Precoated sand recycling system

A technology of coated sand and ebullating bed, which is applied in the direction of burning various fuels, burning block fuels and liquid fuels, burning block fuels and gaseous fuels, etc., which can solve the problem of improving recovery quality and increasing recovery Problems such as cost and structural design are unreasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

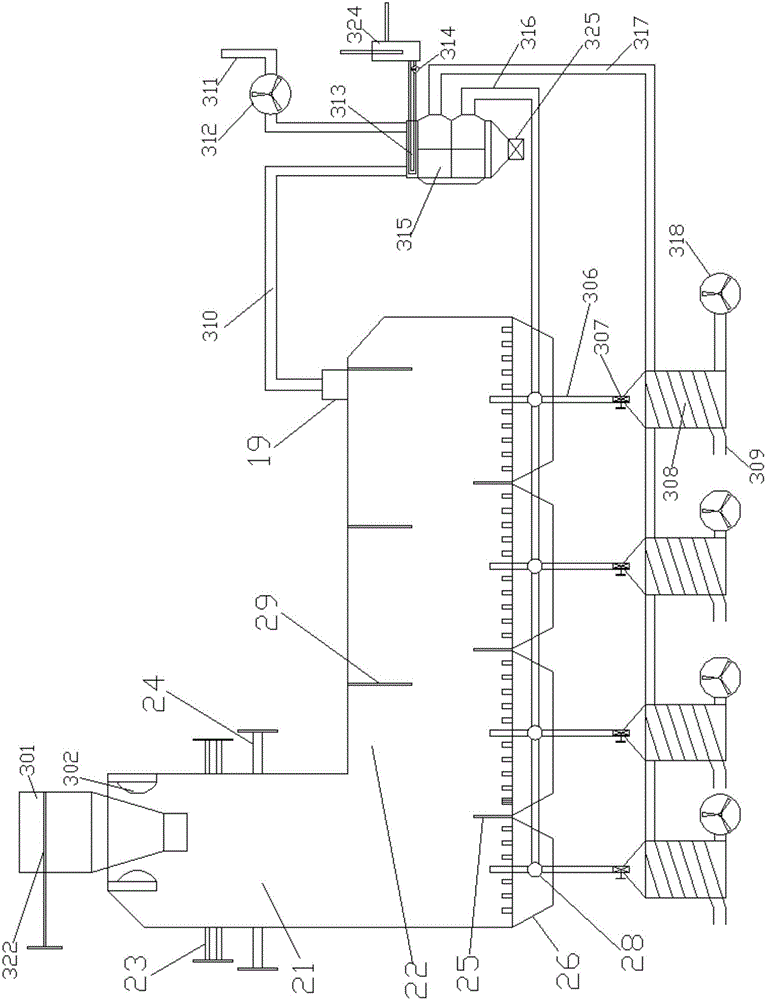

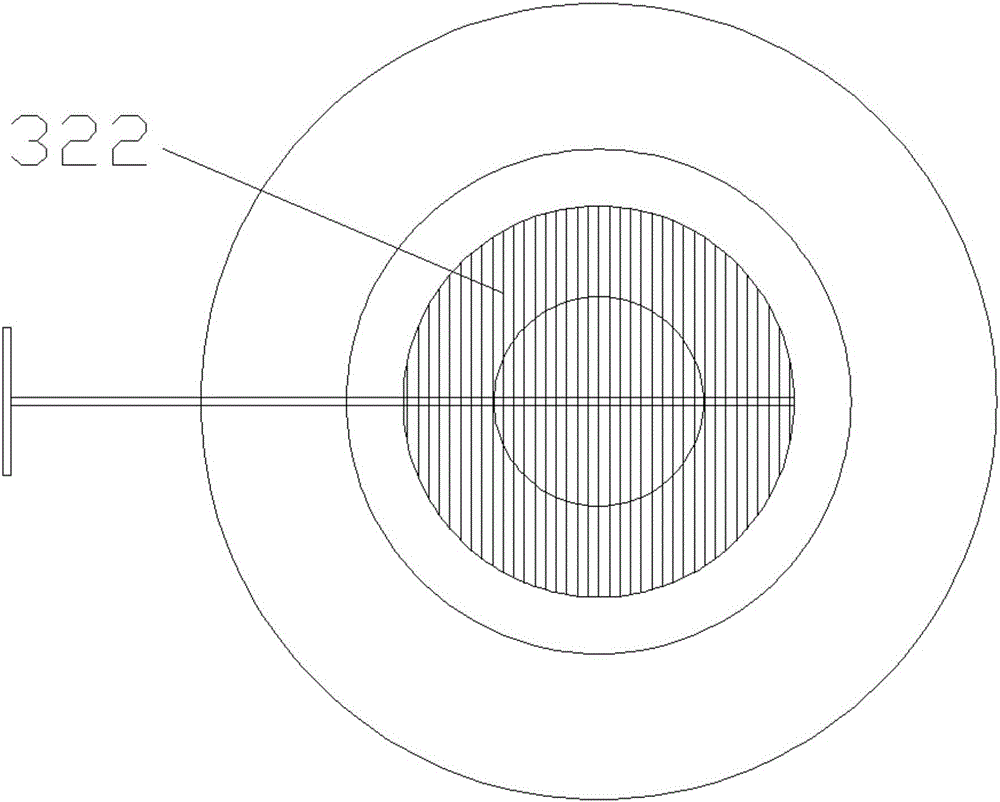

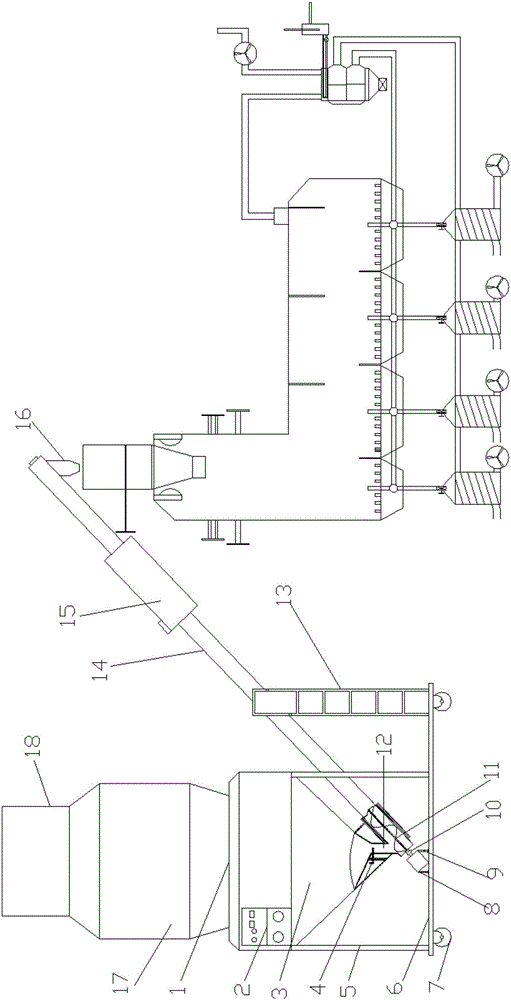

[0033] Such as Figure 1~4 As shown, it shows the specific implementation of the present invention, as shown in the figure, the present invention discloses coated sand recycling system, comprises vertical suspended combustion furnace 21 and horizontal ebullating bed 22, and vertical suspended combustion furnace is vertical It is arranged on a horizontal fluidized bed and communicated with the horizontal fluidized bed; the section of the vertical suspension combustion furnace is square, and four burners 23 are installed on the square furnace. The center line is cut in the same imaginary circle clockwise or anticlockwise along the same edge; the bottom of the horizontal fluidized bed is divided into several uniform bottom air distribution bins 26 by lower partitions 25, and each bottom air distribution bin A hot air port 28 is provided; a smoke exhaust port 19 for smoke exhaust is provided on the horizontal fluidized bed;

[0034] As shown in the figure, the smoke outlet on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com