Method for adjusting wall temperature of opposed firing boiler after low-load milling stop

An adjustment method and hedging combustion technology, which is applied in the direction of combustion method, combustion chamber, and controlled combustion, can solve problems such as wall temperature rise, and achieve the effects of not avoiding overheating, fast adjustment speed, and preventing overheating problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

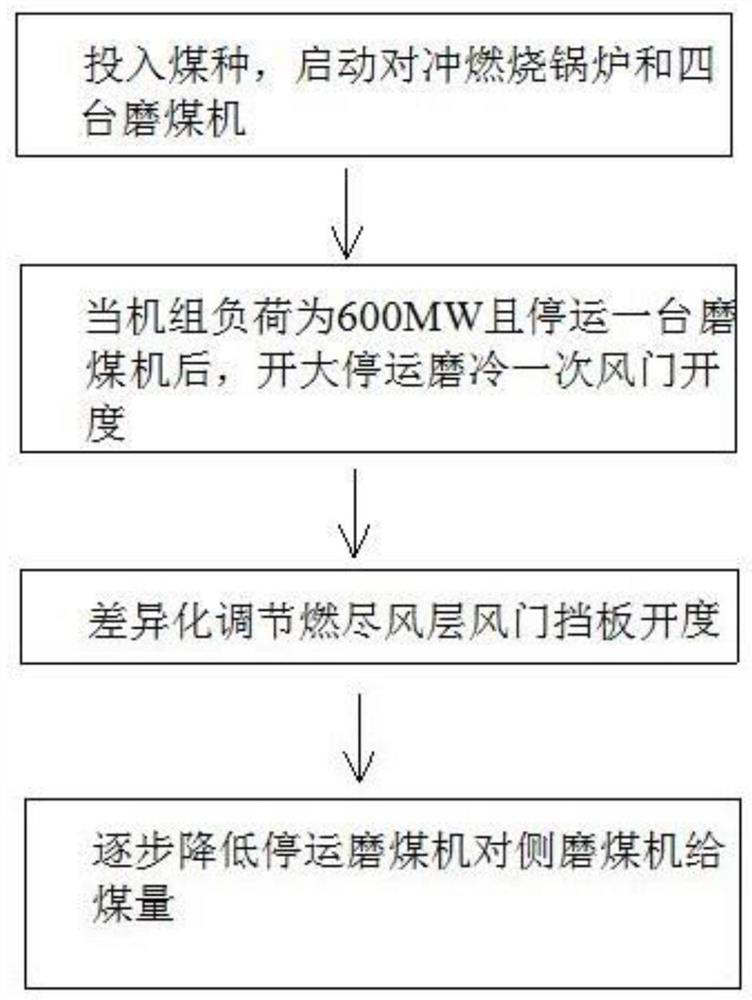

Method used

Image

Examples

Embodiment

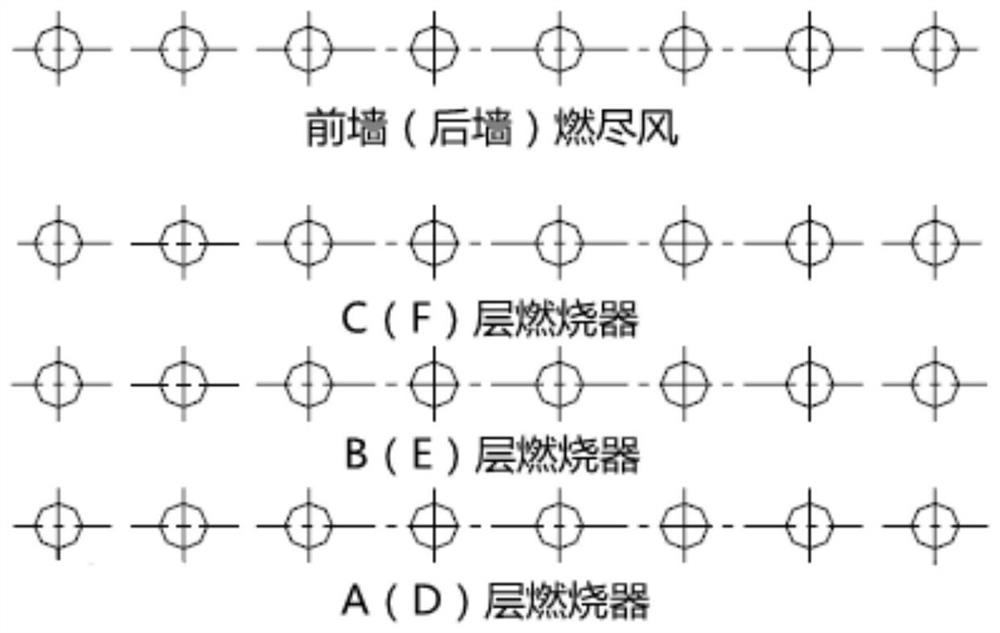

[0031] Unit 3 of a certain power plant is a 1050MW coal-fired turbogenerator set. The combustion equipment is a swirl pulverized coal burner that adopts the opposite combustion method of the front and rear walls. There are a total of 6 layers of