Glass melting furnace and method for melting glass

A technology of glass melting furnace and melting glass, which is applied in glass furnace equipment, glass production, glass manufacturing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] specific implementation plan

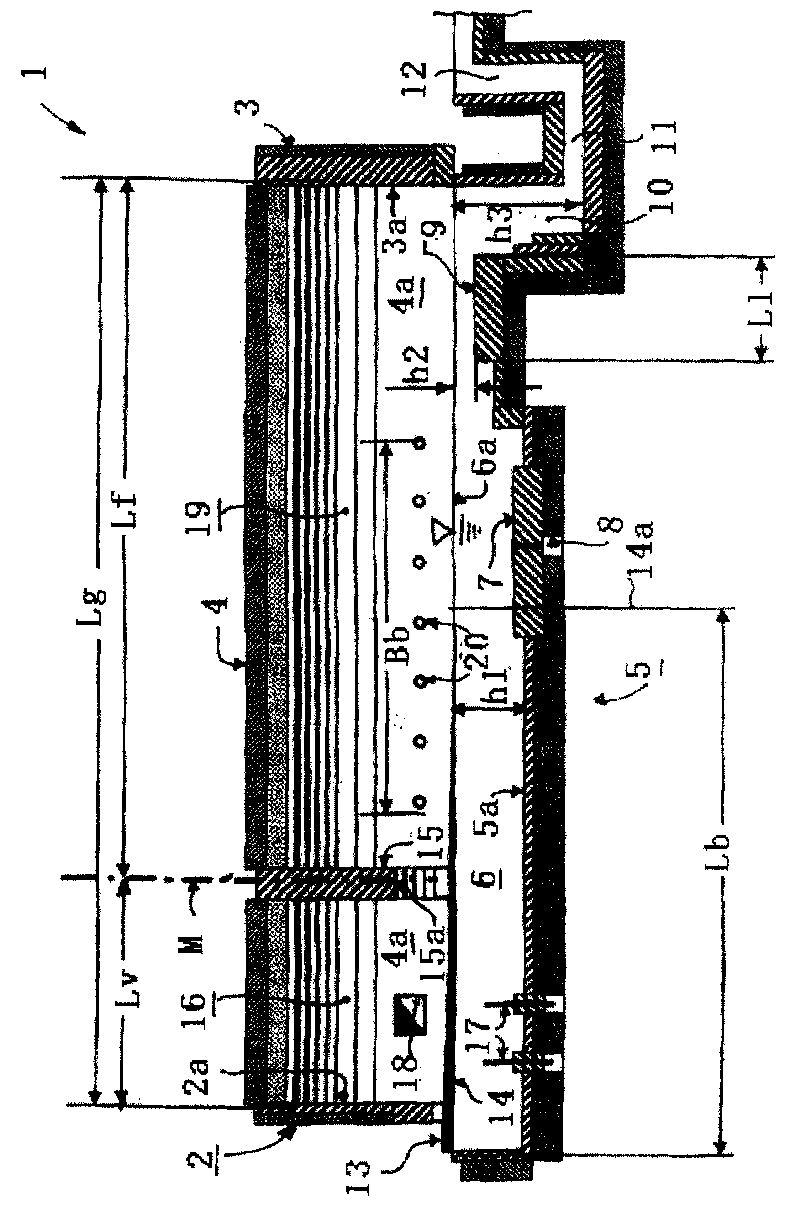

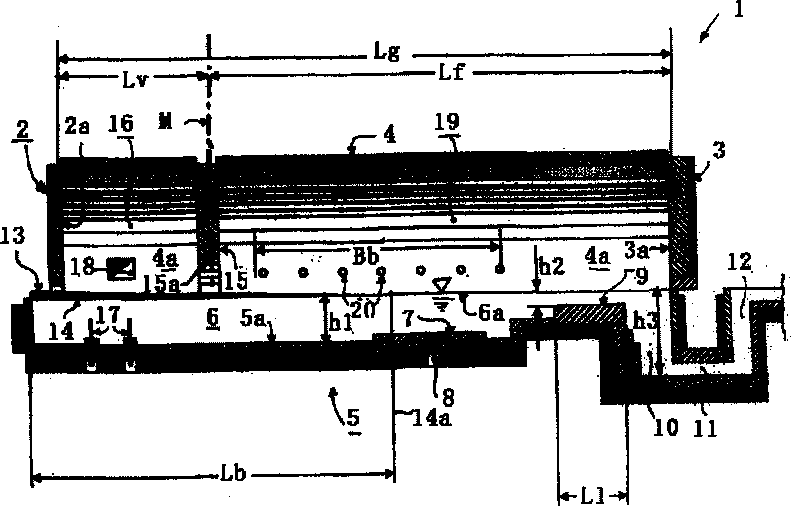

[0043] An exemplary embodiment of the invention and its mode of operation as well as further advantages are explained in more detail below on the basis of a single schematic diagram. This is a longitudinal section through the middle of a glass furnace.

[0044] A top furnace 1 has a first top wall 2 on the feed side and a second top wall 3 on the discharge side, with a vaulted roof 4 in between. The roof 4 has two vertical side walls 4a, which are only visible from behind. Below the top furnace 1 there is a tank 5 for receiving and processing glass melt 6, the melting mirror of which is indicated at 6a. The trough 5 has a trough base 5a on which a pressure plate 7 with a row of water spouts 8 stands upwards. After the platen 7 is pressed, the groove bottom 5a crosses the raised bottom surface 9 in a ladder shape, followed by a homogenization zone 10, a small channel 11 on the bottom surface and a raised channel 12.

[0045] Below the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com