Gas-intensive complete equipment for baking tobaccos by biomass charcoal

A gas-intensive, biomass charcoal technology, used in biofuels, lighting and heating equipment, dry gas layout, etc., can solve problems such as air pollution, production efficiency reduction, carbon emissions, etc. Continuous, hot air continuous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

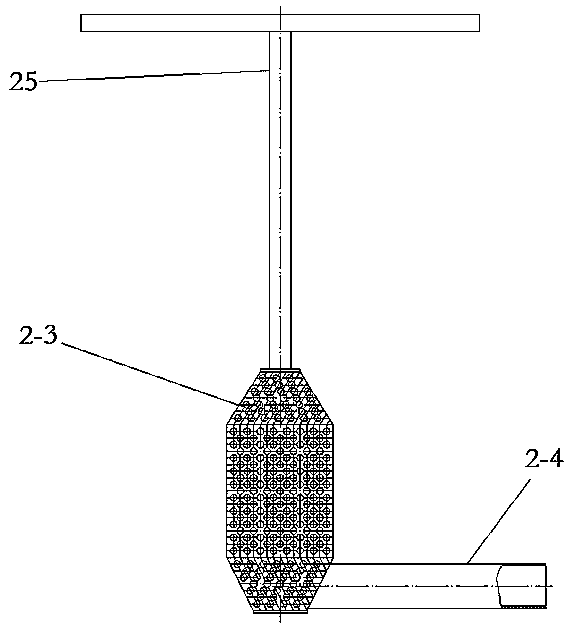

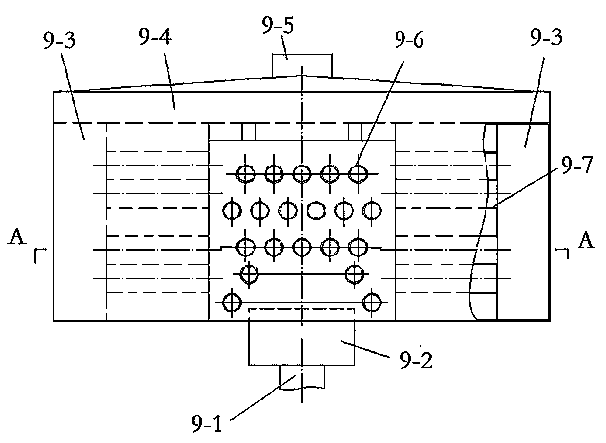

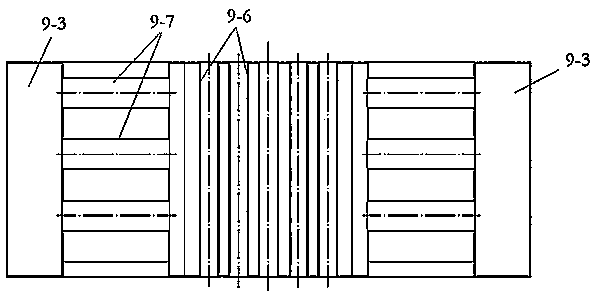

[0026] See figure 1 , The specific content of the present invention is as follows: the carbonized material is tobacco stalk and agricultural and forestry waste, and the specification is 3-5 centimeters. The dryer 21 adopts a J16 dryer, the feed conveyor 16 adopts a 50 belt conveyor, and the feed conveyor 16 transports the material to the inlet of the dryer, and the outlet of the dryer is connected to an XLG type cyclone Type dust collector 19 and induced draft fan 20; the dust particles in the material drying process are processed by the induced draft fan through the XLG cyclone type dust collector. The discharge port of the drying machine is provided with a discharge conveyor 18, and the discharge conveyor 18 adopts a 50 belt conveyor; see figure 1 , 2 , set up two carbonization furnaces 2 dedicated to flue-cured biomass biomass, the tail end of the discharge conveyor of the dryer is connected to the feed port 2-1 of the carbonization furnace 2 dedicated to flue-cured bioma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com