Battery heat management system realized by using heat pump technology

A technology of battery thermal management and heat pump technology, applied in the field of battery thermal management systems, can solve the problems of increasing the risk of liquid leakage, product cost, and a large amount of space in the liquid cooling system, and achieve low noise, good temperature consistency, and small temperature difference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

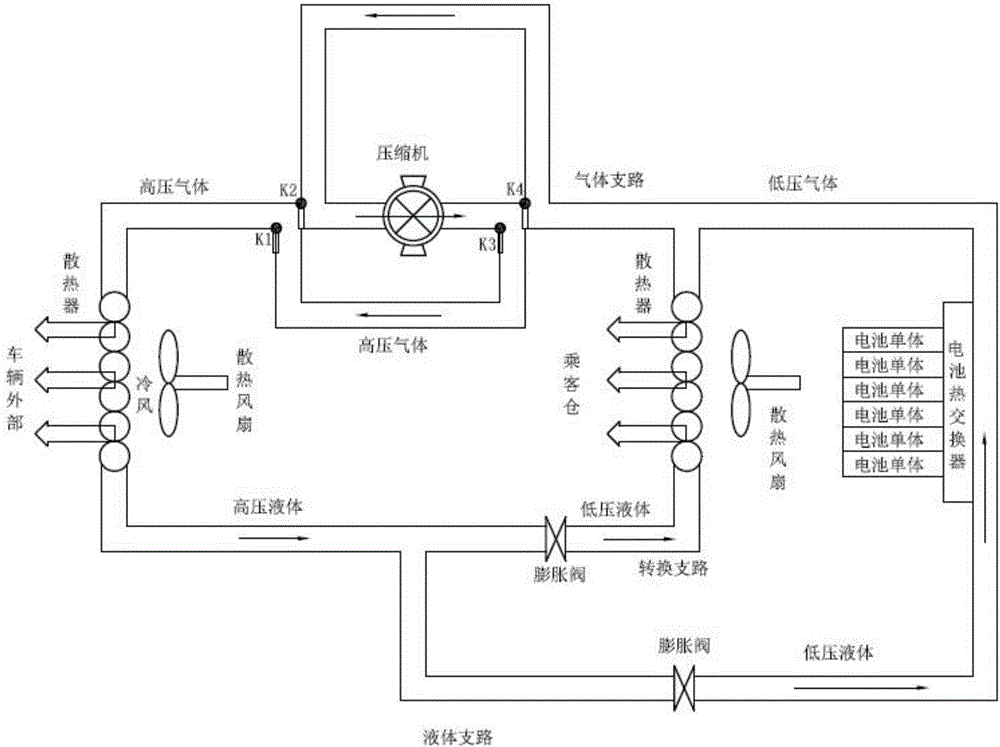

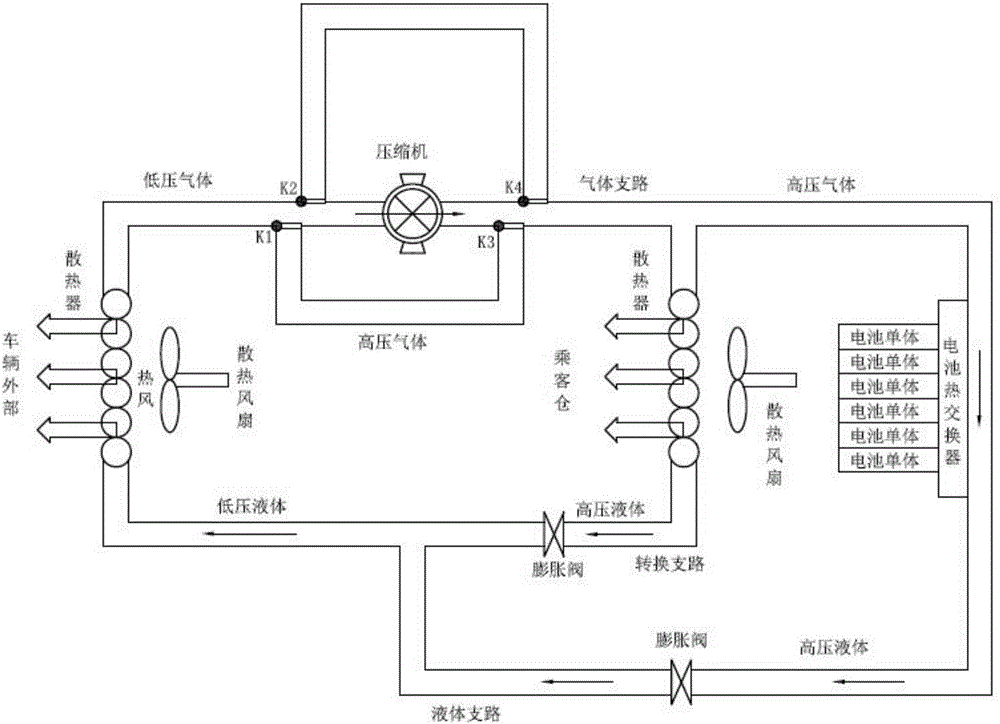

[0018] Through the following examples, combined with the attached Figure 1-2 , the technical solution of the present invention will be further specifically described.

[0019] figure 1 For the cooling principle of the battery system, when the management system monitors that the temperature of the battery is higher than the set threshold, it controls the K1, K2, K3, and K4 valves of the multi-way valve to switch to the cooling cycle mode. After the coolant passes through the battery heat exchanger, it absorbs the heat of the battery. After absorbing the heat, the coolant is vaporized into a low-pressure gas. After the low-pressure gas passes through the compressor, it becomes a high-pressure gas. After passing through the radiator, the high-pressure gas releases heat and is transformed into a high-pressure liquid again. , After the high-pressure liquid passes through the expansion valve, the expansion valve throttles, lowers the pressure, and lowers the temperature of the hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com