swirl pulverized coal burners, and the front and rear walls are respectively arranged with 3 layers. There are 8 swirling pulverized coal burners on the front and rear walls of each floor, and each pulverizing system provides air powder mixture for the 8 pulverized coal burners on the corresponding floor. One layer of exhaust air is arranged above the swirl pulverized coal burners on the front and rear walls; the combustion equipment on the front (rear) wall is arranged as follows figure 2 shown.

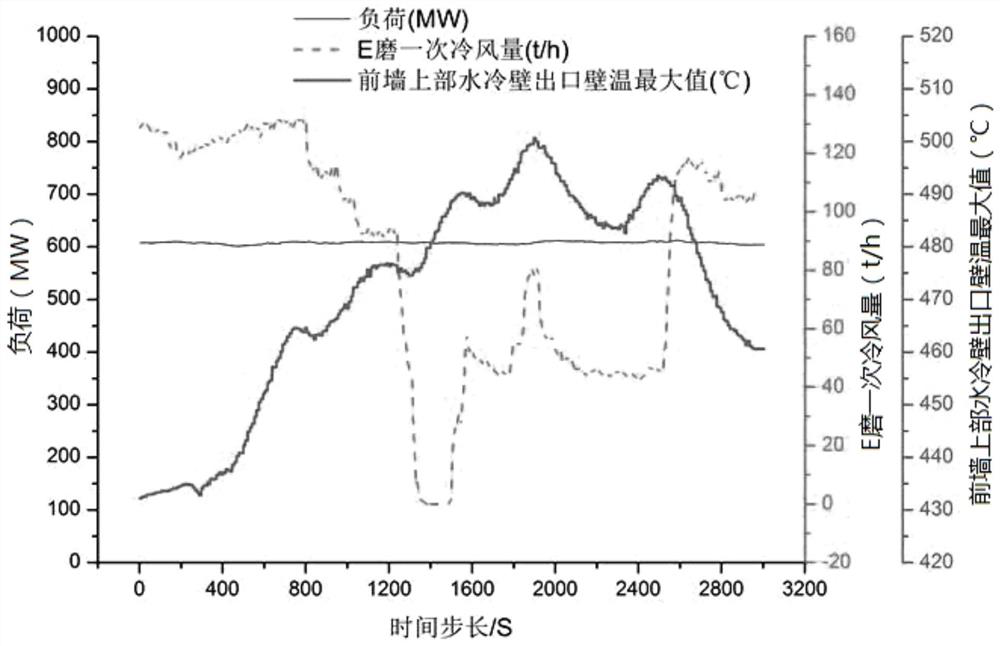

[0032] When the 600MW load is operated with the lower four-layer mill (ABDE), the wall temperature distribution is good, and the outlet wall temperature of the upper water-cooled wall on the front wall is stable at about 430°C, but after th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com