QLED device with graphene oxide interfacial layer and preparation method thereof

An interfacial layer and graphene technology, which is applied in semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor devices, etc., can solve problems such as agglomeration or settlement, uneven interface, affecting device performance and luminous uniformity, and achieve passivation Effects of interface defects, improvement of interface structure, and performance improvement of QLED devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

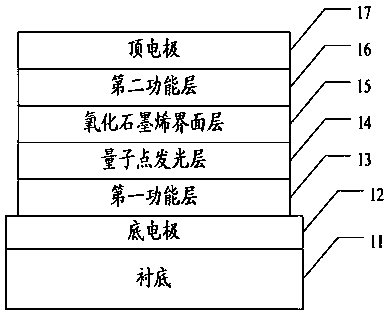

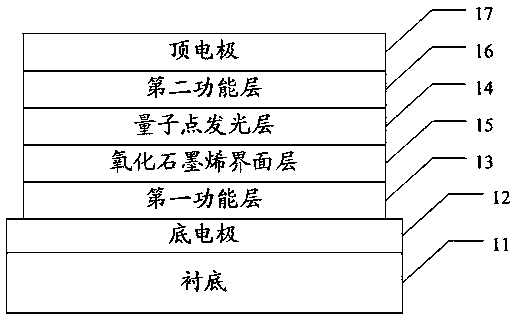

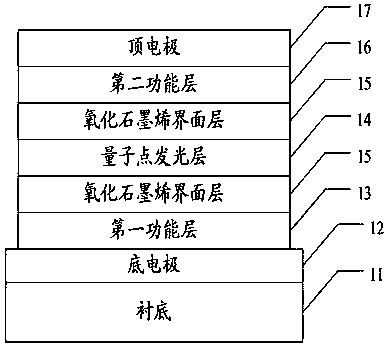

[0063] Based on the above-mentioned QLED device with a graphene oxide interface layer, the present invention also provides a corresponding preparation method for a QLED device with a graphene oxide interface layer, such as Image 6 As shown, it includes the following steps:

[0064] S100, depositing a bottom electrode on the substrate;

[0065] S200, sequentially depositing a first functional layer, a quantum dot light-emitting layer, and a second functional layer on the bottom electrode, wherein, between the first functional layer and the quantum dot light-emitting layer, and / or the quantum dots emit light A functionalized graphene oxide interface layer is also deposited between the layer and the second functional layer;

[0066] S300. Depositing a top electrode on the second functional layer to manufacture a QLED device with a graphene oxide interface layer.

[0067] During specific implementation, the deposition method adopted by the bottom electrode, the top electrode, a...

Embodiment 1

[0072] Spin-coat a layer of PEDOT:PSS film on the ITO conductive glass as a hole injection layer; then spin-coat a layer of TFB layer on the PEDOT:PSS layer; then spin-coat a layer of CdSe / ZnS quantum dot light-emitting layer on the TFB layer; Spin-coat a graphene oxide interface layer on the CdSe / ZnS quantum dot luminescent layer afterwards, wherein, the surface of the graphene oxide layer has a large amount of hydroxyl and carboxyl groups; spin-coat a layer on the above-mentioned graphene oxide interface layer afterwards ZnO layer; and then vapor-depositing a layer of Al cathode layer on the ZnO layer to obtain a quantum dot light-emitting diode.

Embodiment 2

[0074] Spin-coat a layer of PEDOT:PSS film on the ITO conductive glass as a hole injection layer; then spin-coat a layer of TFB layer on the PEDOT:PSS layer; then spin-coat a layer of CdSe / ZnS quantum dot light-emitting layer on the TFB layer; Then on the CdSe / ZnS quantum dot light-emitting layer, spin-coat a layer of graphene oxide interface layer, wherein, the surface of the graphene oxide layer has a large number of hydroxyl groups and mercapto groups; then spin-coat a layer of graphene oxide interface layer on the above-mentioned graphene oxide interface layer An InSnO layer; and then vapor-depositing an Al cathode layer on the InSnO layer to obtain a quantum dot light-emitting diode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com