Non-contact online detection method for chemical milling cutting of large parts

A detection method and large-scale parts technology, applied in the field of laser measurement, can solve the problems of large-scale part boundary detection, low efficiency, and inability to detect parts in real time, and achieve the effect of convenient pose adjustment and high measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings and technical solutions.

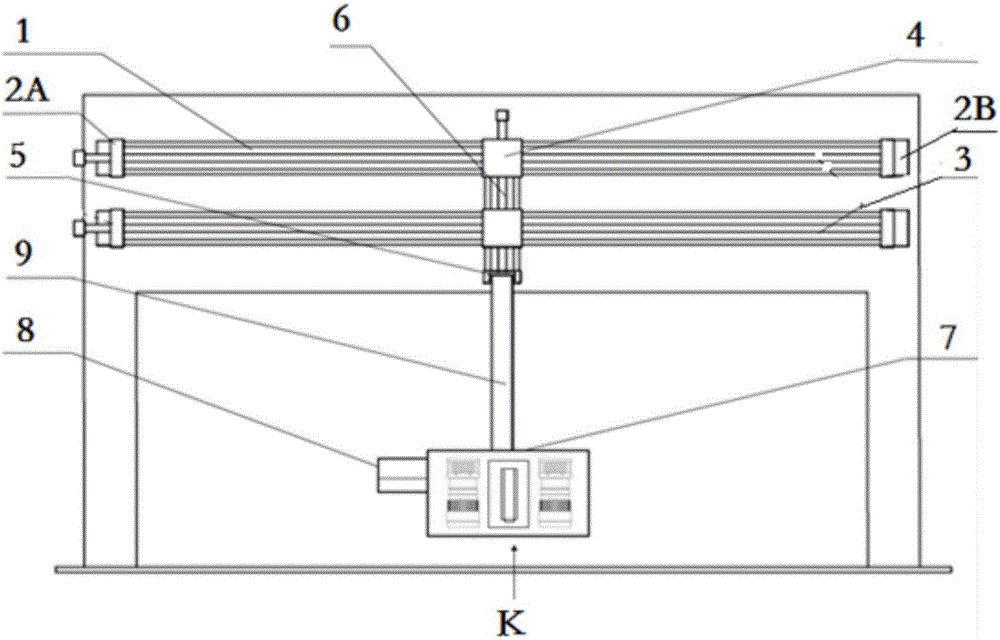

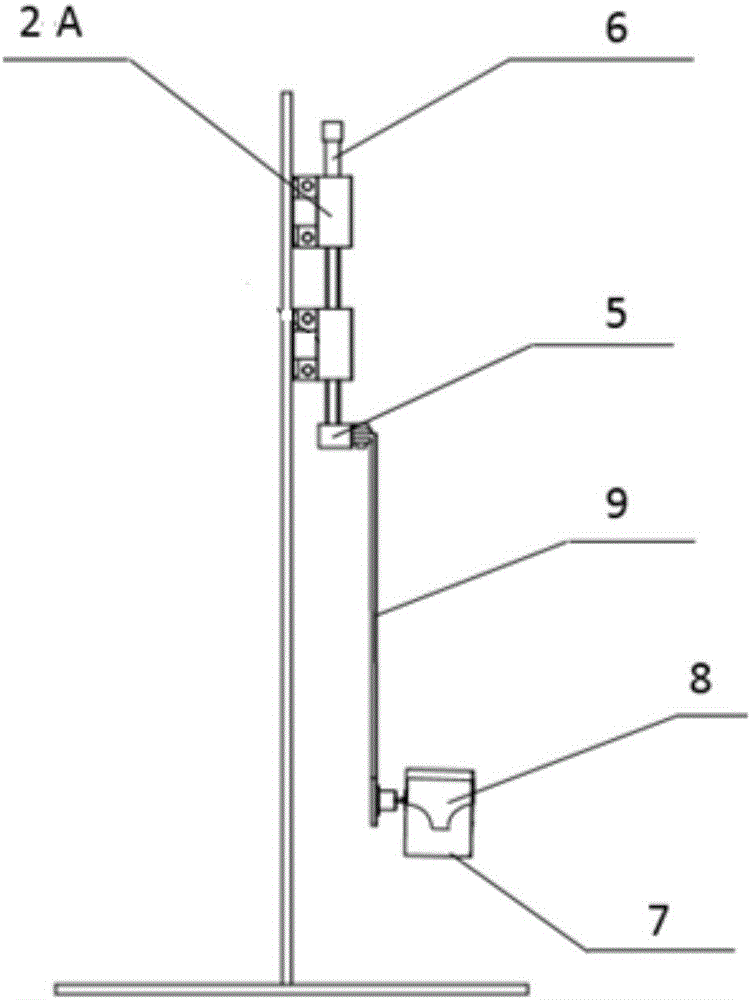

[0038] In this embodiment, the object to be tested is an aluminum sample plate with a flatness of 600*800mm and a flatness of 0.01mm. It has the border left after the milling cut. The laser