Device for maintaining water level of smoke-impact water spinning type LNG (Liquefied Natural Gas) heating gasification furnace

A gasification furnace, water-type technology, applied in the field of equipment for maintaining the water level of the flue gas impacting water-swirling LNG heating gasifier, which can solve the impact damage of flue gas and affect the normal operation of the flue gas impacting water-swirling LNG heating gasifier Operation and other problems to achieve the effect of reducing flue gas temperature, ensuring normal and safe operation, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings.

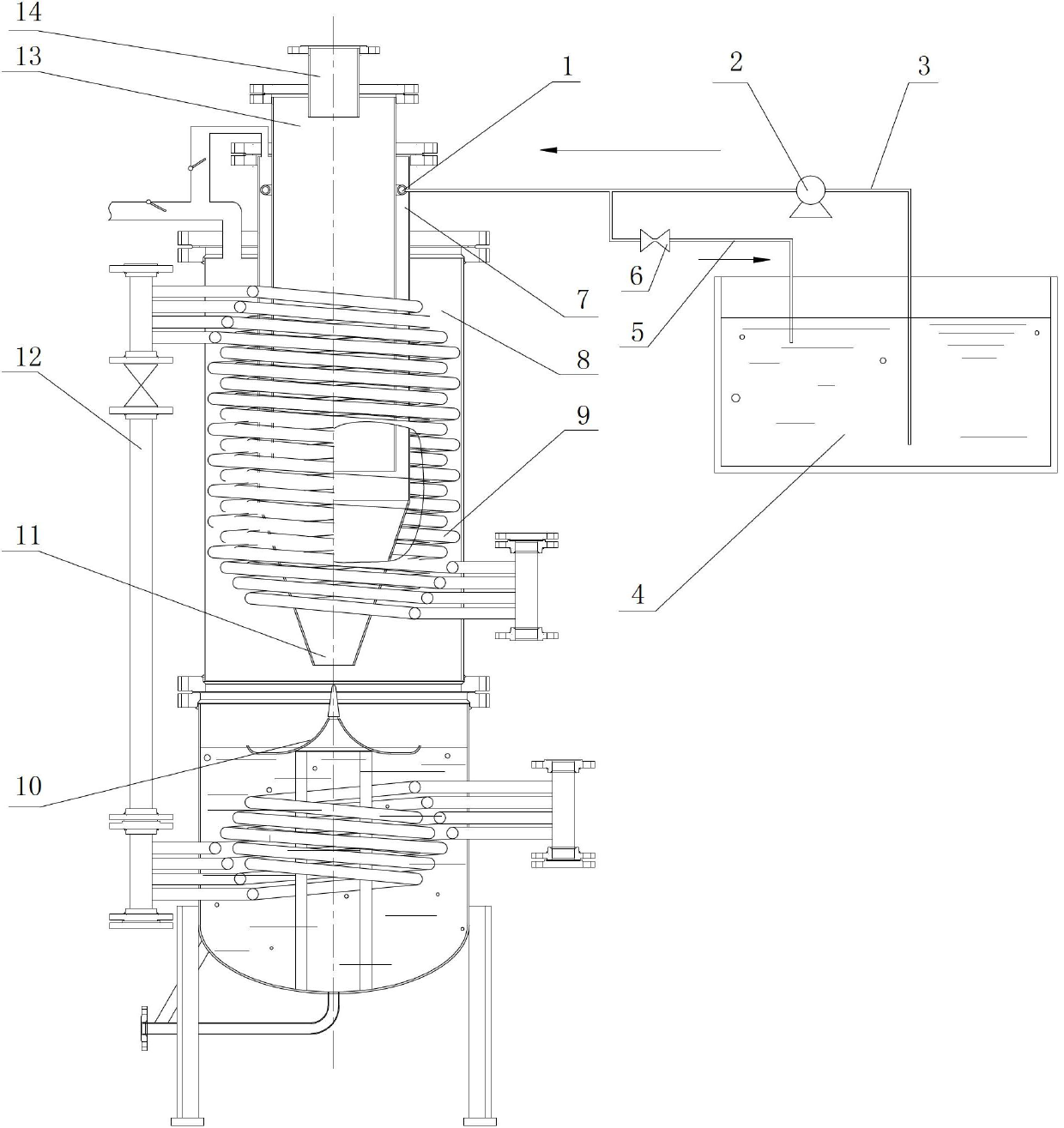

[0039] A device for maintaining the water level of the flue gas impinging hydrocyclone type LNG heating gasifier:

