Ferro-nickel thin-membrane and its preparation

A film and nickel-iron technology, applied in the field of nickel-iron film and its preparation, can solve the problems of difficult ratio control, poor stability of the preparation process and the like, and achieve the effects of easy temperature control, simple method and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

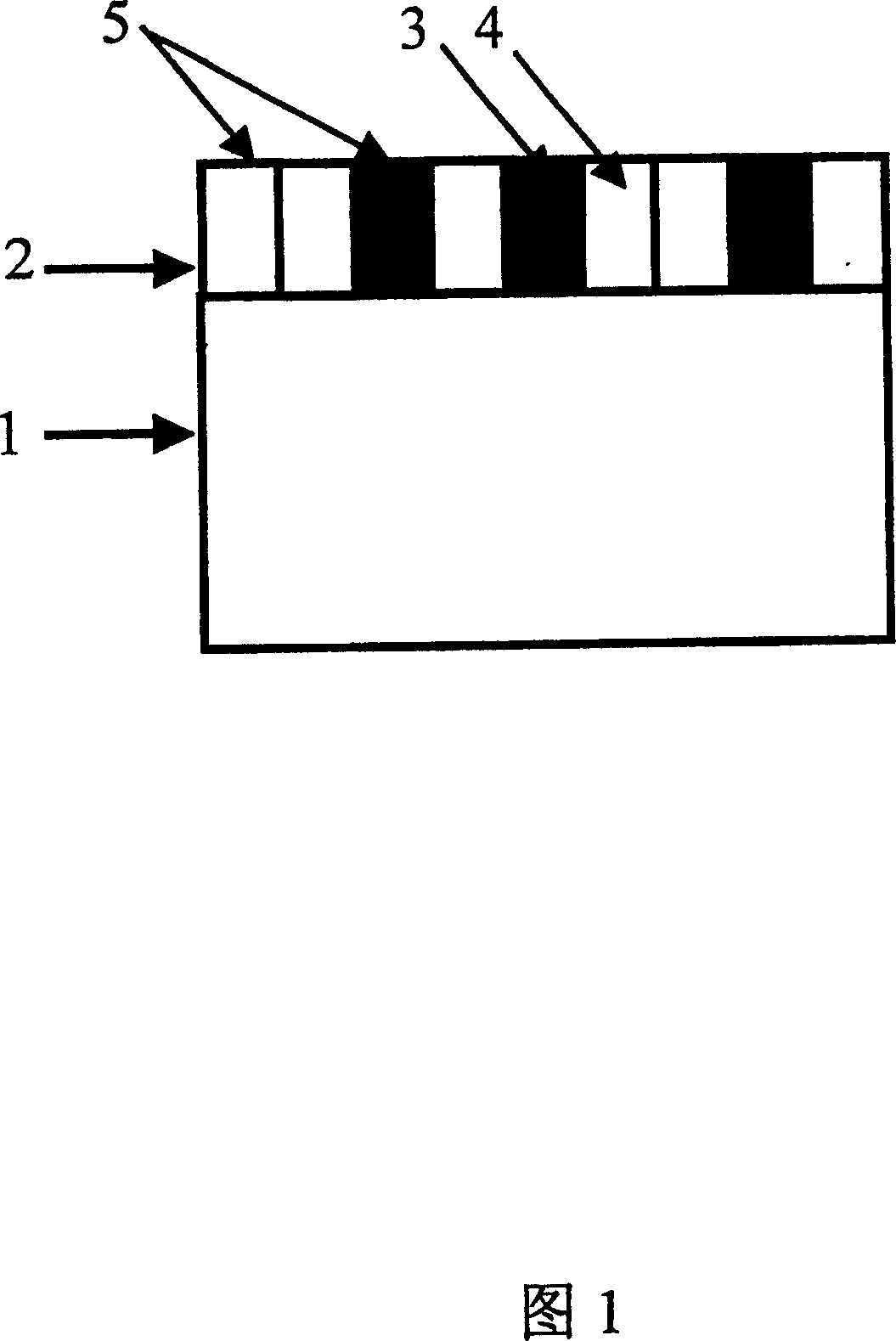

Image

Examples

Embodiment 1

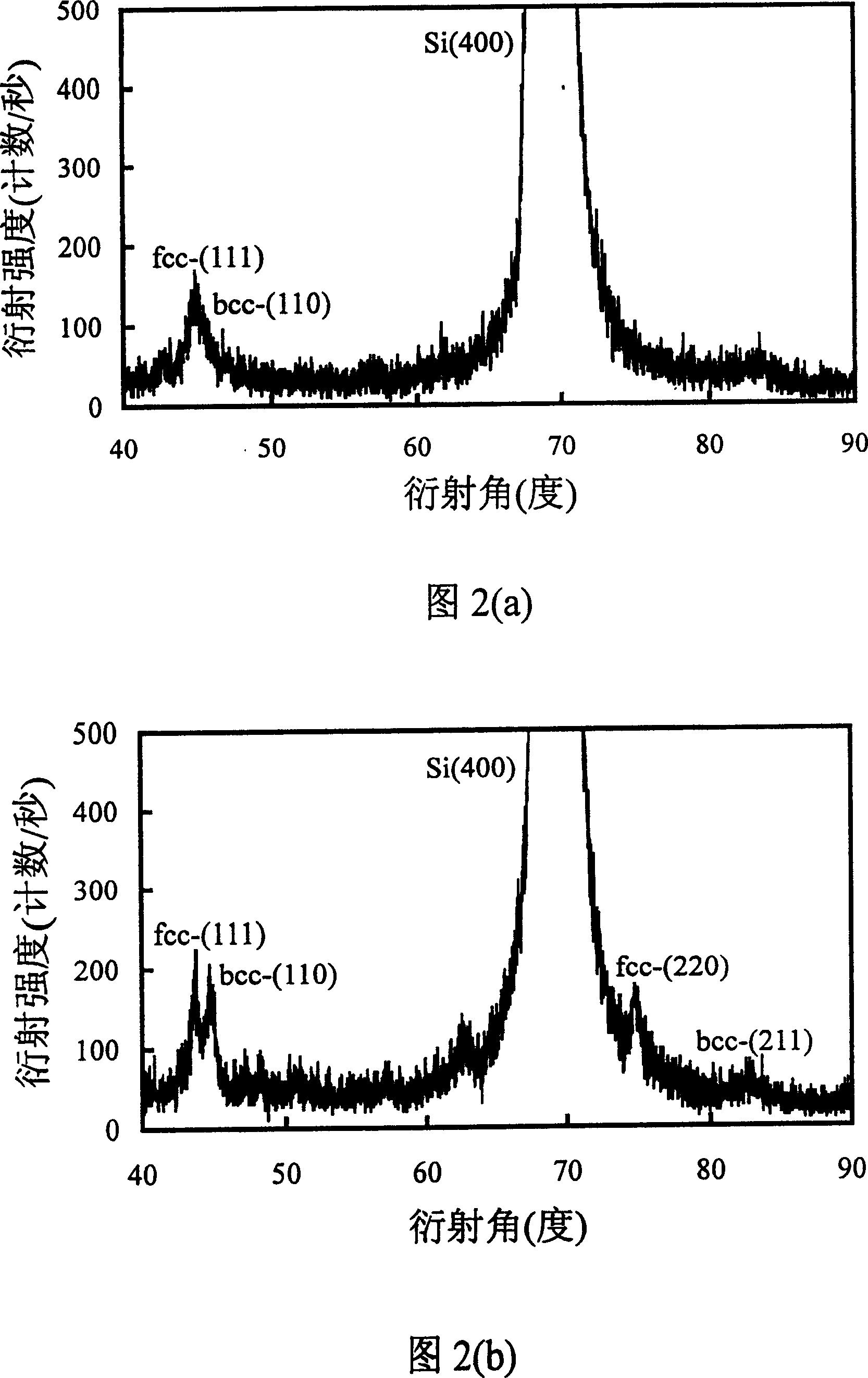

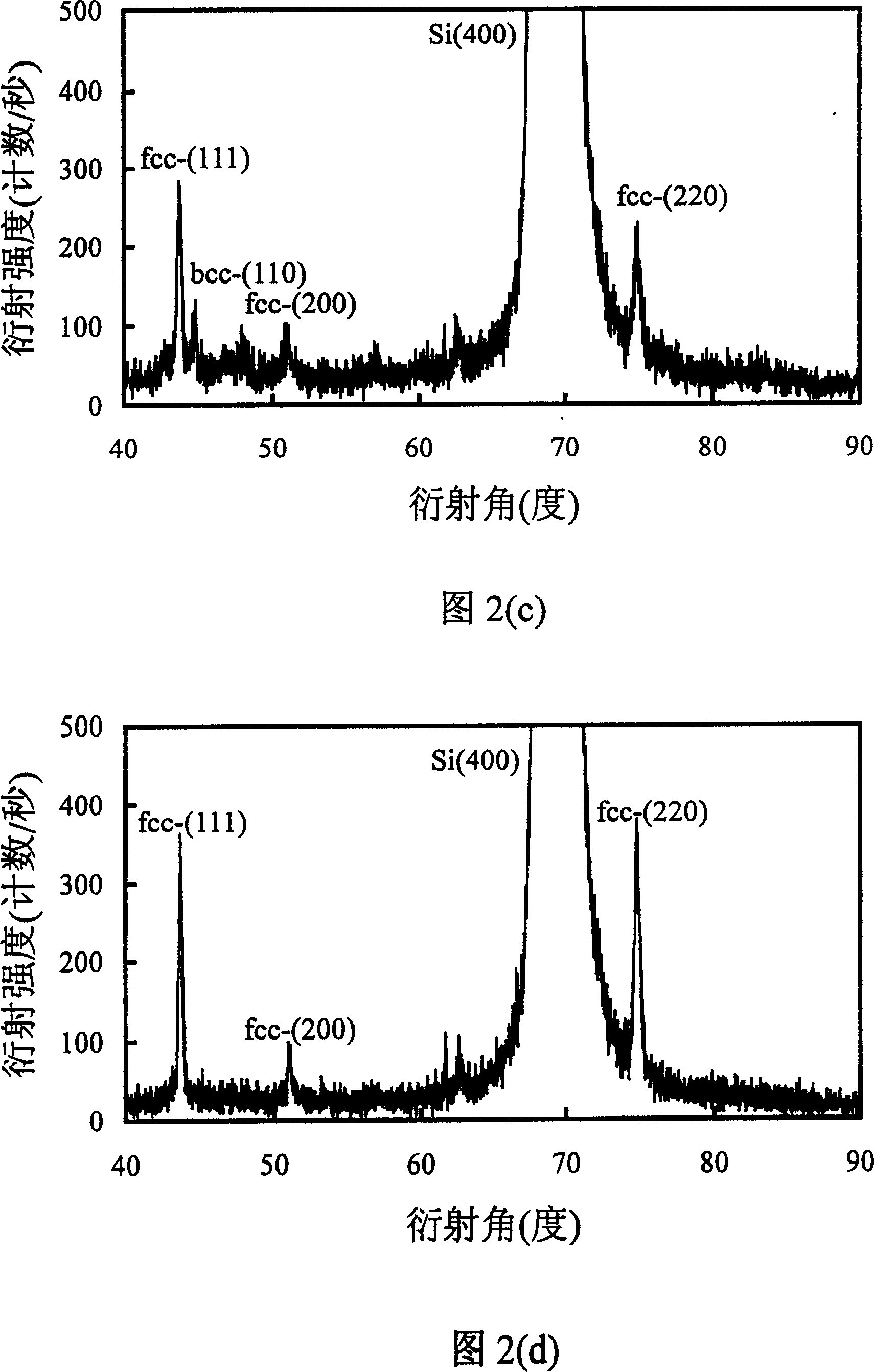

[0018] The Si substrate with thermally oxidized silicon dioxide with a diameter of 50 mm was ultrasonically cleaned in the order of acetone, deionized water and ethanol, and the cleaned substrate was dried with hot air at 60°C. Put the substrate into the coating chamber of the magnetron