tracker model is Leica-AT960LR, the T-Mac model is TMC30-B, and two 3-D cameras and a 50mw blue laser are used for detection experiments.

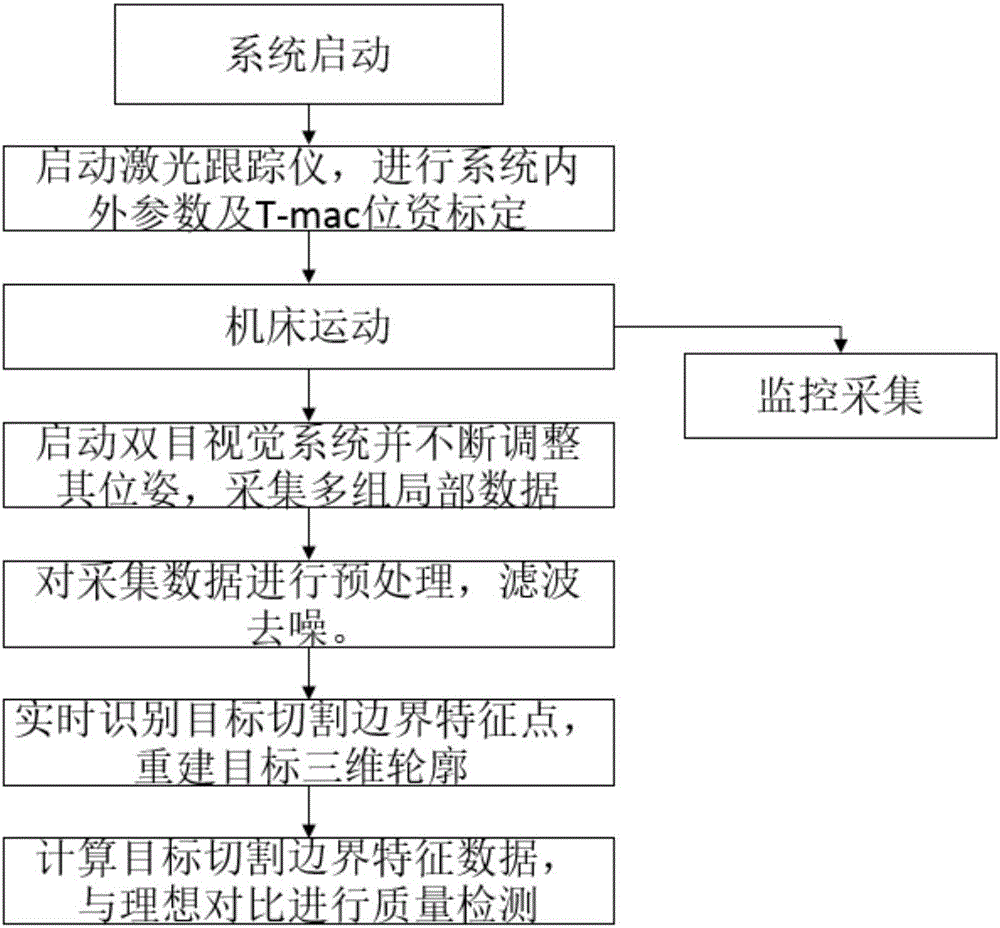

[0039] figure 1 This is the flow chart of the online detection method. The detection method is to hang the binocular vision system on the beam of the machine tool through the horizontal and vertical guide rails, and realize the cutting quality detection of the milling boundary of large aerospace parts by adjusting the pose of the binocular vision system. The specific steps of the method are as follows:

[0040] The first step is to integrate the binocular vision system on the beam of the mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com