Thermomechanical treatment equipment and process method thereof

A deformation heat treatment and process method technology, applied in heat treatment equipment, heat treatment furnaces, manufacturing tools, etc., can solve the problems affecting the fatigue life and tensile strength of coiled tubing, fractures or grooves, coarse grains, etc., and achieve process control visualization. , The effect of eliminating residual stress and improving hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

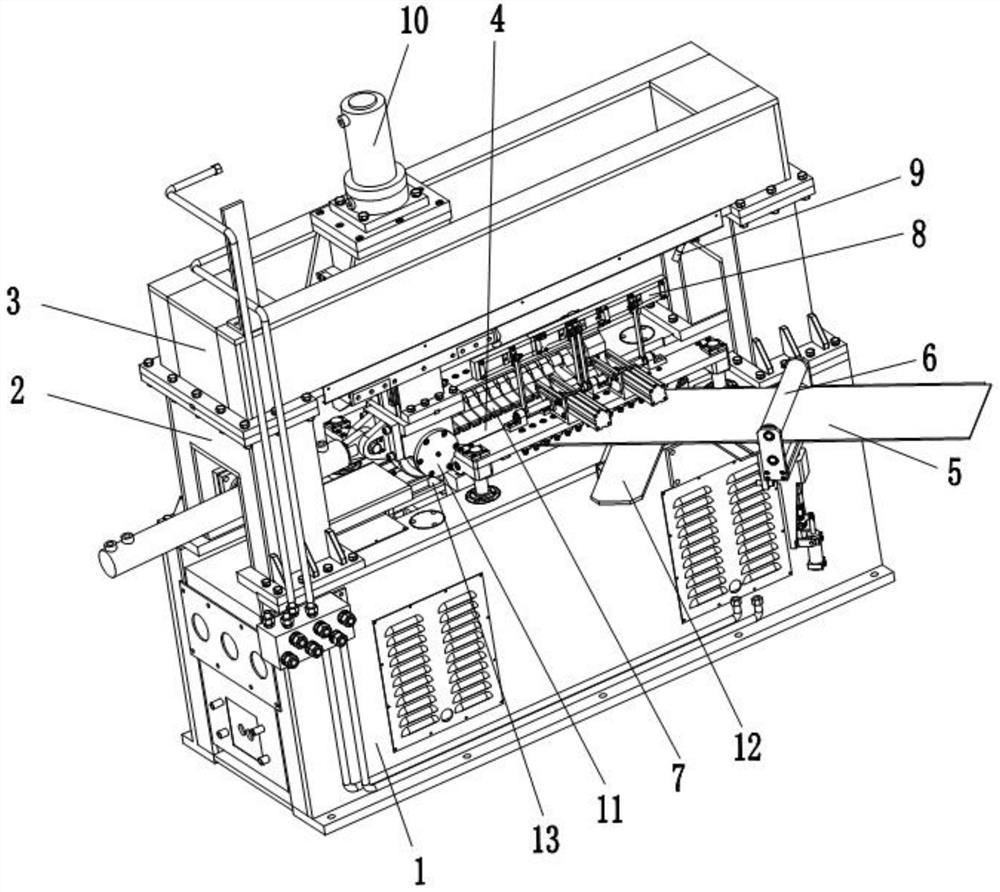

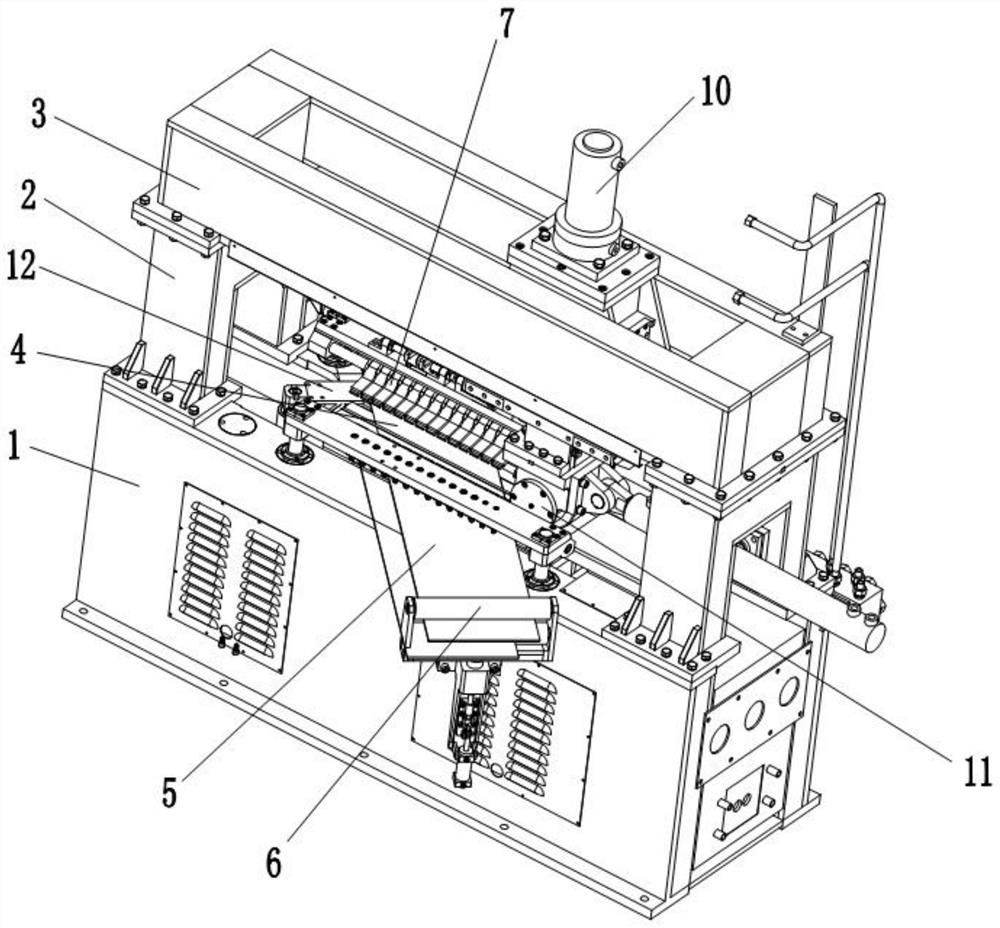

[0027] like figure 1 , figure 2 As shown, a deformation heat treatment equipment includes a body 1, a frame body 2 and a top seat 3, the top seat 3 is connected to the top of the body 1 through the frame body 2, and the upper surface of the body 1 is provided with a processing position 4. A steel belt 5 is placed at the processing position 4, and the steel belt 5 is guided into the processing position 4 by the steel belt guide wheel 6, and the two sides of the processing position 4 can be raised and lowered and symmetrically provided with a steel belt pressing device 7. The upper holding device 7 of the steel strip can press down and clamp the two ends of the steel strip 5, and one side of the processing position 4 is provided with a weld seam protection device that can be buckled on the steel strip 5 8 and the lower backing plate 12 that can move to the bottom of the steel belt 5, the lower heating intermediate frequency probe 13 is set under the processing position 4, and ...

Embodiment 2

[0041] A deformation heat treatment process method, comprising the following steps:

[0042] Step 1, aligning the welding seam of the steel strip 5 and the lower heating intermediate frequency probe 13 through the laser on the top seat 3;

[0043] Step 2, the steel strip upper holding device 7 presses and clamps the two ends of the steel strip 5 to prevent the steel strip 5 from moving;

[0044] Step 3, turn and buckle the weld seam protection device 8 onto the weld seam, and heat at a heating temperature of 700°C-800°C, and keep warm for 8s-15s;

[0045]Step 4, turn the weld protection device 8 away from the weld, lift the upper holding device 7 and the steel belt 5 on the steel belt, put it under the steel belt 5 and move it into the lower backing plate 12, then put down the steel belt 5, and the upper holding device on the steel belt 7 Fix the steel belt 5 downwards, the driving cylinder drives the rolling wheels of the rolling head 11 to move back and forth, and then the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com