Manufacturing method for improving magnetic performance of sintered neodymium-iron-boron magnet

A NdFeB, high magnetic technology, applied in the direction of inductance/transformer/magnet manufacturing, magnetic materials, magnetic objects, etc., can solve the problems affecting the stability of sintered NdFeB magnetic properties, so as to improve the coercive force of magnets and reduce the reaction , Improve the effect of magnetic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

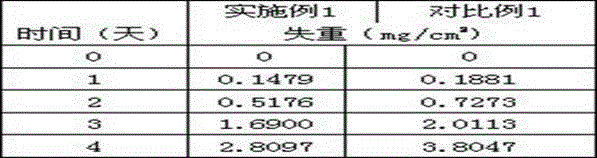

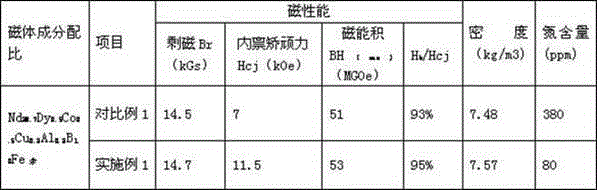

Embodiment 1

[0019] 1) Ingredients: Pure Nd, Co, Cu, Al, Fe and DyFe (Dy: 80wt%, Fe: 20wt%), BFe (B: 20wt%, Fe: 80wt%) according to Nd 28.7 Dy 0.5 co 0.5 Cu 0.2 Al 0.2 B 1.0 Fe 余 Ingredients (percentage by weight) for batching;

[0020] 2) Melting: Melting is carried out by the quick-setting process. During casting, the copper / molybdenum roller speed of the melting furnace is set at 1.6m / s, the casting temperature is 1435°C, and the Ar gas pressure is -0.02~-0.03Mpa negative for casting and cooling. pressure protection;

[0021] 3) Hydrogen crushing: put the above-mentioned cast pieces into a hydrogen crushing furnace for hydrogen crushing, the particle size is controlled to be ≤500μm, the hydrogen content of the powder is ≤800PPm, the discharge of the hydrogen crushing powder is protected by Ar gas, and the pressure of the Ar gas flow is 0.01MPa;

[0022] 4) Powder making: Put the above-mentioned hydrogen broken powder into an airflow mill with an argon gas flow pressure of 0.5-0.7...

Embodiment 2

[0034] 1) Ingredients: PrNd (Nd: 75wt%, Pr: 25wt%), pure Co, Cu, Al, Ga, Fe and BFe (B: 20wt%, Fe: 80wt%) according to Nd 22.5 PR 7.5 co 1.0 Cu 0.2 Al 0.4 Ga 0.2 B 1.0 Fe 余 Ingredients (weight percent) for batching:

[0035] 2) Melting: Melting is carried out by the quick-setting process. During casting, the copper / molybdenum roller speed of the melting furnace is set at 1.4m / s, the casting temperature is 1445°C, and the Ar gas pressure is -0.02~-0.03Mpa negative for casting and cooling. pressure protection;

[0036] 3) Hydrogen crushing: put the above-mentioned cast pieces into a hydrogen crushing furnace for hydrogen crushing, the particle size is controlled to be ≤500μm, the hydrogen content of the powder is ≤800PPm, the discharge of the hydrogen crushing powder is protected by Ar gas, and the pressure of the Ar gas flow is 0.01MPa;

[0037] 4) Powder making: put the above-mentioned hydrogen crushing powder into an airflow mill with an argon flow pressure of 0.5-0.7...

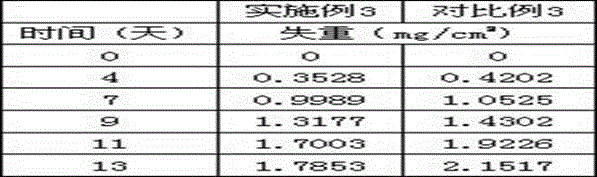

Embodiment 3

[0049] 1) Ingredients: pure Nd, Co, Cu, Al, Fe and DyFe (Dy: 80wt%, Fe: 20 wt%), NbFe (Nb: 20wt%, Fe: 80 wt%), BFe (B: 20wt%) , Fe: 80 wt %) by Nd 27.8 Dy 3.2 co 3.0 Cu 0.2 Al 0.2 Nb 0.1 B 1.02 Fe 余 Ingredients (weight percent) for batching:

[0050] 2) Melting: Put the above-mentioned cast pieces into the hydrogen breaking furnace for hydrogen breaking, and adopt the quick-setting process for melting. When casting, the copper / molybdenum roller speed of the melting furnace is set at 1.2m / s, and the casting temperature is 1450°C. Ar gas pressure is -0.02~-0.03Mpa negative pressure protection for cooling and cooling;

[0051] 3) Hydrogen crushing: put the above-mentioned cast pieces into a hydrogen crushing furnace for hydrogen crushing, the particle size is controlled to be ≤500μm, the hydrogen content of the powder is ≤800PPm, the discharge of the hydrogen crushing powder is protected by Ar gas, and the pressure of the Ar gas flow is 0.01MPa;

[0052] 4) Powder makin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com