sputtering coating machine, pump the coating chamber to 1×10 -4 Vacuum in Pascal (Pa). Then, with a double-slope target (Ni 80 Fe 20 target and Fe target) DC plasma magnetron sputtering coater to deposit about 200 nm thick Ni 33 Fe 67 film. The deposition conditions are: argon pressure 1.2 Pascal (Pa), Ni 80 Fe 20 The sputtering power of the target was 84 watts (W), the sputtering power of the Fe target was 173 watts (W), the substrate temperature was 40°C, and the distance from the substrate to each target was 100 mm. Film thickness can be controlled by adjusting the deposition time.

Embodiment 2

[0020] A 50 mm diameter Si substrate with thermally oxidized silicon dioxide was ultrasonically cleaned in the order of acetone, deionized water and ethanol, and the cleaned substrate was dried with hot air at 60°C. Put the substrate into the coating chamber of the magnetron sputtering coating machine, pump the coating chamber to 1×10 -4 Vacuum in Pascal (Pa). Then, with a double-slope target (Ni 80 Fe 20 target and Fe target) DC plasma magnetron sputtering coater to deposit about 200 nm thick Ni 21 Fe 79 film. The deposition conditions are: argon pressure 1.2 Pascal (Pa), Ni 80 Fe 20 The sputtering power of the target was 42 watts (W), the sputtering power of the Fe target was 173 watts (W), the substrate temperature was 40°C, and the distance from the substrate to each target was 100 mm. Film thickness can be controlled by adjusting the deposition time.

[0021] Ni in vacuum 21 Fe 79 film and Ni 33 Fe 67 Film heat treatment, heat treatment conditions: vacuum 4 × ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com