Steel sheet heating method in continuous annealing and continuous annealing facility

A technology of heating method and annealing equipment, applied in lighting and heating equipment, heat treatment equipment, heat treatment furnace, etc., can solve problems such as uneven temperature, and achieve the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

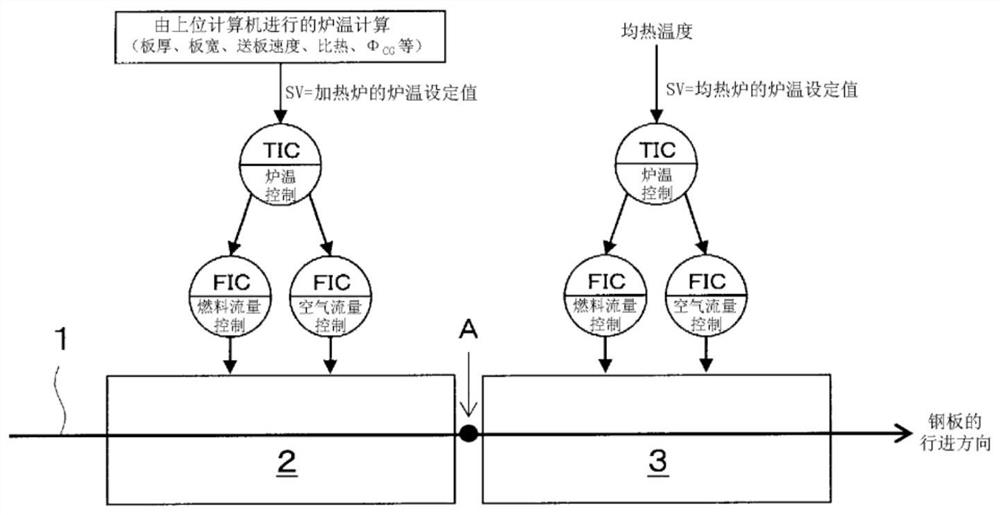

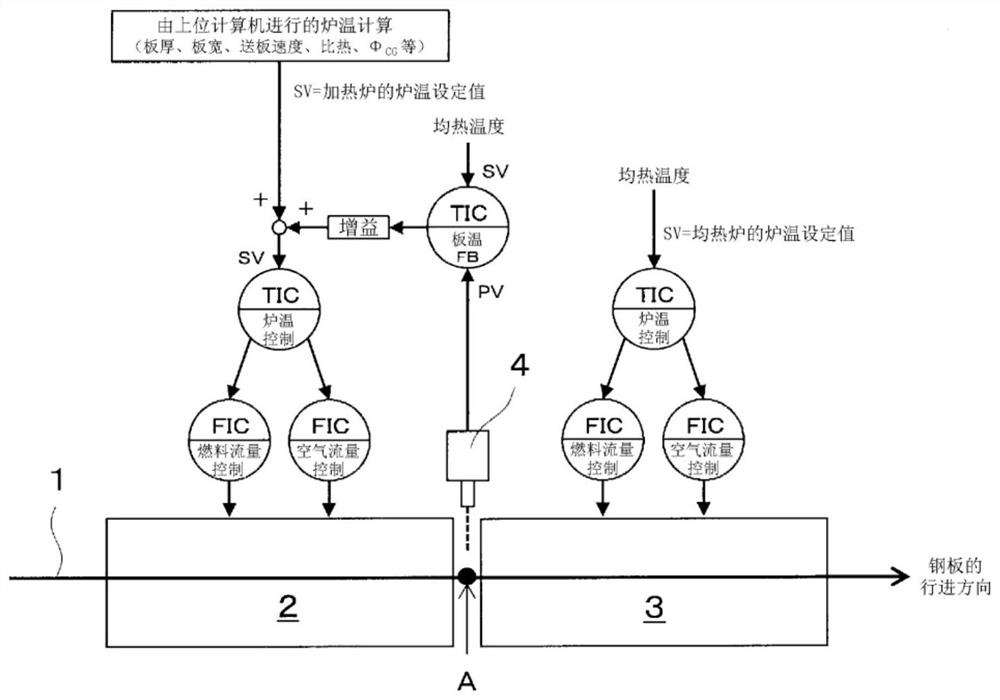

[0048] exist Figure 4 In the continuous annealing equipment shown there is a direct flame heating furnace, a soaking furnace and a cooling furnace, and a direct flame semi-soaking furnace with the function of the present invention is arranged between the above heating furnace and the soaking furnace , the heat treatment which made the soaking temperature into 1000 degreeC was given to the hot-rolled steel plate of plate thickness 2.0mm x plate width 1100mm. In addition, the above-mentioned semi-soaking furnace is a structure in which the second half of the conventional heating furnace is isolated from the front half, and the function of the semi-soaking furnace of the present invention is given. furnace for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com