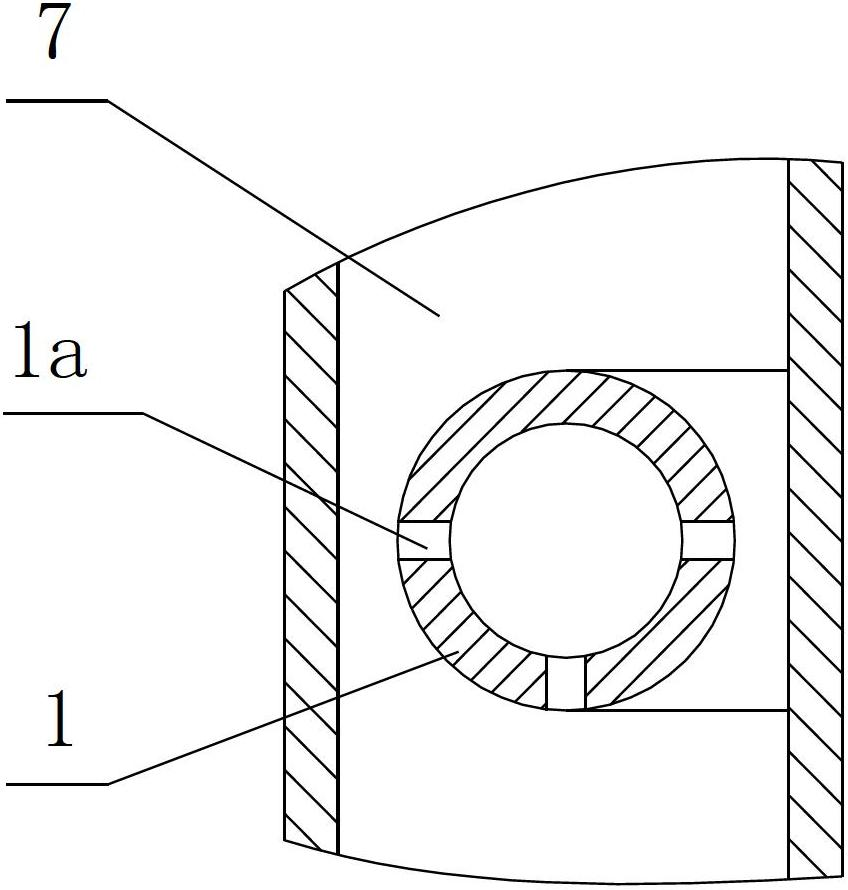

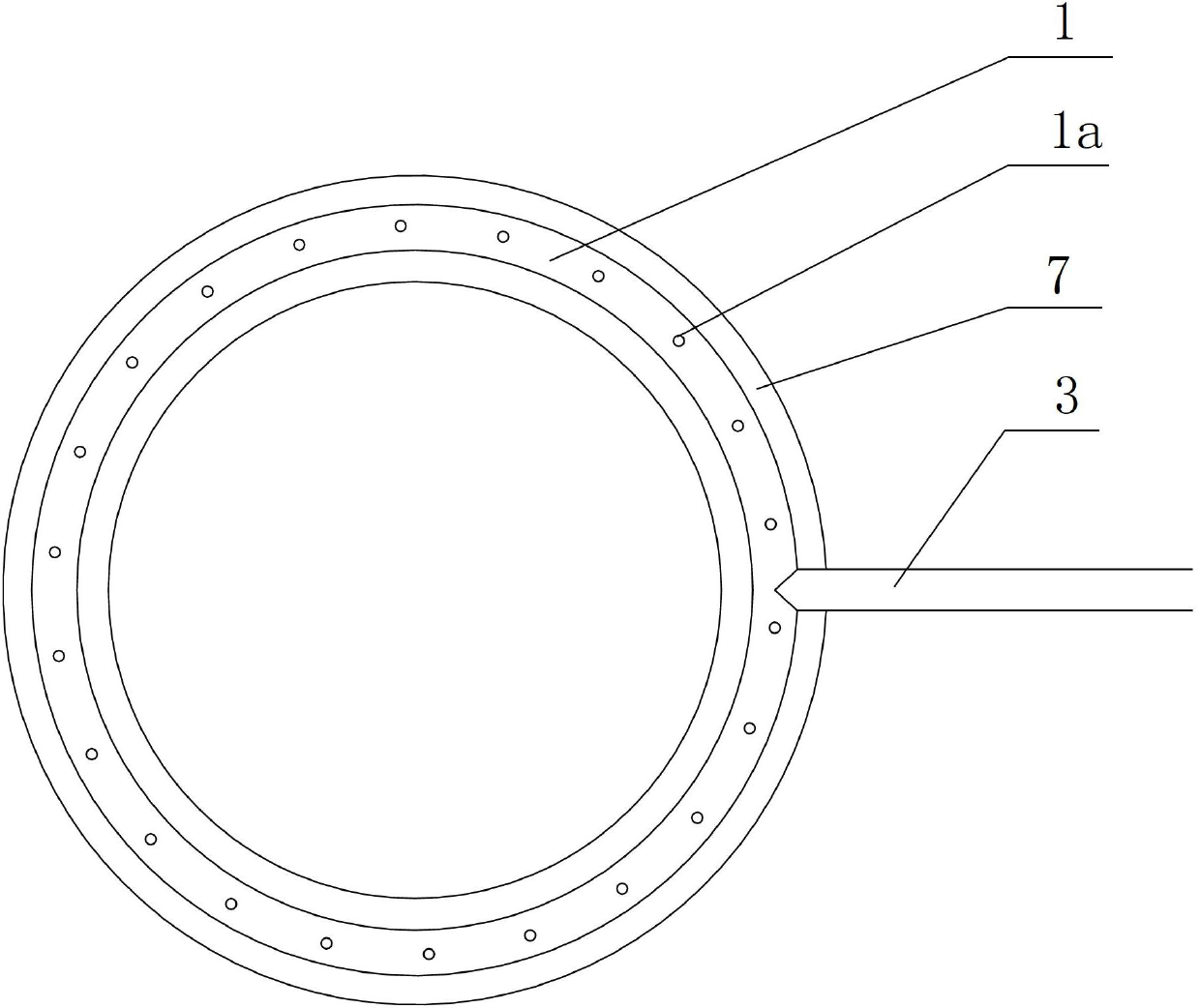

[0040] On the top of the vertical combustion chamber jacket 7 composed of inner and outer cylinders, an annular pipe ring 1 is arranged horizontally, and a plurality of water replenishment holes 1a are opened on the peripheral wall of the annular pipe ring 1; the annular pipe ring 1 is connected to the water tank 4 through the water inlet pipe 3 , the water supply power pump 2 is arranged on the water inlet pipe 3 road.

[0041] The bypass pipe 5 controlled and connected by the regulating valve 6 is connected on the 3 sections of the water inlet pipe between the annular pipe ring 1 and the water pump 2 , and the other end of the bypass pipe 5 is a water return port, which is connected to the water tank 4 . When the water intake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com