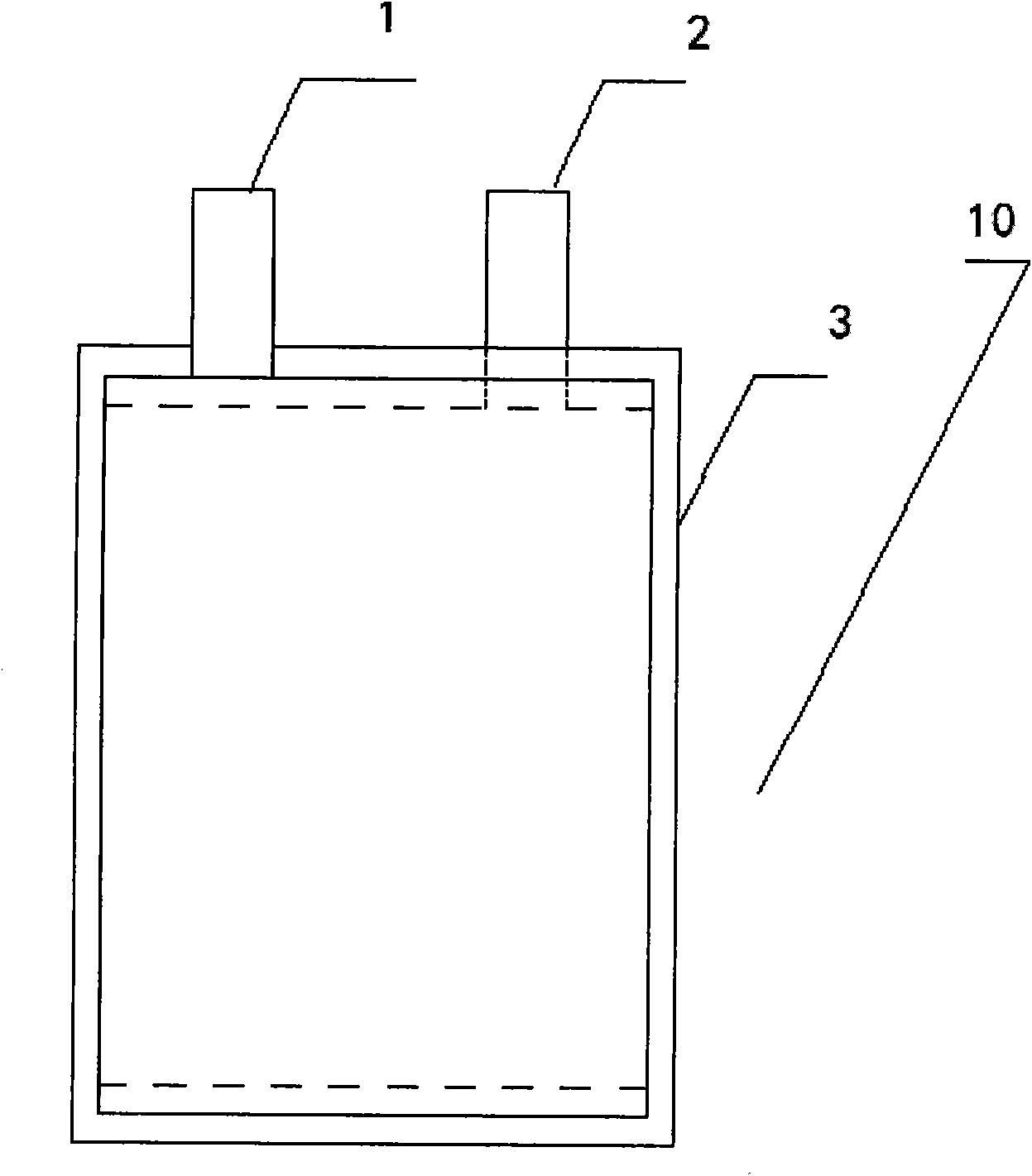

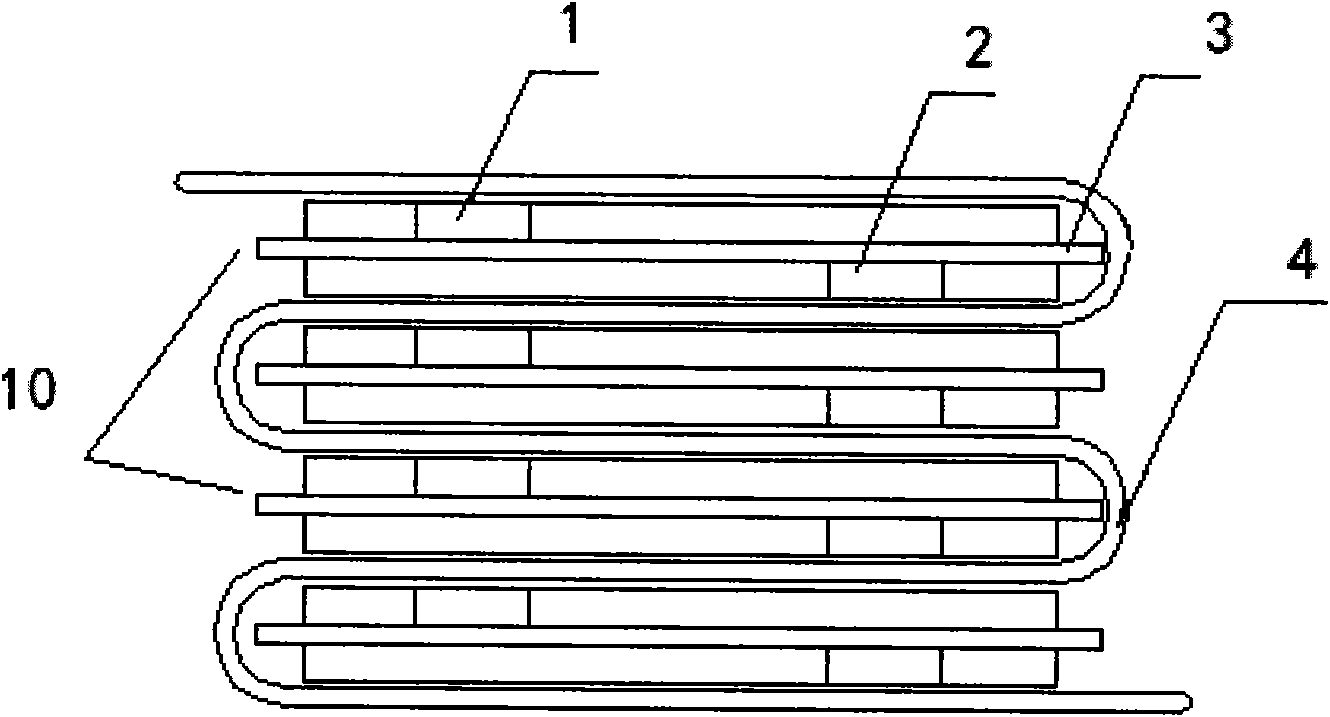

[0026] see figure 1 , 2 , a cell structure of a lithium ion battery, the cell is formed by winding a cell unit 10 by means of a cell separator. The cell unit is made by pressing the square-shaped positive electrode sheet and the negative electrode sheet on both sides of the cell diaphragm 3 correspondingly. Prepare sheet-shaped positive electrode sheets and negative electrode sheets as usual, and make the area of the negative electrode sheet slightly larger than the area of the positive electrode sheet. Divide the diaphragm of the long piece into square monomer diaphragms 3. The length and width of the monomer diaphragm are preferably 1.5mm longer than the length and width of the largest pole piece. The length and width of the pole piece mentioned here do not include the length and width of the pole piece. of the extreme ear part. Then stack and arrange the positive electrode sheet, separator, and negative electrode sheet in order, and make the smaller positive electrod...

