Synthesis method of diethyl phosphite

A technology of diethyl phosphite and triethyl phosphite, which is applied in the field of synthesis of diethyl phosphite, can solve problems such as affecting product yield, increasing production cost, and increasing operational difficulties, so as to achieve low cost and avoid impurities , the effect of good purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

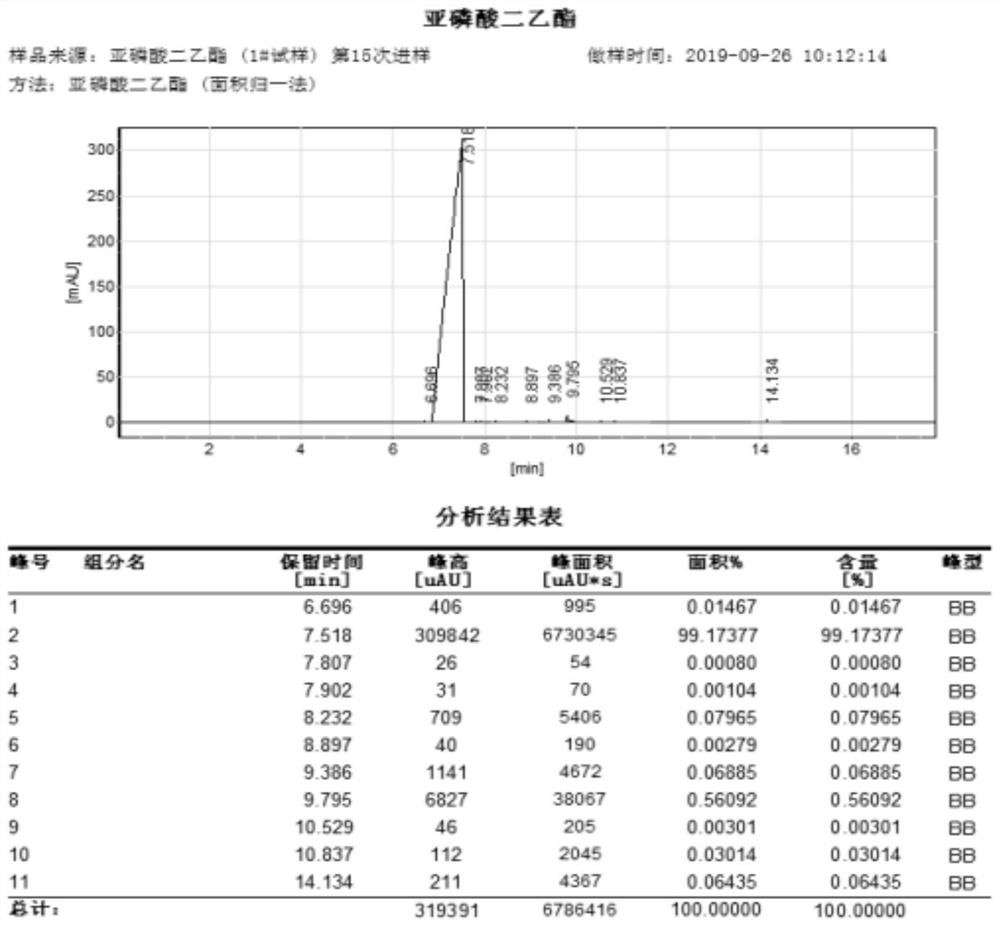

Image

Examples

Embodiment 1

[0022] The specific operation process of this embodiment is shown in Table 1. Take 41.5 g of triethyl phosphite and put it into a four-necked flask at room temperature of 24 ° C, and put the four-necked flask into a water bath. Add four times to the four-neck flask, the temperature of the first phosphorous acid addition is 24°C, and the amount of phosphorous acid added is 1.025g and stir for 15 minutes; due to the exothermic reaction, when the first addition and the reaction is completed, the temperature of the reaction system rises to 27°C, add 2.05g of phosphorous acid for the second time and stir for 15 minutes, the reaction system will heat up to 32°C due to the exothermic reaction, and cool down with cold water; For the third time, 3.075 g of phosphorous acid was added, and stirred for 15 minutes. The reaction system heated up to 33°C due to the exothermic reaction, and the temperature was lowered with cold water; Add 4.1g of phosphorous acid four times, and stir for 15 m...

Embodiment 2

[0026] The specific operation process of this embodiment is shown in Table 2. Take 41.5 g of triethyl phosphite and put it into a four-necked flask at room temperature of 24 ° C, and put the four-necked flask into a water bath. Add four times to the four-necked flask, the temperature of phosphorous acid added for the first time is 24°C, and the amount of phosphorous acid added is 2g and stirred for 15 minutes; due to the exothermic reaction, when the first addition and reaction are completed, the temperature of the reaction system rises to 28°C, add 2g of phosphorous acid for the second time and stir the reaction for 15 minutes, the reaction system will heat up to 33°C due to the exothermic reaction, and cool down with cold water; Add 2g of phosphorous acid three times, and stir for 15 minutes. The reaction system is heated to 33°C due to the exothermic reaction, and the temperature is lowered with cold water. When the third addition and the reaction is completed, the reaction ...

Embodiment 3

[0031] The specific operation process of this embodiment is shown in Table 3. Take 41.5 g of triethyl phosphite and put it into a four-necked flask at room temperature of 24 ° C, and put the four-necked flask into a water bath. Add four times to the four-necked flask, the temperature of phosphorous acid added for the first time is 24°C, and the amount of phosphorous acid added is 2g and stirred for 15 minutes; due to the exothermic reaction, when the first addition and reaction are completed, the temperature of the reaction system rises to 28°C, add 2g of phosphorous acid for the second time and stir the reaction for 15 minutes, the reaction system will heat up to 33°C due to the exothermic reaction, and cool down with cold water; Add 2g of phosphorous acid three times, and stir for 15 minutes. The reaction system is heated to 33°C due to the exothermic reaction, and the temperature is lowered with cold water. When the third addition and the reaction is completed, the reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com