Embodiment 2

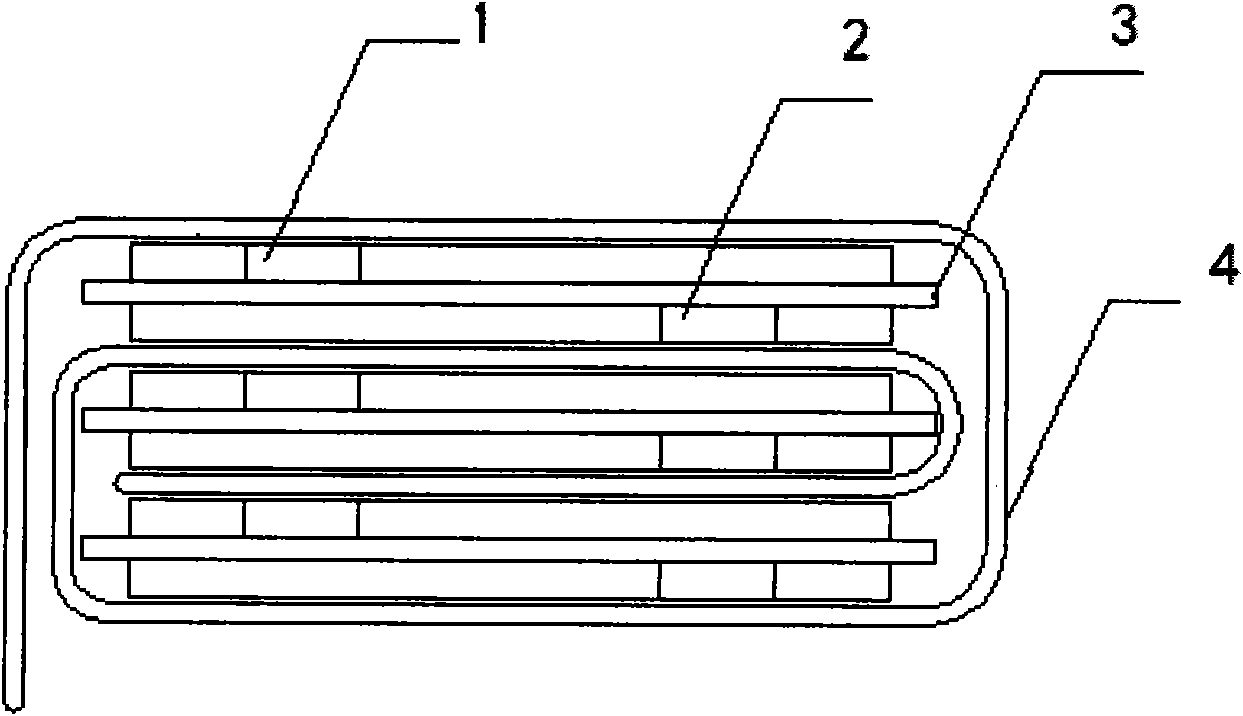

[0031] see image 3 The difference between this embodiment and Embodiment 1 lies in the form in which the elongated cell separator 4 is wound around the cell unit 10 . In this embodiment, the battery cell separator is wound and wrapped one by one in sequence, and is wound layer by layer in the same direction to form a battery cell.

Embodiment 3

[0033] see Figure 4~6 In this embodiment, the cell separator for preparing the cell monomer and the cell separator for winding a plurality of cell cells are integrated. When preparing the cell, first place the two separators in parallel up and down, and then take a negative electrode sheet and a positive electrode sheet and place them on the upper and lower sides of the upper cell separator 41. When placing the positioning, make the positive electrode of the positive electrode sheet The ear 2 is located in the same direction as the negative ear 1 of the negative electrode sheet in the same direction as the upper cell diaphragm, and at the same time, it is ensured that the positive ear and the negative ear are separated on both sides. After placing and positioning the above-mentioned pair of negative electrode sheets and positive electrode sheets, place the second pair at its adjacent position. The positive electrode sheet and negative electrode sheet of the second pair are pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com